Technology and Applications of fiberglass sheet 4×8

Fiberglass sheets sized 4×8 feet are versatile materials widely used across various industries due to their exceptional properties. Composed of glass fibers embedded in a resin matrix, these sheets offer high strength-to-weight ratios, corrosion resistance, and durability.

Applications:

1. Construction and Architecture: Fiberglass sheets are popular in construction for applications such as roofing, siding, and insulation panels. They offer weather resistance and thermal insulation properties.

2. Transportation: In the automotive and aerospace industries, fiberglass sheets are used for manufacturing vehicle panels, interior components, and aircraft structures due to their lightweight nature and strength.

3. Marine: They are integral in boat building and marine applications, providing waterproofing and structural integrity without succumbing to saltwater corrosion.

4. Industrial Equipment: Fiberglass sheets serve as protective barriers, enclosures, and covers for machinery and equipment due to their resistance to chemicals and high temperatures.

5. Renewable Energy: In wind energy, fiberglass composites are used in the construction of turbine blades, harnessing their strength and flexibility.

Technological Advancements:

1. Advanced Composites: Innovations include hybrid composites combining fiberglass with other materials like carbon fiber for enhanced performance.

2. Manufacturing Techniques: Advanced molding and shaping techniques enable complex designs and improved efficiency in production.

3. Environmental Considerations: Development focuses on recyclability and sustainability, reducing environmental impact.

In conclusion, fiberglass sheets sized 4×8 feet are indispensable in various sectors due to their lightweight, durable, and versatile nature. Ongoing advancements in technology continue to expand their applications across industries, driving further innovation and sustainability in their use.

Quality Testing Methods for fiberglass sheet 4×8 and how to control quality

Quality testing methods for fiberglass sheet 4×8 typically include both physical and performance-based evaluations to ensure durability and reliability:

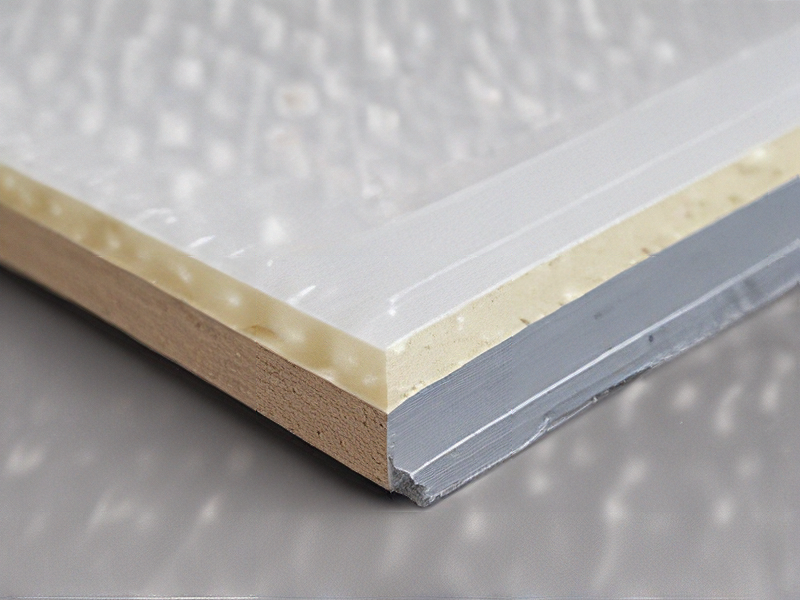

1. Dimensional Inspection: Measure thickness, width, and length to verify compliance with specifications.

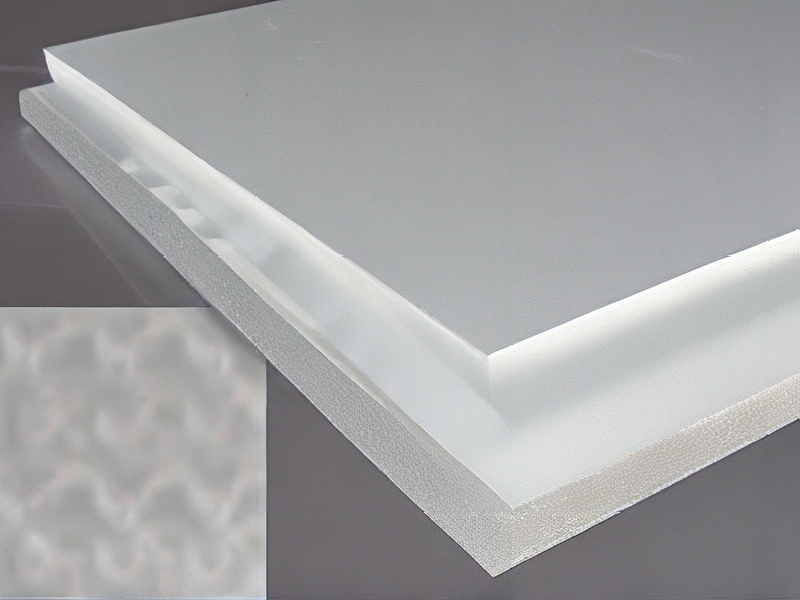

2. Visual Inspection: Check for surface defects such as cracks, bubbles, or uneven texture.

3. Tensile Strength Testing: Assess the material’s ability to withstand pulling forces to ensure it meets strength requirements.

4. Flexural Strength Testing: Determine how much force can be applied before the sheet breaks or deforms, indicating its flexibility and resilience.

5. Chemical Resistance Testing: Expose samples to various chemicals to verify resistance levels, crucial for applications involving exposure to corrosive environments.

6. Weatherability Testing: Subject samples to UV radiation and temperature extremes to assess how well they retain properties over time.

To control quality:

– Establish Clear Specifications: Define exact tolerances for dimensions, strength, and other critical parameters.

– Supplier Quality Assurance: Regular audits and inspections of raw materials and production processes.

– Process Controls: Implement checkpoints during manufacturing to catch defects early.

– Training and Certification: Ensure personnel are trained in quality standards and testing procedures.

– Feedback Loop: Continuously gather and analyze customer feedback and field performance data to inform improvements.

By employing these methods and controls, manufacturers can maintain high-quality standards for fiberglass sheets, ensuring they meet the rigorous demands of various applications effectively.

Tips for Procurement and Considerations when Purchasing from fiberglass sheet 4×8

When procuring fiberglass sheets, especially the standard 4×8 size, consider the following tips to ensure you make an informed purchase:

1. Quality Standards: Verify that the fiberglass sheets meet industry standards such as ASTM or ISO. High-quality sheets have consistent thickness, uniform resin distribution, and proper fiber alignment.

2. Supplier Reputation: Choose reputable suppliers with positive reviews and a history of delivering quality products. Check for certifications and compliance with safety and environmental regulations.

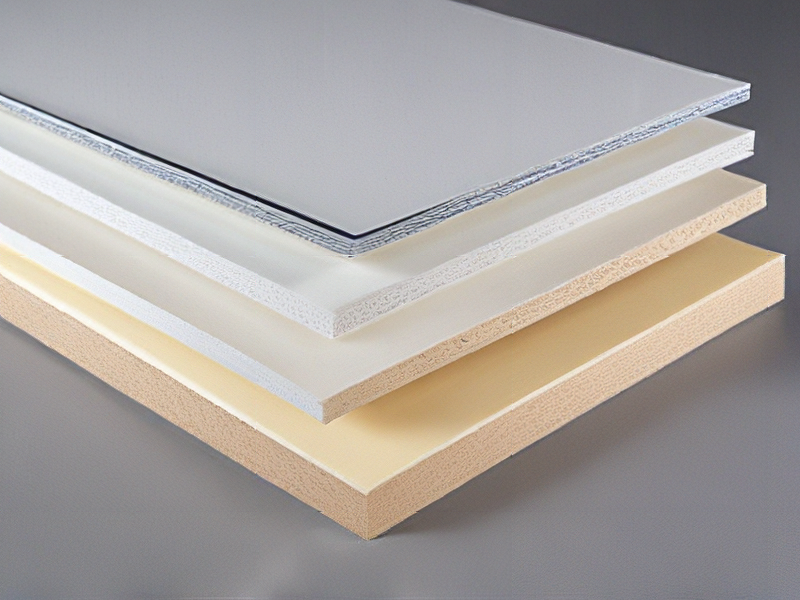

3. Material Specifications: Understand the specific needs of your project. Consider the type of resin (polyester, vinyl ester, or epoxy) and the reinforcement pattern (woven, chopped strand mat, etc.) as these affect durability, flexibility, and resistance to chemicals and UV.

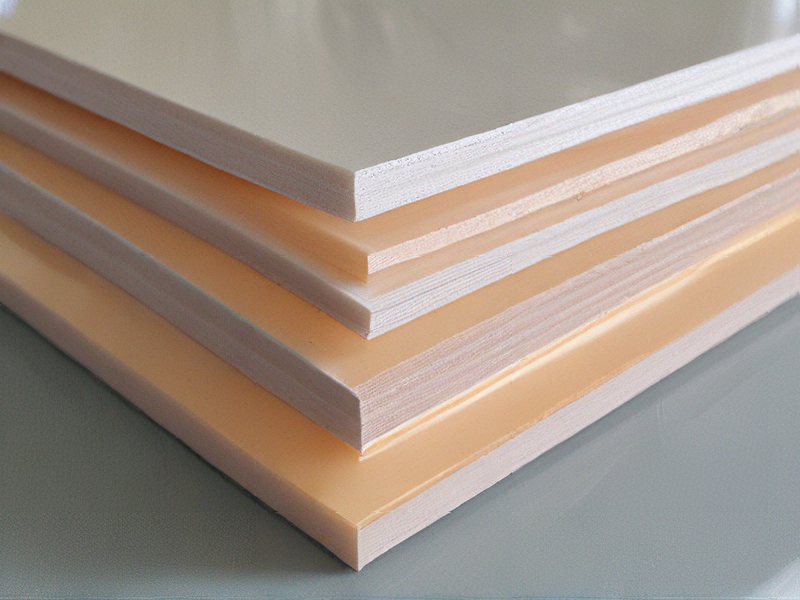

4. Thickness and Weight: Ensure the thickness (typically measured in mils) and weight of the sheets align with your application requirements. Thicker sheets offer better strength but are heavier and potentially more expensive.

5. Surface Finish: Decide between smooth or textured finishes based on the intended use. Smooth finishes are ideal for applications requiring easy cleaning, while textured surfaces provide better grip and can hide minor surface imperfections.

6. Temperature and Chemical Resistance: Check the operational temperature range and chemical resistance. Fiberglass sheets should withstand the environmental conditions they will be exposed to.

7. Cutting and Installation: Assess the ease of cutting and installation. Some fiberglass sheets may require specialized tools for cutting and shaping, impacting labor costs and project timelines.

8. Cost and Budgeting: Compare prices from multiple suppliers but avoid compromising on quality for cost savings. Consider bulk purchasing for discounts if your project size justifies it.

9. Delivery and Lead Time: Confirm delivery schedules and lead times with suppliers. Ensure they can meet your project deadlines to avoid delays.

10. Post-Purchase Support: Opt for suppliers who offer post-purchase support, including technical assistance and warranty services, to address any issues that may arise.

By considering these factors, you can make a well-informed decision when purchasing fiberglass sheets, ensuring they meet the specific needs of your project efficiently and cost-effectively.

FAQs on Sourcing and Manufacturing from fiberglass sheet 4×8 in China

FAQs on Sourcing and Manufacturing Fiberglass Sheets (4×8) in China

1. Why source fiberglass sheets from China?

China is a leading producer of fiberglass products, offering competitive prices, extensive manufacturing capabilities, and a broad range of suppliers. The country’s well-established supply chain ensures high quality and efficient production.

2. What are the common applications of 4×8 fiberglass sheets?

4×8 fiberglass sheets are widely used in construction, automotive, marine, and industrial applications due to their strength, durability, and resistance to corrosion and weathering.

3. How do I find reliable suppliers in China?

Utilize platforms like Alibaba, Global Sources, and Made-in-China. Look for suppliers with verified credentials, positive reviews, and strong communication skills. Visiting trade shows and fairs such as the Canton Fair can also be beneficial.

4. What factors should I consider when choosing a supplier?

Consider the supplier’s experience, production capacity, quality control processes, certifications (e.g., ISO), and willingness to provide samples. Also, assess their response time and ability to meet your specifications.

5. How can I ensure the quality of fiberglass sheets?

Request samples before placing bulk orders. Conduct factory audits or hire third-party inspection agencies to check for compliance with international standards. Regularly communicate with the supplier to address any quality concerns.

6. What are the typical lead times for manufacturing?

Lead times can vary depending on order size and customization requirements, generally ranging from 2 to 6 weeks. Discuss lead times with the supplier and factor in shipping duration to your location.

7. What is the cost range for 4×8 fiberglass sheets?

The cost depends on factors like thickness, surface finish, and quantity. Prices typically range from $20 to $50 per sheet, but bulk orders may attract discounts.

8. How is shipping and logistics handled?

Most suppliers offer FOB (Free on Board) terms. Engage a reliable freight forwarder to manage shipping, customs clearance, and delivery. Ensure the supplier provides proper packaging to prevent damage during transit.

9. Are there any import duties or regulations?

Check the import regulations and duties in your country. Collaborate with a customs broker to navigate tariffs, documentation, and compliance with local standards.

By addressing these key questions, you can streamline the process of sourcing and manufacturing fiberglass sheets in China, ensuring a smooth and efficient experience.