Technology and Applications of acrylic sheet laser cutter

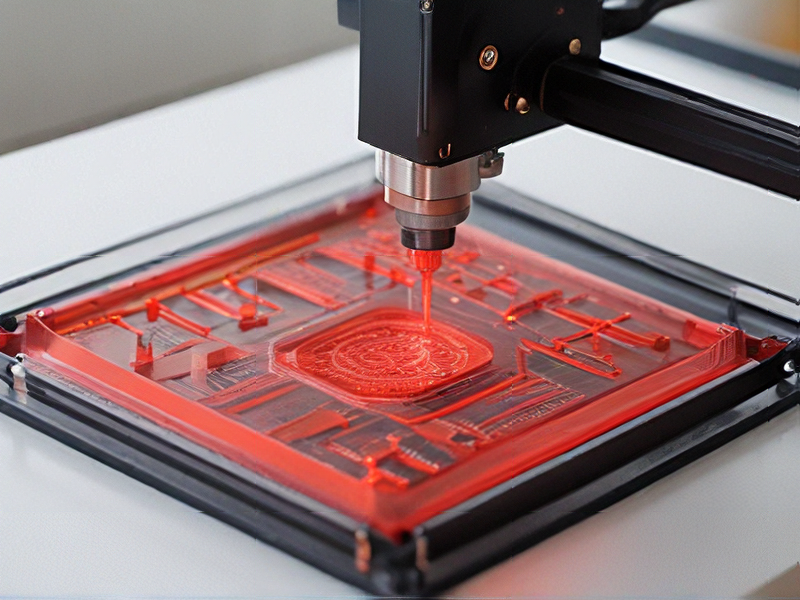

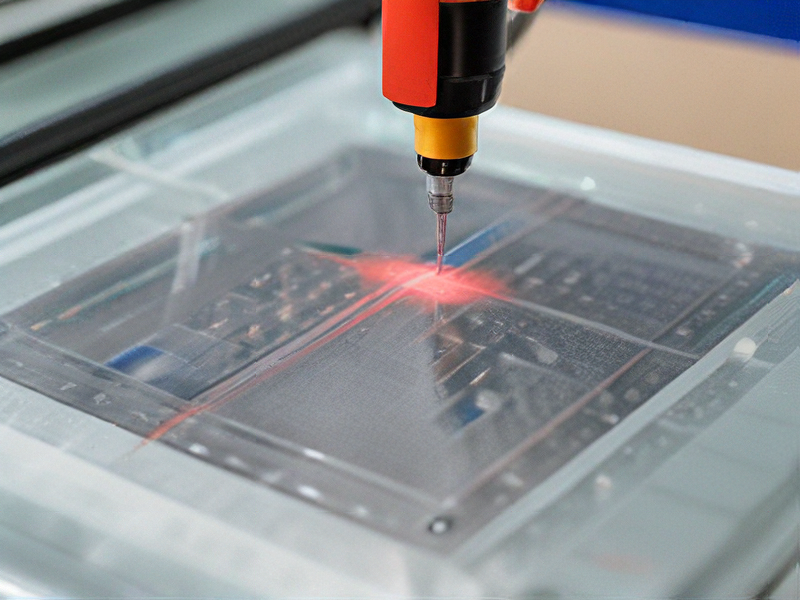

Acrylic sheet laser cutters are advanced tools used for precision cutting and engraving of acrylic materials. These devices utilize a focused laser beam, typically CO2 lasers, to cut through or engrave the acrylic with high accuracy. The technology behind these cutters involves the emission of a laser beam that is directed onto the acrylic sheet. The intense heat from the laser vaporizes the material along the cutting path, resulting in clean and smooth edges.

Technology

1. Laser Source: Most commonly, CO2 lasers are used, which are efficient for cutting non-metallic materials like acrylic.

2. Control Systems: CNC (Computer Numerical Control) systems are integrated for precise control of the laser path, allowing for intricate designs and complex patterns.

3. Cooling Systems: To prevent overheating and damage, laser cutters are equipped with cooling systems, usually involving water or air cooling.

4. Exhaust Systems: These remove fumes and particles generated during the cutting process, ensuring a clean and safe working environment.

Applications

1. Signage: Acrylic laser cutters are widely used to create high-quality signs with detailed designs and polished edges.

2. Display Products: They are used in fabricating display stands, showcases, and point-of-sale products, offering clarity and aesthetic appeal.

3. Architectural Models: The precision of laser cutters makes them ideal for creating detailed architectural models and prototypes.

4. Art and Decor: Artists and designers use these cutters to produce intricate artwork, decorations, and personalized items.

5. Industrial Components: In manufacturing, acrylic laser cutters are employed to create components for various industrial applications, including machine parts and protective covers.

Overall, acrylic sheet laser cutters combine advanced laser technology with precise control systems to offer versatile applications across various industries. Their ability to produce clean cuts and detailed engravings makes them indispensable tools in modern fabrication and design.

Quality Testing Methods for acrylic sheet laser cutter and how to control quality

Quality testing methods for an acrylic sheet laser cutter typically involve several key steps to ensure the output meets desired standards:

1. Dimensional Accuracy: Use calipers or digital measurement tools to verify that cut acrylic pieces match specified dimensions within acceptable tolerances.

2. Edge Quality: Inspect cut edges visually and by touch to ensure they are smooth and free from chipping, burning, or roughness that could affect aesthetics or functionality.

3. Alignment and Positioning: Check the alignment of laser cuts relative to the acrylic sheet to ensure they are placed correctly according to design specifications.

4. Material Integrity: Examine acrylic sheets for signs of heat damage, warping, or discoloration caused during the cutting process.

5. Prototype Testing: Conduct functional tests using sample pieces to verify that the laser-cut acrylic parts fit together accurately and perform as intended in their final application.

To control quality effectively:

1. Regular Maintenance: Maintain the laser cutter according to manufacturer guidelines to prevent issues that could affect cutting precision and quality.

2. Calibration Checks: Regularly calibrate the laser cutter to ensure it cuts acrylic sheets with consistent accuracy and quality.

3. Operator Training: Provide comprehensive training to operators on using the laser cutter correctly and identifying potential quality issues early.

4. Quality Control Checks: Implement a systematic quality control process where samples from each production batch are inspected according to predetermined criteria.

5. Feedback Loop: Establish a feedback mechanism where operators can report issues encountered during cutting, enabling prompt resolution and continuous improvement.

By integrating these testing methods and quality control measures, manufacturers can ensure that laser-cut acrylic sheets meet high standards of precision, consistency, and performance in various applications.

Tips for Procurement and Considerations when Purchasing from acrylic sheet laser cutter

When procuring acrylic sheet laser cutters, consider these key tips and factors:

1. Machine Specifications: Ensure the cutter meets your requirements for cutting thickness, bed size, and laser power. Check if it supports the types of acrylic sheets you intend to use (e.g., thickness, colors).

2. Quality and Precision: Look for machines known for high precision cutting to minimize wastage and ensure accurate designs. Check reviews and testimonials for reliability.

3. Ease of Use: User-friendly interfaces and software are crucial for efficiency. Ensure the machine’s software is intuitive and supports the file formats you commonly use (e.g., .AI, .DXF).

4. Maintenance and Support: Consider availability of technical support and maintenance services. A reliable supplier should offer training, troubleshooting guides, and timely support.

5. Safety Features: Laser cutters pose safety risks. Ensure the machine has adequate safety features such as enclosures, emergency stop buttons, and proper ventilation systems.

6. Cost and Return on Investment (ROI): Compare prices against features and benefits. Calculate potential ROI based on production capacity, material savings, and labor costs.

7. Supplier Reputation: Choose a reputable supplier known for quality products and customer service. Check warranties, return policies, and customer feedback.

8. Compatibility with Accessories: If you need specific accessories (e.g., rotary attachments for engraving cylindrical objects), ensure compatibility with the chosen laser cutter model.

9. Future Scalability: Consider your future needs for production scalability. Choose a laser cutter that can grow with your business demands.

10. Environmental Impact: Assess energy consumption and environmental impact. Opt for energy-efficient models and inquire about environmental certifications.

By carefully evaluating these factors, you can make an informed decision when purchasing an acrylic sheet laser cutter that aligns with your operational needs and budget.

FAQs on Sourcing and Manufacturing from acrylic sheet laser cutter in China

FAQs on Sourcing and Manufacturing from Acrylic Sheet Laser Cutter in China

1. Why source acrylic sheet laser cutters from China?

China offers a wide range of acrylic sheet laser cutters at competitive prices. The country’s advanced manufacturing capabilities and extensive supply chain ensure high-quality products and innovative designs.

2. How do I find reliable suppliers?

Use platforms like Alibaba, Made-in-China, and Global Sources. Look for suppliers with high ratings, positive reviews, and verified status. Request samples and visit factories if possible.

3. What are the key considerations when choosing a supplier?

Evaluate the supplier’s production capacity, quality control processes, certifications (such as ISO 9001), and experience in exporting to your region. Also, consider their communication skills and responsiveness.

4. What are the common types of acrylic sheet laser cutters?

CO2 laser cutters are the most common for acrylic due to their efficiency and precision. They come in various power levels, typically ranging from 40W to 150W, suitable for different cutting and engraving tasks.

5. What is the typical lead time for production and delivery?

Lead times vary but generally range from 15 to 45 days, depending on the order size and customization requirements. Shipping times can add another 7 to 30 days, depending on the shipping method and destination.

6. How can I ensure the quality of the products?

Conduct a thorough inspection before shipment. You can hire third-party inspection agencies to verify product quality, compliance with specifications, and packaging standards.

7. What are the payment terms commonly used?

Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and sometimes escrow services. An initial deposit of 30% is standard, with the balance paid before shipment.

8. Are there any import duties or regulations I should be aware of?

Yes, check your country’s import regulations and duties for laser cutting equipment. Ensure the products comply with local safety standards and certifications.

9. Can I customize my laser cutter?

Yes, many Chinese suppliers offer customization options, including power settings, cutting bed sizes, software compatibility, and additional features like rotary attachments for cylindrical objects.

10. What after-sales support can I expect?

Reliable suppliers provide after-sales support such as technical assistance, spare parts, and warranty services. Clarify the terms of support and warranty coverage before purchasing.