Technology and Applications of cnc machine meaning

Technology and Applications of CNC Machines

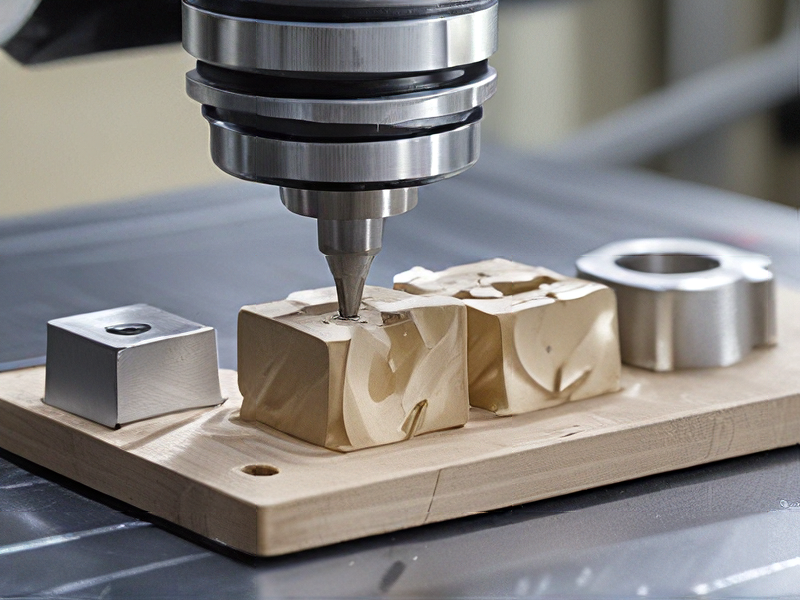

CNC (Computer Numerical Control) machines are automated machining tools that are operated by precisely programmed commands encoded on a storage medium, as opposed to being manually controlled via handwheels or levers. The technology involves the use of computers to control machine tools such as lathes, mills, routers, and grinders.

Technology:

1. Programming Languages: CNC machines typically use G-code, a language that provides the necessary instructions to the machine’s microcontroller.

2. Precision and Automation: They employ advanced software for design (CAD – Computer-Aided Design) and manufacturing (CAM – Computer-Aided Manufacturing), enabling high precision and repeatability.

3. Feedback Systems: CNC machines use feedback loops to ensure accuracy, making real-time adjustments during the machining process.

Applications:

1. Manufacturing: Widely used in the production of metal and plastic parts in industries such as automotive, aerospace, and electronics. They facilitate the mass production of components with intricate details.

2. Prototyping: CNC machines allow for rapid prototyping, enabling designers to quickly produce and test designs.

3. Medical Industry: Used for creating complex surgical instruments, prosthetics, and implants with high precision.

4. Woodworking: CNC routers and mills are used for detailed woodworking tasks, from cabinetry to intricate carvings.

5. Engraving: Employed for engraving metals, plastics, and other materials, useful in creating detailed designs and texts.

6. Textile Industry: CNC machines cut fabric with high precision and speed, improving efficiency and reducing waste.

In summary, CNC machines integrate computer technology with traditional machining processes to enhance precision, efficiency, and flexibility across various industries. Their ability to produce complex parts with high accuracy makes them invaluable in modern manufacturing and other specialized fields.

Quality Testing Methods for cnc machine meaning and how to control quality

Quality testing methods for CNC (Computer Numerical Control) machines ensure precision and reliability of manufactured parts. Key methods include:

1. Dimensional Inspection: Using tools like calipers, micrometers, and coordinate measuring machines (CMMs) to verify part dimensions against CAD specifications.

2. Surface Finish Analysis: Measuring surface roughness using profilometers to ensure parts meet required smoothness criteria.

3. Material Hardness Testing: Verifying hardness using methods such as Rockwell or Brinell testing to ensure parts withstand operational stresses.

4. Visual Inspection: Assessing parts for defects, burrs, or irregularities that could affect functionality or aesthetics.

5. Functional Testing: Simulating operational conditions to ensure parts perform as intended under load or stress.

To control quality:

1. Establish Standards: Define clear quality standards based on customer requirements and industry norms.

2. Routine Maintenance: Regularly calibrate machines and tools to maintain accuracy.

3. Training and Skills: Train operators on proper machine use and quality control procedures.

4. Documentation: Maintain comprehensive records of inspections and tests performed.

5. Continuous Improvement: Implement feedback loops to identify and rectify quality issues promptly.

By integrating these methods and controls, manufacturers can consistently produce CNC machined parts that meet high-quality standards.

Tips for Procurement and Considerations when Purchasing from cnc machine meaning

When procuring CNC (Computer Numerical Control) machines, consider several key factors to ensure you make an informed decision:

1. Machine Specifications: Evaluate the machine’s capabilities such as spindle speed, axis travel, and tolerance levels. Match these specifications with your operational needs and the types of materials you plan to work with.

2. Manufacturer Reputation: Research the manufacturer’s reputation for reliability, customer support, and product quality. Reviews and testimonials from other users can provide valuable insights.

3. Technology and Innovation: Consider the level of automation and integration capabilities. Modern CNC machines often come with advanced features like CAD/CAM compatibility, robotic loading, and remote monitoring, which can enhance productivity.

4. Cost and ROI: Compare prices from different suppliers and balance initial costs with long-term benefits. Factor in maintenance, training, and operational costs over the machine’s lifespan to assess ROI accurately.

5. Support and Training: Ensure the supplier offers adequate training and technical support. CNC machines require skilled operators and regular maintenance to operate efficiently and minimize downtime.

6. Space and Installation: Assess your facility’s space and infrastructure requirements. Ensure there’s enough room for installation, operation, and potential future expansions or upgrades.

7. Compatibility and Integration: Consider how the CNC machine integrates with your existing equipment and software systems. Compatibility with your current workflow can streamline operations and reduce implementation challenges.

8. Safety and Compliance: Verify that the machine meets industry safety standards and regulatory requirements. This ensures a safe working environment and compliance with legal obligations.

By carefully evaluating these factors, you can make a well-informed decision when procuring CNC machines, ensuring they meet your operational requirements and provide a solid return on investment.

FAQs on Sourcing and Manufacturing from cnc machine meaning in China

FAQs on Sourcing and Manufacturing from CNC Machine Meaning in China

1. What is a CNC machine?

CNC (Computer Numerical Control) machines are automated milling devices that make industrial components without direct human assistance. They use programmed commands to control machinery and tools.

2. Why source CNC machines from China?

China is a global leader in manufacturing, offering competitive pricing, high-quality products, and a wide variety of CNC machines. Chinese manufacturers often provide customization options and have a well-established supply chain.

3. How do I find reliable CNC machine manufacturers in China?

Use platforms like Alibaba, Global Sources, and Made-in-China to find suppliers. It’s crucial to check their certifications, read reviews, and possibly visit their factories to ensure credibility.

4. What are the common types of CNC machines available in China?

Common types include CNC milling machines, CNC lathes, CNC routers, and CNC plasma cutters. Each type serves different purposes and industries.

5. What should I consider when choosing a CNC machine manufacturer?

Consider factors like the manufacturer’s experience, the quality of their machines, customer service, customization capabilities, and after-sales support.

6. How do I ensure the quality of CNC machines from China?

Perform due diligence by requesting samples, conducting factory audits, and ensuring the manufacturer adheres to international quality standards like ISO 9001.

7. What are the costs involved in sourcing CNC machines from China?

Costs include the machine price, shipping, customs duties, and possibly travel expenses for factory visits. It’s essential to get detailed quotations and understand all expenses beforehand.

8. What are the common payment terms?

Typical payment terms include Telegraphic Transfer (T/T), Letter of Credit (L/C), and sometimes PayPal for smaller transactions. An initial deposit followed by the balance upon shipment is standard practice.

9. How long does it take to receive a CNC machine from China?

Lead times can vary from a few weeks to several months depending on the complexity of the machine and the manufacturer’s schedule. Shipping time adds an additional 2-6 weeks.

10. What after-sales services can I expect?

Reliable manufacturers offer warranties, technical support, and spare parts. Ensure you understand the terms and conditions of these services before purchasing.

These FAQs provide a comprehensive overview of sourcing and manufacturing CNC machines from China, ensuring informed decisions and successful transactions.