Technology and Applications of cnc machines for metal

Technology and Applications of CNC Machines for Metal

CNC (Computer Numerical Control) machines are automated tools controlled by computers executing pre-programmed sequences of machine control commands. They have revolutionized metalworking, offering precision, efficiency, and versatility.

Technology

1. Software Integration: CNC machines use CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software to design and produce parts. These programs translate design specifications into numerical codes, which guide the machine’s movements.

2. Types of CNC Machines:

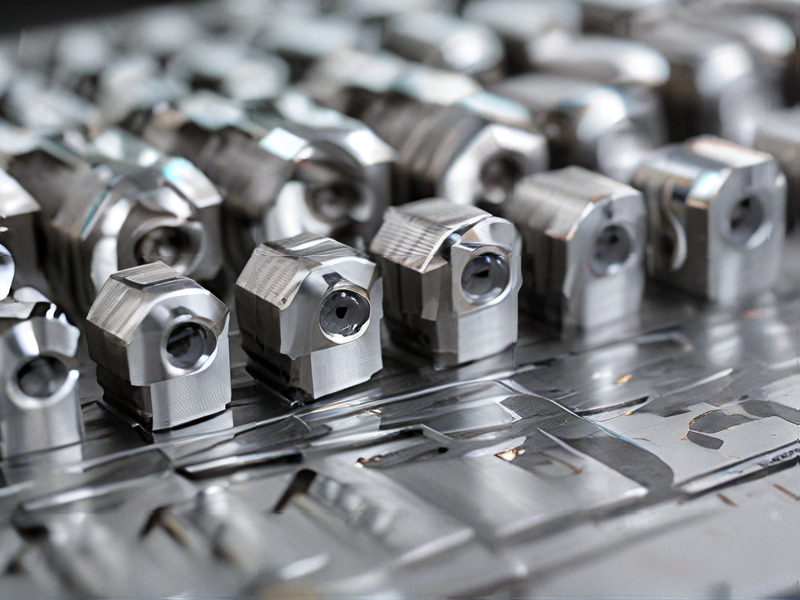

– CNC Milling Machines: Utilize rotary cutters to remove material from a workpiece. They are ideal for complex geometries and surface finishes.

– CNC Lathes: Rotate the workpiece against a cutting tool, perfect for symmetrical objects like cylinders and cones.

– CNC Plasma Cutters: Use a high-velocity jet of ionized gas to cut through metal, suitable for thick sheets.

– CNC Laser Cutters: Employ focused laser beams for cutting or engraving, ideal for thin materials and detailed work.

– CNC Grinders: Use abrasive wheels to achieve fine finishes and precise dimensions.

Applications

1. Aerospace: CNC machines produce high-precision components like turbine blades and structural parts, ensuring reliability and safety in aircraft.

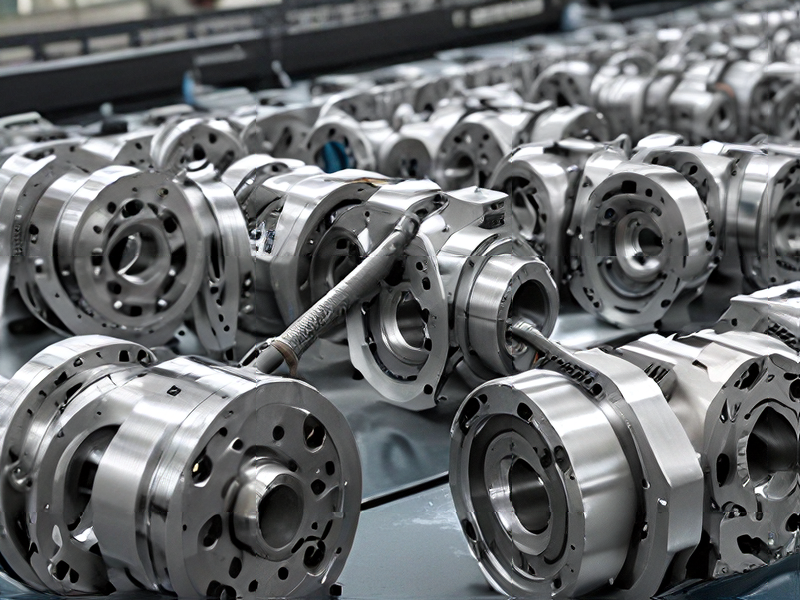

2. Automotive: They manufacture engine blocks, transmission parts, and custom car components, enhancing performance and efficiency.

3. Medical Devices: CNC technology creates surgical instruments, implants, and prosthetics with high accuracy and consistency, critical for patient safety.

4. Industrial Equipment: CNC machines produce gears, pumps, and machinery parts that require durability and exact specifications.

5. Consumer Electronics: They fabricate metal casings, connectors, and heat sinks, essential for modern gadgets’ functionality and design.

CNC machines have become indispensable in metalworking, enabling complex designs, reducing production time, and minimizing human error. Their adaptability across various industries highlights their critical role in modern manufacturing.

Quality Testing Methods for cnc machines for metal and how to control quality

Quality testing methods for CNC machines used in metalworking typically involve several key approaches:

1. Dimensional Inspection: This includes using precision measurement tools like calipers, micrometers, and coordinate measuring machines (CMM) to verify that parts meet specified dimensional tolerances.

2. Surface Finish Evaluation: Instruments such as profilometers are used to assess the surface roughness and finish of machined parts, ensuring they meet required specifications.

3. Visual Inspection: This involves visually examining parts for defects such as cracks, burrs, or irregularities that could affect performance or aesthetics.

4. Material Testing: Methods like spectroscopy and hardness testing ensure that the materials used in machining meet required mechanical properties and composition standards.

5. Performance Testing: Running sample parts through simulated operating conditions to verify functionality, durability, and reliability.

To control quality effectively:

– Establish Standards: Define clear quality standards and specifications for machined parts.

– Regular Calibration: Ensure CNC machines and measuring instruments are regularly calibrated to maintain accuracy.

– Training and Skills Development: Train operators in proper machining techniques and quality inspection methods.

– Documentation and Traceability: Maintain comprehensive records of inspections, tests, and any deviations from standards.

– Continuous Improvement: Implement feedback loops to identify areas for improvement in processes and quality controls.

By employing these methods and controls, manufacturers can ensure that CNC machines produce metal parts that meet or exceed customer expectations and industry standards.

Tips for Procurement and Considerations when Purchasing from cnc machines for metal

When procuring CNC machines for metalworking, consider several crucial factors to ensure you make an informed decision:

1. Machine Specifications: Evaluate the machine’s capabilities in terms of size, axis movement, spindle speed, and tolerance levels. Ensure it meets your specific production needs for metalworking tasks.

2. Technology and Features: Look for advanced features such as automatic tool changers, coolant systems, and software compatibility. These can enhance productivity and operational efficiency.

3. Manufacturer Reputation: Choose reputable brands known for quality and reliability. Check reviews, customer feedback, and the manufacturer’s history in producing CNC machines.

4. Support and Service: Ensure the supplier provides adequate training, installation support, and ongoing maintenance services. Reliable technical support can minimize downtime and ensure smooth operations.

5. Cost and Return on Investment (ROI): Consider not only the initial purchase cost but also long-term operational costs, including maintenance, energy consumption, and potential for future upgrades. Calculate ROI based on increased productivity and reduced scrap rates.

6. Safety and Compliance: Verify that the CNC machine complies with safety standards and regulations. Safety features like emergency stop buttons and safety guards are essential for protecting operators.

7. Compatibility with Existing Equipment: If you have existing machinery or software systems, ensure compatibility with the new CNC machine to avoid integration issues.

8. Training and Skills: Assess the training requirements for your operators. Invest in training programs to ensure they can effectively operate and maintain the CNC machine.

9. Supplier Relationship: Build a good relationship with your supplier or manufacturer. Clear communication and understanding can lead to better service and support.

By carefully considering these factors, you can make a well-informed procurement decision that aligns with your operational needs and budgetary constraints when purchasing CNC machines for metalworking.

FAQs on Sourcing and Manufacturing from cnc machines for metal in China

Certainly! When sourcing CNC machining services for metal in China, it’s crucial to consider several FAQs:

1. Quality Assurance: Ensure the manufacturer adheres to international quality standards like ISO. Request samples and inspect their machining capabilities.

2. Cost Efficiency: China often offers competitive pricing, but beware of extremely low quotes that may compromise quality.

3. Communication: Clear communication is vital. Confirm their proficiency in English or arrange for a translator to avoid misunderstandings.

4. Lead Times: Discuss production timelines and ensure they align with your project deadlines. Factor in shipping times as well.

5. Customization and Flexibility: Verify if the manufacturer can accommodate your specific requirements, such as materials, finishes, and complex geometries.

6. Prototyping and Testing: Inquire about their prototyping process and how they handle iterative changes based on testing feedback.

7. Intellectual Property Protection: Understand the manufacturer’s policies regarding intellectual property rights to safeguard your designs and innovations.

8. Logistics and Shipping: Determine shipping methods and costs. Clarify responsibilities for customs clearance and potential import taxes.

9. Payment Terms: Agree on clear payment terms to avoid any financial disputes during or after production.

10. References and Reviews: Check for client testimonials or ask for references to gauge their reputation and reliability.

By addressing these FAQs, you can navigate sourcing and manufacturing from CNC machines for metal in China more effectively, ensuring a successful partnership that meets your project’s needs.