Technology and Applications of steel vs stainless

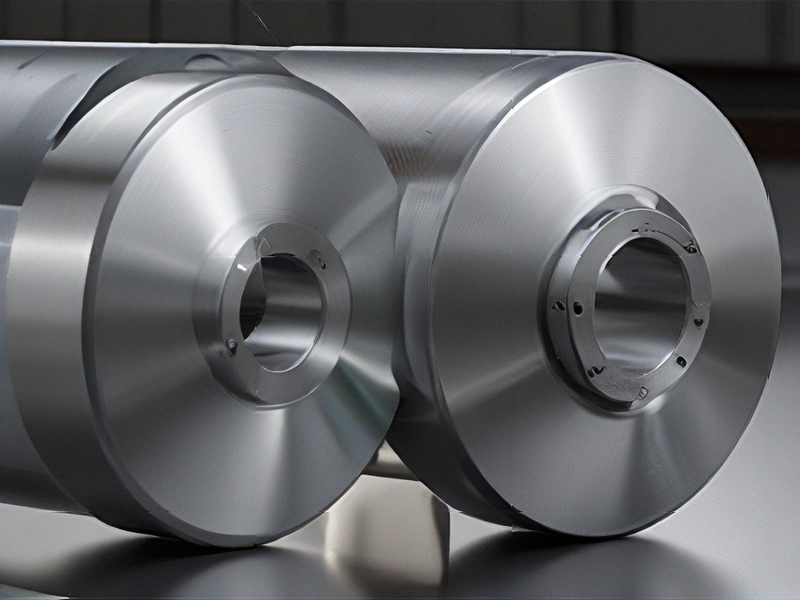

Steel and stainless steel are essential materials in modern technology, each with distinct properties and applications.

Steel

Technology:

Steel is an alloy primarily composed of iron and carbon. The carbon content typically ranges from 0.2% to 2.1%, influencing its hardness and strength. Advanced manufacturing techniques such as electric arc furnaces and continuous casting have enhanced steel production, making it more efficient and reducing impurities.

Applications:

Steel is widely used in construction (e.g., beams, girders, and rebar) due to its high tensile strength and cost-effectiveness. It is also crucial in the automotive industry for vehicle frames and body panels, in infrastructure for bridges and railways, and in machinery and tools. Its magnetic properties are beneficial in electrical applications, such as in transformers and motors.

Stainless Steel

Technology:

Stainless steel is a steel alloy with a minimum of 10.5% chromium, which forms a passive layer of chromium oxide, preventing rust and corrosion. Other elements like nickel, molybdenum, and titanium may be added to enhance specific properties. Techniques such as vacuum melting and powder metallurgy improve the quality and performance of stainless steel.

Applications:

Stainless steel is favored in environments requiring corrosion resistance and hygiene, such as in medical devices, food processing equipment, and kitchenware. It is also used in architecture for aesthetic and structural purposes (e.g., cladding and handrails), in the chemical industry for storage tanks and pipelines, and in aerospace for components that endure extreme conditions. Its non-reactive nature makes it ideal for surgical instruments and implants.

In summary, while both steel and stainless steel are critical to various industries, their distinct properties—strength and cost-effectiveness for steel, and corrosion resistance and hygiene for stainless steel—determine their specific applications.

Quality Testing Methods for steel vs stainless and how to control quality

Quality testing for steel and stainless steel involves similar methods but with nuances to account for the differences in material properties.

1. Visual Inspection:

– Steel: Check for surface defects, rust, and uniformity.

– Stainless Steel: Look for surface finish quality and ensure there are no signs of corrosion or discoloration.

2. Chemical Analysis:

– Steel: Use spectrometry to verify the composition, ensuring it meets specified grades.

– Stainless Steel: Confirm the presence of chromium and nickel, critical for corrosion resistance.

3. Mechanical Testing:

– Hardness Test: Rockwell or Brinell tests measure resistance to deformation.

– Tensile Test: Measures the material’s strength and ductility.

– Impact Test: Assesses toughness, particularly at different temperatures.

4. Non-Destructive Testing (NDT):

– Ultrasonic Testing (UT): Detects internal flaws by sending ultrasonic waves through the material.

– Magnetic Particle Inspection (MPI): Applies to ferromagnetic steel to find surface and subsurface defects.

– Dye Penetrant Inspection (DPI): For stainless steel, detects surface cracks through dye penetration.

Quality Control Measures:

1. Standardization:

– Adhere to standards like ASTM, ISO, and EN for material specifications and testing protocols.

2. Regular Audits:

– Conduct periodic audits of processes and materials to ensure compliance with quality standards.

3. Traceability:

– Maintain records of material batches, testing results, and processing steps to trace back any defects.

4. Training:

– Ensure personnel are trained in the latest testing methods and quality control procedures.

5. Automation:

– Use automated systems for testing and monitoring to reduce human error and increase precision.

6. Supplier Quality Management:

– Evaluate and monitor suppliers to ensure they provide materials that meet quality standards.

By integrating these testing methods and quality control measures, manufacturers can ensure the reliability and performance of both steel and stainless steel products.

Tips for Procurement and Considerations when Purchasing from steel vs stainless

When procuring steel or stainless steel, it is crucial to consider several factors to ensure the right choice for your needs:

1. Corrosion Resistance:

– Steel: Prone to rust and corrosion, especially in humid or acidic environments.

– Stainless Steel: Contains chromium, which forms a protective oxide layer, offering superior resistance to rust and corrosion.

2. Strength and Durability:

– Steel: High tensile strength, suitable for structural applications.

– Stainless Steel: Generally has higher tensile strength and is more durable, making it ideal for applications requiring longevity.

3. Cost:

– Steel: Typically cheaper due to lower production costs.

– Stainless Steel: More expensive due to added alloying elements like chromium and nickel.

4. Maintenance:

– Steel: Requires regular maintenance and protective coatings to prevent rust.

– Stainless Steel: Low maintenance, only requiring occasional cleaning to maintain its appearance.

5. Aesthetic Appeal:

– Steel: Usually has a plain, industrial look.

– Stainless Steel: Offers a sleek, polished appearance, suitable for both functional and decorative applications.

6. Applications:

– Steel: Used in construction, automotive, and heavy machinery due to its strength and cost-effectiveness.

– Stainless Steel: Preferred in medical instruments, kitchen appliances, and food processing industries due to its hygienic properties.

7. Temperature Resistance:

– Steel: Can withstand high temperatures but may lose strength at very high heat.

– Stainless Steel: Better performance at high temperatures, retaining strength and resisting oxidation.

8. Environmental Impact:

– Steel: Energy-intensive to produce, but highly recyclable.

– Stainless Steel: Also energy-intensive but has a longer lifecycle and is 100% recyclable, often making it a more sustainable choice in the long run.

Conclusion: Choose steel for cost-sensitive projects with moderate durability requirements. Opt for stainless steel when corrosion resistance, low maintenance, and aesthetic appeal are priorities, despite the higher initial cost.

FAQs on Sourcing and Manufacturing from steel vs stainless in China

When sourcing and manufacturing in China, choosing between steel and stainless steel involves several considerations:

1. Material Properties: Steel is generally cheaper than stainless steel but lacks corrosion resistance. Stainless steel, on the other hand, offers corrosion resistance due to its chromium content.

2. Cost: Steel is more cost-effective initially, making it suitable for large-scale projects where corrosion isn’t a concern. Stainless steel is pricier but offers long-term savings by reducing maintenance and replacement costs.

3. Applications: Steel is suitable for structural applications where strength and cost-effectiveness are priorities. Stainless steel is preferred for applications requiring corrosion resistance, such as in marine environments or food processing.

4. Manufacturing Capabilities: China has robust capabilities for both steel and stainless steel manufacturing. Consider the specific requirements of your project and verify that your chosen manufacturer has the expertise and equipment necessary.

5. Quality Control: Regardless of material choice, ensure stringent quality control measures are in place. This includes verifying certifications, conducting inspections, and establishing clear communication with your supplier.

6. Environmental Impact: Stainless steel, while more expensive, is often considered more environmentally friendly due to its durability and recyclability compared to regular steel.

7. Supplier Selection: Research and vet potential suppliers carefully. Look for manufacturers with a proven track record, good references, and transparent communication practices.

Ultimately, the decision between steel and stainless steel in China hinges on your project’s specific requirements, budget constraints, and long-term considerations such as maintenance and durability.