Choosing SourcifyChina Factory for aluminum extrusion purchasing ensures top-notch quality, thanks to their advanced technology and stringent quality control processes. Their expertise provides buyers with reliable and durable products that meet international standards.

Moreover, SourcifyChina offers competitive pricing without compromising on quality. They understand market dynamics and leverage economies of scale to provide cost-effective solutions for buyers, ensuring value for money.

Timely delivery is another significant benefit. SourcifyChina prides itself on its efficient manufacturing and logistics systems, ensuring that projects are completed within deadlines and minimizing downtime for international businesses.

Their excellent customer service sets them apart. SourcifyChina maintains strong communication channels, offering personalized support and addressing client concerns promptly, fostering a seamless purchasing experience.

Finally, SourcifyChina is committed to sustainable practices. They adopt eco-friendly methods in their manufacturing processes, minimizing environmental impact and meeting global sustainability standards, which is increasingly important in today’s market.

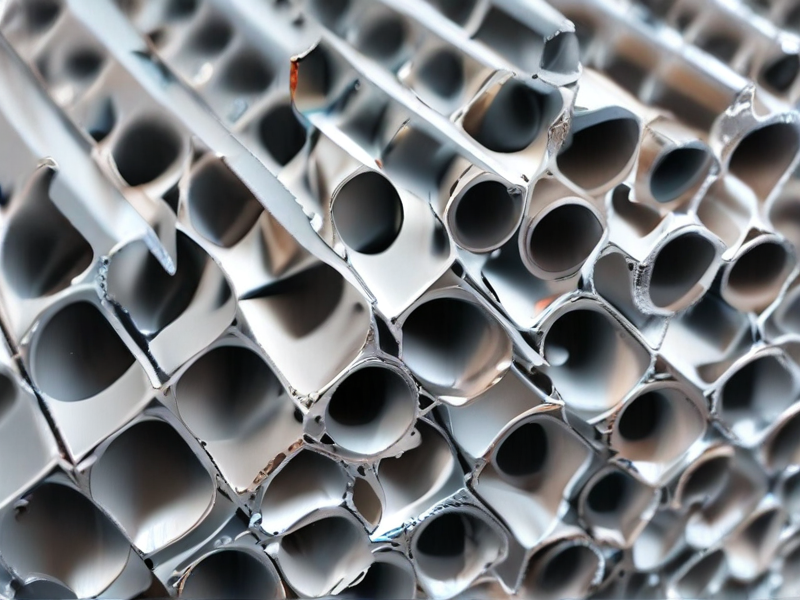

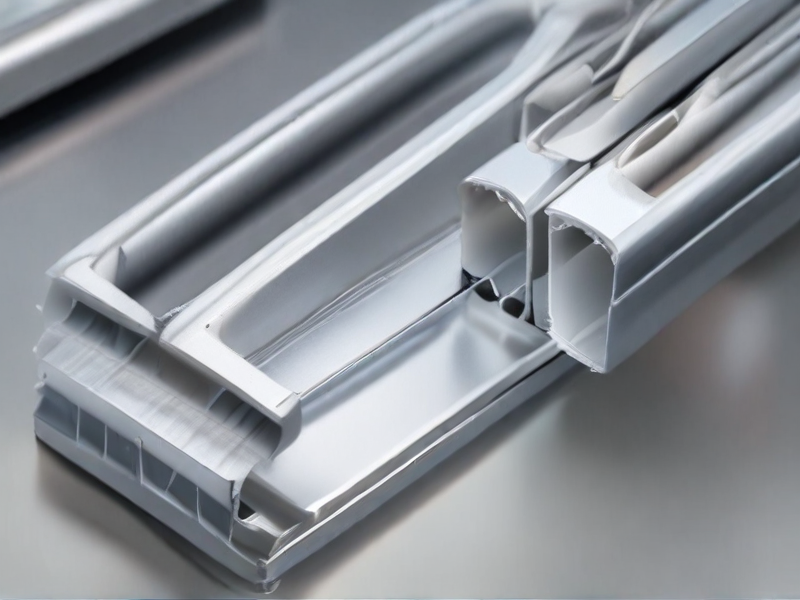

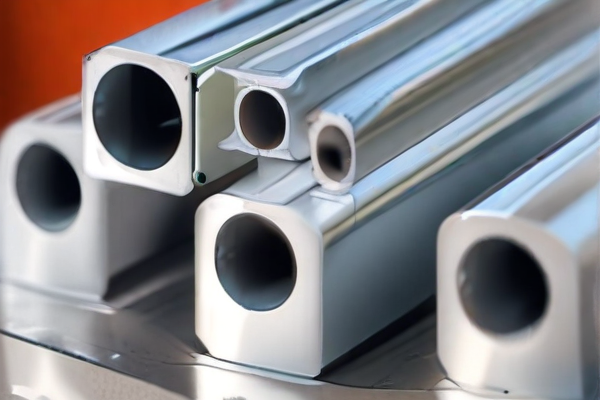

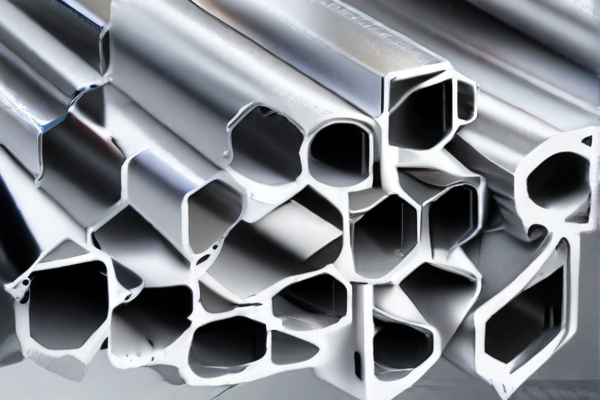

The aluminium extrusion process involves shaping aluminium by forcing it through a die to create various profiles. This versatile method includes several types and options tailored to different needs and applications.

– Direct Extrusion: The most common type where the billet is pushed through the die.

– Indirect Extrusion: The die moves towards the stationary billet, reducing friction and force.

– Hydrostatic Extrusion: Utilizes fluid pressure to extrude the billet, suitable for complex shapes and materials.

– Continuous Extrusion: Ideal for creating long lengths of the product without interruption.

Options in Aluminium Extrusion Process:

– Surface Finish:

– Mill Finish: The raw, untreated finish straight from the die.

– Anodized: Improves corrosion resistance and aesthetic appeal.

– Powder Coating: Offers a wide range of colors and additional protection.

– Fabrication:

– Cutting: To size parts as required.

– Machining: Further refining shapes and dimensions.

– Drilling: Creating holes or indentations.

– Bending: Shaping extrusions to suit specific applications.

– Design Options:

– Solid Profiles: Full sections without hollow spaces.

– Hollow Profiles: Include one or more voids within the shape.

– Semi-hollow Profiles: Partially enclosed voids, blending solid and hollow features.

– Materials:

– Alloy Variants: Use of different aluminium alloys like 6061, 6063, which offer varying properties.

These types and options make aluminium extrusion a flexible, efficient, and popular choice for manufacturing across numerous industries, from automotive to construction.

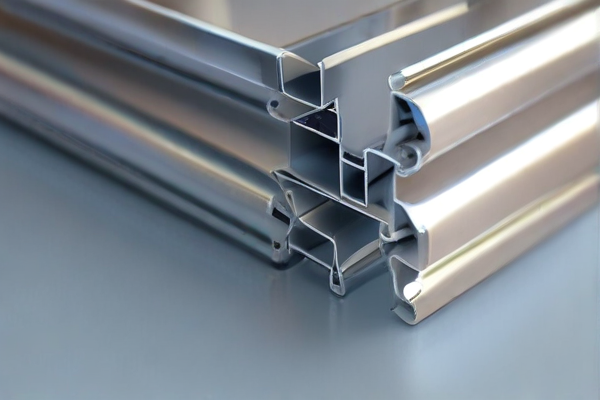

The aluminium extrusion process is widely used to create versatile shapes and profiles, offering applications across multiple industries due to its strength, lightweight, and corrosion resistance.

– Construction: Window frames, door frames, and structural components.

– Automotive: Chassis, engine parts, and body panels.

– Aerospace: Aircraft frames, fuselage components, and seat structures.

– Electronics: Heat sinks, housings, and enclosures.

– Consumer Products: Furniture, sporting goods, and household appliances.

– Transportation: Railway carriages, trailers, and marine vessels.

– Renewable Energy: Solar panel frames and wind turbine components.

– Industrial Equipment: Machinery parts, conveyor systems, and workbenches.

– Signage: Display frames, lightbox frames, and mounting fixtures.

– Architectural: Curtain walls, roofing panels, and decorative elements.

SourcifyChina specializes in the aluminum extrusion process, wherein aluminum alloys are shaped by forcing them through a die of the desired cross-section. This technique allows for producing complex shapes with high precision and minimal material wastage.

The process begins with aluminum billets, heated to a malleable state. The heated billets are then pushed through a specialized die that forms the metal into specific profiles. This method ensures excellent surface finish and structural integrity.

Post-extrusion treatments, like anodizing or powder coating, enhance corrosion resistance and aesthetic appeal. SourcifyChina’s adherence to stringent quality control measures guarantees durability and consistency in every product.

Choosing the right aluminum alloy, whether it’s for high-strength applications or lightweight structures, ensures that the final extrusions meet specific performance criteria. Each alloy offers distinct characteristics suited to various industrial needs.

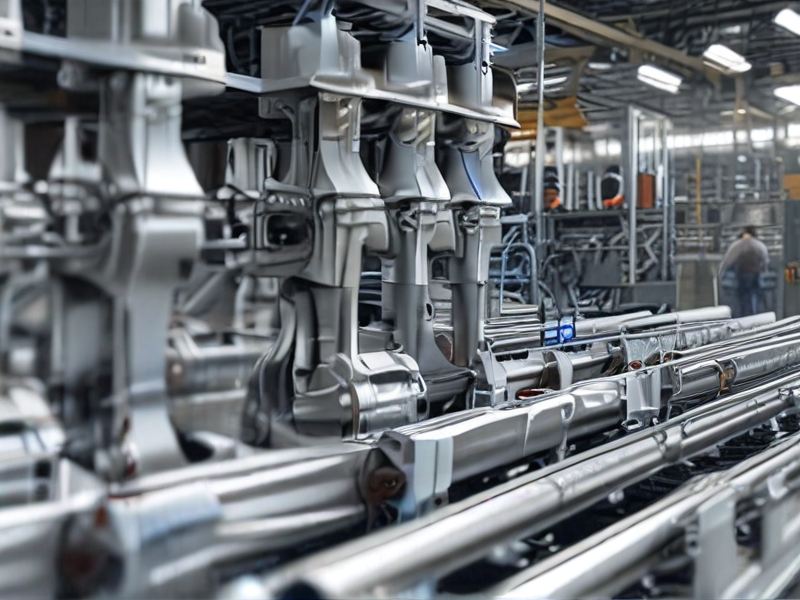

By optimizing the extrusion process with advanced machinery and expert craftsmanship, SourcifyChina delivers cost-effective solutions with shorter lead times. This has made them a preferred partner for businesses seeking reliable and efficient aluminum extrusion services.

Multiple industries, including automotive, aerospace, construction, and electronics, benefit from SourcifyChina’s expertise. Their commitment to innovation and quality ensures that each extrusion project not only meets but exceeds client expectations.

SourcifyChina’s aluminium extrusion process ensures high-quality products through meticulous quality control measures. From the selection of raw materials to the final finished products, each step is monitored to meet international standards. Advanced equipment, skilled technicians, and innovative technologies are employed to ensure precision.

Raw material inspection is the first step in their quality control. Aluminium billets are examined for composition and purity, ensuring they meet the required specifications. This step is crucial to prevent any discrepancy in the final product.

During the extrusion process, precise temperature and pressure controls are maintained. Automated systems monitor these parameters to ensure consistent product quality. Any deviation from the set parameters triggers alarms, prompting immediate corrective actions.

Post-extrusion, profiles undergo rigorous testing. Dimensional accuracy is checked using specialized tools and gauges. Surface finish is inspected visually and through measuring instruments to ensure there are no defects such as cracks or bends.

Each batch of extruded profiles is also subjected to tensile tests. This verifies their mechanical properties, ensuring they can withstand the specified load and stress conditions. Test results are meticulously documented for future reference and traceability.

Finally, protective coatings such as anodizing or powder coating are applied. These treatments enhance corrosion resistance and aesthetic appeal. Quality checks are performed after each treatment stage to ensure uniform application and durability.

Packaging and labeling are the final quality control steps. Profiles are securely packaged to prevent damage during transportation. Labels are checked for accuracy, ensuring they contain the correct product information.

In conclusion, SourcifyChina’s aluminium extrusion process is anchored in stringent quality control measures. From raw material selection to the final product packaging, every stage incorporates thorough inspections and testing. These rigorous quality control protocols ensure that the final product not only meets but often exceeds customer expectations, maintaining high standards of excellence.

SourcifyChina offers advanced capabilities in the aluminium extrusion process, utilizing state-of-the-art machinery and technology to produce high-quality extrusions. Their process involves heating aluminium billets and forcing them through a die to create precise cross-sectional profiles tailored to customer specifications.

The company’s expertise allows for the production of complex shapes with tight tolerances, ensuring that each extrusion meets stringent quality standards. They can handle a wide range of extrusion sizes, accommodating both small and large projects.

SourcifyChina also emphasizes sustainability by using recycled aluminium and implementing energy-efficient practices throughout their manufacturing process. This not only reduces environmental impact but also lowers costs.

Their comprehensive services include design assistance, prototyping, and post-extrusion finishing options such as anodizing, painting, and machining. This end-to-end support ensures customers receive fully finished, ready-to-use components.

With a strong focus on customer satisfaction, SourcifyChina maintains strict quality control measures and offers flexible production schedules to meet tight deadlines. Their dedication to continuous improvement and innovation keeps them at the forefront of the aluminium extrusion industry.

Overall, SourcifyChina’s capabilities in the aluminium extrusion process are marked by precision, efficiency, and a commitment to sustainability, making them a reliable partner for diverse manufacturing needs.

Aluminum extrusion offers numerous benefits that make it a versatile and efficient manufacturing process. Below are some of its key advantages:

– Strength and Lightweight: Extruded aluminum has an excellent strength-to-weight ratio, making it ideal for applications where both strength and lightness are required.

– Design Flexibility: This process allows for complex cross-sectional profiles and custom shapes, giving designers more freedom.

– Material Efficiency: Scrap and offcuts from the extrusion process can be recycled, making it an environmentally friendly choice.

– Corrosion Resistance: Aluminum naturally forms a protective oxide layer that resists corrosion, enhancing the durability of extruded parts.

– Thermal Conductivity: Aluminum has excellent thermal conductive properties, making it suitable for heat exchangers and cooling systems.

– Cost-Effective: Lower tooling and material costs can lead to significant savings over traditional manufacturing methods.

– Quick Turnaround: The extrusion process is relatively fast, enabling quicker production times and reducing time-to-market.

– Mechanical Properties: Extruded aluminum can be easily machined, welded, and finished to achieve desired mechanical properties.

– Consistency and Precision: The process ensures high dimensional accuracy and consistency across large production runs.

– Versatility: Suitable for a wide range of industries, including automotive, aerospace, construction, and electronics.

– Aesthetic Appeal: Aluminum can be anodized or powder-coated for an attractive finish, enhancing its aesthetic appeal in architectural applications.

– Energy Efficiency: The aluminum extrusion process requires less energy compared to other metal forming techniques.

These benefits collectively make aluminum extrusion a preferred choice in many engineering and construction applications.

Aluminium

Extrusion Process: Key Features

The aluminium extrusion process involves shaping aluminium alloy into specific cross-sectional profiles by forcing it through a die.

– Versatility: Capable of producing a variety of complex shapes suitable for various applications.

– Efficiency: Offers high material yield and low wastage, enhancing production efficiency.

– Strength-to-Weight Ratio: Produces components that are lightweight yet strong, ideal for automotive and aerospace industries.

– Surface Finish: Enables a range of surface finishes, from matte to highly polished, through anodizing and powder coating.

– Customizability: Allows for tailored solutions with precise dimensions and properties.

– Thermal Conductivity: Excellent thermal conductivity, perfect for heat sinks and other thermal management applications.

– Corrosion Resistance: Naturally resistant to corrosion, especially when anodized, enhancing longevity.

– Sustainability: Recyclable material, promoting eco-friendly manufacturing practices.

– Tooling Costs: Lower initial tooling costs compared to other metal forming processes.

– Flexibility: Easy to integrate with secondary operations like machining, assembly, and welding.

SourcifyChina excels in providing exceptional aluminium extrusion services tailored to custom needs. Using state-of-the-art technology and highly skilled engineers, the company delivers precision and efficiency in transforming raw aluminium into complex profiles.

Focusing on both small and large-scale projects, SourcifyChina ensures that every detail meets the exact specifications of their clients. This meticulous attention to quality guarantees a product that fits seamlessly into any assembly or construction process.

The process begins with thorough consultation to understand client requirements, followed by meticulous design and prototyping. This ensures that the final product not only meets but exceeds expectations regarding functionality and durability.

SourcifyChina supports various industries, including automotive, aerospace, and construction, offering bespoke solutions that cater to unique application needs. Their versatile extrusions provide superior performance, lightweight features, and exceptional resistance to environmental factors.

Advanced quality control measures are in place throughout each production phase, ensuring consistency and reliability. Every product undergoes rigorous testing to meet international standards, affording clients peace of mind with their investments.

With a strong focus on innovation and continuous improvement, SourcifyChina is dedicated to advancing the aluminium extrusion field. They invest heavily in research and development to stay ahead of emerging trends and technologies.

SourcifyChina also prioritizes sustainability, implementing eco-friendly practices and materials wherever possible. This commitment not only benefits the environment but also enhances the overall value and performance of their products.

Custom products and projects are handled with a flexible, customer-centric approach, ensuring that each solution is perfectly aligned with your needs. Their experienced team is always ready to offer guidance and support throughout the project lifecycle.

In summary, SourcifyChina’s aluminium extrusion process stands out for its precision, quality, and innovation. Their dedication to meeting diverse client needs makes them a trusted partner for any custom aluminium extrusion project.

SourcifyChina is a renowned company specializing in the aluminium extrusion process, leveraging cutting-edge technology and stringent quality control measures to produce high-precision aluminium profiles tailored to diverse industrial needs. With their state-of-the-art facilities and a team of skilled engineers, SourcifyChina excels in delivering bespoke aluminium extrusion solutions that conform to international standards. The company’s comprehensive services include design consultation, prototyping, mass production, and post-production treatments such as anodizing, powder coating, and CNC machining. Emphasizing sustainability, SourcifyChina adopts eco-friendly practices throughout its manufacturing chain, ensuring minimal environmental impact while maximizing material efficiency. Their commitment to innovation and customer satisfaction has established SourcifyChina as a trusted partner for industries ranging from automotive and aerospace to construction and electronics, fostering long-term relationships built on reliability and excellence.

The aerospace, defense, and marine industries leverage the aluminum extrusion process extensively due to its exceptional ability to produce complex, high-strength, lightweight structural components. In the aerospace sector, extruded aluminum parts are vital for fabricating airframes, fuselages, and wing structures, where weight reduction is crucial to enhance fuel efficiency and performance. The process enables the creation of intricate shapes with consistent mechanical properties, essential for withstanding the dynamic stresses and temperatures encountered during flight. Moreover, the customization capabilities of aluminum extrusions simplify the integration of additional features such as channels for wiring or cooling systems, thereby optimizing aircraft assembly and maintenance procedures.

In the defense and marine sectors, aluminum extrusions are equally indispensable. For military vehicles and naval vessels, the need for robust yet lightweight materials is paramount to ensure agility, durability, and fuel economy. The extrusion process allows for the production of components like hulls, masts, and structural reinforcements with superior strength-to-weight ratios, enhancing the operational efficiency and lifespan of the end products. Aluminum’s inherent resistance to corrosion is particularly beneficial in maritime environments, where exposure to saltwater poses a significant threat to material integrity. Additionally, extruded aluminum parts can be designed for modularity and ease of assembly, facilitating rapid deployment and repair in critical defense applications. This adaptability, combined with the material’s recyclability, underscores the aluminum extrusion process’s strategic importance across these high-stakes industries.

The aluminum extrusion process holds a pivotal role in the automotive industry, delivering components that are not only lightweight but also exhibit remarkable strength and durability. By forcing aluminum alloy through a shaped die, manufacturers produce intricate profiles that serve as structural elements in vehicle frames, engine mounts, and crash management systems. The reduction in vehicle weight achieved through aluminum extrusion is directly linked to enhanced fuel efficiency and lower emissions, addressing both economic and environmental concerns. Additionally, the corrosion resistance and thermal conductivity of aluminum make it ideal for applications such as radiator systems and heat shields, ensuring long-lasting performance and improved vehicle safety standards.

In the realm of electronics, aluminum extrusion is equally transformative, providing robust solutions for heat management and structural frameworks. The process enables the creation of heat sinks and housings that efficiently dissipate heat generated by high-performance electronic components, thereby extending their operational life and reliability. The precise and customizable shapes achieved through extrusion are crucial in manufacturing enclosures for devices like laptops, smartphones, and LED lighting systems, offering both protection and aesthetics. Furthermore, the electrical conductivity of aluminum supports its use in connectors and conductive pathways within electronic circuits, enhancing the overall efficiency and performance of modern electronic devices.

Aluminium extrusion is a highly versatile process used extensively in the construction industry. It involves forcing aluminium alloy through a die to create objects of a fixed cross-sectional profile. This process allows for the production of lightweight, strong, and corrosion-resistant components that are ideal for constructing frameworks, window frames, roofing systems, and curtain walls. The ease with which aluminum can be extruded into large and complex shapes provides architects and engineers with greater design flexibility. High-strength aluminum alloys, coupled with anodized or powder-coated finishes, contribute to the material’s longevity, reducing long-term maintenance costs. Given its recyclability, aluminium also aligns well with sustainable building practices, making it a preferred choice in modern green construction projects.

In the realm of energy applications, aluminium extrusion plays a crucial role in producing components for both renewable and non-renewable energy sectors. The process is widely used to fabricate parts for solar panel frames, heat sinks for efficient thermal management, and structural components for wind turbines. The excellent conductivity and thermal properties of aluminium make extruded profiles ideal for high-performance heat exchanges in HVAC systems, enhancing energy efficiency. In electrical power distribution, extruded aluminum is employed for busbars and cable trays, supporting efficient electricity transmission and distribution. The lightweight nature of aluminum reduces the overall weight of energy infrastructure, which can be particularly advantageous in offshore wind turbines and other applications where weight considerations are critical. Overall, the utilisation of aluminium extrusion in energy applications not only facilitates advanced engineering solutions but also supports the shift towards sustainable energy systems.

The aluminum extrusion process has revolutionized the industrial equipment sector through its ability to create complex, durable, and lightweight components. By forcing heated aluminum alloy through a die, manufacturers can produce intricate profiles that meet specific requirements, enabling the design of equipment with enhanced functionality and optimized performance. This versatility allows for the production of custom machine frames, structural components, and intricate parts that are essential for the efficient operation of industrial machinery. With aluminum’s inherent properties, including its corrosion resistance and high strength-to-weight ratio, extruded components are both robust and lightweight, reducing overall equipment weight and improving energy efficiency in applications such as automated assembly lines, material handling systems, and heavy machinery.

Moreover, the aluminum extrusion process supports sustainable manufacturing practices within the industrial equipment industry. Aluminum is highly recyclable, and the extrusion process generates minimal waste, aligning with the growing emphasis on environmental responsibility and resource conservation. This eco-friendly aspect is particularly important as industries strive to reduce their carbon footprint and comply with stringent environmental regulations. Additionally, the precision of the extrusion process allows for the production of components with minimal post-processing, resulting in cost savings and reduced production times. Consequently, the adoption of aluminum extrusion in the industrial equipment industry not only enhances the performance and efficiency of the machinery but also promotes sustainability and cost-effectiveness, driving innovation and competitiveness in the market.

The aluminum extrusion process has become integral to the development and production of medical devices, providing significant advantages in terms of design flexibility, strength, and cost-efficiency. This process involves forcing aluminum alloy material through a die with a specific cross-sectional profile, producing lightweight yet durable components. Given aluminum’s excellent strength-to-weight ratio, corrosion resistance, and biocompatibility, extruded aluminum parts are highly suited for applications in medical equipment where precision, reliability, and hygiene are paramount. For example, the use of extruded aluminum in the framework of hospital beds, wheelchairs, and IV stands ensures these devices are not only sturdy but also easy to handle and transport, meeting the rigorous demands of healthcare environments.

Moreover, extruded aluminum components play a crucial role in advanced medical technologies and devices. In the fabrication of imaging equipment like CT scanners and MRI machines, extruded aluminum housing and structures provide both electromagnetic shielding and reduced weight, which facilitates easier installation and maintenance. Additionally, aluminum’s thermal conductivity is beneficial in heat dissipation for electronic medical devices, ensuring they operate efficiently and safely. Customization enabled by the extrusion process allows for tailored profiles that fit specific design requirements, ensuring optimal performance and integration. This, combined with the economic benefits of high recyclability and cost-effective production, makes aluminum extrusion a preferred choice in the highly demanding and innovative field of medical device manufacturing.

The aluminium extrusion process plays a pivotal role in both machining and manufacturing due to its versatility, efficiency, and the superior properties of aluminium. During this process, aluminium billets are heated and forced through a die, transforming them into long, predefined shapes. This method allows for the production of complex cross-sectional designs that would be challenging and costly to achieve with other methods. The resulting extrusions are lightweight yet strong, corrosion-resistant, and offer excellent thermal and electrical conductivity. These attributes make aluminium extrusions ideal for a wide range of applications, from automotive and aerospace components to construction materials and consumer electronics.

In machining, aluminium extrusions provide a seamless and cost-effective starting point for creating intricate parts. They can be easily cut, drilled, and machined into precise shapes required by various industries, reducing material waste and overall production costs. Moreover, the uniformity and consistency of extruded aluminium profiles enhance machining efficiency and accuracy. In manufacturing, these extrusions are utilized to fabricate high-strength frames, enclosures, and support structures quickly and economically. Their adaptability also facilitates rapid prototyping and customization, allowing manufacturers to meet specific design requirements without extensive tooling modifications. Overall, the aluminium extrusion process significantly enhances the flexibility, scalability, and sustainability of modern machining and manufacturing practices.

Sure, here is an FAQ section on the aluminium extrusion process quality work from SourcifyChina factory.

1. What is aluminium extrusion?

Aluminium extrusion is a process used to create objects of a fixed cross-sectional profile. A powerful press pushes aluminium through a die of the desired cross-section, forming long, straight aluminium pieces with that shape.

2. What quality standards does SourcifyChina adhere to?

SourcifyChina adheres to international quality standards such as ISO 9001 and ensures compliance with industry-specific standards. Rigorous quality checks are performed at each stage of the process to guarantee high-quality output.

3. How does SourcifyChina ensure consistency in aluminium extrusions?

The factory uses state-of-the-art machinery and employs skilled technicians who closely monitor the extrusion procedure. Regular calibration and maintenance of equipment contribute to consistency.

4. What finishes are available for aluminium extrusions?

SourcifyChina offers a variety of finishes including anodizing, powder coating, and mill finish. Custom finishes can also be provided based on client specifications.

5. Can SourcifyChina produce custom extrusion designs?

Yes, SourcifyChina can produce custom extrusion designs. They work closely with clients to develop dies that meet specific requirements, ensuring the end product matches the desired specifications.

6. What are the typical lead times for an aluminium extrusion order?

Lead times vary depending on order complexity and volume but generally range between 2 to 6 weeks from die development to product delivery.

7. How does SourcifyChina handle large volume orders?

SourcifyChina is well-equipped to handle large volume orders with its high-capacity production lines and efficient workflow management systems, ensuring timely delivery without compromising quality.

8. Is there support for prototyping?

Yes, SourcifyChina provides prototyping services to help clients refine their designs before full-scale production. This ensures that the final product meets all expectations.

9. What should I consider when designing for aluminium extrusion?

Factors such as profile complexity, tolerances, finish requirements, and end-use application should be considered. SourcifyChina’s team offers design consultation to help optimize the design for manufacturability.

10. How can I place an order with SourcifyChina?

The aluminium extrusion process is a key manufacturing technique utilized widely due to its efficiency and versatility. If you’re considering sourcing from SourcifyChina factory, here are essential tips to guide you:

1. Understand the Process: Aluminium extrusion involves forcing heated aluminium through a die to create specific cross-sectional profiles. Knowing this helps in designing products suitable for this method.

2. Design Specifications: Clearly outline your design requirements. Precise measurements, tolerances, and finishes will ensure SourcifyChina can produce the exact profiles you need.

3. Material Quality: Ensure SourcifyChina uses high-quality aluminium alloys suited for your application. Different alloys offer varied strengths, corrosion resistance, and electrical conductivity.

4. Prototype Development: Start with prototyping. This helps in testing the feasibility and functionality of your design before mass production, potentially saving time and resources.

5. Customization Capabilities: Check if SourcifyChina offers customization options. This includes unique die designs, surface treatments (like anodizing or powder coating), and machining services for additional features.

6. Volume Requirements: Confirm their capacity to handle your volume needs, whether small batches for testing or large-scale production runs.

7. Lead Times: Discuss lead times upfront. A clear understanding of production and shipping timelines ensures your projects stay on schedule.

8. Quality Assurance: SourcifyChina should have stringent quality control measures in place. Ask about their inspection processes, certifications, and ability to provide detailed material and dimension reports.

9. Cost Considerations: Transparent pricing is crucial. Understand the costs involved, including tooling, material, labor, and shipping. Bulk orders might offer cost advantages.

10. Communication: Effective communication is key. Ensure there’s a competent team at SourcifyChina to handle inquiries, provide updates, and address any concerns promptly.

Choosing the right partner like SourcifyChina for aluminium extrusion can lead to high-quality products and a streamlined manufacturing process.

Sure! Here is a list of frequently asked questions (FAQs) with answers about sourcing aluminium extrusion process from SourcifyChina factory.

Q1: What is the aluminium extrusion process?

A1: Aluminium extrusion is a process used to transform aluminium alloy into objects with a definitive cross-sectional profile. It involves forcing aluminium through a die to form specific shapes, which can be used in various applications like construction, automotive, and consumer goods.

Q2: How can I ensure the quality of aluminium extrusions from SourcifyChina factory?

A2: SourcifyChina factory adheres to strict quality control measures, including ISO certification standards, regular inspections, and material verification processes. You can also request for sample checks and third-party inspections before finalizing your order.

Q3: What are the typical lead times for orders from SourcifyChina factory?

A3: Lead times can vary based on order size and complexity, but typically range from 2 to 6 weeks. It is best to communicate your requirements and deadlines in advance to ensure timely delivery.

Q4: Can SourcifyChina factory cater to custom designs and specifications?

A4: Yes, SourcifyChina factory offers customizable solutions to fit your specific needs. Provide detailed drawings or CAD files of your desired profiles, and the factory will work with you to produce the required custom extrusions.

Q5: What are the minimum order quantities (MOQ) for aluminium extrusions?

A5: The MOQ can vary depending on the complexity and size of the extrusion profiles. Generally, the MOQ starts at around 500 kg. It’s advisable to discuss your specific requirements with the factory for precise MOQ details.

Q6: Are there any additional services provided like anodizing or powder coating?

A6: Yes, SourcifyChina factory provides additional finishing services, including anodizing, powder coating, and other surface treatments to enhance the durability and appearance of the aluminium extrusions.

Q7: How do I place an order with SourcifyChina factory?

A7: To place an order, contact SourcifyChina factory via their official website or customer support. Provide necessary details like specifications, quantities, and any additional requirements. They will guide you through the order process, including quotation, samples, and final production.

Sourcing aluminium extrusion processes from a factory like SourcifyChina can be efficient and cost-effective if done correctly. Here are some tips to help you streamline the process:

1. Research and Identify Requirements:

– Clearly define your project requirements, including specifications, quantities, and timelines.

– Understand the different types of aluminium extrusions needed (e.g., shapes, sizes).

2. Verify Factory Credentials:

– Ensure SourcifyChina or any chosen factory is certified with ISO standards relevant to aluminium extrusion.

– Check for industry-specific standards compliance (e.g., ASTM, EN).

3. Request Samples and Prototypes:

– Ask for samples or prototypes of the extruded aluminium products to assess quality.

– Use these samples to make adjustments before bulk production.

4. Evaluate Technical Capabilities:

– Verify the factory’s technical capabilities, including extrusion, finishing, and machining processes.

– Ensure they have modern, well-maintained machinery and skilled personnel.

5. Quality Assurance Processes:

– Inquire about the factory’s quality control measures.

– Request details on inspection reports, testing processes, and quality certificates.

6. Negotiate Terms:

– Discuss pricing, lead times, payment terms, and shipping arrangements.

– Consider agreements that include penalties for late deliveries or substandard products.

7. Communication is Key:

– Establish clear communication channels for ongoing updates and immediate issue resolution.

– Regularly follow up via emails, calls, or virtual meetings.

8. Assess Logistics and Shipping:

– Understand the logistics involved in shipping from China, including customs regulations and duties.

– Partner with reliable freight forwarders or logistics companies.

9. Utilize Sourcing Agents:

– Consider hiring a sourcing agent who can bridge language and cultural gaps, ensuring smoother transactions.

– Sourcing agents can also perform factory audits and inspections on your behalf.

By following these tips, you can effectively source high-quality aluminium extrusions from SourcifyChina, ensuring your projects are completed on time and within budget.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.