Technology and Applications of cnc machine projects

CNC (Computer Numerical Control) machines are automated tools controlled by a computer, revolutionizing manufacturing and fabrication. These machines execute precise movements based on pre-programmed instructions, enhancing accuracy, efficiency, and repeatability in production processes.

Technology of CNC Machines

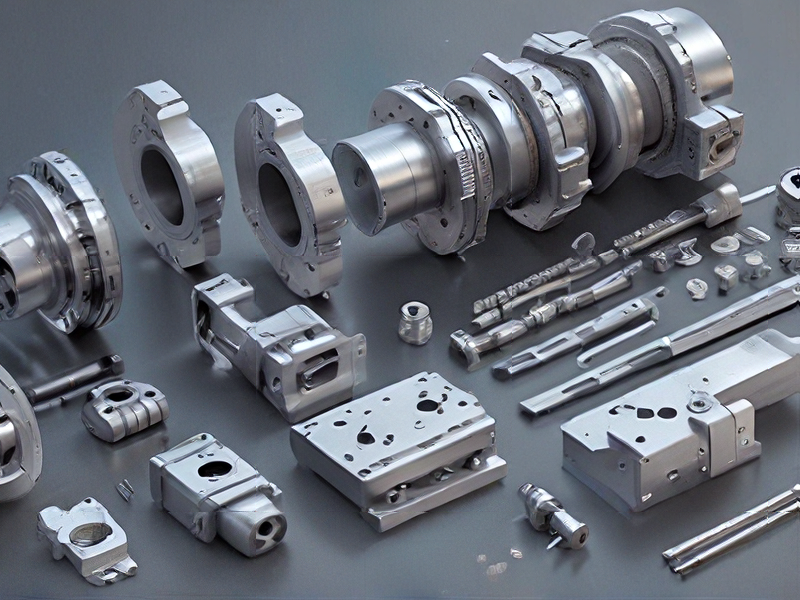

1. Components:

– Control Unit: The brain of the CNC machine, interpreting and executing the G-code instructions.

– Motors and Drives: Facilitate precise movements of the machine’s axes.

– Spindle: Holds and rotates the cutting tool.

– Feedback Systems: Ensure the accuracy of movements through sensors and encoders.

2. Software:

– CAD (Computer-Aided Design): Software used to create detailed 2D or 3D designs.

– CAM (Computer-Aided Manufacturing): Translates CAD designs into G-code, the language CNC machines understand.

3. Types of CNC Machines:

– Milling Machines: Used for cutting and shaping solid materials.

– Lathes: Rotate the workpiece against cutting tools for shaping.

– Laser Cutters: Use a high-powered laser to cut or engrave materials.

– 3D Printers: Additive manufacturing processes to create objects layer by layer.

Applications of CNC Machines

1. Manufacturing:

– Automotive: Precision parts production like gears, shafts, and engine components.

– Aerospace: High-tolerance components for aircraft and spacecraft.

– Electronics: Manufacturing of circuit boards and enclosures.

2. Prototyping:

– Rapid production of prototypes to test designs before mass production.

3. Custom Fabrication:

– Creation of bespoke items in industries like jewelry, medical implants, and furniture.

4. Education and Research:

– Used in educational institutions for training and research in engineering and design.

CNC technology continues to evolve, integrating with IoT (Internet of Things) and AI (Artificial Intelligence) for smarter, more efficient operations, paving the way for innovations like smart manufacturing and Industry 4.0.

Quality Testing Methods for cnc machine projects and how to control quality

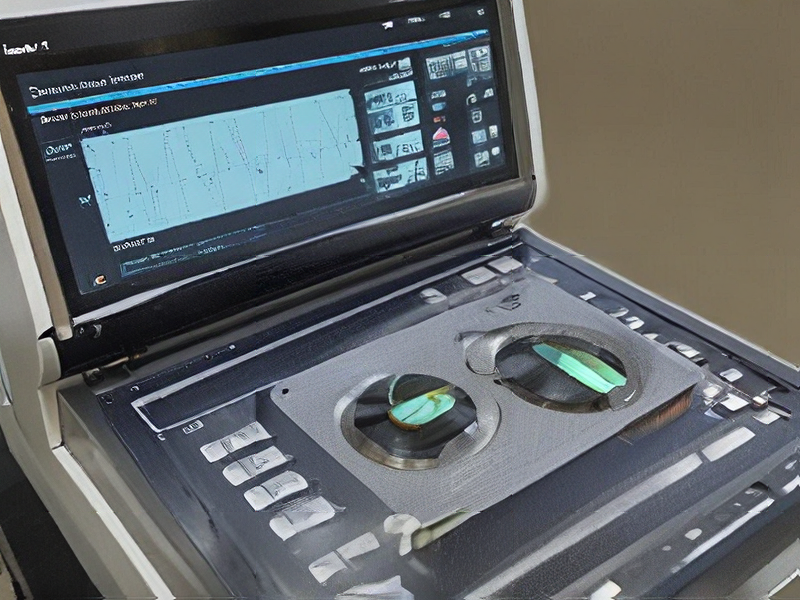

Quality testing methods for CNC machine projects typically include both in-process and final inspections to ensure precision and functionality. In-process testing involves monitoring dimensions and tolerances during machining using tools like calipers, micrometers, and height gauges. This ensures each component meets design specifications as it’s being manufactured.

Final inspection methods include dimensional checks using Coordinate Measuring Machines (CMM) for accurate measurements of complex geometries. Surface finish measurements gauge the smoothness of machined surfaces, crucial for parts that require sealing or low friction. Functional testing involves simulating real-world conditions to verify performance, such as load testing for strength or dynamic testing for moving parts.

To control quality, implementing Statistical Process Control (SPC) monitors key process parameters to detect variations before they affect product quality. Documenting and analyzing data from inspections and tests help identify trends and potential issues early on. Continuous training for operators and engineers ensures adherence to quality standards and fosters a culture of quality consciousness.

Regular calibration of CNC machines and inspection tools maintains accuracy. Establishing clear quality standards and procedures ensures consistency across production batches. Supplier audits and material traceability further enhance quality control by ensuring raw materials meet specifications. Ultimately, a comprehensive quality management system integrates these methods to deliver CNC machined parts that meet or exceed customer expectations.

Tips for Procurement and Considerations when Purchasing from cnc machine projects

When embarking on CNC machine procurement, consider these essential tips to ensure successful project execution:

1. Define Project Requirements: Clearly outline your project needs, including size, materials, and expected output volume. This clarity helps in selecting the appropriate CNC machine type (e.g., milling, lathe) and specifications.

2. Budget Planning: Establish a realistic budget that includes not only the machine cost but also installation, training, maintenance, and potential upgrades. Ensure the chosen machine aligns with your financial constraints.

3. Supplier Evaluation: Research and assess multiple suppliers. Consider factors such as reputation, customer reviews, support services, and warranty offerings. A reliable supplier enhances machine reliability and post-purchase satisfaction.

4. Machine Specifications: Review technical specifications thoroughly. Focus on aspects like machining capabilities (accuracy, speed), software compatibility, tooling options, and automation features. Align these with your project requirements for optimal performance.

5. Training and Support: Evaluate training programs provided by the supplier. Adequate operator and maintenance training are crucial for maximizing machine efficiency and longevity. Additionally, inquire about technical support availability and response times.

6. Future Expansion: Anticipate future needs and ensure the chosen CNC machine can accommodate growth or diversification of projects. Flexibility in terms of upgrades and compatibility with additional tools or software is advantageous.

7. Quality Assurance: Prioritize machine quality and reliability. Verify certifications, such as ISO standards, and inquire about testing procedures during manufacturing. Quality machines minimize downtime and maintenance costs.

8. Integration with Existing Systems: If integrating with existing equipment or software, confirm compatibility and any necessary modifications. Seamless integration streamlines operations and reduces implementation challenges.

9. Environmental Considerations: Assess energy consumption, noise levels, and environmental impact of the CNC machine. Opt for energy-efficient models and inquire about sustainability initiatives by the supplier.

By following these tips, you can effectively navigate the procurement process for CNC machine projects, ensuring alignment with project goals, budget constraints, and operational requirements.

FAQs on Sourcing and Manufacturing from cnc machine projects in China

FAQs on Sourcing and Manufacturing CNC Machine Projects in China

1. Why source CNC machine projects from China?

China offers cost-effective manufacturing solutions due to lower labor costs and advanced production capabilities. Many Chinese manufacturers are equipped with state-of-the-art CNC technology and can handle large-scale production efficiently.

2. How do I find reliable CNC machine manufacturers in China?

Use online platforms like Alibaba, Global Sources, and Made-in-China to find suppliers. Verify their credentials, read reviews, and ask for samples. Attending trade shows and factory visits can also provide firsthand insight into their operations.

3. What are the common challenges in sourcing from China?

Communication barriers, quality control issues, and longer shipping times are common challenges. It’s crucial to establish clear specifications and maintain regular communication with your supplier to mitigate these risks.

4. How can I ensure the quality of CNC machined parts?

Request detailed product specifications and material certifications. Use third-party inspection services to verify product quality before shipment. Conduct periodic audits of the manufacturing process to ensure consistency.

5. What are the typical lead times for CNC projects?

Lead times can vary based on the complexity of the project and the manufacturer’s workload. Generally, it ranges from a few weeks to a couple of months. Confirm timelines with your supplier and plan accordingly to avoid delays.

6. What payment terms are common in China?

Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and sometimes PayPal for smaller transactions. A typical arrangement might be a 30% deposit upfront with the balance paid before shipment.

7. How do I handle shipping and customs?

Engage with freight forwarders experienced in international shipping. They can assist with documentation, customs clearance, and logistics to ensure smooth delivery. Be aware of import duties and taxes applicable in your country.

8. What steps should I take to protect my intellectual property (IP)?

Sign non-disclosure agreements (NDAs) and non-compete clauses with your supplier. Register your IP in China to have legal protection. Working with manufacturers that have a good track record and reputation can also minimize risks.

By addressing these key areas, you can navigate the complexities of sourcing and manufacturing CNC machine projects in China more effectively.