Title: “Reliable CNC Lathe Metal Manufacturing by SourcifyChina Factory: High-Quality Precision and Efficiency”

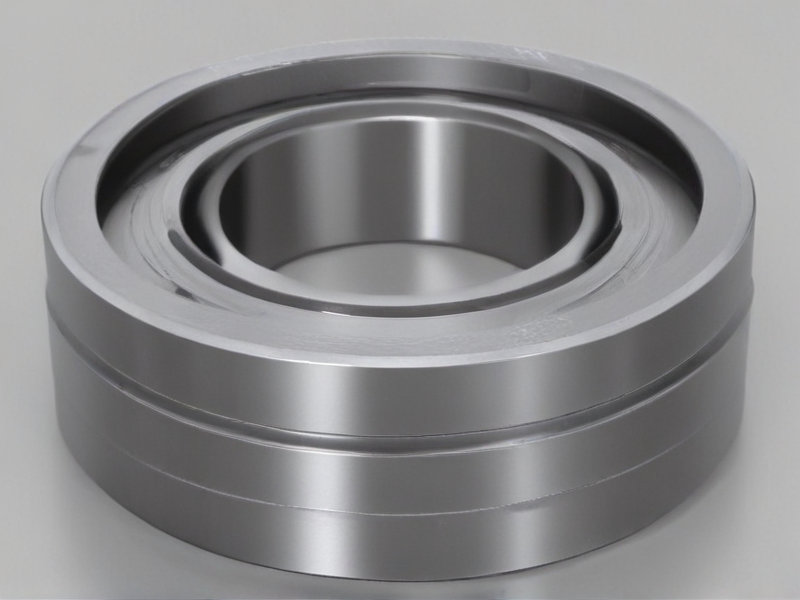

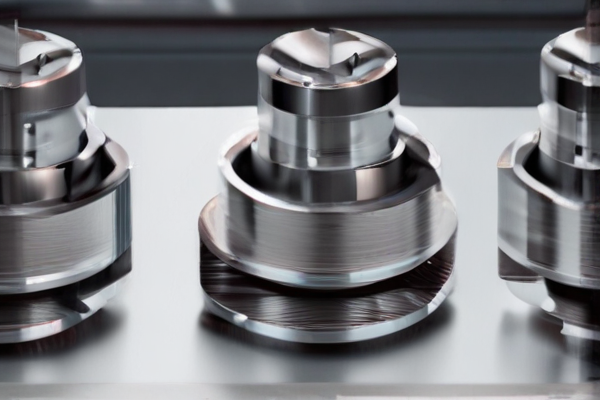

SourcifyChina is a trusted name in the CNC lathe metal manufacturing industry, known for its high-quality precision and efficiency. Our factory is equipped with state-of-the-art machinery and skilled professionals who ensure that every product meets stringent quality standards. We specialize in producing complex metal parts for various industries, including automotive, aerospace, and medical. Our commitment to excellence and customer satisfaction has earned us a reputation for reliability and innovation. By partnering with SourcifyChina, clients benefit from cost-effective solutions and timely delivery, making us the go-to source for all CNC lathe metal manufacturing needs.

Why Choose SourcifyChina Factory for Purchasing CNC Lathe Metal from China?

SourcifyChina Factory offers top-tier CNC lathe metal products, ensuring high precision and quality. Their advanced technology and rigorous quality control meet international standards, making them a reliable choice for buyers.

They provide competitive pricing without compromising quality, giving buyers excellent value for their money. Their cost-effective solutions help businesses maximize their budget while maintaining product excellence.

With a strong focus on customer satisfaction, SourcifyChina Factory offers exceptional support and after-sales service. Their dedicated team ensures smooth communication and timely resolution of any issues, enhancing the overall purchasing experience.

SourcifyChina Factory boasts extensive experience in the industry, backed by a skilled workforce and state-of-the-art machinery. Their expertise and capabilities ensure the production of complex and precise metal components tailored to specific buyer requirements.

The factory’s commitment to sustainable practices and eco-friendly production methods aligns with global environmental standards. Buyers can confidently choose SourcifyChina Factory, knowing they are partnering with a responsible and ethical manufacturer.

In summary, SourcifyChina Factory stands out for its high-quality products, competitive pricing, excellent customer service, industry expertise, and commitment to sustainability, making it the ideal choice for purchasing CNC lathe metal from China.

CNC lathes for metalworking are essential tools in modern manufacturing, offering precision and efficiency. These machines come in various types, each suited for different applications and materials.

– Horizontal CNC Lathes: Standard design, ideal for cylindrical parts, available in different sizes and capabilities.

– Vertical CNC Lathes: Best for large, heavy workpieces, offering stability and ease of loading.

– Swiss-type CNC Lathes: Perfect for small, high-precision parts, common in the medical and electronics industries.

– Multi-axis CNC Lathes: Feature additional axes for complex geometries, reducing the need for multiple setups.

– Twin-spindle CNC Lathes: Allow simultaneous machining on both ends of a workpiece, increasing productivity.

Key Options and Features:

– Tool Turrets: Multiple tools can be mounted for automated tool changes.

– Live Tooling: Enables milling, drilling, and tapping operations in addition to turning.

– Bar Feeders: Automate the feeding of bar stock, essential for high-volume production.

– Part Catchers: Automatically collect finished parts, reducing handling time.

– Automatic Tool Changers: Enhance efficiency by quickly switching between tools.

– Tailstocks and Steady Rests: Provide additional support for longer workpieces.

– Chip Conveyors: Automate the removal of metal shavings, keeping the work area clean.

– Coolant Systems: Essential for maintaining tool life and workpiece quality by reducing heat and friction.

These features and options allow CNC lathes to cater to a wide range of manufacturing needs, from simple turning tasks to complex, multi-axis machining operations.

CNC lathes are versatile tools for precision metalworking, widely used in various industries. They automate the cutting, drilling, and shaping of metal parts, ensuring high accuracy and efficiency.

Applications of CNC Lathe Metal:

– Automotive Industry: Manufacturing engine components, transmission parts, and other precision metal parts.

– Aerospace: Producing high-precision aircraft parts like turbine blades and structural components.

– Medical Equipment: Crafting surgical instruments, orthopedic implants, and dental components with exact specifications.

– Electronics: Fabricating housings, connectors, and heat sinks for electronic devices.

– Oil and Gas: Creating robust components for drilling and extraction equipment.

– Defense: Manufacturing firearm components, missile parts, and other military hardware.

– Marine Industry: Producing parts for ships and underwater equipment.

– Custom Manufacturing: Designing bespoke metal parts for specialized machinery and tools.

– Furniture Industry: Creating metal fittings and decorative elements.

– Construction: Producing durable metal frameworks and structural components.

CNC lathes ensure consistency, reduce material waste, and enhance productivity, making them indispensable in modern manufacturing.

CNC lathes are crucial in the aerospace, defense, and marine industries for their precision and efficiency in metalworking. These sectors demand high-quality components that can withstand extreme conditions and stress. CNC lathes provide the ability to produce complex and intricate parts with tight tolerances, essential for aircraft, defense equipment, and marine vessels. By automating the machining process, CNC lathes ensure consistent quality and reduce the risk of human error, which is vital for safety-critical applications. The materials commonly machined include high-strength alloys, stainless steel, and titanium, all of which are known for their durability and performance in harsh environments.

In the aerospace industry, CNC lathes are used to manufacture components such as engine parts, landing gear, and structural elements. Defense applications include the production of weaponry, vehicle parts, and communication equipment, where precision and reliability are paramount. For the marine sector, CNC lathes help create parts for propulsion systems, hull components, and navigation aids. The versatility of CNC lathes allows for rapid prototyping and production scaling, enabling these industries to innovate and respond quickly to technological advancements and changing demands. Overall, CNC lathes play a pivotal role in enhancing the performance, safety, and longevity of aerospace, defense, and marine equipment.

In the automotive industry, CNC (Computer Numerical Control) lathes play a pivotal role in the precision machining of metal components. These advanced machines are essential for producing high-quality parts such as engine cylinders, crankshafts, and transmission components. The CNC lathe’s ability to perform intricate cutting, drilling, and turning operations with exacting accuracy ensures that automotive parts meet stringent performance and safety standards. Moreover, the automation capabilities of CNC lathes reduce the need for manual intervention, enhancing production efficiency and consistency. This level of precision and efficiency is critical in the automotive sector, where even minor deviations can significantly impact the functionality and longevity of the vehicle.

In the electronics industry, CNC lathes are equally valuable, especially in the manufacture of metal enclosures and components for devices such as smartphones, laptops, and other electronic gadgets. The fine precision of CNC lathes allows for the creation of intricate designs and detailed features that are necessary for compact and complex electronic assemblies. Additionally, CNC lathes can work with a variety of metals, including aluminum and copper, which are commonly used in electronic components due to their excellent conductive properties. The high repeatability and precision of CNC lathes ensure that each part is produced to exact specifications, which is crucial for maintaining the performance and reliability of electronic products. Thus, CNC lathes are indispensable in ensuring the high standards required in both automotive and electronics manufacturing.

CNC lathe metal machines play a crucial role in the construction industry by enabling the precise and efficient fabrication of metal components. These machines use computer numerical control (CNC) to automate the process of cutting, drilling, and shaping metal parts, ensuring high accuracy and repeatability. In construction, CNC lathes are employed to create various structural elements such as beams, columns, and custom metal fittings. The ability to produce complex shapes and detailed features quickly reduces production time and costs, enhancing the overall efficiency of construction projects. Additionally, the precision of CNC lathes helps in maintaining the structural integrity of buildings, leading to safer and more reliable constructions.

In the energy sector, CNC lathe metal machines are indispensable for manufacturing critical components of energy systems, including turbines, pipelines, and various engine parts. The high precision and consistency provided by CNC lathes ensure that these components meet stringent quality and performance standards, which is vital for the reliability and efficiency of energy generation and distribution. For instance, the intricate parts of wind turbines and gas engines require meticulous machining to function effectively under high stress and extreme conditions. By leveraging CNC technology, the energy industry can produce durable and high-performing equipment, contributing to the sustainability and advancement of energy infrastructure. Overall, CNC lathe metal machines significantly enhance productivity and quality in both construction and energy sectors, driving innovation and reliability.

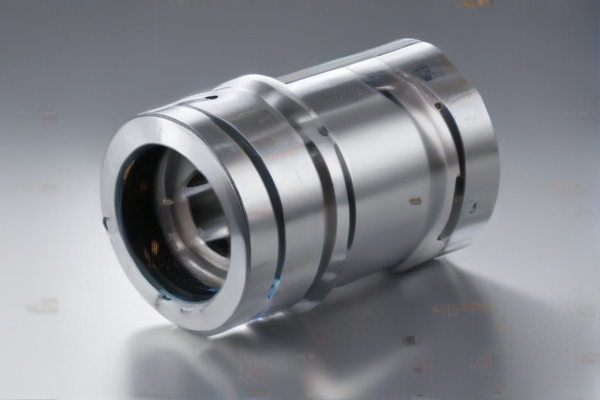

CNC (Computer Numerical Control) lathes are pivotal in industrial equipment, revolutionizing metal machining with their precision and efficiency. These machines utilize computer programming to control cutting tools that shape metal workpieces with unparalleled accuracy. CNC lathes excel in turning operations, where the workpiece rotates while the cutting tool moves along its axis, enabling the creation of intricate cylindrical and conical shapes. This automation reduces human error and enhances repeatability, crucial for manufacturing components with tight tolerances demanded by various industries.

In industrial settings, CNC lathe machines play a crucial role in producing components across diverse sectors such as aerospace, automotive, and medical equipment. Their ability to handle a wide range of materials, from aluminum and steel to exotic alloys, makes them versatile assets in modern manufacturing. CNC lathes can execute complex operations like threading, facing, and grooving with ease, accommodating both high-volume production runs and customized, one-off parts. As technology advances, these machines continue to integrate new features such as multi-axis capabilities and advanced monitoring systems, further boosting productivity and ensuring consistent quality. The CNC lathe stands as a cornerstone in industrial equipment, embodying precision, reliability, and adaptability essential for today’s manufacturing demands.

In the realm of medical devices, CNC lathe metal components play a crucial role in ensuring precision, reliability, and safety. CNC (Computer Numerical Control) lathes are instrumental in crafting intricate parts with exact specifications, vital for devices ranging from surgical instruments to diagnostic tools. The capability of CNC lathes to work with a variety of metals including stainless steel, titanium, and aluminum allows manufacturers to meet the stringent requirements of medical device production. These machines excel in creating components like screws, pins, and housings that must adhere to precise tolerances to function effectively in medical settings where accuracy is paramount. The use of CNC lathes ensures that each part is crafted consistently and efficiently, contributing to the overall quality and reliability of medical devices used in patient care and treatment.

Moreover, CNC lathe technology offers versatility in design and production, enabling the customization of medical device components to meet specific needs. Whether it’s the fabrication of orthopedic implants or the assembly of imaging equipment, CNC lathes provide manufacturers with the capability to produce complex geometries and fine details that traditional machining methods may struggle to achieve. This versatility not only enhances the performance of medical devices but also facilitates advancements in healthcare technology by supporting the development of more sophisticated and minimally invasive solutions. In essence, CNC lathe metal machining in the context of medical devices represents a blend of precision engineering and technological innovation aimed at improving patient outcomes through reliable and high-quality instrumentation.

CNC (Computer Numerical Control) lathes are pivotal in modern machining and manufacturing, especially for metalworking. These advanced machines are designed to produce precise and complex parts by automatically controlling cutting tools and workpieces via computer programming. Unlike traditional manual lathes, CNC lathes offer unparalleled accuracy and repeatability, making them ideal for high-volume production runs and intricate designs. The use of CNC technology in lathes allows for the execution of complex geometries with minimal human intervention, significantly reducing the likelihood of human error and increasing production efficiency. Additionally, CNC lathes can handle a wide variety of metals, from soft aluminum to hard titanium, providing versatility for manufacturers.

The benefits of CNC lathes in metalworking extend beyond precision and efficiency. These machines are capable of performing multiple operations such as turning, facing, threading, and drilling, all within a single setup. This multi-functionality not only saves time but also minimizes the need for multiple machines, reducing floor space requirements and operational costs. CNC lathes are also programmable, enabling quick adjustments and modifications to be made to the production process, which is crucial for prototyping and custom manufacturing. Furthermore, the integration of advanced features like live tooling and sub-spindles enhances the capability of CNC lathes, allowing for more complex parts to be produced without additional setups. As a result, CNC lathes are indispensable in the manufacturing sector, driving advancements in industries ranging from automotive to aerospace.

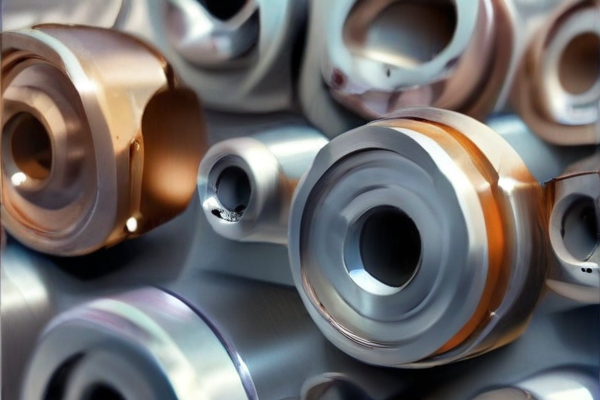

SourcifyChina CNC lathe metal components are primarily crafted from high-quality materials like stainless steel, aluminum, and brass. These metals are chosen for their durability and resistance to wear and corrosion, ensuring longevity in various applications.

Stainless steel is particularly favored for its strength and rust resistance, making it ideal for parts exposed to harsh environments. Its ability to maintain integrity under stress is crucial for reliable performance in machinery and equipment.

Aluminum is lightweight yet robust, offering excellent machinability and thermal conductivity. It’s used extensively in aerospace, automotive, and consumer electronics due to its balance of strength and weight.

Brass, an alloy of copper and zinc, is prized for its malleability and conductivity. It’s often used in electrical components and fittings, providing a reliable and durable solution in electrical and plumbing industries.

In summary, SourcifyChina’s CNC lathe metal components are made from premium materials like stainless steel, aluminum, and brass. These materials are selected for their specific properties, ensuring high performance, reliability, and durability across various industries.

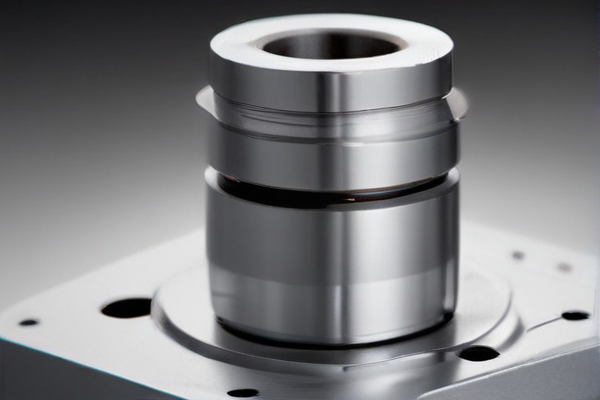

SourcifyChina ensures top-notch quality control in its CNC lathe metal manufacturing process. Each step is meticulously planned, from raw material selection to the final inspection, ensuring high precision and reliability in every product.

The process starts with sourcing premium metals, verified for purity and structural integrity. These materials are then subjected to rigorous testing to meet industry standards. The quality of raw materials is crucial for the overall success of the manufacturing process.

During production, state-of-the-art CNC lathe machines are utilized, which are regularly calibrated and maintained. This ensures that each component is machined to exact specifications, minimizing any deviations and defects.

Operators are highly trained, following strict protocols and quality assurance guidelines. Regular training programs and certifications are conducted to keep the team updated with the latest technological advancements and quality control techniques.

Inspection and testing are integral parts of the manufacturing process. Advanced measurement tools and techniques, such as coordinate measuring machines (CMMs), are employed to verify the dimensions and tolerances of the parts.

Finally, a comprehensive final inspection is conducted. Each part undergoes a thorough quality check, including visual inspections and functional tests, ensuring they meet customer requirements and industry standards before shipping.

SourcifyChina offers advanced CNC lathe capabilities, providing precision and efficiency in metalworking. Their technology ensures high accuracy and repeatability, ideal for complex and detailed metal parts.

The CNC lathes can handle a variety of metals, including aluminum, steel, and titanium. This versatility makes them suitable for diverse industries such as automotive, aerospace, and medical devices.

SourcifyChina’s CNC lathe services include both prototyping and full-scale production. They support rapid turnaround times, helping businesses meet tight deadlines without compromising quality.

Their expert team works closely with clients to ensure that specifications are met precisely. This collaborative approach guarantees satisfaction and optimal results.

In conclusion, SourcifyChina’s CNC lathe capabilities are comprehensive, covering a wide range of materials and applications. Their focus on precision, efficiency, and customer collaboration sets them apart in the metalworking industry.

The Advantages of CNC Lathe for Metalworking

CNC (Computer Numerical Control) lathes offer numerous advantages for metalworking, enhancing efficiency, precision, and versatility. Here are some key benefits:

– Precision and Accuracy: CNC lathes can produce highly precise and accurate components, ensuring tight tolerances and consistent quality.

– Automation and Efficiency: Automated operations reduce the need for manual intervention, leading to faster production times and lower labor costs.

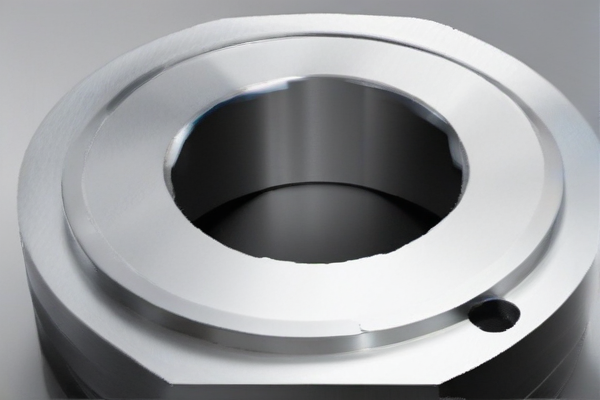

– Complex Geometries: Capable of creating intricate and complex shapes that would be difficult or impossible with manual lathes.

– Consistency: Ensures uniformity across large production runs, reducing the risk of human error.

– Versatility: Suitable for a wide range of materials and applications, from small components to large, heavy-duty parts.

– Reduced Waste: Improved accuracy minimizes material waste, contributing to cost savings.

– Flexibility: Easily programmable to switch between different tasks and designs, enhancing production flexibility.

– Safety: Reduced manual handling lowers the risk of accidents and injuries.

– Maintenance and Monitoring: Integrated systems allow for real-time monitoring and maintenance, reducing downtime.

– Cost-Effective: Long-term savings due to lower labor costs, reduced waste, and higher production rates.

These benefits make CNC lathes an essential tool in modern metalworking, providing significant improvements over traditional methods.

CNC lathes for metalworking are precision machines used to create intricate parts and components. They offer numerous advanced features, making them indispensable in modern manufacturing.

– High Precision: CNC lathes can achieve extremely tight tolerances, ensuring the accuracy of metal parts.

– Automated Operation: These machines operate autonomously after setup, reducing the need for constant human supervision.

– Versatility: Capable of handling a wide variety of materials including steel, aluminum, and titanium.

– Efficiency: CNC lathes enhance production speed and consistency, leading to higher output and reduced waste.

– Complex Designs: They can produce complex geometries that would be difficult or impossible to achieve with manual lathes.

– Repeatability: Once programmed, CNC lathes can replicate the same design with precision, ideal for mass production.

– Tool Turrets: Equipped with multiple tools, allowing for seamless transitions between different machining operations.

– User-Friendly Interface: Modern CNC lathes come with advanced control systems that are easy to program and operate.

– Safety Features: Built-in safety mechanisms protect operators and ensure smooth operation.

– Maintenance Alerts: These machines often have diagnostic systems that alert users to maintenance needs, reducing downtime.

In summary, CNC lathes for metalworking combine precision, efficiency, and versatility, making them essential tools for manufacturing complex and high-quality metal parts.

“SourcifyChina specializes in custom CNC lathe metal products, offering precision and quality tailored to diverse projects. Their CNC capabilities ensure exact specifications are met, enhancing project efficiency.”

“They excel in handling complex designs, leveraging advanced CNC technology to deliver intricate components. From prototypes to mass production, SourcifyChina ensures consistency and reliability.”

“Their expertise spans various industries, including automotive and aerospace, providing solutions that meet rigorous standards. Customization options cater to unique project requirements, ensuring optimal performance and durability.”

“SourcifyChina’s commitment to quality extends through rigorous testing and meticulous attention to detail. Their CNC lathe metal products are crafted with precision, adhering to international benchmarks.”

SourcifyChina is a reputable company specializing in the manufacturing of CNC lathe metal products. With a strong emphasis on precision engineering, they offer a comprehensive range of services that cater to various industries including automotive, aerospace, and electronics. Utilizing state-of-the-art CNC lathe machines, SourcifyChina ensures high-quality, customized metal parts that meet stringent international standards. Their expertise spans across different types of metals such as aluminum, steel, and brass, allowing them to produce components with exceptional accuracy and durability. The company’s commitment to innovation and quality is evident in their rigorous quality control processes and continuous investment in advanced technology. SourcifyChina’s customer-centric approach ensures that each project is tailored to the specific needs of their clients, providing reliable and efficient solutions. This dedication to excellence has established SourcifyChina as a trusted partner in the CNC machining industry, renowned for delivering superior products and services.

CNC (Computer Numerical Control) lathe metal machining plays a crucial role in the aerospace, defense, and marine industries due to its precision and efficiency. In aerospace, CNC lathes are essential for producing high-precision components such as turbine blades, engine parts, and structural elements. The ability to machine complex geometries with tight tolerances ensures the reliability and performance of critical systems. These parts often require materials like titanium and aluminum, which are challenging to work with but essential for their strength-to-weight ratio. The precision offered by CNC lathe metal machining helps in maintaining the stringent safety and performance standards of the aerospace industry.

In the defense sector, CNC lathe metal machining is used to manufacture a wide range of components, from small arms and ammunition parts to larger systems like missile components and armored vehicle parts. The accuracy and repeatability of CNC machining are vital for the functionality and interoperability of defense equipment. Similarly, in the marine industry, CNC lathes produce parts for propulsion systems, hull fittings, and other critical components. These parts must withstand harsh marine environments, necessitating the use of durable materials and precise machining to ensure long-term reliability and performance. The versatility of CNC lathe metal machining makes it indispensable for producing high-quality, high-performance parts across these demanding industries.

CNC (Computer Numerical Control) lathe machines have revolutionized the automotive industry by enabling the precise and efficient production of metal components. In automotive applications, CNC lathes are used to manufacture engine parts such as crankshafts, camshafts, and cylinder heads. These components require high precision and consistency to ensure optimal engine performance and longevity. CNC lathes allow for the production of complex geometries with tight tolerances, which are critical for reducing friction and wear in moving parts. Additionally, these machines enhance productivity by automating repetitive tasks and reducing human error, leading to faster turnaround times and lower production costs.

In the electronics industry, CNC lathe metal machining plays a crucial role in the fabrication of various components and enclosures. CNC lathes are employed to produce connectors, heat sinks, and housings that are essential for the functionality and durability of electronic devices. The ability of CNC lathes to work with various metals, including aluminum and copper, allows for the creation of components that can effectively dissipate heat and provide reliable electrical connections. Moreover, the precision offered by CNC machining ensures that even the smallest parts meet stringent quality standards, which is vital for the performance and safety of electronic products. This technology supports the development of miniaturized and complex electronic devices, driving innovation in the electronics sector.

CNC (Computer Numerical Control) lathes are pivotal in the construction industry for their precision and efficiency in fabricating metal components. These machines are used to produce a wide array of parts such as structural beams, columns, and custom fittings essential for building frameworks. By automating the cutting, drilling, and shaping processes, CNC lathes enhance the consistency and accuracy of metal parts, ensuring they fit perfectly within the structural design. This precision reduces the risk of structural failures and accelerates the construction timeline. Moreover, CNC lathes enable the creation of intricate designs that were previously difficult or impossible to achieve with manual machining, allowing architects and engineers to push the boundaries of innovation in building design.

In the energy sector, CNC lathe metal machining is indispensable for manufacturing components used in various energy systems, including wind turbines, hydroelectric plants, and nuclear reactors. For instance, the precise machining of turbine blades and rotors, which must operate under extreme conditions, is crucial for the efficiency and safety of power generation. CNC lathes produce these parts with high precision, ensuring optimal performance and longevity. Additionally, in the oil and gas industry, CNC lathes are employed to fabricate complex parts such as valve bodies, pump housings, and pipeline components, which require exact tolerances to function correctly under high pressure and corrosive environments. By enhancing the quality and reliability of these critical components, CNC lathes contribute significantly to the stability and efficiency of energy production and distribution systems.

The industrial equipment industry heavily relies on CNC lathe metal technology due to its precision and efficiency. CNC (Computer Numerical Control) lathes are essential for creating intricate and high-precision metal parts used in various industrial applications. These machines operate based on programmed commands that precisely control the cutting tools and workpieces, ensuring consistent and accurate production of components. This level of precision is crucial for industries such as aerospace, automotive, and medical devices, where the tolerances are incredibly tight, and the quality of each part can significantly impact the performance and safety of the final product.

Moreover, CNC lathe metal technology enhances productivity by allowing for automated and continuous operation, reducing the need for manual intervention and minimizing human error. This automation translates to higher production speeds and lower labor costs, making it an economically advantageous choice for manufacturers. Additionally, CNC lathes can handle complex geometries and diverse materials, from soft metals like aluminum to hard alloys like titanium, providing versatility across various applications. This flexibility is particularly beneficial in the rapid prototyping and production of customized parts, where quick turnaround times and adaptability to design changes are essential. As a result, CNC lathe metal technology stands as a cornerstone in the modern industrial equipment landscape, driving innovation and efficiency across multiple sectors.

CNC (Computer Numerical Control) lathe machines are crucial in the medical device industry due to their precision, efficiency, and ability to produce complex metal components. These machines are extensively used to manufacture various medical devices, such as surgical instruments, orthopedic implants, and dental prosthetics. CNC lathes allow for the creation of parts with intricate geometries and tight tolerances, which are essential for the high standards of medical devices. The ability to program CNC lathes ensures consistent production quality and reduces the risk of human error, thereby enhancing the safety and reliability of medical devices.

In addition to precision, CNC lathe metal applications in the medical field also offer flexibility in material selection. Medical devices often require materials that are biocompatible and durable, such as titanium, stainless steel, and other specialized alloys. CNC lathes can efficiently machine these materials, creating custom components tailored to specific patient needs. This capability is particularly important for producing implants that must fit precisely within the human body. Moreover, the speed and automation provided by CNC technology enable rapid prototyping and mass production, accelerating the development and availability of innovative medical solutions. Overall, CNC lathe metal applications significantly contribute to the advancement of medical technology, ensuring high-quality, reliable, and safe medical devices.

A CNC lathe for metal is a pivotal tool in both machining and manufacturing, offering precision and efficiency in shaping metal parts. These computer-controlled machines utilize rotating operations to remove material from a workpiece, creating components with exacting tolerances. In machining, CNC lathes are invaluable for producing parts with complex geometries and smooth finishes. They handle various tasks, including turning, threading, and drilling, allowing manufacturers to produce parts with consistent quality and repeatability. The ability to program CNC lathes ensures that each part meets the specified dimensions and requirements, minimizing errors and material waste.

In manufacturing, CNC lathes play a crucial role in automating production processes, significantly enhancing productivity and reducing manual labor. They are widely used in industries such as aerospace, automotive, and medical device manufacturing, where precision and reliability are paramount. CNC lathes can operate continuously, producing large volumes of components with minimal human intervention. This automation capability not only speeds up production but also ensures uniformity across batches, which is essential for high-quality end products. Additionally, the versatility of CNC lathes in handling various metals, from aluminum to hardened steel, makes them indispensable in modern manufacturing settings.

Certainly! Here’s a concise FAQ list regarding CNC lathe metal quality work from SourcifyChina:

1. What materials do SourcifyChina use for CNC lathe metal work?

SourcifyChina utilizes a range of materials including aluminum, steel, stainless steel, brass, and various alloys, ensuring suitability for diverse applications.

2. How does SourcifyChina ensure precision in CNC lathe machining?

SourcifyChina employs advanced CNC machines equipped with high-precision tools and stringent quality control measures to ensure precise tolerances and superior finishing.

3. What surface finishes are available for CNC lathe metal products?

SourcifyChina offers a variety of finishes such as anodizing, powder coating, polishing, and plating, tailored to meet aesthetic and functional requirements.

4. Can SourcifyChina handle custom CNC lathe metal projects?

Yes, SourcifyChina specializes in custom projects, accommodating specific designs, dimensions, and material requirements to meet client specifications.

5. How does SourcifyChina ensure quality control in manufacturing?

SourcifyChina adheres to ISO-certified processes, conducts rigorous inspection at each production stage, and provides detailed quality reports to ensure consistent high-quality output.

6. What is the typical lead time for CNC lathe metal orders from SourcifyChina?

Lead times vary depending on order complexity and quantity. SourcifyChina provides detailed production schedules upon order confirmation.

7. Does SourcifyChina offer logistics support for international shipments?

Yes, SourcifyChina provides comprehensive logistics support, including packaging and shipping arrangements, to ensure safe and timely delivery worldwide.

These FAQs address common inquiries regarding CNC lathe metal quality work from SourcifyChina, highlighting their capabilities, quality standards, and customer support offerings.

Tips for CNC Lathe Metal Manufacturing from SourcifyChina Factory

1. Understand CNC Lathe Basics:

– CNC (Computer Numerical Control) lathes automate metal cutting using coded instructions.

– They provide precision, efficiency, and repeatability in manufacturing.

2. Material Selection:

– Choose appropriate metals (aluminum, steel, titanium) based on project requirements.

– Consult SourcifyChina for material properties and compatibility.

3. Design Considerations:

– Design parts with manufacturability in mind. Avoid overly complex shapes unless necessary.

– Use CAD software to create detailed models, ensuring all dimensions are precise.

4. Tooling:

– Select the right cutting tools and inserts for the metal type and desired finish.

– Regularly maintain and replace tools to ensure quality and prevent machine damage.

5. Programming:

– Write efficient G-code programs, optimizing for speed and precision.

– Utilize simulation software to test programs before actual machining.

6. Quality Control:

– Implement stringent quality checks, using CMM (Coordinate Measuring Machines) for precision measurement.

– Maintain ISO or other relevant certifications to ensure product standards.

7. Efficiency and Cost Management:

– Optimize batch sizes and production runs to balance cost and time efficiency.

– Utilize SourcifyChina’s capabilities for cost-effective bulk production.

8. Collaboration and Communication:

– Maintain clear and consistent communication with SourcifyChina for project updates and adjustments.

– Leverage their expertise to troubleshoot issues and improve manufacturing processes.

9. Customization and Flexibility:

– Take advantage of SourcifyChina’s ability to customize solutions based on specific needs.

– Be flexible with design changes to accommodate manufacturing capabilities.

10. Lead Time Management:

– Plan production schedules with realistic lead times to avoid delays.

– Work closely with SourcifyChina to manage expectations and delivery timelines.

Following these tips can help streamline the CNC lathe metal manufacturing process with SourcifyChina, ensuring high-quality and cost-effective production.

Sure, here’s a concise FAQ for sourcing CNC lathe metal from SourcifyChina factory:

—

1. What types of CNC lathe metals can I source from SourcifyChina?

SourcifyChina offers a wide range of CNC lathe metals including aluminum, stainless steel, brass, titanium, and various alloys to suit diverse machining requirements.

2. How do I place an order with SourcifyChina?

You can place an order by contacting their sales team through their website or email. Provide your specifications, quantity, and any special requirements to receive a quote.

3. What is the minimum order quantity (MOQ) for CNC lathe metals?

The MOQ varies depending on the type of metal and specific requirements. It’s best to contact SourcifyChina directly to get precise information based on your needs.

4. How long does it take to receive my order?

Delivery times depend on the order size and complexity. Typically, production and shipping take between 2 to 6 weeks. SourcifyChina provides estimated delivery times upon order confirmation.

5. Can I request custom specifications for CNC lathe metals?

Yes, SourcifyChina accommodates custom specifications including dimensions, tolerances, and finishes. Provide detailed requirements to ensure accurate production.

6. What quality control measures are in place?

SourcifyChina employs strict quality control procedures including material inspection, dimensional accuracy checks, and surface finish evaluations to ensure high-quality products.

7. What payment methods does SourcifyChina accept?

They accept various payment methods including wire transfer, PayPal, and letters of credit. Terms and conditions can be discussed with their sales team.

8. Is there after-sales support available?

Yes, SourcifyChina offers after-sales support to address any issues or concerns. Contact their customer service for assistance with your order.

9. Are there any discounts for bulk orders?

Bulk orders may be eligible for discounts. Discuss your order volume with the sales team to negotiate potential savings.

10. How can I track my order?

SourcifyChina provides order tracking through their logistics partners. You will receive tracking information once your order is shipped.

—

This FAQ should provide a clear and concise overview for potential buyers interested in sourcing CNC lathe metals from SourcifyChina.

Sourcing CNC lathe metal from SourcifyChina factory can be streamlined with the following tips:

1. Define Specifications:

– Clearly outline the specifications of the CNC lathe you need, including size, material, precision, and any additional features.

2. Research the Supplier:

– Check SourcifyChina’s credibility. Look for reviews, certifications (like ISO), and any case studies or testimonials.

3. Request a Quote:

– Contact SourcifyChina with detailed requirements to get an accurate quote. Include expected quantity, delivery timeline, and any customization needs.

4. Quality Assurance:

– Ask about their quality control processes. Ensure they provide quality assurance documentation, such as inspection reports and material certificates.

5. Sample Order:

– Place a small sample order to evaluate the product quality and ensure it meets your standards before committing to a larger purchase.

6. Negotiate Terms:

– Discuss and negotiate payment terms, shipping conditions, and return policies. Consider terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight).

7. Communication:

– Maintain clear and frequent communication with the factory. Use emails, video calls, or on-site visits if possible.

8. Legal and Compliance:

– Verify compliance with international trade laws and regulations. Ensure all necessary documentation is in place for customs clearance.

9. Logistics:

– Plan your logistics carefully. Decide on shipping methods (air, sea, or land) based on urgency and budget.

10. Long-term Relationship:

– Build a strong relationship with the factory for future cooperation. Regular feedback and a good rapport can lead to better service and potential cost savings.

By following these steps, you can efficiently source high-quality CNC lathe metal from SourcifyChina, ensuring a smooth and reliable procurement process.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.