Technology and Applications of bend machine

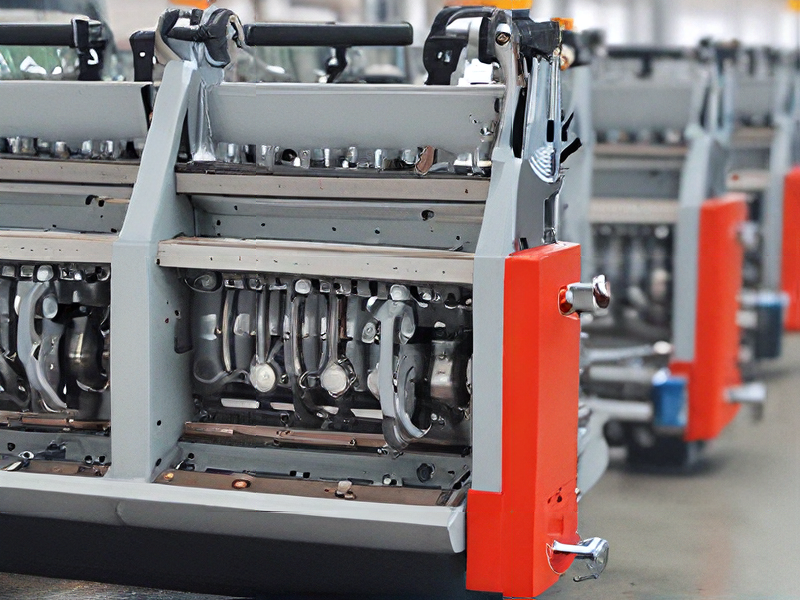

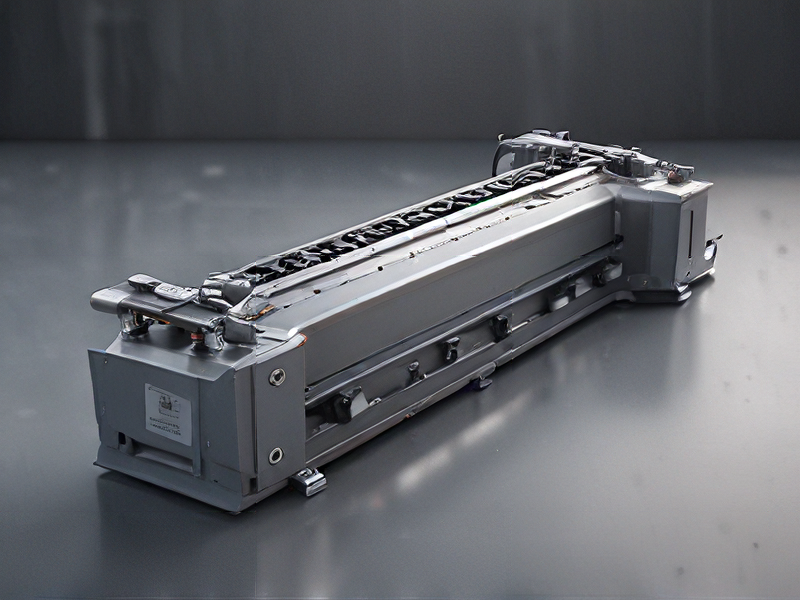

A bend machine, commonly known as a bending machine, is used to bend various materials, such as metal, into desired shapes and angles. These machines are essential in manufacturing and construction industries for creating components with precision.

Technology

1. Types of Bend Machines:

– Press Brake: Utilizes a punch and die to create precise bends in metal sheets.

– Roll Bending Machine: Uses rollers to bend pipes, tubes, or plates into curved shapes.

– Folding Machine: Primarily used for bending thin sheets by clamping the material and folding it along a straight edge.

– Rotary Draw Bender: Ideal for bending pipes and tubes with tight radius requirements.

2. Control Systems:

– Manual: Operator manually controls the bending process.

– NC (Numerical Control): Automated but requires manual input for each operation.

– CNC (Computer Numerical Control): Fully automated, allowing for high precision and complex bending tasks.

3. Sensors and Feedback Systems:

– Modern machines are equipped with sensors that provide real-time feedback, ensuring high accuracy and repeatability.

Applications

1. Automotive Industry: Used for manufacturing various components like exhaust pipes, frames, and brackets.

2. Construction: Bending machines create structural components like beams, columns, and reinforcements.

3. Aerospace: Precision bending of lightweight metals for aircraft components.

4. Furniture: Creating metal frames and decorative elements.

5. Shipbuilding: Bending large metal sheets and plates for hull construction.

6. HVAC: Forming ducts, pipes, and structural parts for heating, ventilation, and air conditioning systems.

7. Custom Fabrication: Tailoring parts for specific industrial or artistic projects.

Conclusion

Bending machines integrate advanced technologies to enhance efficiency and precision, catering to various industries’ diverse needs. Their ability to produce complex shapes and maintain high accuracy makes them indispensable in modern manufacturing.

Quality Testing Methods for bend machine and how to control quality

Quality testing methods for a bending machine are crucial to ensure the precision and reliability of the bending process. The following methods are commonly employed:

1. Dimensional Inspection: Using tools like calipers, micrometers, and coordinate measuring machines (CMM), the dimensions of the bent parts are measured to ensure they meet specified tolerances.

2. Visual Inspection: This involves examining the bent parts for visible defects such as cracks, surface irregularities, or improper bends. It’s a quick method to identify obvious issues.

3. Mechanical Testing: Tests such as tensile strength, hardness, and fatigue tests are conducted to verify the material properties have not been adversely affected by the bending process.

4. Bend Angle Measurement: Specialized tools like digital protractors or bend angle gauges are used to measure the bend angles precisely and ensure they meet design specifications.

5. Non-Destructive Testing (NDT): Methods such as ultrasonic testing, magnetic particle testing, or dye penetrant testing can detect internal or surface defects without damaging the part.

6. Springback Testing: Measuring the amount of springback (the tendency of the material to return to its original shape) helps in adjusting the bending process parameters to achieve accurate results.

Quality Control Measures

1. Calibration and Maintenance: Regular calibration and maintenance of the bending machine ensure its accuracy and longevity. Keeping the equipment in optimal condition prevents deviations in the bending process.

2. Process Monitoring: Implementing real-time monitoring systems to track the machine’s performance and detect any anomalies early.

3. Operator Training: Ensuring operators are well-trained and understand the machine’s functionality and the importance of precision in the bending process.

4. Standard Operating Procedures (SOPs): Establishing and adhering to SOPs for every step of the bending process to maintain consistency and quality.

5. Quality Audits: Conducting regular internal and external audits to ensure compliance with quality standards and continuous improvement.

6. Feedback Loop: Establishing a feedback system to learn from defects or issues and implement corrective actions to prevent recurrence.

By employing these testing methods and quality control measures, the quality of parts produced by bending machines can be effectively managed and improved.

Tips for Procurement and Considerations when Purchasing from bend machine

Tips for Procurement

1. Define Requirements Clearly: Specify the materials, dimensions, tolerances, and other critical specifications.

2. Evaluate Suppliers: Check supplier credibility through references, certifications, and past performance.

3. Request for Proposals (RFP): Issue detailed RFPs to multiple vendors to get competitive quotes.

4. Negotiate Terms: Discuss pricing, delivery schedules, payment terms, and warranties.

5. Quality Control: Implement strict quality checks and ask for samples or prototypes before finalizing.

6. Sustainability: Consider suppliers with sustainable practices and certifications.

Considerations when Purchasing from a Bend Machine

1. Capabilities: Ensure the bend machine meets your technical requirements, including material compatibility and bend radius.

2. Technology: Look for advanced features such as CNC controls for precision and efficiency.

3. Durability and Maintenance: Check for robust construction and easy maintenance.

4. Support and Training: Evaluate the availability of technical support and training for your staff.

5. Cost vs. Value: Balance initial costs with long-term benefits such as reduced labor and material waste.

6. Compliance: Ensure the machine complies with industry standards and safety regulations.

7. After-Sales Service: Check the reputation of the manufacturer for after-sales service and support.

By following these guidelines, you can make informed decisions that ensure quality, efficiency, and cost-effectiveness in your procurement process.

FAQs on Sourcing and Manufacturing from bend machine in China

Certainly! Here are some FAQs on sourcing and manufacturing from a bend machine in China:

1. What are the advantages of sourcing bend machines from China?

China offers competitive pricing due to lower manufacturing costs and a wide range of suppliers, providing options for different budget and quality requirements.

2. How can I ensure quality when sourcing from China?

Conduct thorough supplier due diligence, including factory audits and requesting samples. Implementing clear quality control measures and inspections throughout production is crucial.

3. What are common challenges when sourcing bend machines from China?

Challenges may include language barriers, cultural differences, longer lead times, and potential logistical issues. Clear communication and detailed contracts can help mitigate these.

4. Are there specific certifications or standards to look for in Chinese bend machine manufacturers?

Look for certifications such as ISO 9001 for quality management and CE marking for compliance with European standards. Ensure the manufacturer adheres to industry-specific standards relevant to your market.

5. What are typical payment terms when dealing with Chinese suppliers?

Payment terms often include a deposit upfront (30-50%) with the balance paid upon completion or shipment. Negotiate terms that balance risk and incentivize quality.

6. How can I protect my intellectual property (IP) when manufacturing in China?

Use contracts that clearly define ownership and confidentiality clauses. Consider registering patents and trademarks in China and implementing security measures during production.

7. What steps should I take to manage shipping and logistics?

Plan ahead for shipping times and customs procedures. Work with experienced freight forwarders and consider insurance options to protect against potential risks during transit.

Navigating these aspects thoughtfully can streamline the process of sourcing and manufacturing bend machines from China while minimizing risks and ensuring product quality and compliance.