Technology and Applications of cnc g code

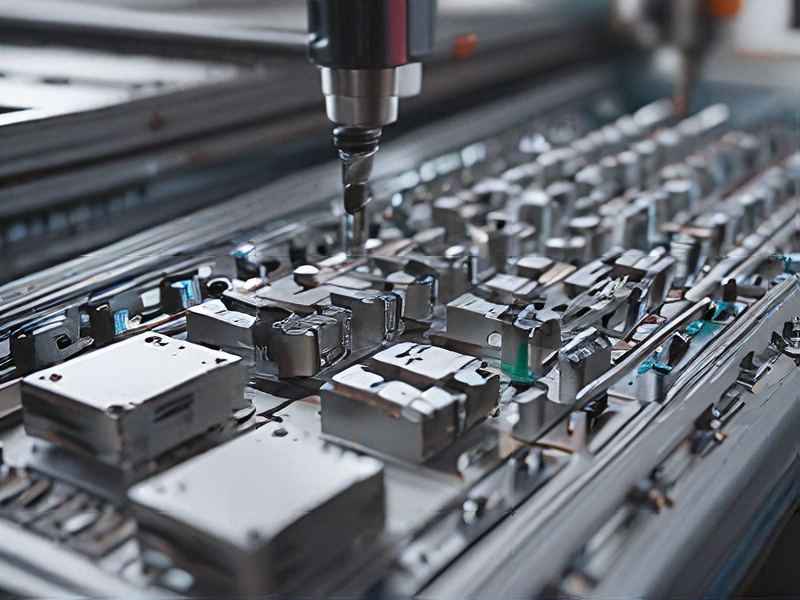

CNC (Computer Numerical Control) G-code is a programming language used to control CNC machines, which are essential in modern manufacturing. CNC machines execute precise movements and operations by interpreting G-code commands, enabling the automated production of parts with high accuracy and repeatability.

Technology of CNC G-code

1. Structure and Syntax: G-code consists of commands that control the movements and operations of CNC machines. These commands include instructions for moving the machine along the X, Y, and Z axes, controlling spindle speeds, and managing tool changes. Each line of G-code typically begins with a letter (G, M, T, etc.) followed by a number, which specifies the type of action to perform.

2. Controllers: CNC machines are equipped with controllers that read G-code and translate it into electrical signals to drive motors and other machine components. These controllers ensure the precise execution of programmed instructions.

3. Simulation Software: Before running G-code on actual machines, simulation software is often used to visualize and verify the tool paths. This helps in detecting potential errors and optimizing the machining process.

Applications of CNC G-code

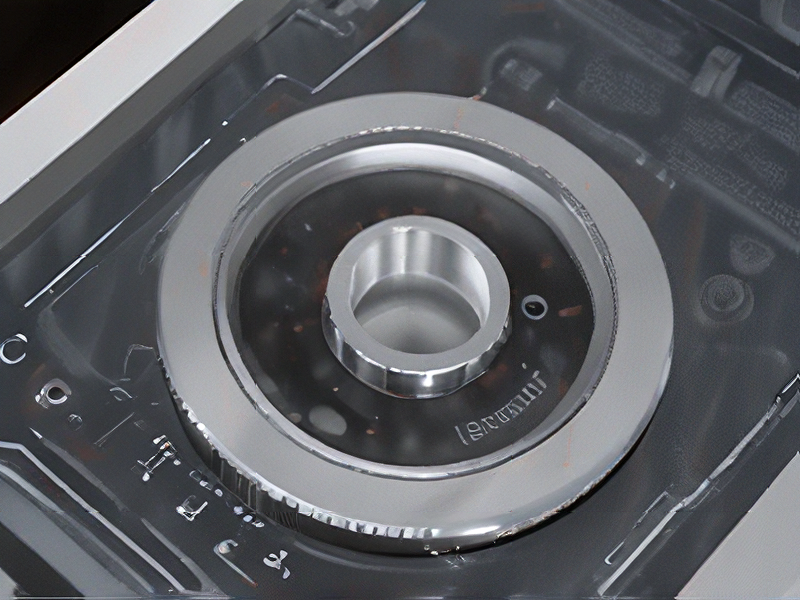

1. Manufacturing: CNC G-code is widely used in industries such as automotive, aerospace, and electronics to produce complex parts with high precision. It is crucial for creating engine components, circuit boards, and aircraft parts.

2. Prototyping: Engineers and designers use CNC machines to create prototypes quickly and accurately. G-code allows for rapid iteration and testing of designs before mass production.

3. Custom Fabrication: G-code enables the production of custom parts for various applications, including medical implants, custom jewelry, and architectural components.

4. Art and Craft: Artists and craftsmen utilize CNC machines to create intricate designs and patterns in materials like wood, metal, and plastic, expanding the possibilities for creative expression.

In summary, CNC G-code is integral to modern manufacturing, offering precision and efficiency across diverse industries. Its applications range from large-scale industrial production to custom fabrication and artistic endeavors.

Quality Testing Methods for cnc g code and how to control quality

Quality testing of CNC G-code ensures smooth and accurate machine operation, producing precise parts.

Methods:

* Simulations: Software like CAM systems allow “dry runs” of the G-code, visualizing toolpaths and identifying potential collisions or errors before cutting material.

* Post-processor Verification: Review the generated G-code for syntax errors, incorrect variable references, or formatting issues using dedicated post-processor checkers.

* Manual Inspection: Experienced programmers can manually scrutinize the code for logic flaws, improper feed rates, or unrealistic tool movements.

Quality Control:

* Clear Documentation: Precisely define machining parameters, tolerances, and tool specifications in the project documentation.

* Version Control: Track changes to the G-code using version control systems to ensure accountability and facilitate rollback if needed.

* Parameter Libraries: Utilize standardized parameter libraries for common operations to minimize human error and promote consistency.

* Regular Training: Equip programmers with ongoing training on best practices, code standards, and the latest CAM software features.

Following these practices helps maintain high-quality G-code, reducing waste, rework, and costly production delays.

Tips for Procurement and Considerations when Purchasing from cnc g code

When procuring and purchasing from a CNC G-code supplier, consider the following tips:

1. Vendor Reputation: Choose suppliers with proven reliability and positive customer feedback. Look for certifications or memberships in industry associations.

2. Quality Assurance: Ensure the supplier adheres to stringent quality control measures. Request sample G-code files to verify precision and adherence to specifications.

3. Customization and Flexibility: Verify the supplier’s ability to customize G-code to your specific requirements. Flexibility in accommodating design changes is crucial.

4. Technical Support: Reliable technical support is essential. Ensure the supplier offers comprehensive support for troubleshooting and optimizing G-code for your machinery.

5. Cost and Value: Compare costs among suppliers, but also consider the value. Cheaper options may lead to lower quality and higher long-term expenses due to errors and rework.

6. Delivery Time: Confirm lead times and ensure they align with your project schedules. Reliable and timely delivery can significantly impact your production efficiency.

7. Compatibility: Ensure the G-code provided is compatible with your CNC machinery. Incompatible code can cause machine errors and production delays.

8. Data Security: Protect your designs by choosing suppliers who prioritize data security and confidentiality. Secure transmission methods and data handling protocols are vital.

9. Scalability: Assess the supplier’s capacity to scale production as your demands grow. This ensures a consistent supply chain as your business expands.

10. Return and Refund Policies: Understand the supplier’s return and refund policies in case the delivered G-code does not meet your standards.

By considering these factors, you can make informed procurement decisions, ensuring high-quality, efficient, and cost-effective CNC operations.

FAQs on Sourcing and Manufacturing from cnc g code in China

Certainly! When sourcing and manufacturing CNC G-code in China, here are some frequently asked questions (FAQs) to consider:

1. How do I find reliable CNC machining suppliers in China?

– Utilize online platforms like Alibaba or Made-in-China for initial searches. Verify supplier credibility through reviews, certifications, and direct communication.

2. What are the typical lead times for CNC machining in China?

– Lead times vary based on complexity and volume. Generally, they range from 2-4 weeks for prototypes and 4-8 weeks for larger production runs.

3. How can I ensure quality control when manufacturing CNC parts in China?

– Implement rigorous quality control measures such as inspections, sample approvals, and specifying quality standards in contracts. Consider third-party inspection services if needed.

4. What are the common challenges in outsourcing CNC manufacturing to China?

– Language barriers, time zone differences, intellectual property protection, and logistical issues are frequent challenges. Clear communication and legal safeguards are crucial.

5. How can I protect my intellectual property (IP) when outsourcing CNC production to China?

– Use non-disclosure agreements (NDAs), patent protections, and work with reputable suppliers with a history of respecting IP rights. Consider registering your designs or patents in China if applicable.

6. What payment methods are typically used for CNC manufacturing in China?

– Wire transfers, letters of credit, and payment platforms like PayPal or Alibaba’s Escrow are common. Ensure terms are agreed upon in contracts to mitigate financial risks.

7. What are the advantages of sourcing CNC manufacturing from China?

– Lower labor costs, access to advanced manufacturing technologies, scalability, and a vast supplier base offering competitive pricing are key advantages.

8. What environmental regulations should I consider when sourcing from China?

– Ensure compliance with local environmental laws and regulations. Verify suppliers’ environmental certifications and practices to align with your sustainability goals.

Navigating these considerations can help optimize sourcing and manufacturing processes when dealing with CNC G-code production in China.