Technology and Applications of majestic metals

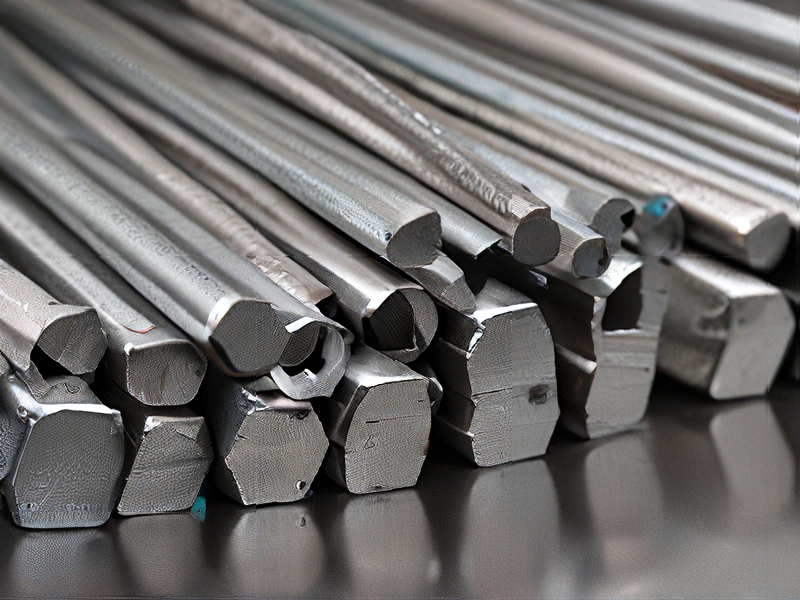

Majestic metals, such as titanium, tungsten, and platinum, are renowned for their exceptional properties and diverse applications.

Titanium is celebrated for its strength-to-weight ratio and corrosion resistance. It is widely used in aerospace for its lightweight yet robust nature, making it ideal for aircraft components and spacecraft. In medical applications, titanium’s biocompatibility makes it a preferred material for implants and prosthetics.

Tungsten stands out for its extreme hardness and high melting point. It is primarily used in the production of cutting tools, as its durability enhances performance. Additionally, tungsten is employed in lighting technology, such as incandescent light bulbs, where its high melting point allows it to withstand high temperatures.

Platinum is valued for its chemical inertness and catalytic properties. It is crucial in automotive catalytic converters, which help reduce vehicle emissions. In the jewelry industry, platinum’s luster and resistance to tarnish make it a premium choice for high-end pieces. Its role in various chemical processes, including petroleum refining, underscores its importance in industrial applications.

These metals’ unique properties drive innovation across multiple fields, from aerospace and medical technology to manufacturing and environmental management.

Quality Testing Methods for majestic metals and how to control quality

Quality testing for “majestic metals” (assuming you mean high-value metals like gold, silver, platinum, etc.) encompasses various methods to ensure purity, composition, and mechanical properties.

Purity Assessment:

* Fire Assay: A traditional method using heat to separate the metal from impurities, leaving behind a refined sample for weight and composition analysis.

* X-Ray Fluorescence (XRF): A non-destructive technique that uses X-rays to determine the elemental composition of the metal.

* Atomic Absorption Spectroscopy (AAS): Analyzes the absorption of light by atoms in a sample to determine the concentration of specific elements.

Mechanical Property Testing:

* Tensile Testing: Measures the metal’s strength, ductility, and elasticity under tensile force.

* Hardness Testing: Evaluates the metal’s resistance to indentation, often using scales like Vickers or Rockwell.

Quality Control:

* Strict Material Sourcing: Obtaining metals from reputable suppliers with proven quality standards.

* In-Process Inspections: Regular checks during manufacturing to ensure adherence to specifications.

* Final Product Testing: Comprehensive analysis of finished products before release.

* Statistical Process Control (SPC): Using statistical methods to monitor and control manufacturing processes, minimizing variations.

By implementing these rigorous testing methods and quality control measures, manufacturers can ensure the integrity and reliability of “majestic metals” in various applications.

Tips for Procurement and Considerations when Purchasing from majestic metals

When procuring from Majestic Metals, consider these tips and key considerations to ensure a successful purchasing experience:

Tips for Procurement

1. Research and Evaluate:

– Company Reputation: Check customer reviews and industry ratings. Majestic Metals is known for quality, so verify their track record.

– Product Range: Ensure they offer the specific metals and alloys you need.

2. Supplier Communication:

– Clear Specifications: Provide detailed specifications, including grades, dimensions, and any processing requirements.

– Lead Times: Confirm delivery schedules to align with your project timelines.

– Payment Terms: Understand their payment policies and negotiate terms that fit your budget cycle.

3. Quality Assurance:

– Certifications: Verify that the products meet industry standards (e.g., ISO, ASTM).

– Sample Testing: Request samples or test reports to ensure material quality before bulk orders.

4. Pricing and Contracts:

– Competitive Quotes: Obtain quotes from multiple suppliers for comparison.

– Volume Discounts: Inquire about discounts for large orders.

– Contract Terms: Ensure contracts cover all terms, including warranties, return policies, and liability clauses.

Considerations When Purchasing

1. Material Specifications:

– Application Suitability: Ensure the metals meet the specific needs of your application (e.g., corrosion resistance, tensile strength).

2. Supplier Reliability:

– Past Performance: Look into the supplier’s history of meeting delivery deadlines and maintaining quality.

– Capacity: Ensure they have the capacity to fulfill large or ongoing orders.

3. Logistics:

– Shipping Costs: Factor in transportation costs and potential customs duties if ordering internationally.

– Handling and Storage: Consider how the metals will be handled and stored upon arrival to prevent damage.

4. Sustainability:

– Eco-Friendly Practices: Assess if Majestic Metals follows sustainable sourcing and manufacturing practices.

By following these tips and considerations, you can make informed decisions and establish a reliable supply chain with Majestic Metals.

FAQs on Sourcing and Manufacturing from majestic metals in China

FAQs on Sourcing and Manufacturing from Majestic Metals in China

#### 1. What products does Majestic Metals manufacture?

Majestic Metals specializes in the production of a wide range of metal products, including sheet metal, fabricated metal parts, and custom metal components. Their offerings span various industries, such as automotive, construction, electronics, and consumer goods.

#### 2. Where are Majestic Metals’ manufacturing facilities located?

Majestic Metals operates several state-of-the-art manufacturing facilities in key industrial regions of China, ensuring proximity to major ports for efficient shipping and logistics.

#### 3. How can I ensure the quality of products from Majestic Metals?

Majestic Metals employs stringent quality control measures, including ISO certification and regular audits. Clients can request product samples, third-party inspections, and detailed quality reports to verify standards.

#### 4. What are the typical lead times for production?

Lead times vary depending on the complexity and volume of the order. Generally, the production lead time ranges from 4 to 8 weeks. It’s advisable to discuss specific timelines with Majestic Metals based on your project requirements.

#### 5. Can Majestic Metals handle custom designs and specifications?

Yes, Majestic Metals offers customized manufacturing services. Clients can provide their own designs or collaborate with the company’s engineering team to develop bespoke solutions that meet their precise specifications.

#### 6. What is the process for placing an order?

To place an order, clients typically follow these steps:

1. Submit an inquiry with detailed requirements.

2. Receive a quotation and confirm terms.

3. Provide design files and specifications.

4. Approve samples (if required).

5. Finalize the contract and initiate production.

#### 7. What are the payment terms?

Payment terms are usually negotiable. Common terms include a 30% deposit upon order confirmation, with the balance payable upon completion or before shipment. Other arrangements can be made based on mutual agreement.

#### 8. How does Majestic Metals handle shipping and logistics?

Majestic Metals manages the entire shipping process, offering options for FOB, CIF, and DDP terms. They work with reliable logistics partners to ensure timely and cost-effective delivery worldwide.

#### 9. What support does Majestic Metals provide post-production?

Majestic Metals offers post-production support, including warranty services, replacement of defective parts, and ongoing customer service to address any concerns or issues that arise after delivery.

For more detailed information, clients can contact Majestic Metals directly through their website or customer service channels.