Choosing “SourcifyChina” Factory for purchasing a baling machine ensures access to high-quality manufacturing standards and competitive pricing. The factory leverages advanced technology and skilled labor to produce reliable, durable machines that meet international standards.

“SourcifyChina” offers customized solutions to cater to specific buyer needs, ensuring optimal machine performance and efficiency. Their robust customer support assists buyers through every step, from selection to installation.

By partnering with “SourcifyChina,” buyers benefit from efficient production timelines and strict quality control measures. This ensures timely delivery and superior products, reducing downtime and increasing productivity.

Moreover, “SourcifyChina” Factory emphasizes sustainable practices, using eco-friendly materials and processes. This commitment to sustainability aligns with global environmental standards, making them an ideal choice for environmentally conscious buyers.

In conclusion, “SourcifyChina” Factory stands out for its commitment to quality, customization, and sustainability. Their comprehensive support and reliable products make them a trusted partner for buyers seeking top-tier baling machines from China.

A baling machine compresses materials like hay, paper, and plastic into compact bales for easy storage, transport, or recycling. Various types cater to different needs and materials.

– Vertical Balers: Best for small to medium-sized operations; suitable for cardboard, paper, and plastics.

– Horizontal Balers: Ideal for high-volume applications; handle large quantities of recyclable materials.

– Two-Ram Balers: Enhanced compression capabilities; often used for bulky or high-resistance materials.

– Single-Ram Balers: Efficient and versatile; used in industries with moderate recycling demands.

– Automatic Balers: High efficiency with minimal manual intervention; suitable for large-scale recycling facilities.

– Closed-Door Balers: Secure baling process; ideal for sensitive or high-value materials.

– Open-End Balers: Continuous operation; perfect for high-output environments.

– Manual-Tie Balers: Cost-effective; require manual wire-tying.

– Auto-Tie Balers: Automated tying mechanism; increases productivity and reduces labor costs.

These options provide flexibility for various operational needs, enhancing recycling and waste management efficiency.

A baling machine compacts recyclable materials, agricultural products, and waste into manageable bales, enhancing storage, transport efficiency, and recycling processes.

– Recycling: Compresses paper, cardboard, plastics, and metals for efficient recycling.

– Agriculture: Bales hay, straw, and silage for easier storage and transport.

– Waste Management: Reduces volume of municipal, commercial, and industrial waste.

– Manufacturing: Compacts scrap materials, such as textiles and rubber, for reuse.

– Logistics: Streamlines storage and transportation of goods by reducing their bulk.

– Retail: Manages packaging waste, especially cardboard and plastic wrap.

– Construction: Compresses debris, reducing disposal costs and space requirements.

– Automotive: Bales used tires and metal parts for recycling and disposal.

– Mining: Compacts waste materials and ores for efficient transport.

– Hospitality: Manages waste from food packaging and other disposable items.

By using a baling machine, businesses can optimize their waste management practices, improve recycling rates, and reduce overall environmental impact.

A baling machine in the Aerospace, Defense, and Marine sectors plays a crucial role in managing and recycling waste materials generated during manufacturing and maintenance operations. These industries produce significant quantities of metal scrap, composite materials, and other industrial waste, necessitating efficient waste management solutions. Baling machines compress these materials into compact, manageable bales, facilitating easier storage, transportation, and recycling. This process not only reduces the physical space required for waste storage but also minimizes the environmental impact by promoting recycling and reducing landfill usage. The use of baling machines aligns with sustainability goals and regulatory compliance, ensuring that waste management practices are both effective and eco-friendly.

In addition to waste management, baling machines contribute to operational efficiency and cost savings in the Aerospace, Defense, and Marine industries. By compressing waste materials, these machines help streamline logistics, reduce transportation costs, and improve overall workflow within manufacturing and maintenance facilities. For instance, compacted bales are easier to handle and transport compared to loose waste, enabling more efficient use of storage and shipping resources. Furthermore, the recyclability of compressed materials can lead to significant cost recoveries, as recycled materials can be reintroduced into the production cycle. This not only lowers raw material costs but also supports a circular economy, enhancing the sustainability and economic viability of operations in these high-tech industries.

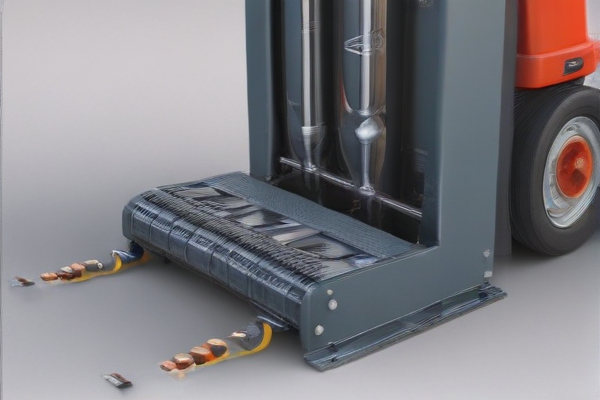

In the automotive industry, baling machines play a critical role in the efficient handling and recycling of scrap materials. These machines compress and bundle waste such as metal shavings, used parts, and damaged panels, significantly reducing the volume of scrap and making it easier to transport and recycle. By converting bulky waste into compact bales, automotive manufacturers and recyclers can optimize storage space and streamline logistics. Additionally, the use of baling machines helps in complying with environmental regulations by ensuring proper disposal and recycling of metal waste, ultimately contributing to a more sustainable manufacturing process.

Similarly, in the electronics sector, baling machines are essential for managing electronic waste (e-waste). With the rapid turnover of electronic devices, the industry generates vast amounts of discarded circuit boards, cables, and components. Baling machines compress these materials into manageable bales, facilitating their safe and efficient transport to recycling facilities. This process not only helps in reclaiming valuable metals like gold, silver, and copper from e-waste but also reduces the environmental impact of improper disposal. By enabling more effective recycling practices, baling machines support the electronics industry’s efforts to minimize waste and promote resource recovery, aligning with global sustainability goals.

A baling machine, crucial in the construction and energy sectors, is primarily used for compacting waste materials into manageable bales. In construction, these machines efficiently handle debris like wood, metal, and concrete fragments, reducing their volume for easier transportation and disposal. By compressing bulky materials, baling machines help construction sites maintain cleanliness and organization, improving safety and efficiency. Additionally, the compacted bales are easier to recycle, contributing to the sustainability practices increasingly adopted within the industry.

In the energy sector, baling machines play a significant role in managing waste from biomass production and other renewable energy processes. These machines compact agricultural residues, wood chips, and other biomass materials into dense bales, optimizing storage and transportation. The compact bales ensure that biomass fuel is easily handled and fed into energy production systems, enhancing the efficiency of bioenergy plants. By facilitating the effective management and utilization of waste materials, baling machines support the production of renewable energy, promoting a more sustainable and eco-friendly energy landscape.

A baling machine, commonly used in industrial settings, is designed to compress and package materials into compact, manageable bales. These machines play a crucial role in the recycling and waste management sectors by efficiently reducing the volume of materials like paper, cardboard, plastic, and metals. By creating uniform bales, baling machines facilitate easier handling, transportation, and storage. This not only optimizes space utilization but also streamlines logistics, reducing overall operational costs. Modern baling machines come with advanced features such as automated tying systems, programmable controls, and safety mechanisms, ensuring high efficiency and safe operation.

In addition to waste management, baling machines are essential in the agricultural industry, where they are used to compress and bind hay, straw, and other crop residues. This process enhances the storage and transportability of agricultural products, preserving their quality and making them easier to handle. The versatility of baling machines extends to various configurations, including vertical and horizontal models, catering to different material types and processing volumes. Vertical balers are typically more compact and suitable for smaller operations, while horizontal balers are designed for high-volume, continuous use. Overall, the adoption of baling machines significantly contributes to operational efficiency, environmental sustainability, and cost savings across multiple industries.

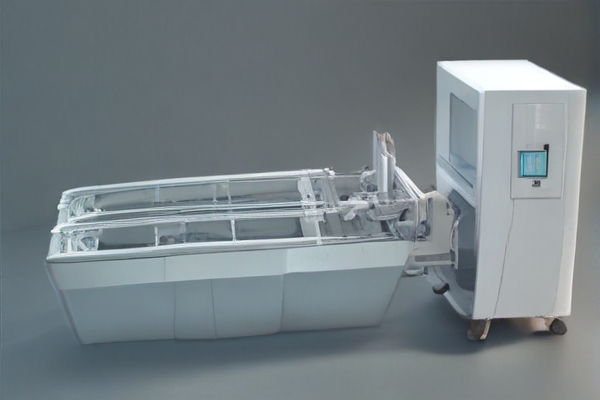

Baling machines, while traditionally associated with agricultural and industrial sectors for compacting and packaging materials such as hay, paper, and recyclables, have found innovative applications within the medical devices industry. In this context, baling machines are employed to manage medical waste, ensuring safe and efficient disposal of biohazardous materials. These machines compress waste, including used gloves, masks, gowns, and other single-use medical items, into compact bales that are easier to handle, transport, and incinerate. This process not only minimizes the volume of waste but also reduces the risk of contamination and infection by securely containing hazardous materials until they can be safely processed or disposed of according to regulatory standards.

Furthermore, baling machines contribute to the sustainability initiatives within the healthcare sector by enabling the recycling of non-contaminated medical packaging and materials. For instance, plastics, cardboard, and other recyclable materials from medical device packaging can be baled and sent to recycling facilities, thus diverting significant amounts of waste from landfills. By incorporating baling machines into their waste management protocols, healthcare facilities can improve operational efficiency, adhere to environmental regulations, and promote a safer, cleaner environment both within the facility and in the broader community. The integration of baling machines into medical waste management systems represents a crucial step towards achieving comprehensive and sustainable healthcare operations.

A baling machine is an essential piece of equipment in the machining and manufacturing industries, designed to compress and bundle materials such as scrap metal, paper, cardboard, and plastic into dense, manageable bales. This process not only optimizes storage space but also simplifies the handling and transportation of recyclable materials, contributing to a more efficient waste management system. Baling machines come in various types, including vertical, horizontal, and automatic balers, each tailored to specific material types and operational needs. Vertical balers are commonly used for smaller volumes of waste, while horizontal balers are preferred for higher volumes and continuous operation. Automatic balers, equipped with advanced features such as conveyor systems and automated tying mechanisms, enhance productivity by reducing manual labor and cycle times.

In manufacturing settings, baling machines play a crucial role in promoting sustainability and reducing environmental impact. By compacting waste materials into tightly bound bales, these machines facilitate recycling processes, ensuring that valuable resources are reintroduced into the production cycle rather than ending up in landfills. Additionally, the use of baling machines can significantly cut down on waste disposal costs by decreasing the frequency of waste pickups and optimizing load sizes for transport vehicles. This not only leads to cost savings but also reduces the carbon footprint associated with waste transportation. As industries continue to prioritize eco-friendly practices, the integration of efficient baling systems is becoming increasingly vital for maintaining both economic and environmental sustainability.

The SourcifyChina baling machine primarily uses high-strength steel for its frame, ensuring durability and robustness. This material choice provides the necessary structural integrity for handling heavy loads and high-pressure conditions, extending the machine’s lifespan.

The hydraulic system components are made from premium-grade stainless steel. This choice enhances corrosion resistance and maintains efficiency, even under demanding operational conditions. Stainless steel is also easy to clean and maintain, which is critical in environments where hygiene is essential.

For the cutting blades and wear parts, hardened steel is utilized. This material is chosen for its superior hardness and resistance to wear and tear, ensuring consistent performance and reducing maintenance costs over time. Hardened steel components contribute significantly to the machine’s reliability and efficiency.

Finally, the electronic controls and wiring are encased in durable, heat-resistant plastic. This not only protects the electronics from environmental damage but also ensures safe operation. Heat-resistant plastic prevents overheating and potential electrical failures, enhancing the overall safety of the baling machine.

In summary, the SourcifyChina baling machine combines high-strength steel, premium stainless steel, hardened steel, and durable plastic to deliver a reliable, efficient, and long-lasting piece of equipment. This thoughtful selection of materials ensures the machine’s performance and durability in various industrial applications.

SourcifyChina ensures high quality in its baling machine manufacturing through a rigorous quality control process. Each machine undergoes detailed design evaluations to meet specific customer requirements.

The production process involves selecting premium materials, ensuring durability and reliability. Skilled technicians oversee each step, from cutting and welding to assembly, ensuring precision.

Quality control checkpoints are strategically placed throughout the manufacturing process. These include inspections for structural integrity, operational functionality, and safety compliance, ensuring each machine meets industry standards.

Before delivery, every baling machine undergoes extensive testing. Performance tests replicate real-world conditions to verify efficiency and robustness.

Customer feedback is integral to SourcifyChina’s continuous improvement. This feedback informs adjustments and innovations, maintaining their commitment to producing high-quality baling machines.

The SourcifyChina baling machine offers impressive capabilities for various industries. It efficiently compresses waste materials, reducing their volume for easier handling and disposal. This machine is designed for high performance, ensuring consistent and reliable operation.

Equipped with advanced technology, the SourcifyChina baling machine can handle diverse materials such as cardboard, plastics, and textiles. Its robust construction guarantees longevity and minimal maintenance requirements. The user-friendly interface simplifies operation, making it accessible even to those with minimal technical expertise.

Safety features are a key aspect of the SourcifyChina baling machine. It includes emergency stop functions and automatic shutdowns to prevent accidents. Additionally, its compact design allows for easy integration into existing workflows, optimizing space utilization.

The SourcifyChina baling machine is also environmentally friendly, contributing to waste management and recycling efforts. By compressing materials efficiently, it aids in reducing landfill usage and promotes sustainable practices. In summary, the SourcifyChina baling machine combines efficiency, safety, and eco-friendliness, making it an ideal choice for modern waste management needs.

A baling machine offers significant advantages for waste management and recycling by compressing materials into compact, manageable bales. This enhances operational efficiency and reduces storage space.

– Space Efficiency: Compresses large volumes of materials, saving valuable storage space.

– Cost Reduction: Lowers transportation costs by enabling more material to be transported at once.

– Improved Waste Management: Facilitates easier and more organized waste handling.

– Environmental Benefits: Promotes recycling and reduces landfill usage, contributing to environmental sustainability.

– Increased Safety: Minimizes risks associated with handling loose waste materials.

– Labor Efficiency: Reduces the need for manual handling, thereby lowering labor costs and improving productivity.

A baling machine is an essential tool in agriculture and recycling, designed to compress materials into compact, manageable bales. Its functionality extends across various industries due to its efficiency and versatility.

Key features of a baling machine include:

– Compression Power: High-pressure capabilities to compress materials into dense bales.

– Automatic Operation: Many models offer automated cycling and tying, reducing manual labor.

– Versatility: Can handle a wide range of materials, including hay, cardboard, plastic, and metal.

– Durability: Built with robust materials to withstand continuous operation and harsh conditions.

– Safety Features: Equipped with safety interlocks and emergency stop buttons to ensure operator safety.

– Efficiency: Designed to maximize throughput and minimize downtime, increasing productivity.

– Adjustable Bale Size: Allows customization of bale dimensions to meet specific storage and transport needs.

– Energy Efficiency: Modern models often incorporate energy-saving features to reduce operational costs.

– Portability: Some balers are mobile, making them easy to move and operate in different locations.

– Maintenance Access: Easy access for maintenance and cleaning, ensuring long-term performance.

– Control Systems: Advanced models come with programmable control systems for precise operation.

– Noise Reduction: Incorporates noise-reducing technology to ensure a quieter working environment.

These features make baling machines indispensable for efficiently managing and processing bulk materials in various settings.

SourcifyChina offers a diverse range of baling machines designed to meet the specific needs of various industries. Their custom products include specialized balers for materials such as paper, plastic, and textiles, ensuring optimal efficiency.

Each baling machine is engineered with precision, incorporating the latest technology to enhance performance and durability. Customers can choose from a variety of models tailored to their operational requirements, promoting productivity and cost-effectiveness.

SourcifyChina’s commitment to quality is evident in their rigorous testing and quality control processes. Every machine undergoes thorough inspections to ensure it meets the highest standards of reliability and safety.

Beyond standard offerings, SourcifyChina excels in creating bespoke solutions. They work closely with clients to understand their unique challenges and design custom baling machines that integrate seamlessly into existing workflows.

Their project portfolio showcases successful implementations across multiple sectors, demonstrating their capability to deliver on complex and demanding projects. Clients benefit from comprehensive support, from initial consultation to installation and maintenance.

With a focus on innovation and customer satisfaction, SourcifyChina continues to set benchmarks in the baling machine industry. Their expertise ensures that every project, regardless of scale, achieves the desired outcomes efficiently and effectively.

SourcifyChina is a leading manufacturer and supplier of baling machines, renowned for its commitment to providing high-quality and innovative waste management solutions. The company specializes in producing a diverse range of balers, designed to compact various types of materials including cardboard, plastic, and metal, catering to industries such as recycling, packaging, and logistics. Located in China, SourcifyChina leverages advanced technology and stringent quality control processes to ensure its products meet global standards. Their baling machines are celebrated for their efficiency, durability, and ease of use, making them a preferred choice for businesses seeking to optimize their waste handling and recycling operations. With a customer-centric approach, SourcifyChina offers customized solutions tailored to the specific needs of their clients, alongside comprehensive after-sales support. This dedication to excellence and customer satisfaction has solidified their reputation as a reliable partner in the baling industry, both domestically and internationally.

Baling machines, traditionally associated with agricultural applications, have found significant utility in the aerospace, defense, and marine sectors. In aerospace, these machines are used for compacting lightweight yet voluminous materials such as foams, insulation, and packaging materials used in the transportation and storage of sensitive components. The baled materials ensure efficient space utilization and cost savings in logistics. Additionally, these machines help manage waste generated during manufacturing processes, facilitating recycling and maintaining a cleaner production environment.

In the defense and marine industries, baling machines play a crucial role in handling various waste materials generated aboard ships and during military operations. These machines compress materials like cardboard, plastic, and other non-hazardous waste, significantly reducing the storage space needed on vessels and bases. This reduction in volume not only improves operational efficiency but also enhances environmental stewardship by simplifying the recycling process. Moreover, in remote or mobile military operations, compacting waste materials can minimize environmental impact and logistical challenges associated with waste disposal. Thus, baling machines contribute to the sustainability and operational efficiency of these critical sectors.

Baling machines play a critical role in the automotive industry by efficiently handling the substantial volume of scrap materials generated during manufacturing and maintenance processes. These machines compress and bundle materials such as metal shavings, aluminum, and steel scrap, making storage and transportation more manageable. By reducing the volume of waste, baling machines help automotive manufacturers streamline recycling processes, lower disposal costs, and improve environmental sustainability. Moreover, the compact bales produced facilitate easier handling and transport to recycling facilities, ensuring that valuable materials are efficiently repurposed into new automotive components.

In the electronics sector, baling machines are indispensable for managing e-waste, which comprises discarded electronic devices and components. These machines compress electronic waste into dense, manageable bales, significantly reducing the space required for storage and making the logistics of recycling operations more efficient. By enabling the organized collection and transportation of e-waste, baling machines aid in the recovery of precious metals and other valuable materials, thus supporting the recycling industry’s efforts to minimize environmental impact. Additionally, the use of baling machines helps electronics manufacturers and recyclers comply with stringent regulations regarding e-waste management, promoting sustainable practices and reducing the environmental footprint of electronic products.

In the construction industry, baling machines play a critical role in managing and recycling construction waste. These machines compact materials like cardboard, plastic, and metal scraps into dense, manageable bales, facilitating easier transportation and disposal. By reducing the volume of waste, baling machines help construction sites maintain a cleaner and safer environment, minimize storage space requirements, and lower disposal costs. Additionally, the use of baling machines promotes sustainability by enabling the recycling of materials, thereby reducing the environmental impact associated with construction activities. This efficient waste management process aligns with the increasing emphasis on green building practices and sustainable construction.

In the energy sector, baling machines are integral to biomass energy production. These machines compress agricultural residues, such as straw, hay, and corn stalks, into dense bales that serve as biomass fuel. The compact bales are easier to handle, transport, and store, making the logistics of biomass energy production more efficient. By converting agricultural waste into energy, baling machines contribute to renewable energy initiatives and help reduce dependence on fossil fuels. This process not only provides a sustainable energy source but also adds economic value to agricultural byproducts, offering farmers an additional revenue stream. Overall, the application of baling machines in the energy sector supports the transition towards cleaner and more sustainable energy solutions.

Baling machines, pivotal in the industrial equipment industry, are primarily employed to compress materials into compact, manageable bales. This functionality is essential across various sectors, particularly in waste management and recycling, where these machines streamline the handling, transportation, and storage of recyclable materials like cardboard, plastics, and metals. By significantly reducing the volume of waste, baling machines help in lowering transportation costs and minimizing landfill usage, thus contributing to more efficient and environmentally friendly waste management practices. The machines come in different types, including vertical and horizontal balers, each designed to meet specific industrial needs and material types, enhancing operational efficiency and productivity.

In the agricultural sector, baling machines are indispensable for harvesting and storing crops such as hay, straw, and silage. These machines enable farmers to gather and compress these materials into bales that are easier to handle, store, and transport, thereby optimizing space and labor. The ability to produce uniform bales ensures that storage facilities are utilized more effectively, and transportation becomes more cost-efficient. Moreover, the use of baling machines in agriculture helps in preserving the quality of the crops by protecting them from moisture and pests during storage. Overall, baling machines enhance productivity, reduce labor costs, and support sustainable practices in various industrial applications.

Baling machines, traditionally associated with agriculture and recycling, have found innovative applications in the medical devices sector. In hospitals and medical facilities, these machines are utilized to compact and manage medical waste, including used gloves, masks, gowns, and other disposable items. This efficient waste management process ensures that potentially hazardous materials are securely packaged, minimizing the risk of contamination and exposure to healthcare workers and the environment. By reducing the volume of medical waste, baling machines also contribute to lower disposal costs and improved space management within healthcare facilities.

Moreover, baling machines enhance the sustainability practices of medical institutions by enabling the recycling of certain types of medical waste. Materials such as cardboard, plastics, and other non-contaminated packaging materials used in medical devices can be compacted and prepared for recycling. This not only reduces the environmental footprint of healthcare operations but also aligns with regulatory requirements for waste segregation and disposal. In essence, the adaptation of baling machines in the medical sector underscores a commitment to both operational efficiency and environmental stewardship.

Baling machines play a critical role in machining and manufacturing industries by efficiently managing waste and recyclable materials. These machines compress materials such as metal shavings, plastic, and paper into compact bales, making storage and transportation more efficient and cost-effective. In machining environments, baling machines are essential for handling the large volumes of scrap metal produced. By converting loose scrap into dense, manageable bales, these machines not only help in maintaining a clean and organized workspace but also facilitate recycling processes. This compaction significantly reduces the volume of waste, leading to lower disposal costs and enhanced sustainability practices within manufacturing facilities.

In addition to waste management, baling machines contribute to the broader scope of resource optimization in manufacturing. They enable manufacturers to reclaim valuable materials that can be reintroduced into the production cycle, thereby minimizing raw material consumption and reducing overall operational costs. For instance, baling machines used in the automotive and aerospace industries compact aluminum and steel scraps, which can then be melted and reused in new production batches. This recycling loop not only supports environmental conservation efforts but also enhances economic efficiency by lowering the need for new material procurement. Thus, baling machines are integral to both the operational and environmental strategies of modern machining and manufacturing sectors.

FAQ:

Baling Machine Quality Work from SourcifyChina Factory

Q: What types of baling machines does SourcifyChina manufacture?

A: SourcifyChina manufactures a variety of baling machines including vertical balers, horizontal balers, automatic balers, and specialty balers for specific materials like textiles, cardboard, and plastics.

Q: How does SourcifyChina ensure the quality of their baling machines?

A: SourcifyChina ensures quality through stringent quality control processes, including rigorous testing at multiple production stages, use of high-grade materials, and compliance with international standards such as ISO and CE certifications.

Q: Can SourcifyChina customize baling machines to specific requirements?

A: Yes, SourcifyChina offers customization options to meet specific operational needs, including adjustments in size, capacity, and functionality to suit different industry requirements.

Q: What is the lead time for ordering a baling machine from SourcifyChina?

A: The lead time typically ranges from 4 to 8 weeks, depending on the complexity of the order and customization requirements.

Q: Does SourcifyChina provide installation and maintenance services?

A: SourcifyChina offers comprehensive installation and maintenance services, including on-site setup, operator training, and periodic maintenance checks to ensure optimal machine performance.

Q: Are spare parts readily available for SourcifyChina baling machines?

A: Yes, SourcifyChina maintains a robust inventory of spare parts, ensuring quick availability and minimal downtime for maintenance and repairs.

Q: What is the warranty period for SourcifyChina’s baling machines?

A: SourcifyChina provides a standard one-year warranty on all baling machines, covering parts and labor. Extended warranty options are also available upon request.

Q: How can I request a quote or place an order?

A: You can request a quote or place an order by contacting SourcifyChina directly through their website or by emailing their sales team. Detailed specifications and requirements will help expedite the process.

Q: Does SourcifyChina export baling machines internationally?

A: Yes, SourcifyChina exports baling machines to various international markets, ensuring compliance with the destination country’s import regulations and standards.

Q: What after-sales support does SourcifyChina offer?

A: SourcifyChina provides extensive after-sales support, including technical assistance, troubleshooting, spare parts supply, and regular maintenance services to ensure long-term customer satisfaction.

Baling machine manufacturing is a specialized field that involves designing and producing equipment for compressing and packaging various materials like hay, cardboard, and plastics. SourcifyChina, a notable manufacturer, offers key insights for effective baling machine production:

1. Understand Market Needs: Focus on the specific requirements of your target market, whether it’s agricultural, recycling, or industrial sectors. Different materials and applications demand unique baling specifications.

2. Innovative Design: Prioritize designing machines that are efficient, reliable, and user-friendly. Integrate modern technologies such as automated control systems and IoT capabilities to enhance performance and ease of operation.

3. Quality Materials: Use high-quality, durable materials for manufacturing to ensure longevity and robustness of the baling machines. This reduces maintenance costs and increases customer satisfaction.

4. Energy Efficiency: Design machines that consume less power without compromising performance. Energy-efficient machines are more attractive to customers seeking to reduce operational costs.

5. Customization: Offer customization options to cater to specific customer needs. Providing tailored solutions can give you a competitive edge in the market.

6. Compliance and Standards: Ensure that your machines comply with international standards and certifications. This includes safety standards and environmental regulations, which are crucial for global market acceptance.

7. After-Sales Support: Provide comprehensive after-sales support, including training, maintenance services, and spare parts supply. This helps in building long-term relationships with customers.

8. Cost-Effectiveness: Balance between cost and quality. Efficient manufacturing processes and cost control can help in offering competitive prices without compromising on quality.

9. Marketing and Branding: Develop a strong brand presence through effective marketing strategies. Highlight your unique selling propositions (USPs) such as advanced technology, superior quality, and exceptional customer service.

10. Continuous Improvement: Stay updated with industry trends and continuously improve your products based on customer feedback and technological advancements.

By implementing these strategies, manufacturers like SourcifyChina can maintain a competitive edge in the baling machine industry.

What types of baling machines does SourcifyChina offer?

SourcifyChina provides a range of baling machines, including vertical and horizontal balers, auto-tie balers, and two-ram balers. These machines cater to various materials such as cardboard, plastic, textiles, and metals.

How can I place an order for a baling machine?

To place an order, visit SourcifyChina’s website, select the desired baling machine, and submit a request for a quote. Alternatively, you can contact their sales team directly via email or phone.

What is the lead time for delivery?

The lead time varies depending on the model and customization requirements. Generally, it ranges from 4 to 8 weeks. Contact SourcifyChina for specific delivery timelines.

Can I customize the baling machine to fit my specific needs?

Yes, SourcifyChina offers customization options. You can specify the size, power, capacity, and additional features required for your application. Discuss your requirements with their technical team for tailored solutions.

What are the payment terms?

Payment terms typically include a 30% deposit upon order confirmation, with the balance payable before shipment. SourcifyChina accepts various payment methods, including wire transfers and letters of credit.

Do you offer installation and training services?

Yes, SourcifyChina provides installation and training services. Their technicians can assist with on-site setup and train your staff to operate the machinery efficiently.

What is the warranty period for the baling machines?

SourcifyChina offers a one-year warranty on all baling machines, covering parts and labor. Extended warranty options are available upon request.

How do you handle after-sales service and support?

After-sales support includes technical assistance via phone or email, on-site repair services, and a supply of spare parts. SourcifyChina ensures prompt and reliable service to minimize downtime.

Are there any safety features included with the baling machines?

Yes, SourcifyChina’s baling machines come with several safety features, such as emergency stop buttons, safety interlocks, and protective guards, ensuring safe operation.

Can I visit the factory to inspect the machines before purchasing?

Yes, SourcifyChina welcomes factory visits. Schedule an appointment to tour their facilities, meet the team, and inspect the machinery firsthand.

Sourcing a baling machine from SourcifyChina factory requires careful attention to detail to ensure you get a high-quality product that meets your needs. Here are some tips to guide you through the process:

1. Define Your Requirements:

– Identify the specific type of baling machine you need (e.g., vertical, horizontal, manual, automatic).

– Determine the material to be baled (e.g., cardboard, plastic, metal) and the required bale size and weight.

2. Research and Verify the Supplier:

– Visit the SourcifyChina factory’s website and review their product offerings.

– Check their certifications, such as ISO, CE, or other relevant quality standards.

– Look for customer reviews and testimonials to gauge their reputation.

3. Request Detailed Information:

– Ask for product catalogs, specifications, and brochures.

– Request a quote including the price, delivery time, and shipping costs.

– Inquire about the warranty, after-sales service, and spare parts availability.

4. Evaluate Product Quality:

– Request samples or visit the factory if possible.

– Ask for references from previous customers.

– Confirm the machine’s compliance with safety and regulatory standards.

5. Negotiate Terms:

– Discuss payment terms, including any deposits and final payments.

– Negotiate for favorable terms such as bulk discounts or long-term supply agreements.

6. Inspect Before Shipping:

– Arrange for a pre-shipment inspection to ensure the machine meets your specifications.

– Use third-party inspection services if needed.

7. Arrange Logistics:

– Plan for shipping, customs clearance, and local transportation.

– Ensure proper packaging to prevent damage during transit.

8. Maintain Communication:

– Keep in regular contact with the supplier to monitor progress and address any issues promptly.

By following these steps, you can effectively source a baling machine from SourcifyChina factory, ensuring a smooth transaction and a quality product.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.