Technology and Applications of cnc machine for metal

CNC (Computer Numerical Control) machines revolutionize metalworking by automating precision machining processes. These machines, controlled by computer software, perform tasks such as cutting, drilling, milling, and turning on metal workpieces with high accuracy and repeatability.

Technology of CNC Machines for Metal

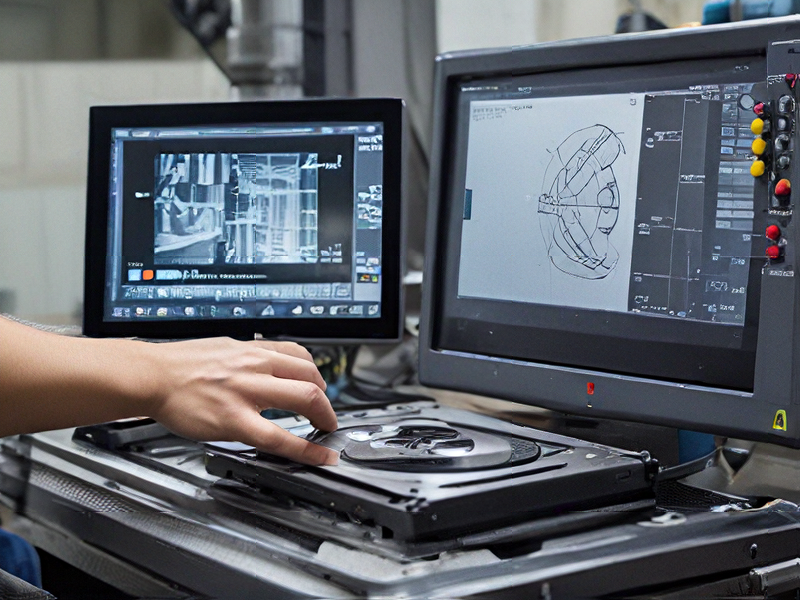

1. Software Integration: CNC machines use CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software to design and generate tool paths.

2. Controllers: The heart of CNC technology, controllers translate digital designs into precise movements of the machine’s tools.

3. Motion Control: Using servo motors and feedback systems, CNC machines achieve high precision in multiple axes (usually 3 to 5).

4. Tooling: Various cutting tools, including drills, mills, and lathes, are used to shape the metal according to specifications.

Applications of CNC Machines for Metal

1. Automotive Industry: CNC machines manufacture engine components, transmission parts, and intricate body parts.

2. Aerospace Industry: High-precision parts for aircraft, including turbines, fuselage components, and landing gear, are produced using CNC technology.

3. Medical Devices: CNC machining is critical for creating surgical instruments, implants, and prosthetics with exacting standards.

4. Defense Industry: CNC machines produce parts for firearms, military vehicles, and other defense equipment.

5. Manufacturing: General manufacturing relies on CNC machines for creating parts used in machinery, electronics, and consumer products.

6. Art and Design: Artists and designers use CNC technology to create detailed metal sculptures, jewelry, and custom-designed pieces.

Advantages

– Precision and Accuracy: CNC machines offer micron-level precision, crucial for industries demanding high accuracy.

– Repeatability: Once programmed, CNC machines can produce identical parts consistently.

– Efficiency: Automation reduces manual labor and increases production speed.

– Flexibility: CNC machines can switch between different tasks and materials with minimal setup time.

CNC machines have transformed metalworking, providing unmatched precision, efficiency, and versatility across various industries.

Quality Testing Methods for cnc machine for metal and how to control quality

Quality testing for CNC machines used in metalworking involves several methods to ensure precision, accuracy, and consistency. Here are some key techniques and control measures:

Methods

1. Dimensional Inspection:

– CMM (Coordinate Measuring Machine): Measures the physical geometrical characteristics of an object.

– Calipers and Micrometers: For measuring thickness, diameter, and length.

2. Surface Inspection:

– Surface Roughness Testers: Evaluate the surface finish.

– Optical Microscopes: Inspect surface defects and quality.

3. Non-Destructive Testing (NDT):

– Ultrasonic Testing: Detects internal flaws.

– Magnetic Particle Inspection: Finds surface and near-surface defects.

4. Performance Testing:

– Laser Interferometry: Assesses machine accuracy.

– Ball Bar Test: Evaluates the geometric accuracy of machine movement.

5. Material Testing:

– Hardness Testing: Measures material resistance to deformation.

– Tensile Testing: Determines material strength and ductility.

Quality Control

1. Calibration:

– Regular calibration of measuring instruments and CNC machines ensures accuracy.

2. Preventive Maintenance:

– Scheduled maintenance to prevent breakdowns and ensure consistent performance.

3. Training and Certification:

– Operators should be well-trained and certified to handle CNC machines.

4. Process Monitoring:

– Real-time monitoring of machining processes using sensors and software to detect anomalies.

5. Statistical Process Control (SPC):

– Use statistical methods to monitor and control the machining process, ensuring the output remains within specified limits.

6. Documentation and Traceability:

– Maintain detailed records of machine settings, maintenance, and inspection results to ensure traceability and accountability.

By implementing these testing methods and control measures, manufacturers can maintain high-quality standards in CNC metalworking processes.

Tips for Procurement and Considerations when Purchasing from cnc machine for metal

When purchasing a CNC machine for metal procurement, several key considerations can ensure you make an informed decision:

1. Machine Capability: Evaluate the CNC machine’s specifications such as spindle power, maximum cutting diameter, and axis travel. Ensure it meets your specific metalworking needs.

2. Accuracy and Precision: Look for machines with high accuracy levels (measured in microns) and repeatability. This is crucial for consistent and quality metal parts production.

3. Machine Rigidity: Metal machining requires stable and rigid machines to handle the forces involved in cutting metals effectively. Opt for machines built with strong, durable materials.

4. Software Compatibility: Check if the CNC machine’s control software is user-friendly and compatible with your existing CAD/CAM software. This ensures seamless integration into your production workflow.

5. Maintenance and Support: Consider the availability of technical support, spare parts, and maintenance services. Reliable after-sales support can minimize downtime and ensure optimal machine performance.

6. Cost and Budget: Balance the initial cost of the CNC machine with its long-term benefits and operational costs. Factor in installation, training, and potential upgrades when budgeting.

7. Reviews and Reputation: Research user reviews and manufacturer reputation to gauge reliability, performance, and customer satisfaction.

8. Future Expansion: Anticipate future production needs and assess if the machine can be upgraded or expanded to accommodate growing demands.

By carefully evaluating these factors, you can select a CNC machine that enhances your metal procurement process, improves productivity, and meets your business objectives effectively.

FAQs on Sourcing and Manufacturing from cnc machine for metal in China

When sourcing CNC machining services for metal in China, it’s crucial to address several key FAQs:

1. Quality Assurance: Ensure the manufacturer follows international standards like ISO 9001 and has a robust quality control process in place to guarantee high-quality parts.

2. Experience and Expertise: Verify the manufacturer’s experience in CNC machining for metal and their familiarity with your specific industry requirements.

3. Communication: Clarify how communication will be handled, considering time zone differences and language barriers. Clear communication channels are essential for project success.

4. Lead Times: Understand the typical lead times for manufacturing and shipping. Factor in any potential delays and ensure they align with your project timeline.

5. Cost and Pricing Structure: Request a detailed breakdown of costs, including unit price, tooling costs, and shipping fees. Be wary of unusually low prices that could indicate compromised quality.

6. Intellectual Property Protection: Discuss measures the manufacturer takes to protect your designs and intellectual property throughout the manufacturing process.

7. Samples and Prototyping: Ask about their process for providing samples and prototyping services. This step is crucial to verify quality and functionality before full-scale production.

8. Environmental and Ethical Practices: Inquire about their environmental policies and ensure they comply with relevant regulations. Additionally, verify their adherence to ethical labor practices.

9. Customization and Flexibility: Assess their capability to accommodate customization requests and any flexibility in production volumes to meet your evolving needs.

10. References and Reviews: Request references from past clients and check online reviews to gauge their reputation and reliability.

Navigating these FAQs will help mitigate risks and ensure a successful partnership with a CNC machining manufacturer in China for metal parts.