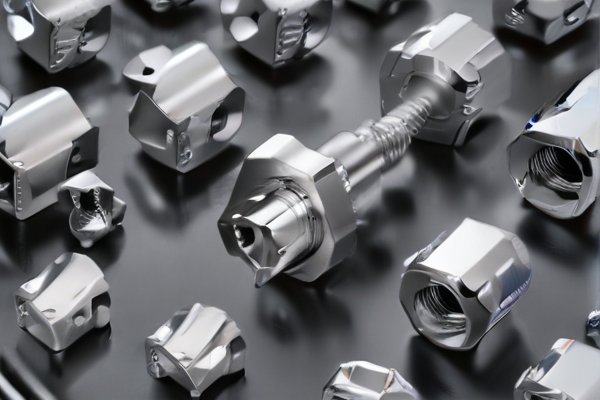

Reliable CNC Bolts Manufacturing: SourcifyChina Factory Excellence

Discover the exceptional quality and reliability of CNC bolts from SourcifyChina, a trusted factory known for precision engineering and manufacturing excellence. Ensure your projects meet the highest standards with SourcifyChina’s durable and accurately crafted bolts.

Choosing SourcifyChina Factory for purchasing CNC bolts from China offers reliability, quality, and cost-effectiveness. They are renowned for their precision manufacturing, ensuring that every bolt meets international standards. This guarantees that your projects benefit from consistent, high-quality components.

SourcifyChina Factory utilizes state-of-the-art technology and employs skilled technicians, which translates to superior products. Their advanced CNC machinery allows for tight tolerances and intricate designs, making them a top choice for buyers seeking precision-engineered bolts.

Moreover, SourcifyChina’s commitment to customer service is exceptional. They provide comprehensive support throughout the purchasing process, from initial inquiry to after-sales service. This dedication to customer satisfaction helps buyers navigate the complexities of international trade smoothly.

Cost efficiency is another compelling reason to choose SourcifyChina Factory. By leveraging China’s competitive manufacturing landscape, they offer high-quality CNC bolts at lower prices. This cost advantage allows buyers to maximize their budget without compromising on quality.

Additionally, SourcifyChina Factory has a robust supply chain network, ensuring timely delivery of orders. Their logistical expertise minimizes delays and ensures that your project timelines are met, enhancing overall efficiency and reliability.

In conclusion, SourcifyChina Factory stands out for its precision, customer service, cost efficiency, and reliable delivery. These attributes make them a preferred partner for sourcing CNC bolts from China, ensuring that buyers receive top-quality products at competitive prices, backed by excellent support and timely delivery.

CNC bolts are precision-engineered fasteners used in CNC machining for secure and precise assembly. They come in various types and options to suit different applications and materials.

– Hex Head Bolts: Commonly used, offering high tensile strength.

– Socket Head Cap Screws: Ideal for tight spaces, providing a clean appearance.

– Flat Head Screws: Used when a flush surface is needed.

– Shoulder Bolts: Allow for rotational movement, often used in pulleys and linkages.

– Carriage Bolts: Feature a round head and square neck, preventing rotation once tightened.

– Set Screws: Designed without a head, used to secure objects within or against another object.

– Stud Bolts: Threaded rods with no head, commonly used in automotive and construction applications.

– Lag Bolts: Heavy-duty screws designed for wood, providing strong fastening power.

– Anchor Bolts: Used to attach structures to concrete, offering strong support.

– U-Bolts: U-shaped bolts used to secure pipes and tubes to flat surfaces.

Options for CNC bolts include:

– Material: Stainless steel, carbon steel, titanium, and aluminum.

– Coatings: Zinc plating, black oxide, and anodizing for corrosion resistance and durability.

– Thread Types: Coarse, fine, metric, and custom threads to match specific requirements.

– Lengths and Diameters: Various sizes to fit different applications.

– Grades: Different strength ratings to ensure proper load-bearing capacity.

These variations ensure that CNC bolts can meet the specific demands of various industrial, automotive, and construction applications.

CNC bolts, precision-engineered fasteners produced through computer numerical control (CNC) machining, are essential for various industries due to their accuracy and durability. They offer consistent quality and customizability for specific applications.

– Automotive Industry: Ensuring high precision in engine and structural components.

– Aerospace Sector: Providing reliable fasteners for aircraft assemblies.

– Medical Devices: Offering secure and precise components for medical equipment.

– Construction: Enhancing structural integrity in buildings and infrastructures.

– Machinery Manufacturing: Providing durable bolts for industrial machines.

– Electronics: Ensuring reliable connections in electronic devices.

– Marine Industry: Offering corrosion-resistant fasteners for marine applications.

– Renewable Energy: Used in wind turbines and solar panel installations.

– Custom Prototyping: Facilitating the creation of tailored prototypes with exact specifications.

– Robotics: Providing precision bolts for assembling robotic components.

SourcifyChina CNC bolts are crafted from high-quality stainless steel, renowned for its excellent durability and resistance to corrosion. This material ensures the bolts maintain their strength and integrity even in harsh environments.

The stainless steel used is often alloyed with elements such as chromium and nickel, enhancing its hardness and mechanical properties. This composition allows for precision engineering, making the bolts suitable for critical applications.

In addition to stainless steel, SourcifyChina also utilizes carbon steel for CNC bolts. This material is chosen for its superior tensile strength and affordability, making it ideal for industrial uses where cost efficiency is crucial.

Aluminum is another material used for these bolts, favored for its lightweight nature and good corrosion resistance. This makes aluminum CNC bolts perfect for aerospace and automotive industries where weight reduction is essential.

Titanium CNC bolts from SourcifyChina offer an excellent strength-to-weight ratio and exceptional corrosion resistance. This premium material is often used in high-performance applications requiring both robustness and low weight.

The company also produces CNC bolts from exotic alloys such as Inconel and Hastelloy. These materials provide extraordinary resistance to extreme temperatures and chemical exposure, ideal for use in demanding industrial environments.

Overall, SourcifyChina’s diverse material selection for CNC bolts ensures they can meet the specific needs of various industries, from general manufacturing to high-tech applications. This versatility and commitment to quality materials make their bolts a reliable choice for engineers and manufacturers worldwide.

of high-quality, reliable CNC bolts. By maintaining rigorous standards and incorporating customer feedback, SourcifyChina continually elevates its manufacturing practices, ensuring the production of bolts that are both robust and precise. This dedication to excellence positions SourcifyChina as a trusted supplier in the industry, known for delivering products that consistently meet the demanding requirements of various applications.

SourcifyChina specializes in producing high-quality CNC bolts, leveraging advanced technology for precision manufacturing. Their capabilities ensure consistent, reliable products tailored to meet diverse industrial requirements.

Utilizing state-of-the-art CNC machines, SourcifyChina manufactures bolts with exceptional accuracy, maintaining strict tolerances. This precision is crucial for applications demanding high performance and durability.

SourcifyChina offers a wide range of CNC bolts in various sizes, materials, and finishes. Their extensive catalog caters to numerous industries, including automotive, aerospace, and construction, ensuring versatility and adaptability.

Customization is a key strength of SourcifyChina. They provide bespoke solutions, collaborating with clients to develop bolts that meet specific design and functional needs. This personalized approach enhances client satisfaction and application efficiency.

Quality control at SourcifyChina is rigorous, with comprehensive testing and inspection processes. This ensures each bolt meets international standards, delivering reliability and safety in critical applications.

The company’s commitment to innovation drives continuous improvement in their manufacturing processes. SourcifyChina integrates the latest advancements in CNC technology to enhance productivity and product quality, staying ahead in the competitive market.

Customer support and after-sales service are integral to SourcifyChina’s operations. Their dedicated team provides prompt assistance, ensuring clients receive the necessary support throughout the product lifecycle.

In conclusion, SourcifyChina stands out in the CNC bolt manufacturing industry due to its precision, customization options, strict quality control, and excellent customer service. Their advanced capabilities make them a preferred choice for businesses seeking reliable and high-quality CNC bolts for various applications.

NC bolts offer a tremendous range of benefits to numerous industries. These bolts are highly precise and durable, making them essential for various applications.

– Precision: CNC bolts are manufactured using Computer Numerical Control machines, ensuring dimensions, which enhance the performance of the machines where they are used.

– Durability These bolts are designed to withstand high levels of stress, ensuring longevity and reliability in heavy-duty operations.

– Versatility: They can serve various industries such as automotive, aerospace, construction, among others, due to their ability to be customized to meet specific requirements.

– Speed: CNC machines can produce bolts at high speed, reducing the lead time. That’s very beneficial for industries with demanding production timelines.

– Cost-Effective: In the long run, CNC bolts may prove to be more economical. Their precision minimizes errors in production and their durability reduce replacement and maintenance costs.

– Uniformity: Every bolt produced is identical to the last, ensuring consistency, a critical factor in industries that rely on interchangeable parts.

– Complex Designs: CNC technology allows for the creation of intricate designs that might not be attainable with traditional manufacturing methods.

– Quality and Safety: The high standard of CNC bolts means higher equipment safety and lowers failure rates, benefiting both operational effectiveness and staff safety.

In conclusion, CNC bolts provide improved reliability, precision, and efficiency, thereby enhancing operational effectiveness in many sectors.

CNC bolts, essential in precision engineering, offer superior accuracy and durability. These fasteners are crafted using Computer Numerical Control (CNC) technology, ensuring consistency and high performance.

Key features of CNC bolts:

– Precision Manufacturing: CNC technology allows for high-precision production, resulting in bolts with exact dimensions and tight tolerances.

– Consistency: Automated CNC processes ensure that every bolt produced is identical, reducing variability and improving reliability.

– Material Versatility: CNC bolts can be made from various materials, including stainless steel, aluminum, titanium, and more, catering to different industrial needs.

– Strength and Durability: High-quality materials and precise manufacturing enhance the strength and longevity of CNC bolts, making them suitable for demanding applications.

– Customizability: CNC technology allows for easy customization, enabling the production of bolts with specific dimensions, threads, and finishes to meet unique requirements.

– Enhanced Thread Quality: CNC machining provides superior thread accuracy and finish, reducing the risk of thread stripping and improving joint integrity.

– Efficiency: CNC machines can produce bolts at a high rate, ensuring a steady supply for large-scale projects and reducing lead times.

– Reduced Waste: The precision of CNC machining minimizes material waste, making the production process more efficient and environmentally friendly.

– Corrosion Resistance: Depending on the material and finishes used, CNC bolts can offer excellent resistance to corrosion, making them ideal for harsh environments.

– Compatibility: CNC bolts are compatible with a wide range of applications, from aerospace and automotive to construction and electronics, due to their precision and reliability.

These features make CNC bolts a preferred choice in industries where accuracy, strength, and consistency are critical.

SourcifyChina specializes in custom CNC bolts, delivering high-precision and durable products tailored to diverse industries. Their bolts are manufactured using state-of-the-art CNC technology, ensuring exact specifications and superior quality.

Clients benefit from SourcifyChina’s comprehensive range of services, from initial design to final production. They collaborate closely with customers to meet unique project requirements, ensuring satisfaction at every step.

SourcifyChina’s expertise extends to various custom projects, including automotive, aerospace, and machinery applications. Their commitment to innovation and quality guarantees products that perform reliably under demanding conditions.

To complete your project with top-notch custom CNC bolts, trust SourcifyChina for unmatched quality, precision, and customer service.

SourcifyChina is a leading manufacturer specializing in high-precision CNC bolts, catering to various industries with their top-tier mechanical components. Based in China, the company has established itself as a reliable source for custom bolts and fasteners, leveraging advanced CNC machining technologies to meet the stringent quality requirements of their clients. SourcifyChina’s CNC bolts are known for their durability, precision, and resistance to wear and tear, making them ideal for applications in automotive, aerospace, and industrial machinery sectors. The company prides itself on its ability to deliver bespoke solutions tailored to specific client needs, ensuring optimal performance and reliability. With a robust supply chain and a commitment to continuous improvement, SourcifyChina not only meets international standards but also provides competitive pricing and timely delivery, making them a preferred partner for businesses seeking dependable CNC bolt solutions.

CNC bolts play a critical role in aerospace, defense, and marine applications due to their precision, durability, and ability to meet stringent industry standards. In the aerospace sector, CNC bolts are used extensively in aircraft structures and engines, where reliability and exact specifications are crucial. The high precision of CNC machining ensures that these bolts fit perfectly, reducing the risk of structural failures. Aerospace components often experience extreme conditions, such as high temperatures and pressures; therefore, CNC bolts made from high-strength materials like titanium and stainless steel provide the necessary resilience and longevity. Additionally, the ability to produce custom bolts with CNC machining allows for tailored solutions that enhance the overall safety and performance of aircraft.

In the defense and marine industries, CNC bolts are equally vital. Military vehicles, naval ships, and submarines rely on these components for their structural integrity and operational efficiency. The defense industry demands components that can withstand harsh environments, including exposure to saltwater, high mechanical loads, and corrosive conditions. CNC bolts manufactured from corrosion-resistant materials ensure the longevity and reliability of military and marine equipment. Furthermore, CNC machining allows for the production of bolts with complex geometries and tight tolerances, essential for the sophisticated assemblies found in defense and marine applications. The adaptability and precision of CNC machining thus play an indispensable role in ensuring the robustness and reliability of critical components in these demanding fields.

CNC bolts find critical applications in both automotive and electronics industries due to their precision manufacturing capabilities and reliable performance. In automotive contexts, CNC bolts are integral components used in engines, transmissions, suspension systems, and other critical assemblies. Their precise threading and dimensional accuracy ensure they can handle the high stresses and vibrations typical in automotive environments, contributing to the overall safety and performance of vehicles. CNC bolts are often made from high-strength materials such as alloy steels or titanium, tailored to withstand specific load requirements and environmental conditions. Their uniformity and consistency also facilitate automated assembly processes, enhancing production efficiency in automotive manufacturing.

In electronics, CNC bolts play a crucial role in securing components within devices and equipment. Whether used in consumer electronics like smartphones and laptops or in industrial electronics such as servers and machinery, these bolts provide secure fastening while maintaining the integrity of delicate electronic components. The precise machining of CNC bolts ensures that they meet exacting specifications for thread fit and torque requirements, which is essential in maintaining the reliability and longevity of electronic devices. Moreover, their often compact size and lightweight nature make them ideal for applications where space and weight considerations are critical. Overall, CNC bolts exemplify the intersection of precision engineering and practical utility, making them indispensable in advancing both automotive and electronics technologies.

In the construction industry, CNC (Computer Numerical Control) bolts offer precision and reliability that significantly enhance structural integrity and project efficiency. These bolts are produced using automated machining processes, ensuring consistent quality and exact specifications that traditional manufacturing methods cannot match. This precision is critical for applications requiring high tolerances and strength, such as in steel frameworks, bridges, and high-rise buildings. The use of CNC bolts reduces the likelihood of structural failures and enhances the overall safety of construction projects. Furthermore, the efficiency of CNC production allows for rapid manufacturing and delivery, which helps keep construction timelines on track and reduces downtime.

In the energy sector, CNC bolts play a crucial role in the assembly and maintenance of complex equipment used in power generation and distribution. For instance, in wind turbines, nuclear reactors, and solar panel installations, the need for highly reliable and durable fastening solutions is paramount. CNC bolts meet these requirements by offering superior tensile strength and resistance to environmental stressors such as corrosion and temperature fluctuations. Their precision manufacturing ensures that they fit perfectly into engineered designs, minimizing the risk of leaks or mechanical failures. Additionally, CNC bolts are essential in the oil and gas industry, where they secure pipelines and drilling equipment that operate under extreme conditions, ensuring both safety and operational efficiency.

The industrial equipment industry significantly benefits from the application of CNC (Computer Numerical Control) bolts, which enhance precision, efficiency, and consistency in manufacturing processes. CNC bolts are designed using advanced CNC machinery that allows for high-precision production with tight tolerances. This precision is crucial in industries such as aerospace, automotive, and heavy machinery, where even minor deviations can lead to significant operational failures. CNC bolts ensure that components are securely fastened, maintaining the integrity and performance of the equipment. The automated nature of CNC machining also reduces human error and increases production speed, making it possible to meet high demand without compromising on quality.

Furthermore, CNC bolts contribute to the customization and scalability of industrial projects. With CNC technology, manufacturers can easily produce bolts in various sizes, shapes, and materials tailored to specific requirements. This flexibility supports the development of specialized machinery and equipment, enabling innovation and adaptation to evolving industrial needs. CNC bolts are also known for their durability and reliability, essential qualities for equipment subjected to extreme conditions and heavy usage. By integrating CNC bolts, the industrial equipment industry can achieve higher standards of safety and performance, ultimately driving growth and technological advancement in the sector.

Medical devices rely heavily on precision and reliability, making CNC bolts an indispensable component in their construction. CNC (Computer Numerical Control) bolts are manufactured using advanced machining techniques that ensure each bolt meets exact specifications with minimal variance. This precision is crucial in medical devices, where even the smallest deviations can affect the device’s functionality and safety. For instance, in surgical instruments, orthopedic implants, and diagnostic equipment, CNC bolts help maintain the structural integrity and precise alignment needed for optimal performance. The ability to produce bolts with tight tolerances and specific material properties enhances the durability and longevity of medical devices, ensuring they can withstand the rigors of use in various medical environments.

Moreover, the use of CNC bolts in medical devices enhances customization and innovation. CNC machining allows for the production of bolts tailored to unique design requirements, facilitating the development of bespoke medical solutions. This is particularly beneficial in personalized medicine, where devices may need to be adapted to individual patient anatomy or specific clinical needs. Additionally, CNC bolts can be made from a variety of biocompatible materials, such as titanium and stainless steel, which are essential for applications that involve direct contact with human tissue. The versatility and adaptability of CNC bolts thus play a critical role in advancing medical technology, enabling the creation of more effective and reliable medical devices.

CNC (Computer Numerical Control) bolts play a crucial role in modern machining and manufacturing, offering precision and efficiency that manual processes cannot match. CNC bolts are fasteners produced using CNC machining, a method where pre-programmed computer software dictates the movement of machinery and tools. This results in bolts with extremely precise dimensions and tolerances, essential for high-stakes industries such as aerospace, automotive, and medical device manufacturing. The precision of CNC machining ensures that each bolt is consistent in quality, which is vital for maintaining the integrity of assemblies that demand exacting standards. Moreover, CNC machining allows for the production of complex bolt geometries and custom threading, expanding the functionality and application of these fasteners.

In manufacturing applications, CNC bolts are integrated into assembly lines to enhance production speed and reliability. Their use reduces the likelihood of assembly errors due to inconsistent bolt dimensions, which can occur with traditionally manufactured bolts. Additionally, the automation inherent in CNC machining minimizes human error and increases throughput, making it possible to produce large quantities of bolts in shorter time frames. This efficiency is particularly beneficial in industries that require rapid production cycles without compromising on quality. Furthermore, CNC bolts’ durability and precision contribute to the longevity and safety of the final products, as they are less likely to fail under stress compared to bolts produced by less precise methods. The adaptability of CNC machining also means that manufacturers can quickly switch between different bolt designs, catering to specific project needs without significant downtime.

#### Q: What is the material quality of CNC bolts produced by SourcifyChina?

A: SourcifyChina ensures that all CNC bolts are made from high-grade materials such as stainless steel, carbon steel, and alloy steel, adhering to international standards.

#### Q: How does SourcifyChina ensure the precision of CNC bolts?

A: Our CNC bolts undergo rigorous quality control processes including precision machining, strict tolerance checks, and thorough inspections to guarantee high accuracy.

#### Q: What are the customization options available for CNC bolts?

A: SourcifyChina offers a variety of customization options including different sizes, thread types, coatings, and material grades to meet specific client requirements.

#### Q: How long is the lead time for an order of CNC bolts?

A: The typical lead time for CNC bolts ranges from 2 to 4 weeks, depending on the order size and customization requirements.

#### Q: What certifications does SourcifyChina hold for manufacturing CNC bolts?

A: SourcifyChina holds ISO 9001 and ISO 14001 certifications, ensuring high standards in quality management and environmental management.

#### Q: Can SourcifyChina provide samples of CNC bolts before placing a bulk order?

A: Yes, we provide samples upon request to ensure that our clients are satisfied with the quality and specifications before proceeding with bulk orders.

#### Q: What is the minimum order quantity (MOQ) for CNC bolts from SourcifyChina?

A: The MOQ varies depending on the type and size of the bolts but generally starts at 500 pieces.

#### Q: How does SourcifyChina handle quality issues or defects?

A: We have a dedicated customer service team that addresses any quality issues promptly. Replacement or refunds are provided based on the situation and our warranty policy.

#### Q: Does SourcifyChina offer packaging and shipping services?

A: Yes, we offer comprehensive packaging and shipping services to ensure the safe delivery of CNC bolts to our clients worldwide.

#### Q: How can I get a quote for CNC bolts from SourcifyChina?

A: You can get a quote by contacting our sales team through our website or email, providing the necessary specifications and quantity details.

This FAQ aims to address common questions and provide concise information about CNC bolts quality work from SourcifyChina factory. For further details, please visit our website or contact us directly.

Sure, here are some key tips on CNC bolts manufacturing from SourcifyChina factory:

1. Material Selection:

– Steel: Commonly used for its strength and durability.

– Stainless Steel: Offers corrosion resistance.

– Aluminum: Lightweight but strong.

2. Precision in Design:

– Utilize CAD (Computer-Aided Design) software to create detailed designs.

– Ensure the design specifications meet the required standards for strength and durability.

1. CNC Machining:

– CNC (Computer Numerical Control) machines are programmed to precisely cut and shape the bolts.

– Ensures high accuracy and consistency in bolt production.

2. Thread Rolling:

– Cold-forming process where threads are rolled onto the bolt.

– Produces stronger threads compared to cutting.

3. Heat Treatment:

– Bolts may undergo heat treatment to enhance strength and hardness.

– Common processes include quenching and tempering.

4. Surface Finishing:

– Apply coatings like zinc plating or anodizing for corrosion resistance and enhanced appearance.

1. Inspection:

– Dimensional inspection to ensure the bolts meet design specifications.

– Thread gauge testing to verify thread accuracy.

2. Testing:

– Mechanical tests such as tensile and hardness tests to ensure strength.

– Corrosion resistance tests for coated bolts.

1. Expertise:

– Skilled engineers and technicians with extensive experience in CNC bolt manufacturing.

2. Advanced Equipment:

– State-of-the-art CNC machines and quality control instruments ensure high-quality production.

3. Customization:

– Ability to produce custom bolts tailored to specific requirements.

4. Cost Efficiency:

– Competitive pricing due to efficient manufacturing processes and sourcing capabilities.

When sourcing CNC bolts from SourcifyChina, focus on the material, precision in design, and thorough quality control to ensure reliable and durable products. Their advanced equipment and experienced team provide a solid foundation for high-quality bolt manufacturing.

By following these tips, you can ensure a successful and efficient CNC bolt manufacturing process from SourcifyChina factory.

Q: What types of CNC bolts does SourcifyChina Factory produce?

A: SourcifyChina Factory produces a variety of CNC bolts, including hex bolts, square bolts, machine bolts, carriage bolts, anchor bolts, eye bolts, and U-bolts, available in a range of materials and finishes.

Q: What kind of materials are used in the of your CNC bolts?

A: We use an array of durable materials such as stainless steel, alloy steel, titanium, aluminum, and brass among others. The choice of material is often determined by the intended application.

Q: Can I get a customized order at SourcifyChina Factory?

A: Absolutely. SourcifyChina Factory specializes in customized orders. Simply provide us with your bolt specifications and we can manufacture a product that matches your unique requirements.

Q: How long does it usually take to complete an order?

A: Lead times vary but typically, it takes around 15-20 days to complete an order, depending on quantity and complexity.

Q: What kind of quality control processes are in place?

A: We adhere to rigorous quality control measures including dimensional checks, hardness testing, and surface finish inspections to ensure our bolts adhere to industry standards.

Q: Do you ship internationally?

A: Yes. SourcifyChina Factory ships globally. We work with trusted logistics providers to ensure safe and timely delivery.

Q: What are your payment terms?

A: Our standard payment terms require a 30% deposit before production, with 70% balance payment before shipment. Though, we can negotiate depending on specific order considerations.

Sourcing CNC bolts from SourcifyChina Factory requires a strategic approach to ensure quality, cost-effectiveness, and reliability. Here are some key tips:

1. Research and Verification: Verify SourcifyChina Factory’s credentials, certifications, and reputation. Look for reviews and feedback from other businesses that have worked with them.

2. Clear Specifications: Provide detailed specifications for the CNC bolts, including dimensions, materials, tolerances, and any special requirements. Precise specs help avoid misunderstandings and ensure the product meets your needs.

3. Sample Orders: Request samples before placing a large order. This allows you to inspect the quality of the bolts and ensure they meet your standards.

4. Quality Control: Establish clear quality control processes. Ask about their quality assurance procedures and consider third-party inspections to verify the quality of the bolts before shipment.

5. Communication: Maintain clear and consistent communication with the factory. Use detailed contracts to outline terms, expectations, and responsibilities to avoid any miscommunications.

6. Lead Times: Confirm production and shipping lead times to ensure they align with your project timelines. Factor in potential delays and plan accordingly.

7. Cost Analysis: Compare the cost of sourcing from SourcifyChina with other potential suppliers. Consider all costs, including shipping, tariffs, and any additional fees, to ensure you’re getting the best deal.

8. Payment Terms: Negotiate favorable payment terms. It’s common to pay a deposit upfront and the balance upon shipment or receipt of goods.

9. Logistics and Shipping: Ensure efficient logistics and shipping arrangements. Use reliable shipping partners and track shipments to avoid delays.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.