Technology and Applications of titanium steel

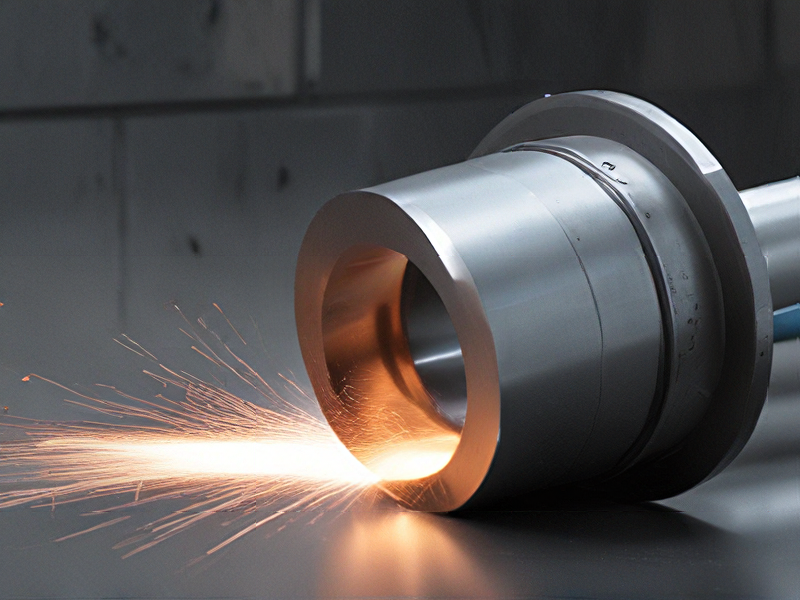

Titanium steel, often referred to as titanium alloy or simply Ti-steel, combines the strength and corrosion resistance of titanium with the affordability and workability of steel. This alloy is primarily used in industries where high strength, low weight, and excellent corrosion resistance are critical factors.

In aerospace applications, titanium steel is favored for its ability to withstand extreme temperatures, high stress, and aggressive environments such as saltwater. Aircraft components like landing gear, structural frames, and engine parts benefit from its lightweight nature and resistance to fatigue and erosion.

In the medical field, titanium steel is widely used for surgical implants and prosthetics due to its biocompatibility and ability to integrate with bone without causing adverse reactions. This makes it ideal for hip replacements, bone plates, and dental implants.

The automotive industry utilizes titanium steel in exhaust systems, suspension components, and engine parts to improve fuel efficiency and durability. Its resistance to heat and corrosion ensures longevity even under harsh conditions.

Sports equipment manufacturers also employ titanium steel in bicycles, golf clubs, and tennis rackets to enhance performance by reducing weight without compromising strength.

In construction, titanium steel finds applications in building structures and offshore platforms where its corrosion resistance extends service life and reduces maintenance costs.

Overall, titanium steel’s versatility across various industries stems from its unique combination of properties, making it a valuable material for applications demanding high performance, durability, and reliability in challenging environments.

Quality Testing Methods for titanium steel and how to control quality

Quality testing methods for titanium steel typically involve both destructive and non-destructive techniques to ensure material integrity and adherence to specifications. Here are some common methods:

1. Chemical Composition Analysis: Using techniques like optical emission spectroscopy (OES) or X-ray fluorescence (XRF) to verify the elemental composition of titanium steel.

2. Mechanical Testing: Includes tensile testing to measure strength, hardness testing (e.g., Rockwell hardness) to assess resistance to deformation, and impact testing to evaluate toughness.

3. Non-Destructive Testing (NDT):

– Ultrasonic Testing (UT): Utilizes high-frequency sound waves to detect internal defects or inconsistencies.

– Radiographic Testing (RT): Involves using X-rays or gamma rays to examine internal structures for defects.

– Magnetic Particle Testing (MT) and Dye Penetrant Testing (PT): Detects surface cracks or discontinuities.

4. Microstructural Analysis: Involves metallography and microscopy to examine the grain structure and ensure it meets specified standards.

5. Corrosion Resistance Testing: Various methods, such as salt spray testing or electrochemical corrosion testing, assess the material’s resistance to corrosion in different environments.

To control quality effectively:

– Establish clear specifications and standards for titanium steel production.

– Implement rigorous testing protocols at various stages of manufacturing.

– Train personnel on testing procedures and ensure equipment calibration.

– Conduct regular audits and inspections of production processes.

– Document and analyze test results to identify trends or areas needing improvement.

By integrating these methods and controls, manufacturers can ensure that titanium steel meets performance requirements and maintains high-quality standards throughout production.

Tips for Procurement and Considerations when Purchasing from titanium steel

When procuring titanium steel, consider the following tips and considerations:

1. Material Specifications: Understand the specific grades of titanium steel needed for your application. Titanium steel comes in various grades with different properties like strength, corrosion resistance, and temperature tolerance.

2. Supplier Reliability: Choose reputable suppliers with a proven track record in providing high-quality titanium steel. Check for certifications and industry standards compliance.

3. Cost Analysis: Titanium steel can be more expensive than other materials. Conduct a cost-benefit analysis to ensure the investment is justified by the material’s benefits like longevity and performance.

4. Quality Control: Ensure rigorous quality control processes are in place. Request material test reports (MTRs) and certificates of compliance to verify the material’s properties and specifications.

5. Customization Needs: Assess if the supplier can provide customized shapes, sizes, or treatments like surface finishing, which might be necessary for your specific requirements.

6. Lead Time and Availability: Confirm the availability of the material and the lead time for delivery. Delays can impact project timelines, so it’s crucial to have a clear understanding of delivery schedules.

7. Compatibility and Integration: Consider the compatibility of titanium steel with other materials used in your project. Ensure that the integration will not lead to galvanic corrosion or other issues.

8. Environmental Impact: Evaluate the environmental policies of the suppliers. Opt for those who follow sustainable practices in their production processes.

9. Technical Support: Select suppliers who offer technical support and advice. This can be invaluable in resolving any issues related to the application and performance of titanium steel.

10. After-Sales Service: Consider the after-sales support and services, including return policies, warranties, and customer service responsiveness.

By focusing on these areas, you can make informed decisions when purchasing titanium steel, ensuring that the material meets your project’s needs effectively and efficiently.

FAQs on Sourcing and Manufacturing from titanium steel in China

When sourcing and manufacturing titanium steel in China, several key FAQs typically arise:

1. Quality Assurance: How can I ensure the quality of titanium steel from Chinese suppliers?

– Answer: It’s crucial to conduct thorough supplier audits, request product samples, and implement quality control measures throughout production.

2. Cost Considerations: What factors influence the cost of titanium steel from China?

– Answer: Costs depend on raw material prices, manufacturing processes, labor costs, and market demand fluctuations.

3. Lead Times: What are typical lead times for manufacturing titanium steel products in China?

– Answer: Lead times vary based on product complexity and order volume. It’s advisable to clarify lead times with suppliers upfront.

4. MOQs (Minimum Order Quantities): Are there minimum order requirements when sourcing titanium steel from China?

– Answer: MOQs vary among suppliers and can be negotiable based on the specific product and supplier relationship.

5. Logistics and Shipping: How should I handle logistics and shipping when importing titanium steel from China?

– Answer: Engage with freight forwarders experienced in handling steel shipments and ensure compliance with import/export regulations.

6. Intellectual Property Protection: How can I protect my designs and intellectual property when manufacturing in China?

– Answer: Implement legal safeguards such as non-disclosure agreements (NDAs) and ensure suppliers respect intellectual property rights.

7. Environmental and Ethical Standards: What measures are in place to ensure environmentally friendly and ethically sourced titanium steel?

– Answer: Verify suppliers’ certifications and compliance with environmental regulations and ethical sourcing standards.

By addressing these FAQs, businesses can navigate sourcing and manufacturing titanium steel in China more effectively, ensuring quality, cost-efficiency, and compliance throughout the supply chain.