Technology and Applications of cnc g codes

CNC (Computer Numerical Control) technology utilizes G-codes for controlling automated machine tools. G-codes are a standardized programming language that instructs CNC machines on how to move, cut, and shape materials. These codes are essential for precision manufacturing in industries such as aerospace, automotive, and electronics.

Key Aspects of CNC G-Codes

1. Basic Structure:

– G-codes (e.g., G00 for rapid positioning, G01 for linear interpolation) direct the machine’s motion.

– M-codes (e.g., M03 to start the spindle, M05 to stop it) handle machine functions like coolant control and spindle speed.

2. Movement Commands:

– G00: Rapid positioning

– G01: Linear interpolation for straight cuts

– G02 and G03: Circular interpolation for clockwise and counterclockwise arcs, respectively

3. Coordinate Systems:

– G-codes use Cartesian coordinates (X, Y, Z) for precise movement.

– G17, G18, and G19 specify the working planes (XY, XZ, YZ).

4. Tool Control:

– G43: Tool length offset

– G49: Cancel tool length offset

Applications

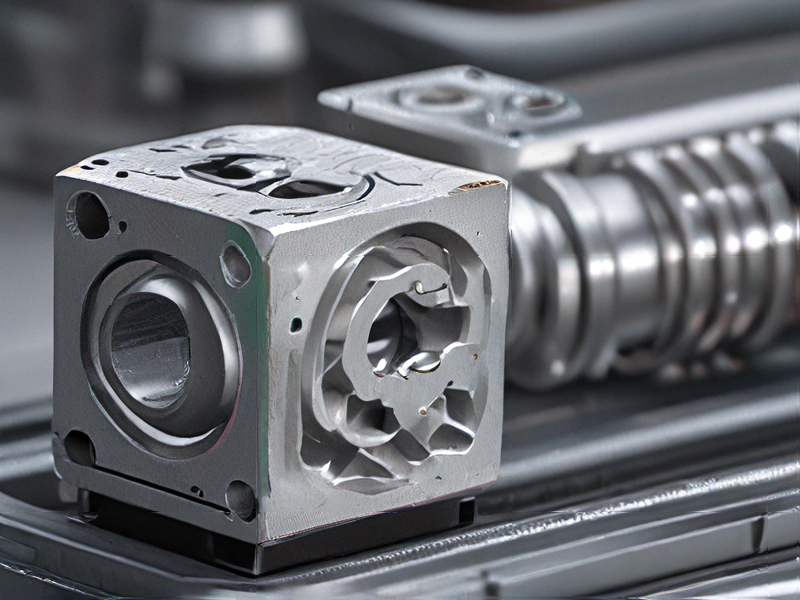

1. Precision Manufacturing:

– CNC machines produce complex and precise parts with high repeatability, essential for aerospace and automotive components.

2. Prototyping:

– Rapid prototyping allows for quick iteration of design concepts, vital for product development.

3. Custom Manufacturing:

– Custom parts for medical devices, jewelry, and other industries benefit from CNC’s ability to produce intricate designs.

4. Mass Production:

– CNC technology enables efficient mass production with minimal human intervention, reducing errors and increasing consistency.

Advancements

Recent advancements in CNC technology include integration with CAD/CAM software, enhancing the design-to-production workflow, and incorporating IoT (Internet of Things) for real-time monitoring and maintenance. These innovations are pushing the boundaries of what CNC machines can achieve, leading to smarter, more efficient manufacturing processes.

In summary, CNC G-codes are fundamental to modern manufacturing, providing precise control over machine operations and enabling the production of complex parts across various industries.

Quality Testing Methods for cnc g codes and how to control quality

Quality testing of CNC G-codes is crucial for ensuring precise and accurate machining. Here are some effective methods and controls:

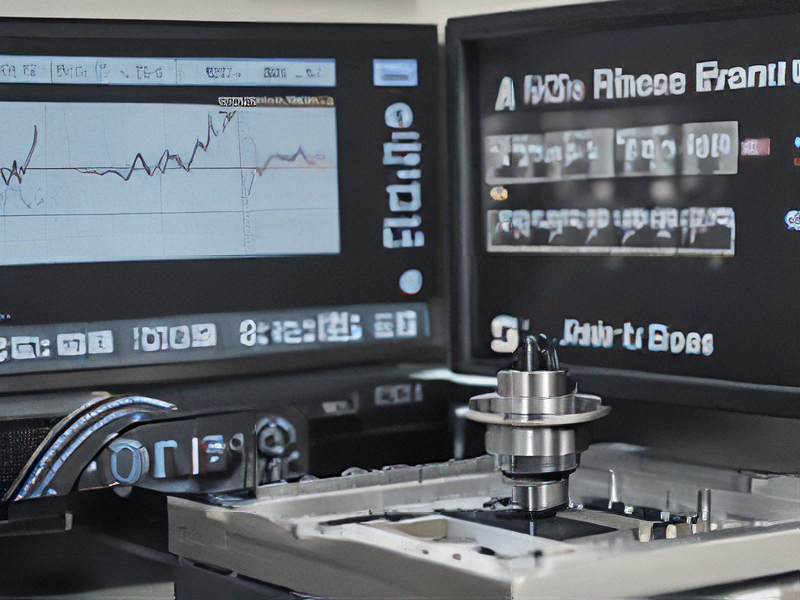

1. Simulation Software:

– Purpose: Verifies the G-code without physical machining.

– Tools: Use software like Vericut, NC Viewer, or CAM packages with built-in simulators.

– Benefits: Identifies potential errors and collisions, reducing scrap and machine downtime.

2. Dry Runs:

– Purpose: Runs the CNC machine without cutting material.

– Process: Executes the G-code with the spindle off or above the workpiece.

– Benefits: Checks for errors in tool paths and machine movements, ensuring no crashes or missteps.

3. Machine Probing:

– Purpose: Uses probes to measure and verify tool and part positions.

– Tools: Equipped in many modern CNC machines.

– Benefits: Ensures accuracy in setups and detects deviations during the process.

4. G-Code Verification Tools:

– Purpose: Specialized software that verifies the syntax and logic of G-codes.

– Tools: G-Code Quality Checker, NC-Checker.

– Benefits: Ensures the G-code conforms to standard practices and checks for common errors.

5. Post-Processing Validation:

– Purpose: Ensures the post-processed G-code matches the intended tool paths.

– Tools: Integrated within CAM systems.

– Benefits: Confirms that the post-processor generates accurate G-code.

Quality Control Practices:

1. Standardization:

– Establish and follow standard operating procedures (SOPs) for G-code generation and verification.

2. Documentation:

– Maintain detailed records of G-code versions, testing results, and any issues found.

3. Training:

– Regularly train operators and programmers on the latest G-code standards and verification techniques.

4. Routine Audits:

– Conduct periodic audits of the G-code creation and verification processes to identify and address weaknesses.

By integrating these methods and practices, CNC machining quality can be significantly enhanced, leading to more efficient and accurate production.

Tips for Procurement and Considerations when Purchasing from cnc g codes

Tips for Procurement and Considerations when Purchasing CNC G Codes

1. Understand Your Needs:

– Application Requirements: Identify the specific applications and the types of CNC machines you’ll be using. This helps in selecting the appropriate G codes tailored to your machinery.

– Complexity and Precision: Consider the complexity of the operations and the level of precision required.

2. Source from Reputable Providers:

– Reliability: Choose suppliers with a good reputation for providing accurate and reliable G codes.

– Support and Updates: Ensure the supplier offers technical support and regular updates to keep the codes compatible with new machines or software versions.

3. Compatibility:

– Machine Compatibility: Verify that the G codes are compatible with your CNC machine models and controllers.

– Software Integration: Ensure the G codes integrate seamlessly with your existing CAD/CAM software.

4. Customization and Flexibility:

– Custom G Codes: Look for suppliers who can provide customized G codes based on your specific requirements.

– Flexibility: Choose G codes that allow for modifications to adapt to changing project needs.

5. Quality Assurance:

– Testing and Validation: Ensure the G codes have been thoroughly tested and validated to avoid production errors.

– Compliance: Check for compliance with industry standards to ensure quality and safety.

6. Cost Considerations:

– Pricing Models: Evaluate different pricing models (one-time purchase vs. subscription) and choose the one that best fits your budget and usage frequency.

– Value for Money: Assess the value offered by the G codes in terms of functionality, reliability, and support.

7. Documentation and Training:

– Comprehensive Documentation: Ensure the G codes come with detailed documentation for easy implementation and troubleshooting.

– Training: Consider providers that offer training sessions to help your team effectively use the G codes.

8. Security:

– Data Security: Verify that the supplier implements strong data security measures to protect your proprietary designs and machine configurations.

By carefully considering these aspects, you can ensure a successful procurement process and optimal performance from your CNC machines.

FAQs on Sourcing and Manufacturing from cnc g codes in China

FAQs on Sourcing and Manufacturing CNC G-Codes in China

1. Why source CNC G-Codes from China?

China offers competitive pricing, advanced technology, and a vast network of skilled manufacturers. This makes it an attractive option for high-quality and cost-effective CNC G-code production.

2. How do I find reliable manufacturers?

Use platforms like Alibaba, Made-in-China, and Global Sources. Look for manufacturers with high ratings, positive reviews, and verified certifications. Visiting trade shows and industry expos can also help identify trustworthy suppliers.

3. What should I consider when choosing a manufacturer?

Evaluate their experience, technical capabilities, and quality control measures. Ensure they can meet your specific requirements and production volumes. It’s crucial to assess their communication skills and responsiveness.

4. How can I ensure the quality of CNC G-codes?

Request samples and conduct thorough testing. Ensure the manufacturer follows international standards and has a robust quality assurance process. Consider hiring a third-party inspection service for additional verification.

5. What is the typical lead time for CNC G-code production in China?

Lead times can vary depending on the complexity and volume of your order. Generally, it ranges from a few weeks to a couple of months. Confirm the timeline with your manufacturer upfront.

6. What are the costs involved?

Costs include design, production, and shipping. Request detailed quotes from multiple manufacturers to compare. Be aware of hidden costs such as taxes, duties, and shipping fees.

7. How can I protect my intellectual property?

Sign non-disclosure agreements (NDAs) and ensure the manufacturer adheres to international IP laws. Register your IP in China for added protection.

8. How do I handle logistics and shipping?

Work with experienced freight forwarders and customs brokers. They can help navigate the complexities of international shipping and ensure your goods arrive safely and on time.

9. What payment methods are accepted?

Common methods include wire transfers (T/T), letters of credit (L/C), and escrow services through platforms like Alibaba. Ensure payment terms are clearly defined in your contract.

10. How can I handle language and cultural barriers?

Hire bilingual staff or use professional translation services. Building a relationship based on trust and understanding can significantly ease communication challenges.

By addressing these FAQs, you can streamline the process of sourcing and manufacturing CNC G-codes in China, ensuring efficiency and quality in your production pipeline.