Technology and Applications of acrylic sheets laser cutting

Acrylic sheets are widely used in various applications due to their versatility and durability. Laser cutting technology has revolutionized the fabrication of acrylic sheets, offering precise and clean cuts without the need for extensive finishing.

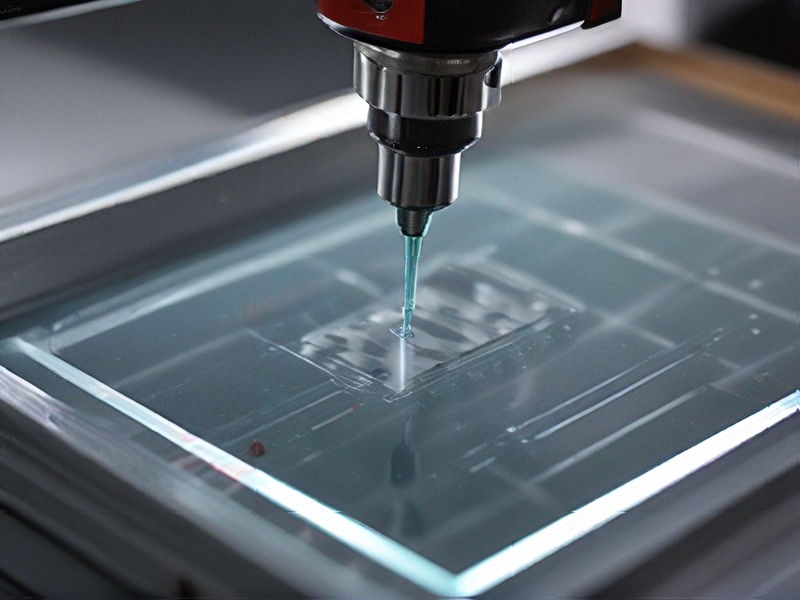

Laser cutting works by directing a high-powered laser beam through optics and focusing it onto the acrylic sheet’s surface. The intense heat generated by the laser vaporizes or melts the material along the cutting line, creating a smooth edge with minimal heat-affected zones. This method allows for intricate designs and precise shapes that are difficult to achieve with traditional cutting tools.

Applications of acrylic sheet laser cutting span several industries, including signage, displays, architectural models, and automotive components. In signage and displays, laser cutting enables the creation of detailed logos, letters, and shapes with polished edges, enhancing aesthetic appeal. Architectural models benefit from accurate cutting of acrylic for prototypes and scale models, showcasing intricate details and designs.

The technology also supports rapid prototyping and customization, as designs can be easily translated into production-ready pieces with minimal setup time. Moreover, laser cutting reduces material waste compared to conventional methods, making it environmentally friendly.

In summary, acrylic sheet laser cutting offers precision, versatility, and efficiency across a wide range of applications. Its ability to produce intricate designs with clean edges makes it a preferred choice in industries where aesthetics and precision are paramount. As technology continues to advance, laser cutting is likely to further expand its applications in acrylic sheet fabrication.

Quality Testing Methods for acrylic sheets laser cutting and how to control quality

Quality testing methods for acrylic sheets laser cutting primarily focus on ensuring precise cuts, minimal thermal damage, and overall product integrity. Here are key methods to control and maintain quality:

1. Dimensional Accuracy: Use precision measuring tools like calipers or coordinate measuring machines (CMMs) to verify that cut acrylic sheets meet specified dimensions within tolerances.

2. Visual Inspection: Conduct visual checks for surface defects such as cracks, chips, or discoloration caused by overheating during laser cutting.

3. Edge Quality Evaluation: Assess the smoothness and clarity of cut edges using magnification or edge profiling tools. Smooth edges indicate proper cutting parameters and minimal thermal damage.

4. Material Integrity Tests: Perform tests to ensure the structural integrity of acrylic sheets post-cutting, including bend tests to check for cracking or brittleness.

5. Sample Testing: Randomly select samples from production batches for comprehensive testing to validate adherence to quality standards.

To control quality effectively:

– Optimize Laser Parameters: Fine-tune laser cutting parameters (e.g., power, speed, focal length) based on acrylic sheet thickness and type to minimize heat-affected zones and ensure clean cuts.

– Regular Maintenance: Maintain laser cutting equipment regularly to prevent deviations in cutting precision and quality.

– Training and Skill Development: Train operators to handle equipment and interpret quality metrics accurately, ensuring consistent quality output.

– Feedback Mechanism: Establish a feedback loop where quality issues are promptly addressed through root cause analysis and corrective actions.

By implementing these methods and controls, manufacturers can uphold high standards for acrylic sheet laser cutting, ensuring customer satisfaction and product reliability.

Tips for Procurement and Considerations when Purchasing from acrylic sheets laser cutting

When procuring acrylic sheets for laser cutting, consider the following tips and key factors:

Quality of Acrylic

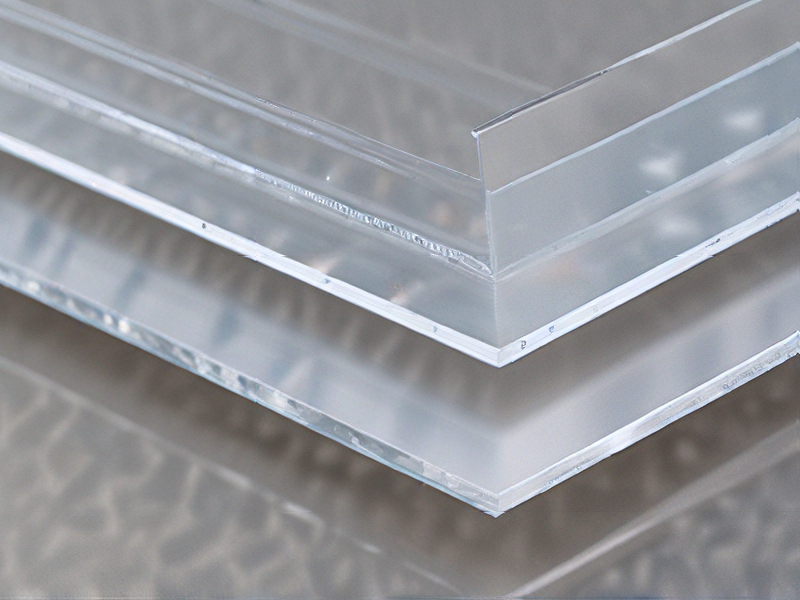

– Material Grade: Choose high-quality cast acrylic sheets over extruded ones. Cast acrylic offers better clarity and uniformity, crucial for precision laser cutting.

– Thickness Consistency: Ensure the thickness of the sheets is uniform across the entire surface to avoid cutting inconsistencies.

Supplier Reliability

– Reputation and Reviews: Select suppliers with a strong reputation and positive reviews. Reliable suppliers provide consistent quality and timely delivery.

– Certifications: Check if the supplier meets industry standards and holds relevant certifications for quality assurance.

Cost Considerations

– Bulk Purchasing: Buying in bulk often reduces costs but ensure the volume matches your needs to avoid unnecessary stockpiling.

– Shipping Costs: Consider the shipping costs, especially for large or heavy orders, as they can significantly impact the overall expense.

Laser Compatibility

– Material Composition: Ensure the acrylic is suitable for laser cutting and doesn’t contain additives that can produce hazardous fumes or damage the laser.

– Protective Film: Opt for acrylic sheets with a protective film to prevent scratches during handling and cutting.

Technical Specifications

– Sheet Size: Match the sheet size with your laser cutter’s bed size to optimize material usage and minimize wastage.

– Cutting Tolerances: Verify the material’s cutting tolerances with your laser cutter’s capabilities to ensure precise cuts.

Environmental Considerations

– Recyclability: Choose acrylic sheets that are recyclable to support sustainability initiatives.

– Waste Management: Implement a waste management plan for acrylic off-cuts and scraps.

Post-Purchase Support

– Technical Assistance: Ensure the supplier provides technical support for troubleshooting any issues related to the material.

– Return Policies: Understand the return policies in case the acrylic sheets do not meet your specifications.

By considering these factors, you can ensure a smooth procurement process and achieve high-quality results in your laser cutting projects.

FAQs on Sourcing and Manufacturing from acrylic sheets laser cutting in China

Certainly! When sourcing acrylic sheets laser cutting services from China, several frequently asked questions (FAQs) typically arise:

1. Quality Assurance: How can I ensure the quality of laser cutting from Chinese suppliers?

– Answer: Look for suppliers with certifications like ISO 9001, which ensures adherence to international quality standards. Request samples and check client testimonials for feedback on their quality consistency.

2. Lead Times: What are the typical lead times for acrylic laser cutting orders from China?

– Answer: Lead times can vary based on order complexity and supplier capacity. Generally, it ranges from a few days to a few weeks. Clarify lead time expectations upfront and ensure they align with your project timeline.

3. Cost Considerations: How do costs for laser cutting in China compare to other regions?

– Answer: Chinese suppliers often offer competitive pricing due to lower labor and material costs. However, consider shipping and import duties when evaluating total costs.

4. Communication and Language: How do I overcome language barriers and ensure effective communication?

– Answer: Choose suppliers with English-speaking staff or employ translators. Clear communication channels (email, video calls) help in conveying specifications accurately.

5. Customization and Prototyping: Can Chinese suppliers accommodate custom designs and prototypes?

– Answer: Many suppliers offer custom laser cutting services and prototype development. Provide detailed CAD drawings or specifications to ensure precise fabrication.

6. Environmental Compliance: What environmental standards do Chinese suppliers adhere to?

– Answer: Ensure suppliers follow environmental regulations and provide materials compliant with relevant standards (e.g., RoHS, REACH).

By addressing these FAQs, you can make informed decisions when sourcing acrylic sheets laser cutting services from China, ensuring quality, cost-effectiveness, and timely delivery aligned with your project needs.