Technology and Applications of anodized metals

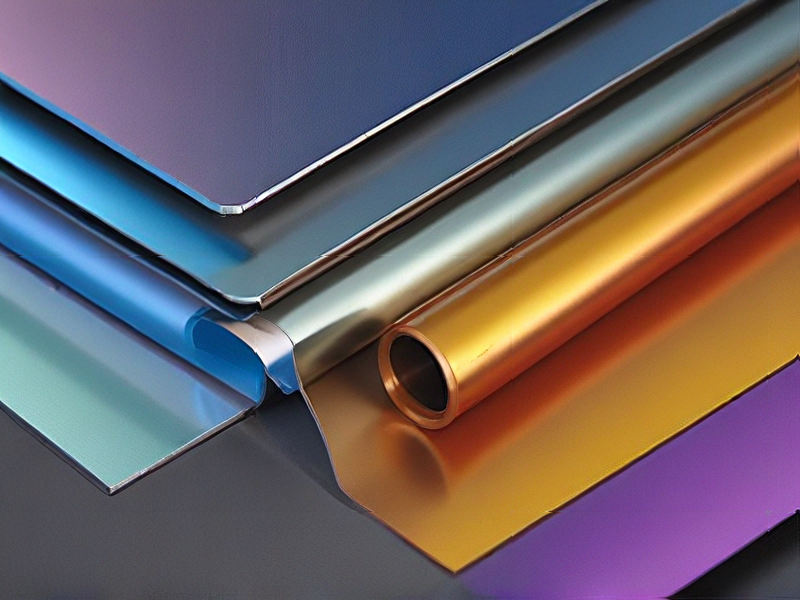

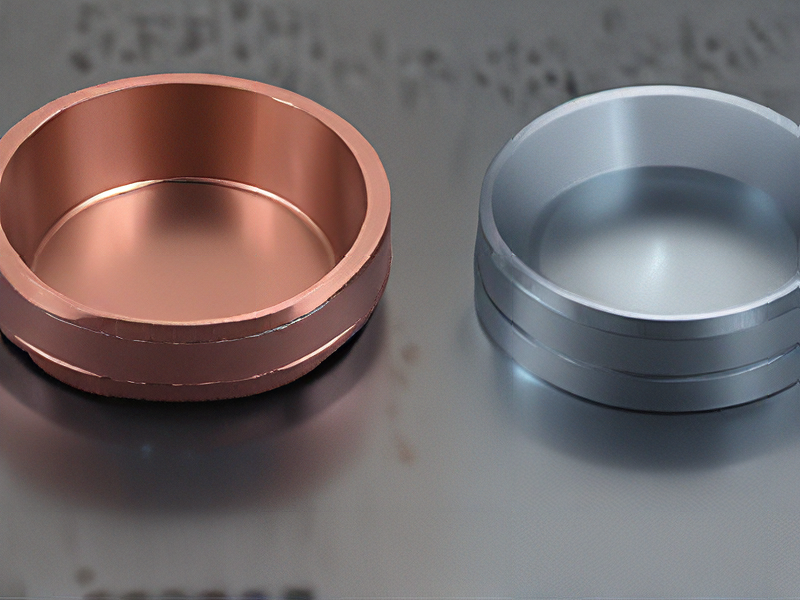

Anodizing is an electrochemical process that enhances the natural oxide layer on the surface of metals, primarily aluminum. The process involves immersing the metal in an acid electrolyte bath and passing an electric current through it, causing oxygen ions to bond with the metal atoms on the surface. This creates a thicker, more durable oxide layer that can improve corrosion resistance, wear resistance, and aesthetic appeal.

Technology of Anodized Metals

1. Anodizing Process:

– Cleaning: The metal is cleaned to remove any dirt, grease, or other contaminants.

– Etching: An alkaline solution is used to etch the metal surface, creating a uniform finish.

– Anodizing: The metal is placed in an acid bath, and an electric current is applied, forming the anodic oxide layer.

– Coloring (Optional): Dyes can be introduced to the porous oxide layer for coloration.

– Sealing: The porous layer is sealed to enhance durability and prevent corrosion.

2. Types of Anodizing:

– Type I (Chromic Acid Anodizing): Produces a thin, protective layer suitable for aerospace applications.

– Type II (Sulfuric Acid Anodizing): Common for general-purpose applications, offering a balance of cost and performance.

– Type III (Hard Anodizing): Produces a thicker, harder layer for high-wear applications.

Applications of Anodized Metals

1. Aerospace and Automotive: Anodized aluminum is used for its lightweight and corrosion-resistant properties in aircraft and automotive components.

2. Architecture: Building facades, window frames, and curtain walls benefit from the aesthetic and durable nature of anodized metals.

3. Consumer Electronics: Devices like smartphones, laptops, and cameras often use anodized aluminum for its sleek finish and durability.

4. Medical Equipment: Anodized metals are used in surgical instruments and devices due to their biocompatibility and resistance to sterilization processes.

5. Cookware: Anodized aluminum cookware is popular for its non-reactive surface and even heat distribution.

Anodizing enhances the properties of metals, making them suitable for a wide range of high-performance and aesthetically demanding applications.

Quality Testing Methods for anodized metals and how to control quality

Quality Testing Methods for Anodized Metals:

1. Thickness Measurement: Use eddy current instruments or micrometers to measure the anodic layer thickness. This ensures consistency with specifications.

2. Sealing Quality Test: Perform dye stain or acid dissolution tests to check if the anodized layer is properly sealed. Proper sealing is crucial for corrosion resistance.

3. Abrasion Resistance: Use Taber abraser tests to determine the wear resistance of the anodized surface. This involves rotating an abrasive wheel against the metal surface.

4. Corrosion Resistance: Conduct salt spray tests (ASTM B117) to simulate harsh environments and observe the metal’s resistance to corrosion.

5. Adhesion Test: Use adhesive tapes or bend tests to ensure the anodic layer adheres well to the substrate. Poor adhesion can lead to flaking or peeling.

6. Color Consistency: Utilize spectrophotometers to check for uniform color across batches. This is essential for aesthetic applications.

7. Surface Finish: Visually inspect or use profilometers to measure surface roughness and ensure a smooth finish, meeting desired specifications.

Quality Control Methods:

1. Standard Operating Procedures (SOPs): Implement SOPs for every stage of the anodizing process. This ensures consistency and repeatability.

2. Regular Calibration: Regularly calibrate measuring instruments and equipment to maintain accuracy in testing and production.

3. Training: Train operators thoroughly on quality standards and testing procedures to minimize human errors.

4. Batch Testing: Perform quality tests on random samples from each batch to detect any inconsistencies early in the process.

5. Documentation: Keep detailed records of all test results and process parameters. This helps in tracing issues and ensuring compliance with standards.

6. Continuous Improvement: Regularly review and update quality control practices based on feedback and advancements in technology.

These methods ensure that anodized metals meet required standards and perform reliably in their intended applications.

Tips for Procurement and Considerations when Purchasing from anodized metals

When procuring anodized metals, several key considerations can ensure you make informed purchasing decisions:

1. Specification Requirements: Clearly define the specifications for the anodized metal needed, including alloy type, thickness, color, and finish. This helps suppliers provide accurate quotes and ensures the material meets your application’s requirements.

2. Quality Standards: Verify that the supplier adheres to relevant quality standards (e.g., ISO certifications). Anodized metals should meet durability, corrosion resistance, and aesthetic criteria suitable for your intended use.

3. Supplier Reliability: Choose suppliers with a proven track record for delivering quality anodized metals on time and within budget. Check references and reviews to assess their reliability and customer satisfaction.

4. Cost and Pricing: Compare quotes from multiple suppliers to ensure competitive pricing while considering factors like volume discounts, shipping costs, and potential additional charges for customization or special finishes.

5. Lead Times and Production Capacity: Understand the supplier’s lead times and production capacity to align with your project timelines. Ensure they can handle your order size without compromising on quality or delivery schedules.

6. Environmental Considerations: Evaluate the supplier’s environmental policies and practices, particularly concerning chemical usage and waste management related to the anodizing process.

7. Communication and Support: Choose suppliers who offer clear communication channels and responsive customer support. This ensures you can address any concerns or changes during the procurement process efficiently.

8. Testing and Inspection: Establish protocols for testing and inspection to verify the quality and consistency of the anodized metals received. This may involve sample testing or onsite inspections before full-scale production.

9. Long-Term Relationship: Consider the potential for a long-term partnership with the supplier, especially if you anticipate ongoing needs for anodized metals. Building a strong relationship can lead to better service and support over time.

By focusing on these considerations, you can streamline your procurement process and ensure you source high-quality anodized metals that meet your project’s specific requirements and standards.

FAQs on Sourcing and Manufacturing from anodized metals in China

Certainly! When sourcing and manufacturing anodized metals in China, here are some frequently asked questions (FAQs) to consider:

1. What is anodizing, and why is it used?

Anodizing is an electrochemical process that enhances the surface of metals like aluminum, providing increased corrosion resistance and durability while offering decorative options.

2. How do I find reliable suppliers for anodized metals in China?

Utilize online platforms, industry trade shows, and referrals. Verify suppliers through certifications, factory audits, and samples to ensure quality and reliability.

3. What factors affect the cost of anodized metals?

Key cost influencers include material type, complexity of design, batch size, finishing requirements, and market fluctuations in raw material prices.

4. What are common challenges in manufacturing anodized metals in China?

Quality control consistency, communication barriers, intellectual property protection, and compliance with environmental and labor regulations can pose challenges.

5. How can I ensure quality when sourcing anodized metals from China?

Implement strict quality assurance protocols, conduct regular inspections during production, and use reputable third-party inspection services to maintain product integrity.

6. What are typical lead times for manufacturing anodized metals?

Lead times vary based on order complexity and supplier capacity. Generally, they range from several weeks to a few months, including processing, anodizing, and shipping.

7. What are the environmental considerations of anodizing in China?

Ensure suppliers adhere to local environmental regulations. Anodizing involves chemicals and waste disposal, so sustainable practices and compliance are crucial.

Navigating these FAQs will help streamline the sourcing and manufacturing process for anodized metals in China, ensuring a successful and efficient partnership with suppliers.