Technology and Applications of heat treating steel

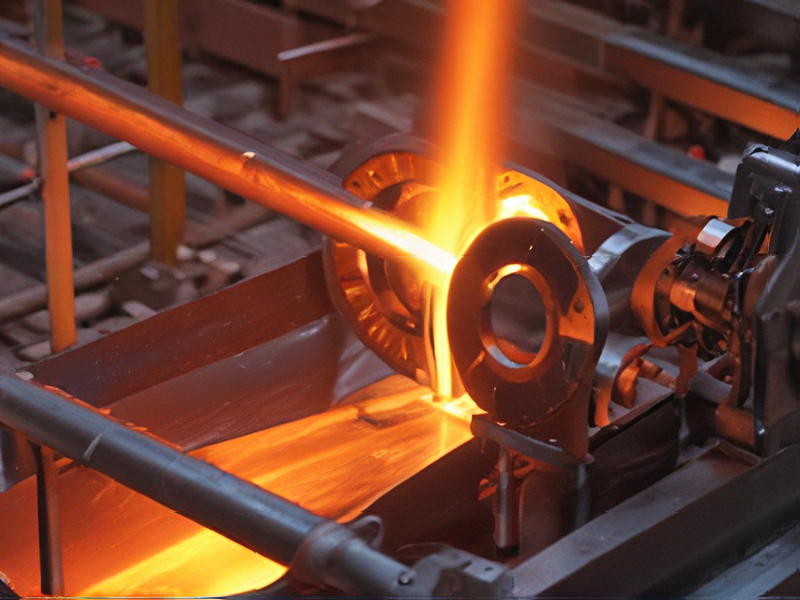

Heat treating steel involves heating and cooling the material to alter its physical and mechanical properties without changing its shape. This process enhances properties like hardness, strength, ductility, and toughness, making steel suitable for various applications.

Technology

1. Annealing: This process involves heating steel to a specific temperature and then cooling it slowly. Annealing relieves internal stresses, softens the metal, improves machinability, and enhances electrical conductivity.

2. Quenching: Steel is heated to a high temperature and then rapidly cooled, usually in water or oil. This increases hardness and strength. Quenching can introduce residual stresses, often requiring subsequent tempering.

3. Tempering: Following quenching, steel is reheated to a lower temperature and then cooled. Tempering reduces brittleness while maintaining the hardness achieved from quenching, resulting in a balanced combination of strength and toughness.

4. Carburizing: This surface-hardening technique involves heating steel in a carbon-rich environment, allowing carbon atoms to diffuse into the surface. This creates a hard, wear-resistant outer layer while retaining a tough interior.

Applications

1. Automotive Industry: Heat-treated steel components such as gears, crankshafts, and springs benefit from enhanced strength and durability, essential for withstanding high stresses and repeated loads.

2. Construction: Structural steel beams and reinforcing bars undergo heat treatment to achieve the necessary strength and toughness, ensuring the stability and longevity of buildings and infrastructure.

3. Tool Manufacturing: Cutting tools, dies, and molds are often made from heat-treated steel to ensure they maintain sharpness, resist wear, and endure the high forces encountered during use.

4. Aerospace: Heat-treated steel is crucial for components like landing gear and turbine blades, which require high strength-to-weight ratios and the ability to withstand extreme conditions.

In summary, heat treating steel is a vital process in enhancing the material’s properties, making it indispensable across various industries for improving performance and extending the lifespan of steel products.

Quality Testing Methods for heat treating steel and how to control quality

Quality testing methods for heat treating steel are crucial for ensuring the desired mechanical properties and performance. The primary methods include:

1. Hardness Testing: Measures the steel’s resistance to indentation, indicating the effectiveness of heat treatment. Common tests include Rockwell, Vickers, and Brinell.

2. Tensile Testing: Assesses the steel’s strength, ductility, and elongation by pulling it until it breaks. This helps determine if the material meets required specifications.

3. Impact Testing: Evaluates the steel’s toughness, particularly its ability to absorb energy during a sudden impact. The Charpy V-notch test is frequently used.

4. Microstructural Analysis: Involves examining the steel’s grain structure using optical or electron microscopy. This helps in identifying phase distributions, grain size, and the presence of defects like cracks or voids.

5. Non-Destructive Testing (NDT): Techniques like ultrasonic testing, magnetic particle inspection, and dye penetrant inspection detect surface and subsurface flaws without damaging the material.

6. Dimensional Inspection: Ensures the steel components maintain their dimensional tolerances post heat treatment, which is vital for parts that require precise fitting.

To control quality in heat treating steel:

1. Standard Operating Procedures (SOPs): Implementing and adhering to SOPs for all heat treatment processes ensures consistency and repeatability.

2. Process Monitoring: Continuously monitoring critical parameters like temperature, time, and cooling rates using automated systems and sensors ensures the process stays within specified limits.

3. Calibration and Maintenance: Regular calibration and maintenance of heat treatment equipment ensure accurate temperature control and uniform heating.

4. Training and Certification: Ensuring operators and technicians are properly trained and certified helps maintain high-quality standards.

5. Traceability: Keeping detailed records of heat treatment cycles, including batch numbers and process parameters, helps trace any issues back to their source for corrective actions.

By integrating these testing methods and quality control measures, the reliability and performance of heat-treated steel can be consistently ensured.

Tips for Procurement and Considerations when Purchasing from heat treating steel

When procuring heat-treated steel, several considerations are crucial to ensure quality and suitability for your needs:

1. Specifications and Standards: Define the required specifications such as material type, dimensions, hardness, and heat treatment requirements (e.g., quenching and tempering).

2. Supplier Qualification: Choose reputable suppliers with a track record of delivering quality heat-treated steel. Verify their certifications (ISO, AS9100, etc.) and capabilities.

3. Material Traceability: Ensure the supplier provides traceability of materials from the mill through heat treatment processes to final delivery.

4. Quality Assurance: Request documentation of quality control processes, including inspections, testing (e.g., hardness tests, microstructure analysis), and certifications.

5. Lead Times and Capacity: Evaluate the supplier’s lead times and production capacity to meet your project timelines and volume requirements.

6. Cost Considerations: Balance cost with quality and reliability. Consider total cost of ownership including procurement, transportation, and potential risks of using subpar materials.

7. Packaging and Delivery: Specify packaging requirements to prevent damage during transportation and storage. Ensure compliance with handling guidelines.

8. Technical Support: Choose suppliers who offer technical support and expertise in heat treatment processes and material selection.

9. Contract Terms and Conditions: Clearly outline terms such as payment schedules, delivery terms (Incoterms), warranties, and dispute resolution mechanisms.

10. Feedback and Continuous Improvement: Establish channels for feedback and improvement with suppliers to enhance future procurement experiences.

By focusing on these considerations, you can mitigate risks and ensure that the heat-treated steel procured meets your quality standards and operational requirements effectively.

FAQs on Sourcing and Manufacturing from heat treating steel in China

When sourcing and manufacturing heat-treated steel in China, several FAQs commonly arise:

1. Quality Control: How can I ensure consistent quality?

– Answer: Implement rigorous supplier audits, specify detailed quality requirements, and conduct regular inspections during production.

2. Lead Times: What are typical lead times for heat-treated steel?

– Answer: Lead times can vary based on complexity and volume but generally range from a few weeks to a couple of months.

3. Cost Factors: What factors influence the cost of heat-treated steel?

– Answer: Factors include material grade, treatment complexity, batch size, and market fluctuations in raw material prices.

4. Environmental Compliance: How can I ensure environmental standards are met?

– Answer: Choose suppliers with ISO certifications or compliance with relevant environmental regulations.

5. Logistics: What are the logistics challenges?

– Answer: Logistics can involve shipping costs, customs procedures, and managing inventory levels to minimize lead times.

6. Communication: How do I overcome language barriers?

– Answer: Engage with suppliers who have English-speaking staff or hire interpreters to facilitate clear communication.

7. Intellectual Property Protection: How do I protect my designs and processes?

– Answer: Use non-disclosure agreements (NDAs) and ensure suppliers respect intellectual property rights.

Navigating these aspects with due diligence and clear communication helps mitigate risks and ensures successful sourcing and manufacturing of heat-treated steel in China.