Technology and Applications of centerless grinding process

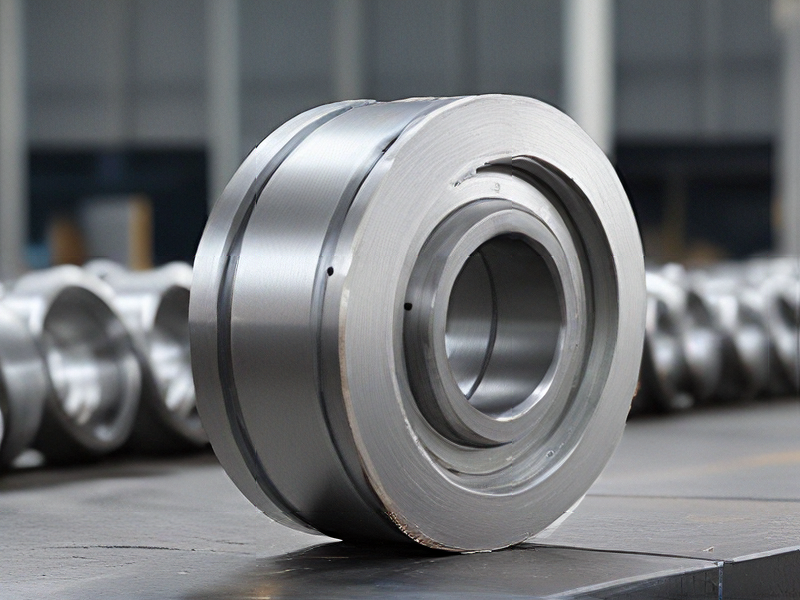

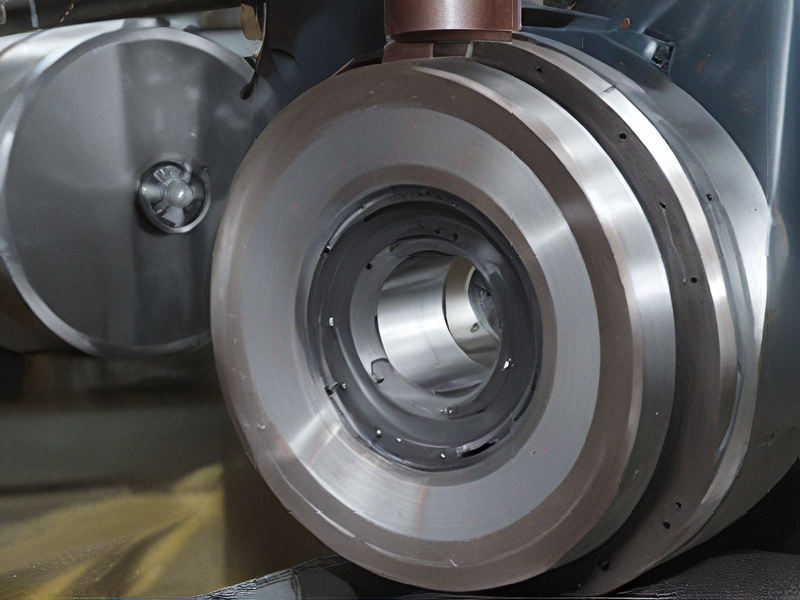

Centerless grinding is a machining process used to achieve roundness, surface finish, and dimensional accuracy for cylindrical components without the need for centers or chucks. It involves feeding the workpiece between two wheels: a grinding wheel and a regulating wheel. The grinding wheel rotates and removes material from the workpiece, while the regulating wheel controls the rotational speed and feed rate of the workpiece.

Applications of centerless grinding are widespread across various industries, including automotive, aerospace, medical, and electronics. It is particularly advantageous for high-volume production of precision components such as shafts, pins, valves, and rollers. The process excels in grinding long, thin workpieces that require close tolerances and smooth finishes.

Key advantages include the ability to process multiple parts simultaneously, reducing cycle times and increasing productivity. It eliminates the need for fixtures or centers, allowing for rapid setup and changeovers between different part sizes. Centerless grinding also offers consistent dimensional accuracy and surface finish, crucial for parts that require tight tolerances.

Technological advancements in centerless grinding include automation and computer numerical control (CNC) integration, enhancing precision and repeatability. Modern machines incorporate sensors and feedback systems to monitor and adjust process parameters in real-time, ensuring consistent quality and optimizing production efficiency.

In conclusion, centerless grinding remains a versatile and efficient machining process suited for a wide range of applications where high precision and productivity are essential. Its continuous development in automation and control systems further enhances its capabilities in modern manufacturing environments.

Quality Testing Methods for centerless grinding process and how to control quality

Quality testing methods for centerless grinding typically include:

1. Dimensional Inspection: Using precision measurement tools such as micrometers, calipers, and gauges to ensure workpiece dimensions meet specifications.

2. Surface Finish Evaluation: Employing surface roughness testers to assess the smoothness and texture of the ground surface.

3. Roundness Measurement: Checking the roundness of the workpiece using roundness testers to ensure it meets tolerance requirements.

4. Visual Inspection: Inspecting for visual defects such as cracks, burns, or other surface imperfections that can affect quality.

To control quality in centerless grinding:

1. Process Monitoring: Continuously monitoring key process parameters such as grinding wheel speed, feed rate, and workpiece material removal rate.

2. Regular Maintenance: Ensuring machines are properly maintained to avoid variations in grinding performance.

3. Training and Skill Development: Providing training to operators to enhance their understanding of the process and improve their ability to identify quality issues.

4. Feedback Loops: Establishing feedback mechanisms to quickly address any deviations from quality standards during production.

By implementing these methods and controls, manufacturers can consistently achieve high-quality results in centerless grinding processes.

Tips for Procurement and Considerations when Purchasing from centerless grinding process

When procuring services from a centerless grinding process, several key considerations ensure a successful partnership:

1. Quality Standards: Prioritize suppliers with ISO certifications or industry-specific quality standards to guarantee precision and consistency in grinding operations.

2. Capability Assessment: Evaluate suppliers based on their equipment capabilities, such as machine capacity, tolerance levels, and material handling expertise, to match your project requirements.

3. Experience and Reputation: Choose vendors with a proven track record in centerless grinding, verified through client testimonials, case studies, or site visits to assess their operational proficiency.

4. Cost and Value: Balance cost-effectiveness with the value offered by suppliers, considering factors like production efficiency, lead times, and added services (e.g., inspection, packaging) that contribute to overall project ROI.

5. Communication and Collaboration: Establish clear communication channels and expectations regarding project specifications, deadlines, and quality metrics to ensure alignment throughout the procurement process.

6. Risk Management: Mitigate risks by discussing contingency plans for potential disruptions, such as machine breakdowns or supply chain issues, to maintain project timelines and minimize operational disruptions.

7. Environmental and Ethical Practices: Prioritize suppliers committed to sustainable practices and ethical sourcing to uphold corporate social responsibility standards and mitigate reputational risks.

By addressing these considerations, organizations can effectively navigate the procurement process for centerless grinding services, ensuring optimal outcomes aligned with quality, cost-efficiency, and operational excellence.

FAQs on Sourcing and Manufacturing from centerless grinding process in China

Certainly! Here are some FAQs regarding sourcing and manufacturing from the centerless grinding process in China:

1. What is centerless grinding?

Centerless grinding is a machining process where a workpiece is supported between two wheels, one of which rotates at high speed to remove material from the workpiece.

2. Why choose centerless grinding in China?

China offers competitive pricing and a wide range of manufacturing capabilities, making it a cost-effective choice for centerless grinding.

3. How to select a reliable centerless grinding supplier in China?

Look for suppliers with ISO certifications, positive customer reviews, and a proven track record in precision machining.

4. What materials can be processed using centerless grinding in China?

Chinese manufacturers can handle various materials including steel, stainless steel, aluminum, brass, and exotic alloys.

5. What are the typical tolerances achievable with centerless grinding in China?

Depending on the material and part specifications, Chinese manufacturers can achieve tight tolerances ranging from ±0.002 to ±0.0001 inches.

6. How does centerless grinding compare to other machining methods in terms of cost and efficiency?

Centerless grinding is often more cost-effective for high-volume production runs due to reduced setup times and faster material removal rates.

7. What quality control measures are employed by Chinese manufacturers during centerless grinding?

Quality control measures may include regular inspections, dimensional checks, and the use of advanced metrology equipment to ensure precise machining.

8. Are there any environmental considerations with centerless grinding in China?

Chinese manufacturers adhere to local environmental regulations and may implement measures such as coolant recycling and waste management.

9. How long does it typically take to complete a centerless grinding project in China?

Project timelines vary based on complexity and order volume but Chinese suppliers often provide efficient turnaround times.

10. What are the shipping and logistics considerations when sourcing centerless grinding services from China?

Consider factors such as shipping costs, lead times, and import/export regulations to optimize logistics for your specific needs.

These FAQs provide a comprehensive overview for those considering sourcing and manufacturing from the centerless grinding process in China.