Technology and Applications of mini cnc machines

Mini CNC (Computer Numerical Control) machines have transformed small-scale manufacturing and DIY projects by offering precision, automation, and versatility in a compact form. These machines are ideal for hobbyists, small businesses, and educational purposes.

Technology

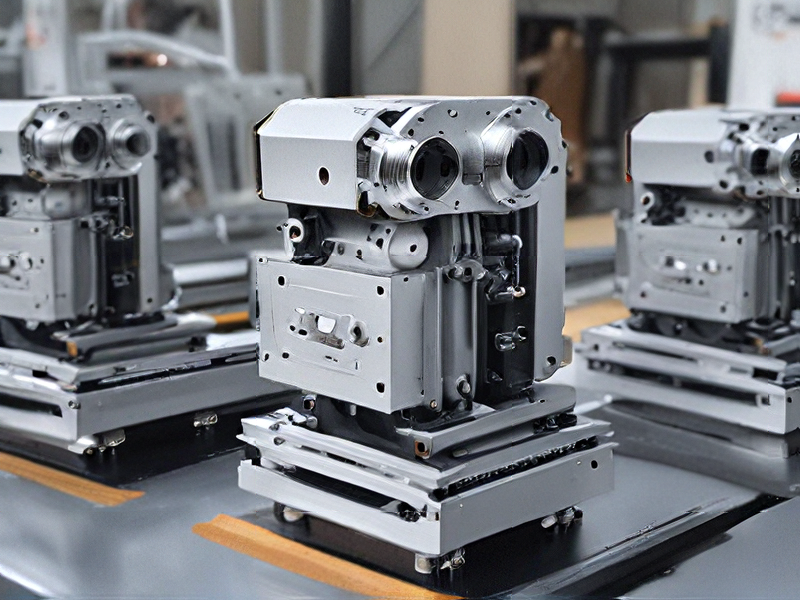

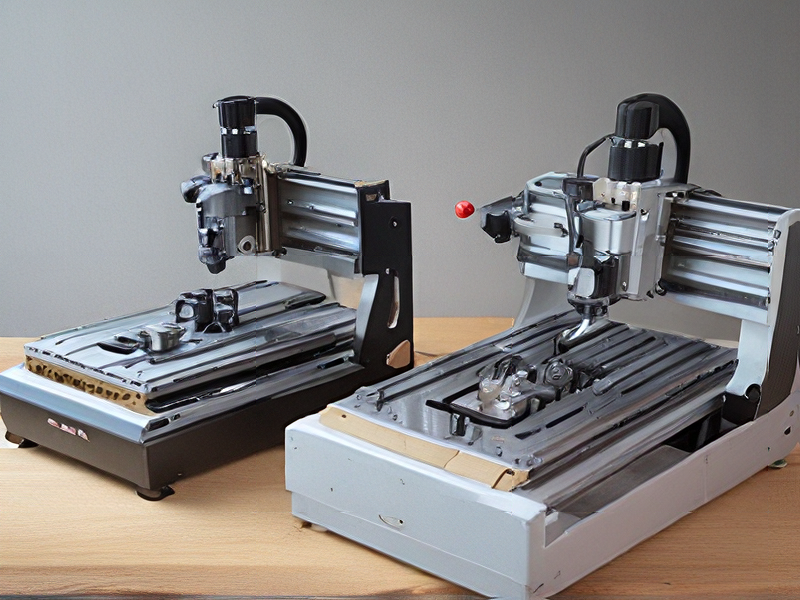

1. Components:

– Frame: Typically made from aluminum or steel, providing stability.

– Spindle: Rotates cutting tools at high speeds for milling, drilling, and cutting.

– Stepper Motors: Precisely control the movement of the machine’s axes.

– Control System: Includes software and hardware to interpret and execute G-code instructions.

2. Software:

– CAD (Computer-Aided Design): Used for designing parts.

– CAM (Computer-Aided Manufacturing): Converts CAD designs into G-code.

– Controller Software: Interfaces with the CNC machine to control its operations.

3. Materials: Mini CNC machines can work with a variety of materials, including wood, plastics, soft metals, and composites.

Applications

1. Prototyping: Essential for creating prototypes in product development, allowing designers to test and refine their ideas quickly.

2. Jewelry Making: Precision milling enables the creation of intricate designs in metals and other materials.

3. PCB Milling: Used for making custom printed circuit boards, crucial for electronics hobbyists and small-scale manufacturers.

4. Engraving: Ideal for personalizing items, from trophies to nameplates, by engraving designs or text.

5. Education: Provides hands-on experience in engineering, robotics, and manufacturing, helping students understand CNC technology and its applications.

Benefits

– Cost-Effective: Lower cost compared to full-sized CNC machines, making advanced manufacturing accessible.

– Precision: High accuracy ensures quality in small parts and complex designs.

– Ease of Use: Modern software interfaces and pre-configured kits make setup and operation straightforward.

– Compact Size: Suitable for small workshops or home use, without requiring significant space.

Mini CNC machines are bridging the gap between traditional handcrafting and industrial manufacturing, empowering individuals and small businesses to innovate and produce high-quality products efficiently.

Quality Testing Methods for mini cnc machines and how to control quality

For mini CNC machines, quality testing methods focus on several key areas to ensure optimal performance and reliability:

1. Dimensional Accuracy: Use precision measurement tools like micrometers and calipers to verify the accuracy of machined components against design specifications.

2. Surface Finish: Evaluate surface roughness using profilometers or visual inspection to ensure parts meet required smoothness and finish standards.

3. Mechanical Performance: Conduct functional tests to assess the machine’s ability to move accurately along all axes, checking for backlash and repeatability.

4. Electrical Systems: Test electrical components and wiring for proper functionality and safety compliance, including voltage checks and continuity testing.

5. Software and Control: Verify CNC programming and control software for correct operation, including program execution, toolpath accuracy, and responsiveness.

To control quality effectively:

– Establish Standards: Define clear quality standards and acceptance criteria for all tested parameters.

– Routine Inspections: Implement regular inspection intervals during production to catch defects early.

– Training: Train personnel in quality control procedures and equip them with appropriate testing tools.

– Documentation: Maintain comprehensive records of quality tests and inspection results for traceability and process improvement.

By integrating these methods and controls into your manufacturing process, you can ensure that mini CNC machines consistently meet high-quality standards and perform reliably for end-users.

Tips for Procurement and Considerations when Purchasing from mini cnc machines

When purchasing mini CNC machines, consider the following tips and factors to ensure you get the best value and performance:

1. Purpose and Application:

– Identify the specific tasks you need the machine for, such as engraving, cutting, or milling. Different models cater to different applications.

2. Material Compatibility:

– Ensure the machine can handle the materials you plan to work with, whether it’s wood, metal, plastic, or composites.

3. Precision and Tolerance:

– Check the machine’s precision and tolerance levels. Higher precision is essential for detailed and accurate work.

4. Build Quality:

– Look for machines made with durable materials like aluminum or steel. A solid frame reduces vibrations and increases accuracy.

5. Software Compatibility:

– Verify that the CNC machine is compatible with popular design software (CAD/CAM). User-friendly software can significantly ease the learning curve.

6. Spindle Power and Speed:

– Consider the spindle’s power and speed. Higher power allows for cutting tougher materials, while variable speed settings offer more control.

7. Working Area:

– Ensure the machine’s working area is sufficient for your projects. A larger workspace offers more flexibility.

8. Ease of Use:

– Look for features like easy tool changing, intuitive controls, and a user-friendly interface. These can save time and reduce frustration.

9. Customer Support and Warranty:

– Check the manufacturer’s customer support and warranty policies. Good support can help with troubleshooting and maintenance.

10. Budget:

– Set a budget considering both the initial purchase and potential additional costs like accessories, maintenance, and software licenses.

11. Reviews and Recommendations:

– Read reviews and seek recommendations from other users. Real-world experiences can provide valuable insights into the machine’s performance and reliability.

12. Safety Features:

– Ensure the machine has adequate safety features, such as emergency stop buttons and protective enclosures.

Careful consideration of these factors can help you select a mini CNC machine that meets your needs and provides reliable, high-quality performance.

FAQs on Sourcing and Manufacturing from mini cnc machines in China

FAQs on Sourcing and Manufacturing from Mini CNC Machines in China

1. Why source mini CNC machines from China?

China offers a vast range of mini CNC machines at competitive prices due to its advanced manufacturing capabilities and economies of scale. The variety of suppliers ensures options for different budgets and specifications.

2. What should I look for in a supplier?

Check for suppliers with a good track record, verified by platforms like Alibaba or Global Sources. Look for ISO certifications, customer reviews, and the ability to provide samples.

3. How do I ensure the quality of the machines?

Request detailed product specifications and quality control reports. Consider hiring a third-party inspection service to verify the quality before shipment.

4. What are the common types of mini CNC machines available?

Common types include milling machines, lathes, and engraving machines. They vary in precision, size, and functionality, so choose based on your specific needs.

5. How do I handle shipping and logistics?

Many suppliers offer FOB (Free on Board) terms, meaning you’ll need to arrange shipping. Use freight forwarders or shipping companies familiar with importing machinery to handle customs and delivery.

6. What are the typical payment terms?

Payment terms often include a down payment (30%) with the balance paid upon shipment. Use secure payment methods like bank transfers or trade assurance services provided by platforms like Alibaba.

7. Are there any import regulations I should be aware of?

Check your country’s import regulations for machinery, including any required certifications or standards. Ensure compliance to avoid delays and additional costs.

8. How can I get technical support?

Many suppliers offer after-sales support, including technical assistance and spare parts. Ensure your supplier has a reliable support system in place.

9. What about warranties and returns?

Check the warranty terms provided by the supplier. Understand their return and refund policies in case the machines do not meet the agreed specifications or are defective.

10. How can I mitigate risks?

Mitigate risks by conducting thorough research, starting with small orders, and building a strong relationship with the supplier. Using trade assurance or escrow services can also provide additional protection.

By considering these factors, you can effectively source and manufacture mini CNC machines from China with confidence.