Choosing “SourcifyChina” Factory for purchasing aluminum extrusion CNC from China ensures unmatched quality control. They employ rigorous inspection procedures, which guarantee high standard products. Leveraging cutting-edge technology, they maintain precision in every extrusion process.

SourcifyChina stands out for its excellent customer service. With dedicated support teams, they address any inquiries or concerns promptly, making the purchasing processes seamless for international buyers.

Their competitive pricing model is another significant advantage. By sourcing directly from the factory, buyers can benefit from lower costs without compromising on quality, enhancing overall value for their investment.

Moreover, “SourcifyChina” possesses extensive industry experience. Their expertise in CNC machining and aluminum extrusion assures reliability and technical proficiency. Their knowledge fosters innovation and efficiency, ensuring buyers receive superior products.

In summary, “SourcifyChina” Factory offers top-notch quality control, exceptional customer service, competitive pricing, and deep industry expertise, making it a leading choice for buyers sourcing aluminum extrusion CNC from China.

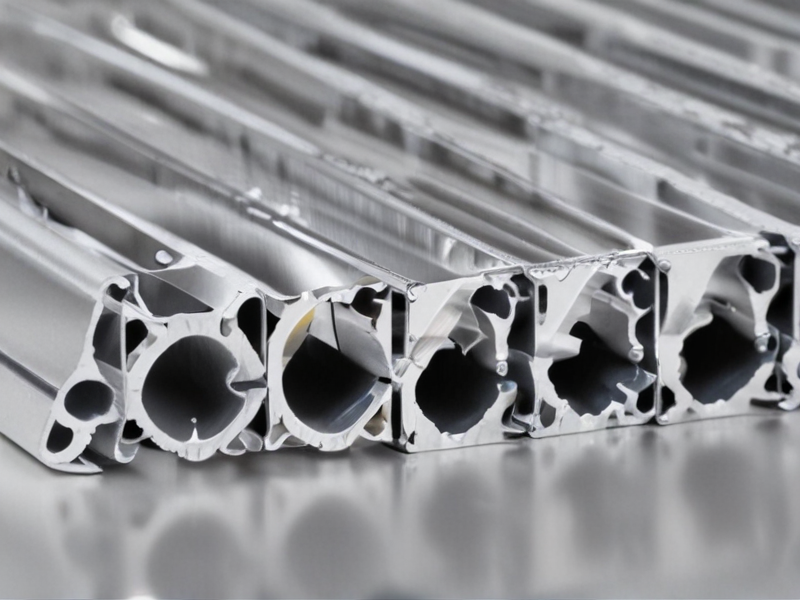

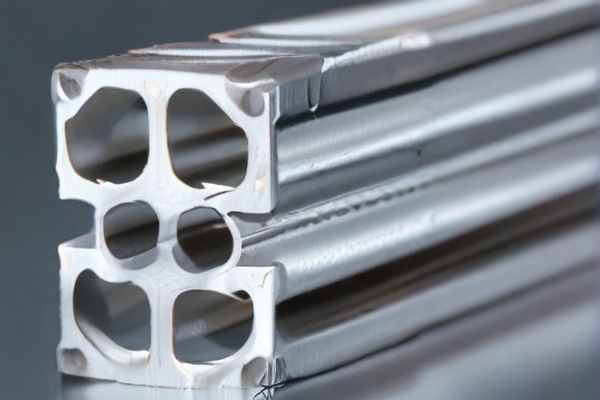

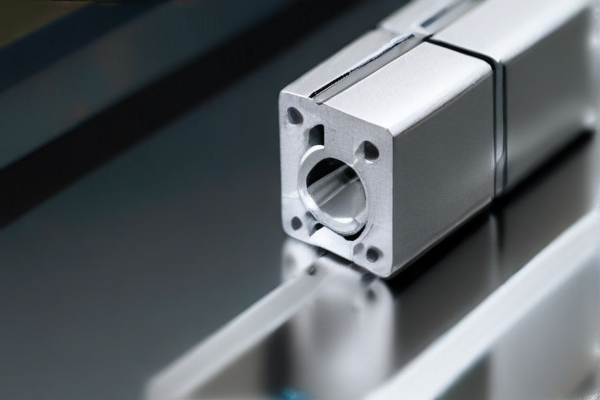

Aluminum extrusion CNC involves shaping aluminum profiles using CNC (Computer Numerical Control) machining for precise and complex designs. This process offers versatility and efficiency, catering to various industrial applications. Key types and options include:

– Standard aluminum extrusions: Predefined shapes for general use.

– Custom aluminum extrusions: Tailored profiles according to specific requirements.

– Heat sinks: Optimized for thermal management solutions.

– Structural extrusions: Used in construction and framing for their high strength.

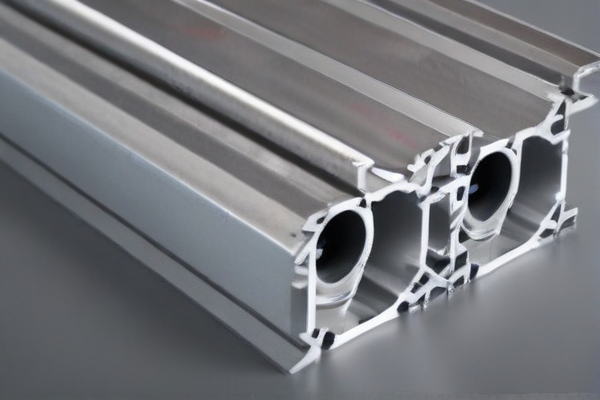

– T-slot extrusions: Versatile profiles for building modular assemblies.

– Anodized extrusions: Enhanced durability and corrosion resistance with aesthetic finishes.

– Powder-coated extrusions: Additional surface protection and color customization.

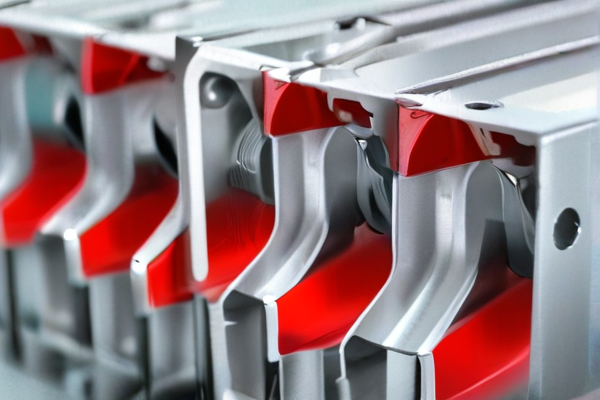

– Multi-slide extrusions: Complex profiles created using multi-slide presses.

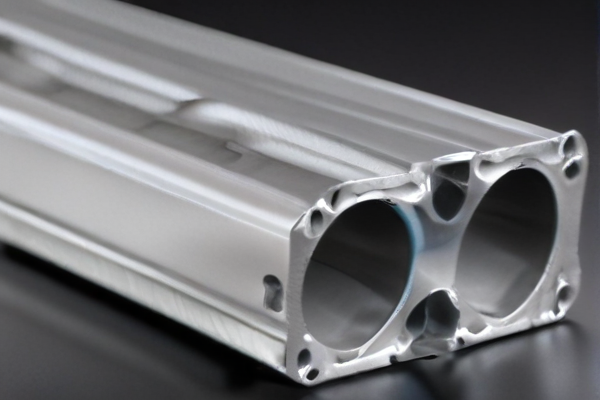

– Hollow extrusions: Lightweight structures with internal cavities.

– Seamless extrusions: Uniform profiles without welded seams for critical applications.

These options provide a myriad of solutions for automotive, aerospace, consumer electronics, and architectural projects, offering both standard and highly specialized aluminum profiles.

Aluminum extrusion CNC applications are diverse, encompassing various industries due to their precision, efficiency, and versatility. Through advanced CNC machining, custom aluminum profiles are fabricated to meet exact specifications, providing a range of innovative solutions.

– Aerospace: Engine components, structural frames, and intricate parts.

– Automotive: Chassis, body panels, transmission housings.

– Construction: Window frames, structural supports, and architectural elements.

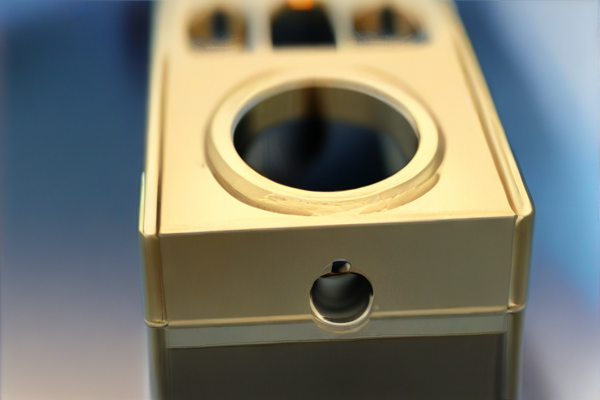

– Electronics: Heat sinks, enclosures for electronic devices, and EMC shielding.

– Renewable Energy: Solar panel frames, wind turbine parts.

– Medical Devices: Equipment housings, surgical instruments, mobility aids.

– Consumer Goods: Furniture, sports equipment, and custom-designed products.

– Industrial Equipment: Machinery parts, conveyor systems, and frame structures.

– Transport: Rail components, marine structures, and bicycle frames.

– HVAC Systems: Frames, ducts, and mounting brackets.

Each application benefits from the precision of CNC machining to create high-quality, durable aluminum parts, tailored to specific industry needs.

“SourcifyChina aluminum extrusion CNC” refers to the high-quality aluminum extrusion parts produced and machined through CNC (Computer Numerical Control) processes by SourcifyChina. Aluminum extrusion involves forcing aluminum alloy through a die to create specific shapes.

The aluminum used by SourcifyChina is typically 6061 or 6063 alloy, known for their excellent mechanical properties and corrosion resistance. These alloys are widely used in aerospace, automotive, and construction due to their strength and durability.

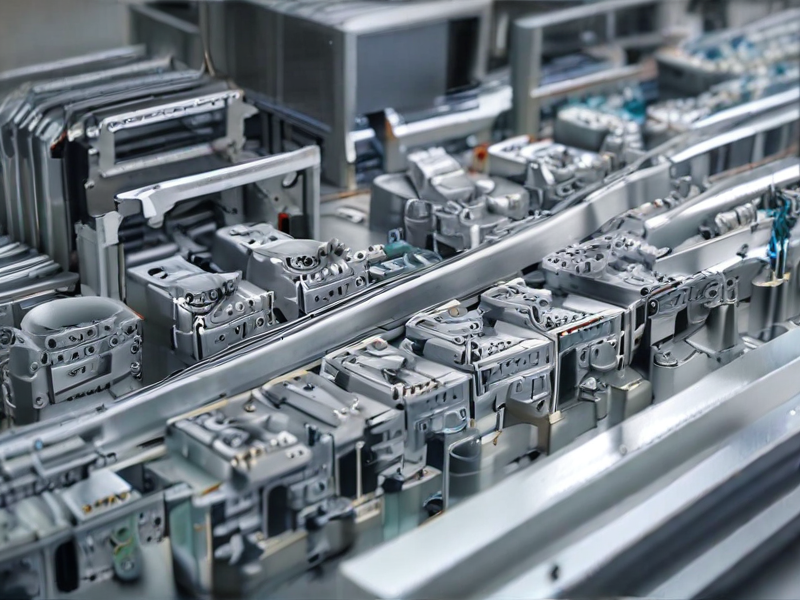

After the extrusion process, the aluminum profiles undergo CNC machining to achieve precise dimensions and intricate designs. CNC machines ensure high accuracy and consistency, which is essential for applications requiring stringent tolerances.

Additionally, finishing processes such as anodizing or powder coating are applied to enhance the aluminum surfaces, providing further resistance to environmental elements and adding aesthetic appeal. These finishes also contribute to the longevity of the parts.

Overall, SourcifyChina focuses on delivering top-notch aluminum extrusion CNC services tailored to meet the specific requirements of various industries. Their expertise ensures that clients receive high-performance and aesthetically pleasing aluminum products.

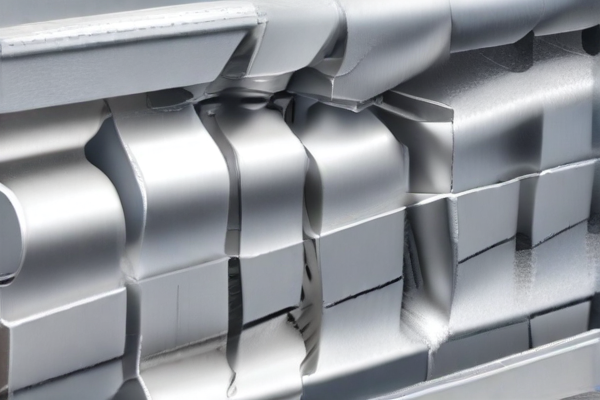

SourcifyChina employs a stringent quality control process in its aluminum extrusion CNC manufacturing. The procedure begins with thorough material selection, ensuring that only high-grade aluminum is used. This initial step is crucial, as raw material quality directly impacts the final product’s durability and performance.

The next phase involves precision machining using state-of-the-art CNC machines. Operators meticulously set up and monitor the machining process to ensure adherence to design specifications. Computer-aided manufacturing (CAM) software aids in achieving consistent, precise results, reducing the margin for human error.

Quality control doesn’t end with machining. Every extruded aluminum component undergoes rigorous inspections. This includes dimensional analysis, surface finish examination, and strength testing. Advanced measurement tools are employed to detect even the slightest deviations from specified tolerances.

SourcifyChina also places significant emphasis on process documentation and traceability. Each production run is documented in detail, enabling easy identification of any issues and facilitating continuous improvement. The documentation includes material certificates, inspection reports, and detailed process records.

In summary, SourcifyChina’s quality control in aluminum extrusion CNC manufacturing is a multi-faceted process. From material selection to final inspections, every step ensures that the products meet the highest industry standards. This meticulous approach guarantees not only the performance and reliability of each component but also customer satisfaction. By maintaining stringent quality control measures, SourcifyChina upholds its commitment to excellence in the manufacturing industry.

SourcifyChina aluminum extrusion CNC capabilities are state-of-the-art, leveraging advanced technology to deliver high-precision and high-quality components. This ensures that every product meets stringent quality standards and specific customer requirements.

One of the primary advantages of SourcifyChina’s CNC machining is its ability to produce complex designs with high efficiency. Precision is maintained even in bulk manufacturing, making it an excellent choice for industries such as automotive, aerospace, and electronics.

Moreover, the company’s services include versatile customization options, from small-scale prototypes to large-volume production. These capabilities cater to the growing demand for specialized and tailored aluminum components.

Additionally, SourcifyChina employs a skilled workforce and utilizes cutting-edge software for design and simulation. This facilitates a seamless workflow from concept to completion, reducing lead times and minimizing risks of errors.

Extensive quality control processes are in place, utilizing advanced inspection equipment and rigorous testing methods. This ensures that each extrusion meets the highest standards and performs reliably in its intended application.

In summary, SourcifyChina’s aluminum extrusion CNC capabilities are comprehensive, efficient, and highly precise. Its technological prowess, combined with a skilled workforce and stringent quality control, make it a trusted partner in various high-stakes industries. Whether for prototyping or mass production, SourcifyChina ensures that customer specifications are met with exceptional accuracy and efficiency.

Aluminum extrusion CNC offers enhanced precision and efficiency, making it integral for various industries that require high-quality components. The following are key benefits:

– Precision and Accuracy: CNC machining ensures tight tolerances and minimal errors.

– Complex Geometries: Allows creation of intricate and complex designs.

– Efficiency: Faster production times compared to traditional methods.

– Material Optimization: Reduces waste by using only the required amount of material.

– Consistency: Delivers consistent, repeatable results in large volumes.

– Strength and Durability: Enhances the mechanical properties of aluminum components.

– Cost-Effective: Reduces labor costs and tool wear.

– Versatility: Suitable for a wide range of applications and industries.

– Automation: Minimizes human intervention, increasing safety.

– Environmental Benefits: Lower energy consumption and recyclable material.

These advantages highlight how aluminum extrusion CNC can significantly improve manufacturing processes.

Aluminum extrusion CNC blends the precision of Computer Numerical Control machining with the versatility of aluminum extrusion techniques, yielding highly accurate and customizable products for various industries.

– Customizability: Allows for intricate shapes and designs tailored to specific requirements.

– Precision: CNC machining ensures high accuracy, tight tolerances, and consistent quality.

– Efficiency: Automated processes reduce production time, increasing overall efficiency.

– Material Properties: Aluminum’s inherent properties like lightweight, strength, and corrosion resistance are maintained.

– Surface Finish: Capable of producing smooth surfaces and fine details, often not requiring additional finishing.

– Sustainability: Aluminum is recyclable, making the process eco-friendly.

– Versatility: Suitable for a wide range of applications, including automotive, aerospace, and consumer electronics.

– Cost-Effective: Reduces waste and manual labor, resulting in cost savings.

– Quality Control: Real-time monitoring and adjustments enhance product consistency and quality.

In summary, aluminum extrusion CNC combines the benefits of customization, precision, and efficiency, leveraged by aluminum’s advantageous material properties to deliver high-quality, versatile, and cost-effective products.

SourcifyChina specializes in aluminum extrusion CNC custom products, providing precise and tailored solutions for various industries. Their expertise in CNC machining ensures high-quality, accurate, and durable aluminum components.

By utilizing advanced machinery and techniques, SourcifyChina manages complex and intricate designs. They cater to diverse applications, including automotive, aerospace, and consumer electronics, ensuring each product meets stringent industry standards.

Their comprehensive project management services include design consultation, prototyping, and full-scale production. SourcifyChina partners closely with clients to understand specifications, ensuring customer satisfaction through the entire manufacturing process.

Custom project requirements are handled with meticulous attention to detail, ensuring optimal performance and longevity of each product. SourcifyChina’s commitment to innovation and quality makes them a reliable partner for aluminum extrusion CNC needs.

This translates into efficient production cycles and cost-effective solutions, benefitting businesses of all sizes. By continuously investing in technology and training, SourcifyChina maintains a cutting-edge advantage in the manufacturing sector.

Clients enjoy tailored solutions that improve operational efficiency and product performance. SourcifyChina’s dedication to excellence and precision makes them a preferred choice for custom aluminum extrusion CNC projects, fostering long-term client relationships.

SourcifyChina Aluminum Extrusion CNC is a premier company specializing in the precision manufacturing of aluminum extrusions and CNC machining services in China. Renowned for its meticulous attention to detail and commitment to quality, SourcifyChina leverages advanced technology and state-of-the-art equipment to deliver tailor-made solutions for a diverse range of industries, including automotive, aerospace, electronics, and construction. The company’s expertise in aluminum extrusion is complemented by its sophisticated CNC machining capabilities, enabling it to produce complex and high-precision components that meet stringent international standards. With a customer-centric approach, SourcifyChina is dedicated to providing exceptional service, fostering long-term partnerships, and delivering cutting-edge products that enhance operational efficiency and innovation for clients worldwide. Their robust quality control processes ensure that every product meets exact specifications, reinforcing the company’s reputation as a trustworthy and reliable partner in the global manufacturing landscape.

Aluminum extrusion combined with CNC (Computer Numerical Control) machining is highly prevalent in aerospace, defense, and marine applications due to its unmatched versatility, precision, and strength-to-weight ratio. In the aerospace industry, these capabilities are essential for producing components like structural frameworks, seat tracks, and landing gear parts where weight minimization without compromising strength is critical. CNC machining brings an added level of precision, allowing for the creation of complex geometries and tight tolerances necessary for the stringent safety and performance standards demanded by aviation authorities. The ability to repeatedly manufacture identical, flawless parts significantly benefits mass production and maintenance cycles in this field.

In the realm of defense, aluminum extrusion with CNC machining addresses the need for durable and lightweight materials for vehicles, weaponry, and protective gear. Military vehicles, drones, and missile components often rely on precisely machined aluminum parts that offer reliable performance in harsh conditions while keeping weight and costs manageable. The marine industry similarly benefits from this technological synergy. Shipbuilding, offshore platforms, and marine equipment necessitate components that resist corrosion while maintaining structural integrity under immense stress and exposure to saltwater. Aluminum’s natural resistance to corrosion is enhanced when CNC precision machining is employed to create intricate designs and customized solutions tailored to specific marine applications. By leveraging aluminum extrusion CNC, these industries achieve optimal performance, reliability, and efficiency in their critical operations.

Aluminum extrusion CNC (Computer Numerical Control) has revolutionized the automotive industry by enabling the production of complex, high-precision components with excellent strength-to-weight ratios. The process involves forcing aluminum through a die to create specific shapes or profiles, which are then intricately machined via CNC technology. This method allows for the creation of lightweight yet durable parts, essential for modern vehicles’ efficiency and performance. Key automotive applications include structural components such as chassis members, crash management systems, and intricate engine components, which benefit from aluminum’s corrosion resistance and thermal conductivity. Additionally, the precision offered by CNC machining ensures that each part meets stringent safety and performance standards, contributing to improved fuel efficiency and reduced emissions in today’s vehicles.

In the realm of electronics, aluminum extrusion CNC plays a crucial role in creating efficient cooling solutions and robust framework elements for a wide array of devices. The electronic components industry relies on aluminum’s excellent thermal conductivity to manage heat dissipation in devices such as heat sinks, radiators, and enclosures for processors and power supplies. The ability to extrude aluminum into intricate finned structures, combined with the precision of CNC machining, allows for optimized thermal management systems that are essential for preventing overheating and ensuring device longevity. Additionally, the lightweight and durable nature of aluminum make it an ideal material for constructing the structural frames and casings of electronics, ranging from smartphones and laptops to large-scale industrial equipment. The versatility of aluminum extrusion CNC thus underpins many of the essential advances in both personal and industrial electronic devices, supporting their functional design and operational reliability.

Aluminum extrusion CNC (Computer Numerical Control) technology has significantly impacted the construction industry by offering versatile and precise manufacturing solutions. This technology enables the creation of complex, custom-designed aluminum profiles that are integral in constructing robust structural frameworks, building facades, and intricate architectural features. The precision of CNC machining ensures that each aluminum component fits together seamlessly, reducing waste and improving structural integrity. Aluminum’s lightweight nature also makes it ideal for construction applications, reducing the overall load while maintaining strength and durability. Furthermore, the corrosion resistance of aluminum extrusions ensures longevity and reduced maintenance costs, making it a preferred material for modern architectural projects.

In the energy sector, aluminum extrusion CNC technology plays a crucial role in the development of efficient and sustainable energy solutions. Custom aluminum extrusions are utilized in the manufacturing of components for solar panels, wind turbines, and energy-efficient lighting systems. The high strength-to-weight ratio of aluminum allows for the production of lightweight yet robust components that can withstand harsh environmental conditions, extending the lifespan of renewable energy systems. Additionally, the precision capabilities of CNC machining enable the production of intricate designs required for heat sinks and other thermal management systems, enhancing the performance and efficiency of energy storage and conversion devices. By leveraging aluminum extrusion CNC technology, the energy industry can continue to innovate and develop more reliable, durable, and efficient solutions, contributing to a sustainable future.

The industrial equipment industry has witnessed transformative advancements with the incorporation of aluminum extrusion CNC (Computer Numerical Control) machining. This technology combines the versatility of aluminum extrusion with the precision of CNC machining, resulting in highly customized, efficient, and durable components essential for industrial applications. Aluminum, with its lightweight, corrosion resistance, and high strength-to-weight ratio, becomes an ideal material when extruded into complex profiles tailored to specific industrial needs. CNC machining further refines these extrusions by precise cutting, drilling, and milling, ensuring that each component meets stringent tolerances and specifications. This meticulous process yields parts that enhance the performance, reliability, and longevity of machinery across various sectors, including manufacturing, aerospace, and automation.

The implications of integrating aluminum extrusion CNC within the industrial equipment sector are profound. For manufacturers, the ability to rapidly prototype and produce parts with exceptional accuracy shortens development cycles and accelerates time-to-market for innovative machinery. For instance, in the automation industry, custom aluminum profiles are crafted to accommodate sensors, actuators, and other critical components with perfect alignment, thereby enhancing the efficiency and productivity of automated systems. Moreover, the inherent recyclability of aluminum aligns with sustainable manufacturing practices, reducing environmental impact. By leveraging the synergy between aluminum extrusion and CNC machining, industrial equipment manufacturers can achieve unparalleled design flexibility, superior mechanical properties, and cost-effective production processes, driving advancements across diverse industrial applications.

Aluminum extrusion combined with CNC (Computer Numerical Control) machining has revolutionized the manufacturing of medical devices. The versatility and precision offered by this technology enable the production of highly intricate and reliable medical instruments and components. The extrusion process allows the creation of complex cross-sectional profiles that are lightweight yet strong, which is essential for devices used in critical medical applications such as surgical tools, imaging equipment, and prosthetic devices. Once extruded, these aluminum components can be further refined and customized using CNC machines, achieving the tight tolerances and sophisticated geometries required for seamless functionality. The ability to mass-produce these intricate parts with high consistency and minimal waste makes aluminum extrusion with CNC highly attractive for the medical industry.

Moreover, aluminum’s inherent properties such as biocompatibility, corrosion resistance, and ease of sterilization make it an ideal material for medical applications. For instance, diagnostic equipment often requires housings and frames that are both sturdy and lightweight; aluminum extrusions deliver on these needs while ensuring ease of machinability and cleanability. Additionally, patient care devices, like wheelchairs and hospital beds, benefit from the high strength-to-weight ratio and flexibility of aluminum extrusions. CNC machining further allows for the creation of tailored solutions for specific patient needs, enhancing the overall quality and effectiveness of medical care. Thus, the integration of aluminum extrusion with CNC machining not only advances the technological aspects of medical devices but also significantly contributes to improving patient outcomes and operational efficiencies within healthcare environments.

Aluminum extrusion CNC (Computer Numerical Control) machining stands as a cornerstone in modern manufacturing due to its precision, efficiency, and versatility. Aluminum extrusion involves forcing aluminum through a die to create specific shapes with cross-sectional profiles. These extrusions are then subjected to CNC machining processes, such as milling, turning, and drilling, to achieve high-precision, custom components tailored to various industrial requirements. The integration of CNC technology allows for exceptional detail, consistency, and complexity in parts that may be impossible to achieve through manual machining techniques. Industries ranging from aerospace and automotive to electronics and construction benefit immensely from the lightweight, durable, and corrosion-resistant properties of aluminum combined with the meticulous accuracy afforded by CNC machining.

The applications of aluminum extrusion CNC are diverse and expansive. In the automotive sector, precision components like brackets, housings, and chassis parts are frequently machined from extruded aluminum, offering an optimal balance between strength and weight. The aerospace industry similarly exploits these advantages, utilizing extruded aluminum for intricate parts that also need to meet stringent safety and performance standards. In the field of electronics, aluminum extrusion CNC machining is invaluable for creating heat sinks and various enclosures that require precise tolerances and intricate geometries. Construction and architectural domains use custom-machined extrusions for structural components, railings, and framework due to aluminum’s favorable strength-to-weight ratio and aesthetic appeal. This blend of extrusion and CNC machining remains pivotal in pushing the envelope of what is achievable in modern product design and manufacturing.

Certainly! Here is a list of FAQs with answers related to manufacturing aluminum extrusion CNC quality work from SourcifyChina factory.

1. What types of aluminum extrusions can SourcifyChina manufacture?

SourcifyChina specializes in a wide range of aluminum extrusions, including profiles for construction, automotive components, industrial uses, and custom designs as per client specifications.

2. What is the maximum length and width for aluminum extrusions?

The maximum length for aluminum extrusions is typically 6 meters, while the width can vary based on specific design requirements. Custom dimensions can also be accommodated on request.

3. What CNC machining capabilities does SourcifyChina offer for aluminum extrusions?

Our factory is equipped with state-of-the-art CNC machines capable of high precision cutting, drilling, milling, and finishing to ensure high-quality and accurate production.

4. Can SourcifyChina handle large volume orders?

Yes, SourcifyChina is equipped to handle both small batch and large volume orders efficiently. Our production lines are optimized for scalability to meet varying demands.

5. What quality control measures are in place?

SourcifyChina implements stringent quality control processes, including material certification, in-process inspections, final product testing, and adherence to ISO standards to ensure the highest quality.

6. How are the products packaged for delivery?

Aluminum extrusions are packaged securely using appropriate materials such as bubble wrap, wooden crates, or custom packaging solutions to prevent damage during transit.

7. What is the typical lead time for orders?

The lead time varies depending on the complexity and size of the order but generally ranges from 2 to 6 weeks. For urgent requirements, express manufacturing options are available.

8. Can you provide samples before mass production?

Yes, we can provide samples for approval prior to mass production to ensure specifications and quality standards are met.

9. What are the payment terms?

Our payment terms are flexible and include options such as T/T, L/C, and other negotiable terms to cater to different client needs.

10. How do I get a quote for my project?

To get a quote, please contact our sales team with detailed project specifications including drawings, material requirements, and quantity. We typically respond with a detailed quote within 24-48 hours.

When considering aluminum extrusion CNC manufacturing from SourcifyChina Factory, there are several tips to ensure high-quality results and a smooth process:

1. Material Selection: Choose the right aluminum alloy for your application. SourcifyChina offers a variety of options, including 6061 and 6063, which are popular for their excellent machinability, strength, and corrosion resistance.

2. Design Optimization: Collaborate with SourcifyChina’s engineers early in the design phase. Optimizing your design for extrusion can significantly reduce material waste and production costs. Features like uniform wall thickness, rounded corners, and specific tolerances should be discussed.

3. Prototyping: Start with a prototype to validate your design. This helps identify any potential issues before moving into mass production, saving both time and money.

4. Quality Assurance: SourcifyChina Factory is known for its rigorous quality control processes. Ensure they conduct thorough inspections including dimensional checks and surface finish assessments to meet your specifications.

5. Surface Finishing: Customize the surface finish according to the application requirements. Options include anodizing, powder coating, and polishing. Each finish offers different advantages, from enhanced durability to improved aesthetics.

6. Lead Time and Production Capacity: Discuss lead times and production capacity to match your project deadlines. SourcifyChina is reputed for its efficiency, but clear communication is key to avoid production delays.

7. Cost Management: Request a detailed quotation including material costs, machining fees, and any additional finishing processes. Bulk orders can often reduce costs per unit.

8. Sustainability: Consider the environmental impact of your manufacturing process. Aluminum is highly recyclable, and SourcifyChina supports sustainable practices to minimize waste.

By adhering to these tips, you can leverage SourcifyChina Factory’s expertise in aluminum extrusion CNC manufacturing to achieve precise, high-quality components tailored to your specific needs.

Q1: What types of aluminum extrusion CNC services does SourcifyChina factory offer?

A1: SourcifyChina factory offers a wide range of aluminum extrusion CNC services including milling, drilling, cutting, and custom machining to meet various industry needs.

Q2: What is the typical lead time for an aluminum extrusion CNC order from SourcifyChina factory?

A2: The typical lead time for an aluminum extrusion CNC order from SourcifyChina factory is 4-6 weeks, depending on the complexity and volume of the order.

Q3: Do you provide custom design and prototyping services?

A3: Yes, SourcifyChina factory provides custom design and prototyping services to ensure that the final product meets your exact specifications.

Q4: What is the minimum order quantity (MOQ) for aluminum extrusion CNC projects?

A4: The MOQ for aluminum extrusion CNC projects varies depending on the complexity of the part, but typically starts at 100 pieces.

Q5: Can SourcifyChina factory handle both small and large-scale production runs?

A5: Yes, SourcifyChina factory is equipped to handle both small-scale and large-scale production runs, providing flexibility based on your needs.

Q6: Are there quality assurance measures in place for CNC machined aluminum extrusions?

A6: SourcifyChina factory implements stringent quality control measures including in-process inspections and final quality checks to ensure high standards are met.

Q7: What materials and finishes are available for aluminum extrusion CNC products?

A7: SourcifyChina factory offers various grades of aluminum and finishing options, such as anodizing, powder coating, and polishing, to suit different applications.

Q8: How can I request a quote for my aluminum extrusion CNC project?

A8: You can request a quote by contacting SourcifyChina factory via their online form, email, or phone, providing details about your project requirements and specifications.

Q9: Is international shipping available for aluminum extrusion CNC products?

A9: Yes, SourcifyChina factory offers international shipping options to deliver products to clients around the globe.

Q10: What payment methods are accepted by SourcifyChina factory?

A10: SourcifyChina factory accepts various payment methods including wire transfers, credit cards, and PayPal to accommodate different client preferences.

Sourcing aluminum extrusion CNC components from SourcifyChina requires a strategic approach to find reliable manufacturers while ensuring quality and timely delivery. Here are some concise tips to help you through the process:

1. Define Your Requirements: Specify detailed dimensions, tolerances, surface finish, and any other technical specifications for the aluminum extrusion CNC parts you need.

2. Use SourcifyChina’s Platform: Leverage SourcifyChina to filter through manufacturers specializing in aluminum extrusions and CNC machining.

3. Check Manufacturer Credentials: Look for certifications like ISO 9001, and review the factory’s quality control processes.

4. Request Samples: Before placing a large order, request prototype samples to evaluate the quality and precision of the machining.

5. Assess Communication: Effective communication is crucial. Ensure the manufacturer responds promptly and understands your technical requirements clearly.

6. Evaluate Production Capacity: Verify the factory’s capacity to handle your order volume within the desired timeline.

7. Review Past Work: Ask for case studies or references from previous clients to gauge the manufacturer’s experience with similar projects.

8. Negotiate Terms: Be clear about pricing, payment terms, delivery schedules, and incoterms (e.g., FOB, CIF).

9. Inspect During Production: If possible, arrange third-party inspections during production to ensure compliance with your specifications.

10. Consider Logistics: Factor in shipping times, costs, and potential customs issues that could delay delivery.

11. Build Long-term Relationships: Establishing a long-lasting partnership with a reliable manufacturer can lead to better pricing and more flexible terms in the future.

By following these tips, you can efficiently source high-quality aluminum extrusion CNC products from SourcifyChina’s factories, ensuring both cost-effectiveness and reliability.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.