“Reliable Anodizing Services with SourcifyChina: High-Quality Manufacturing and Trusted Factory Solutions”

SourcifyChina offers comprehensive anodizing services that ensure durability and quality. Partner with us for reliable, efficient, and high-standard manufacturing solutions tailored to your production needs.

Choosing SourcifyChina Factory for anodizing services ensures high-quality finishes that meet international standards. Their expertise in aluminum anodizing provides durable, corrosion-resistant products suitable for various industries, enhancing the longevity and aesthetic of the components.

SourcifyChina Factory offers competitive pricing without compromising on quality, making them a cost-effective option for businesses. Their advanced technology and skilled workforce drive efficient production processes, which result in shorter lead times and reliable delivery schedules.

Customer satisfaction is a priority at SourcifyChina Factory. They provide comprehensive support throughout the purchasing process, from initial consultation to post-sales service. Their experienced team is always available to address concerns and offer tailored solutions.

By choosing SourcifyChina Factory, buyers benefit from a partner who values transparency and integrity. Detailed progress reports and open communication ensure that clients are kept informed throughout the anodizing process, fostering trust and long-term business relationships.

In conclusion, SourcifyChina Factory stands out for its exceptional quality, competitive pricing, and dedicated customer service. Their commitment to excellence and innovation makes them the ideal choice for buyers seeking reliable anodizing services from China.

Anodizing services involve electrochemical processes to increase the thickness of the natural oxide layer on the surface of metal parts, enhancing durability and aesthetic appeal. Various types and options include:

– Type I (Chromic Acid Anodizing): Offers thin, corrosion-resistant coatings.

– Type II (Sulfuric Acid Anodizing): Common for decorative purposes; thicker coatings than Type I.

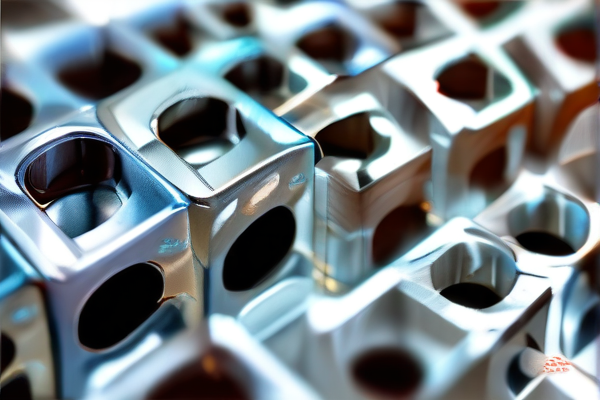

– Type III (Hard Anodizing): Provides heavy-duty, wear-resistant layers ideal for industrial applications.

– Color Anodizing: Adds customizable colors without compromising durability.

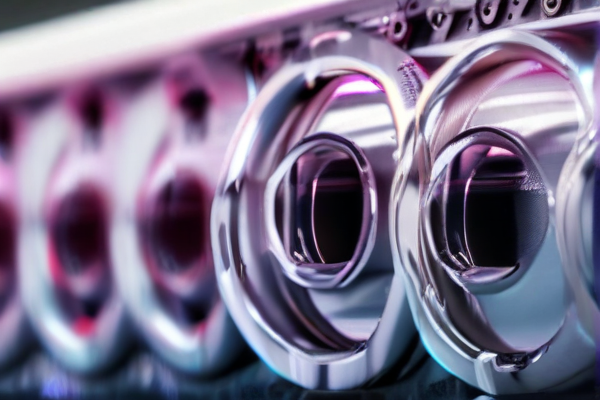

– Bright Anodizing: Ensures a shiny, reflective finish for aesthetic uses.

– Non-hexavalent Anodizing: Eco-friendly alternative reducing harmful chemicals.

– Custom Coatings: Tailored solutions based on specific industry requirements.

– Mid-temperature Anodizing: Balances optimal hardness and sealing, especially for aerospace.

– Continuous Coil Anodizing: Suitable for high-volume production, ensuring consistent quality.

With these various anodizing options, industries can achieve specific performance and visual characteristics for their metal components.

Anodizing services provide protective and aesthetic finishes for metal products, enhancing durability and corrosion resistance. This process is essential across various industries to improve performance and extend the lifespan of metal components.

– Automotive Industry:

– Enhanced corrosion resistance for vehicle parts.

– Improved appearance with decorative finishes.

– Increased durability and performance.

– Aerospace Industry:

– Lightweight protective coatings for aircraft components.

– Extended lifespan of critical parts.

– Enhanced resistance to extreme environmental conditions.

– Construction:

– Protective finishes for exterior metal structures.

– Enhanced weather resistance for building facades.

– Improved aesthetic appeal of architectural elements.

– Electronics:

– Durable, insulating coatings for electronic housings.

– Prevents corrosion on connectors and circuit boards.

– Aesthetic finishes for consumer electronics.

– Marine Industry:

– Corrosion-resistant coatings for marine equipment.

– Enhanced durability in saltwater environments.

– Protection against wear and tear for boat components.

– Medical Industry:

– Biocompatible coatings for medical devices.

– Enhanced durability of surgical instruments.

– Corrosion resistance for medical implants.

– General Manufacturing:

– Improved wear resistance for industrial machinery.

– Protective coatings for metal tools and components.

– Enhanced product longevity and reliability.

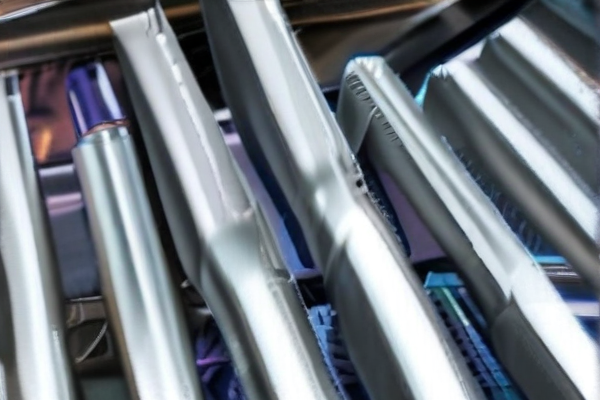

SourcifyChina offers premium anodizing services, a process used to enhance the surface properties of metals, primarily aluminum. This electrochemical process increases corrosion resistance, surface hardness, and aesthetic appeal.

The company specializes in both Type II and Type III anodizing. Type II is known for its thinner coatings, ideal for decorative purposes, while Type III, or hard anodizing, provides a thicker, more durable finish suitable for heavy-duty applications.

Anodizing at SourcifyChina is performed with precise control over color and thickness. This ensures consistent quality and meets specific customer requirements, making their services highly reliable for various industrial needs.

Additionally, their advanced facilities and experienced team enable them to handle large-scale orders efficiently. SourcifyChina’s commitment to quality and customer satisfaction sets them apart in the anodizing industry, ensuring top-notch results for all projects.

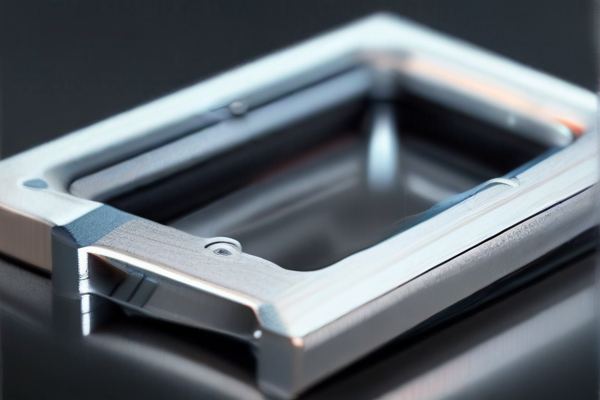

SourcifyChina’s anodizing services adhere to rigorous quality control processes to ensure superior product durability and aesthetic appeal. Each batch undergoes thorough pre-treatment to remove impurities and optimize surface conditions.

The anodizing bath is closely monitored for temperature, pH, and chemical composition, ensuring consistent results. Strict adherence to these parameters helps maintain uniformity and enhances the functional properties of the anodized layer.

Post-anodizing, every item is meticulously rinsed and sealed to prevent corrosion and improve the finish’s longevity. This step is crucial in providing a durable and high-quality product that meets customer specifications.

Final inspections involve precise measurements of thickness and color consistency using advanced equipment. Any deviations from the set standards lead to immediate corrective actions, ensuring that only top-quality products reach the customers.

SourcifyChina’s commitment to quality extends beyond anodizing. Detailed documentation and traceability are maintained throughout the process. This guarantees accountability and continuous improvement, highlighting their dedication to excellence and customer satisfaction.

SourcifyChina offers exceptional anodizing services tailored to meet diverse industrial needs. Their advanced techniques ensure high-quality surface finishes that enhance the durability and aesthetic appeal of aluminum components.

Utilizing cutting-edge equipment, SourcifyChina provides both Type II (decorative) and Type III (hardcoat) anodizing, catering to various applications. Their stringent quality control guarantees consistency and precision in every batch.

Customers benefit from a range of customizable color options, further enabling them to align products with specific brand aesthetics. Additionally, their environmentally friendly processes underscore a commitment to sustainability.

SourcifyChina prides itself on competitive pricing and quick turnaround times, ensuring cost-efficiency and timely delivery. Their customer-centric approach prioritizes client satisfaction, making them a preferred partner in the anodizing industry.

In summary, SourcifyChina’s capabilities encompass a broad spectrum of anodizing services, emphasizing quality, customization, and sustainability, thus meeting and exceeding client expectations efficiently.

Anodizing services offer numerous benefits by enhancing the durability, aesthetic appeal, and functionality of metal surfaces. This process not only improves material longevity but ensures better performance in diverse environments.

Key Benefits of Using Anodizing Services:

– Corrosion Resistance: Anodizing forms a protective oxide layer that significantly increases resistance to corrosion, thereby extending the life of the metal.

– Aesthetic Enhancement: The anodizing process offers a wide range of color options and finishes, greatly improving the visual appeal of metal products.

– Improved Adhesion: Anodized surfaces better adhere to paints, adhesives, and lubricants, enhancing the versatility of the metal for various applications.

– Increased Wear Resistance: The surface hardness gained through anodizing minimizes scratches, dents, and general wear and tear, maintaining product quality.

– Non-Toxic: Anodizing is an environmentally friendly process. It is non-toxic and produces no hazardous waste, aligning with sustainable practices.

– Electrical Insulation: The non-conductive properties of anodized layers are beneficial in electrical applications, providing insulation and reducing the risk of short circuits.

– Cost-Effective: By reducing the need for maintenance and replacements, anodizing proves to be a cost-effective solution for long-term metal protection.

– Eco-Friendly: Anodizing does not involve the use of heavy metals or harmful chemicals, making it an eco-friendly finishing option compared to other methods.

– Light Weight: Anodizing maintains the structural integrity and lightweight nature of metals, crucial for applications where weight is a critical factor.

In conclusion, anodizing services provide a comprehensive suite of benefits ranging from enhanced durability to improved aesthetic appeal, making it a preferred choice across many industries.

Anodizing services provide a protective and decorative oxide layer on metal surfaces, enhancing both durability and appearance.

– Corrosion Resistance: Anodizing significantly increases the metal’s resistance to corrosion, making it suitable for harsh environments.

– Enhanced Durability: The process creates a hard, wear-resistant surface, prolonging the life of the metal.

– Aesthetic Appeal: Available in a variety of colors, anodizing can improve the visual appeal of metals, suitable for architectural purposes.

– Electrical Insulation: Anodized coatings can provide electrical insulation, which is beneficial in electronic applications.

– Improved Adhesion: The porous nature of anodized surfaces offers better adhesion for paints, dyes, or adhesives.

– Environmentally Friendly: Anodizing is a more environmentally sustainable option compared to other metal finishing processes, with fewer harmful by-products.

– Customizable Thickness: The thickness of the anodized layer can be controlled to suit different application requirements.

– Heat Dissipation: The anodized layer can enhance thermal dissipation, useful in heat sink applications.

– Non-Toxic: Suitable for applications requiring contact with food or medical equipment, as the anodized layer is non-toxic.

– Low Maintenance: The resulting finish requires minimal maintenance, saving time and costs over the long term.

– Improved Lubrication: Anodizing can also enhance the metal’s ability to retain lubricants, reducing friction in moving parts.

In summary, anodizing services offer numerous benefits including enhanced durability, corrosion resistance, and aesthetic appeal, making it a versatile option for various industries and applications.

SourcifyChina’s anodizing services offer high-quality surface finishing for aluminum products, enhancing durability and aesthetics. Their state-of-the-art facilities ensure consistent results, meeting stringent quality standards.

Custom products at SourcifyChina are tailored to meet specific customer requirements. Whether it’s for automotive, aerospace, or electronics industries, they deliver precision-engineered components with customized anodized finishes to enhance performance and longevity.

Their anodizing process includes various techniques such as Type I, II, and III anodizing, providing options for different thicknesses and colors. This versatility ensures that each project receives the ideal finish for its intended application.

SourcifyChina’s commitment to excellence and innovation allows them to handle diverse projects efficiently. Their expert team collaborates closely with clients, ensuring that each anodized product aligns with the specified design and functional requirements.

By choosing SourcifyChina for anodizing services, businesses gain access to a reliable partner dedicated to delivering superior anodized products. Their comprehensive approach ensures every project is completed to the highest industry standards, fostering long-term customer satisfaction and success.

SourcifyChina Anodizing Services is a premier provider of high-quality anodizing solutions, committed to enhancing the durability and aesthetic appeal of metal products. With a steadfast focus on innovation and customer satisfaction, the company offers a range of anodizing techniques, including Type I, II, and III anodizing, tailored to meet diverse industrial requirements. SourcifyChina employs state-of-the-art equipment and environmentally sustainable practices to ensure precision and consistency in every project. Their service portfolio caters to a wide array of sectors, from automotive and aerospace to electronics and consumer goods. By integrating rigorous quality control measures, SourcifyChina guarantees superior surface finishes that not only improve corrosion resistance but also provide excellent wear properties. The company’s expert team collaborates closely with clients to deliver customized solutions that meet exact specifications and deadlines. Emphasizing reliability and efficiency, SourcifyChina has established itself as a trusted partner for businesses worldwide looking for top-notch anodizing services.

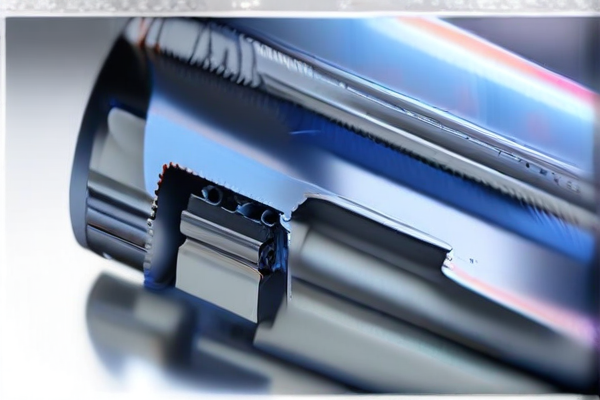

Anodizing services play a crucial role in enhancing the durability and performance of components used in aerospace, defense, and marine applications. In the aerospace sector, anodizing provides a robust corrosion-resistant coating on aluminum parts, including airframes, avionics housings, and structural components. This process not only extends the service life of these critical parts by protecting them against harsh environmental conditions, but it also adds a layer of insulation that improves thermal stability and reduces electromagnetic interference. Consequently, the reliability and safety of aircraft are significantly enhanced, which is paramount given the demanding operational conditions and rigorous safety standards governing the industry.

In the defense and marine sectors, anodizing services offer similar benefits, such as heightened corrosion resistance and improved surface hardness. For military vehicles, naval vessels, and underwater equipment, where exposure to saltwater, humidity, and extreme temperatures is inevitable, anodizing ensures that the aluminum components can withstand these elements without degradation. In defense applications, this translates to greater operational readiness and reduced maintenance costs for equipment ranging from armored vehicles to communication devices. For marine environments, anodized coatings are vital for the longevity of ship hulls, propellers, and other submerged components, minimizing the risk of failure due to corrosion. Overall, anodizing services contribute significantly to the performance, longevity, and reliability of aerospace, defense, and marine technologies.

Anodizing services play a pivotal role in the automotive industry by enhancing the durability and aesthetic appeal of vehicle components. The process of anodizing not only increases the corrosion resistance of aluminum parts but also provides a more durable surface that can withstand harsh environmental conditions such as road salt, moisture, and extreme temperatures. Components such as trim, engine parts, and wheels benefit significantly from anodizing, as the process creates a tough, wear-resistant coating that can prevent the type of surface degradation that leads to mechanical failure. Additionally, anodizing can be dyed in various colors, allowing manufacturers to produce parts with customized and stylish finishes without compromising their functional durability.

In the electronics sector, anodizing services are indispensable for improving the performance and longevity of electronic devices. Aluminum enclosures and heat sinks, commonly used in consumer electronics and industrial applications, are often anodized to enhance their thermal management properties. Anodized coatings improve the thermal conductivity of these components, thereby increasing the efficiency of heat dissipation, which is crucial for maintaining the performance and reliability of electronic devices. Moreover, the electrical insulation properties of anodized layers are beneficial for components that must avoid electrical interference. Anodized finishes can also be applied with precision, ensuring that electronic housings maintain high levels of aesthetic appeal and are less prone to wear and tear, ultimately extending the lifecycle of the devices in which they are used.

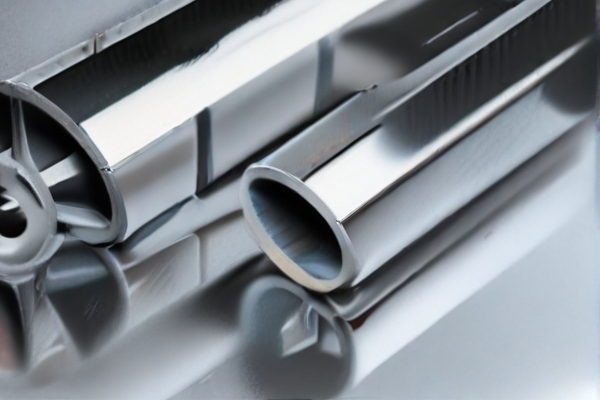

Anodizing services are pivotal in the construction industry, providing enhanced durability and aesthetics to various metal components used in building structures. Through this electrochemical process, a thick layer of oxide is formed on the surface of metals like aluminum, which effectively contributes to resisting corrosion, wear, and environmental degradation. This resistance is crucial for architectural elements such as window frames, curtain walls, and structural components that are exposed to harsh weather conditions. The anodized layer also offers excellent adhesion properties for paints and sealants, ensuring that the aesthetic appeal of buildings maintains its vibrancy and attractiveness over extended periods. Furthermore, anodizing allows for a wide range of color finishes without compromising the metal’s natural appearance, offering architects and designers increased flexibility in their projects.

In the energy sector, anodizing services play an essential role in improving the performance and longevity of crucial components. For instance, in renewable energy applications such as solar power systems, anodized aluminum frames and mounts are extensively used due to their enhanced resistance to the elements, thus ensuring the reliability and efficiency of solar panels over their operational lifespan. Additionally, in wind turbines, anodized parts are employed to reduce the risks of mechanical failures associated with corrosion and wear, thereby enhancing the durability and maintenance intervals of these systems. The enhanced thermal and electrical conductivity of anodized metals also finds applications in energy storage and battery technologies, where optimized heat dissipation is critical for performance and safety. Overall, anodizing services contribute significantly to reducing operational costs and extending the life of energy infrastructure, thereby supporting the broader goals of sustainability and efficiency in the energy sector.

Anodizing services play a crucial role in the industrial equipment industry by enhancing the durability and performance of metal components. This electrochemical process forms a protective oxide layer on the surface of metals, primarily aluminum, which significantly increases their resistance to corrosion and wear. In industrial settings, where equipment is often exposed to harsh environments and heavy use, anodizing provides a vital protective barrier that extends the lifespan of machinery and tools. The anodized layer is not only harder and more resistant to abrasion than untreated metal but also provides improved adhesion for paints and lubricants, thereby reducing maintenance costs and downtime for industrial operations.

Furthermore, anodizing services offer a range of aesthetic and functional benefits that are highly valued in the industrial sector. The anodized coating can be dyed in various colors, allowing for color-coding of components for easy identification and safety purposes. Additionally, the process enhances the thermal and electrical insulating properties of metal parts, which is critical for equipment used in electrical and electronic applications. The uniformity and consistency of the anodized layer ensure that even complex geometries and intricate parts receive equal protection, making anodizing an indispensable service for manufacturers seeking to produce high-quality, reliable industrial equipment.

Anodizing services are critically important in the medical devices industry, where the need for biocompatibility, durability, and cleanliness cannot be overstated. By applying an electrochemical process to aluminum and other metal substrates, anodizing creates a controlled oxide layer that improves the metal’s resistance to corrosion and wear. This is particularly useful for surgical instruments, implants, and other medical apparatus that must endure rigorous sterilization processes and repeated use. The resulting anodized layer also provides excellent adhesion for further coatings, such as antimicrobial layers, thereby enhancing the functionality of medical devices.

In addition to durability, anodizing offers aesthetic and functional benefits by enabling coloration without the use of potentially harmful dyes or paints. This color-coding can be essential for quick identification and efficient organization during medical procedures. Anodized surfaces are also smoother and more uniform, reducing the risk of microbial contamination by eliminating microscopic crevices where bacteria may harbor. The biocompatibility of anodized metals ensures that implants and surgical tools remain safe for use within the human body. Overall, anodizing services significantly contribute to the safety, efficacy, and longevity of medical devices, making them an indispensable part of modern healthcare.

Anodizing services play a crucial role in the machining and manufacturing sectors by enhancing the durability and aesthetic appeal of metal parts, particularly aluminum. The anodizing process involves electrolytically treating the metal surface to form a stable oxide layer. This layer not only increases resistance to corrosion and wear but also provides a porous surface that can be dyed in various colors, catering to both functional and cosmetic requirements. Machining components such as gears, housings, and connectors greatly benefit from anodizing, as it extends their operational life and maintains performance standards in harsh environments. The precision-tuned protective layer renders these parts less susceptible to environmental degradation and mechanical stress.

In the manufacturing domain, anodizing services are essential for industries ranging from aerospace and automotive to consumer electronics and architecture. For instance, in the aerospace industry, anodized aluminum components are valued for their lightweight yet durable nature, which is critical for performance and safety. Automotive manufacturers use anodizing to improve the longevity of engine parts and other components exposed to extreme conditions. In consumer electronics, anodizing not only enhances the visual appeal of devices but also provides an added layer of scratch and wear resistance, thus improving product longevity. Additionally, architectural applications benefit from anodized aluminum for facades and structural elements, combining robustness with aesthetic versatility. Overall, anodizing services are indispensable in creating high-quality, durable, and visually appealing products across various manufacturing sectors.

Sure, here is a concise FAQ for manufacturing anodizing services quality work from SourcifyChina factory:

1. What is anodizing?

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. It is commonly applied to aluminum components.

2. Why should I choose SourcifyChina factory for anodizing services?

SourcifyChina factory is known for its superior quality and precision. Our state-of-the-art equipment, skilled technicians, and strict quality control processes ensure high-quality anodizing that meets or exceeds industry standards.

3. What materials can SourcifyChina anodize?

We primarily anodize aluminum, but we also offer services for other metals such as titanium and magnesium upon special request.

4. What are the benefits of anodizing my components?

Anodizing offers increased corrosion resistance, enhanced aesthetic appearance, improved surface hardness, and longer lifespan for components.

5. How does SourcifyChina ensure the quality of anodizing?

We implement a stringent quality control process that includes thickness measurement, adhesion tests, color consistency checks, and corrosion resistance examinations to ensure top-notch results.

6. Can you provide custom colors for anodized parts?

Yes, we offer a range of standard and custom colors to meet your specific needs. Please contact us with your color requirements, and we will work to match your desired shades.

7. What is the lead time for anodizing services?

Lead times vary depending on the quantity and complexity of the order, but we strive to complete most projects within 5-10 business days. Expedited services are available upon request.

8. Do you offer any post-anodizing treatments?

Yes, SourcifyChina provides additional treatments such as sealing, dyeing, and other surface modifications to further enhance the durability and appearance of anodized components.

9. How can I get a quote for your anodizing services?

Simply contact us through our website with details about your project, including material type, quantity, required finish, and any special requirements. We will provide you with a detailed quote promptly.

10. What sizes and shapes of parts can you anodize?

We can handle a wide range of sizes and shapes. Please provide us with the dimensions and specifications of your parts for evaluation.

With this FAQ, you should have a clearer understanding of our anodizing services and how SourcifyChina ensures quality work for all projects.

When considering anodizing services from SourcifyChina factory, it’s crucial to understand key aspects to optimize your manufacturing process. Here are some tips:

1. Quality Assurance: Ensure the factory adheres to international standards for anodizing quality. Ask for certifications like ISO 9001 to confirm their commitment to quality management.

2. Customization: SourcifyChina likely offers various anodizing finishes. Discuss your specific needs, whether it’s for color, thickness, or surface texture, to match your product requirements precisely.

3. Material Compatibility: Confirm that the factory can handle the specific aluminum alloy you’re using. Different alloys respond uniquely to anodizing, impacting the final result.

4. Sample Testing: Request samples of anodized components to evaluate the finish, durability, and color consistency. This step helps in assessing the factory’s capability before committing to full-scale production.

5. Turnaround Time: Inquire about lead times for anodizing processes. Understanding their production schedule and capacity can help you plan your manufacturing timeline effectively.

6. Cost Efficiency: Compare anodizing costs from SourcifyChina with other potential suppliers. Factor in shipping, possible tariffs, and any additional processing fees to gauge the overall cost efficiency.

7. Communication: Establish clear communication channels. Ensure you have a dedicated point of contact for updates and queries to streamline coordination and reduce potential misunderstandings.

8. Technological Capabilities: Check if SourcifyChina uses advanced anodizing technologies. Modern methods, such as hard anodizing and sulfuric acid anodizing, can offer superior characteristics and performance.

9. Environmental Compliance: Verify if the factory follows eco-friendly practices and complies with local and international environmental regulations. Anodizing processes can produce waste and emissions, so responsible management is essential.

10. After-sales Support: Ensure they offer robust after-sales support, including addressing defects, ongoing maintenance advice, and possible refinishing services.

Following these tips will help you make an informed decision and achieve high-quality anodizing results for your products.

Sure! Below is a list of frequently asked questions (FAQ) along with their answers for sourcing anodizing services from SourcifyChina factory:

What is anodizing, and why should I use this process?

Anodizing is an electrochemical process that converts the metal surface into a durable, corrosion-resistant, anodic oxide finish. It is commonly used for aluminum to enhance its appearance and longevity.

What materials can you anodize?

We specialize in anodizing aluminum but can also handle other metals like titanium and magnesium. Please contact us for specific material requirements.

What types of anodizing services do you offer?

We offer standard anodizing, hard anodizing, and colored anodizing services tailored to meet a variety of industry specifications and customer needs.

How long does the anodizing process take?

Typical turnaround times range from 5-10 business days, depending on the complexity and volume of the order. Expedited services are available upon request.

How should I prepare my parts for anodizing?

Parts should be free of grease, oils, or any contaminants. We recommend sending parts in a cleaned and properly packaged condition to ensure optimal results.

What are your quality control measures?

We use advanced inspection tools and processes including thickness measurements and color consistency checks to ensure high-quality results. Our facility is ISO 9001 certified.

Can you handle large volume orders?

Yes, SourcifyChina factory is equipped to handle both small and large volume orders. We offer scalable solutions to meet your production needs.

Do you provide samples?

Yes, we can provide anodized samples upon request so you can assess the quality and finish before placing a large order.

What is your pricing structure?

Pricing depends on factors such as the type of anodizing, volume, and specific requirements. Contact us for a detailed quote tailored to your needs.

How do I place an order?

You can place an order by contacting us via email or through our online portal. Our customer service team will guide you through the process from start to finish.

Sourcing anodizing services from a factory like SourcifyChina requires careful consideration to ensure quality and reliability. Here are some tips to guide you:

1. Define Your Requirements: Clearly outline your anodizing needs, including the type of metal, color, thickness, and any specific standards or certifications required. This will help the factory understand your expectations.

2. Research and Verify: Investigate SourcifyChina’s reputation. Look for reviews, testimonials, and any case studies showcasing their work. Verify their experience in anodizing, particularly with the materials and specifications you need.

3. Request Samples: Before committing, ask for samples of their anodized products. Evaluate the quality, consistency, and finish to ensure it meets your standards.

4. Assess Communication: Effective communication is crucial. Ensure that the factory has proficient English-speaking representatives or translators to avoid misunderstandings. Prompt and clear responses are indicators of good communication practices.

5. Quality Assurance: Inquire about their quality control processes. Ask if they have certifications like ISO 9001 or other relevant quality standards. This ensures they follow stringent procedures to maintain high-quality outputs.

6. Technical Capabilities: Ensure the factory has the necessary technical capabilities and equipment to handle your anodizing requirements. Modern, well-maintained equipment often translates to better quality and efficiency.

7. Lead Times and Scalability: Discuss production lead times and their capacity to scale up production if needed. Reliable factories should provide realistic timelines and demonstrate flexibility in handling varying order sizes.

8. Cost Transparency: Obtain detailed quotes, including any potential additional costs such as shipping, taxes, and duties. This will help you understand the total cost and avoid surprises.

9. Visit the Factory: If possible, visit the factory to inspect their facilities and meet the team. This provides firsthand insight into their operations and builds trust.

10. Contractual Agreement: Ensure all terms, including quality standards, delivery timelines, payment terms, and penalties for non-compliance, are clearly documented in a formal contract.

By following these steps, you can effectively source anodizing services from SourcifyChina, ensuring quality, reliability, and a smooth production process.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.