“SourcifyChina: Your Reliable Source for Precision CNC Milled Parts from Leading Chinese Factories”

Discover how SourcifyChina connects you with top-notch CNC milled parts manufacturers in China, ensuring exceptional quality, reliability, and cost-efficiency for your production needs.

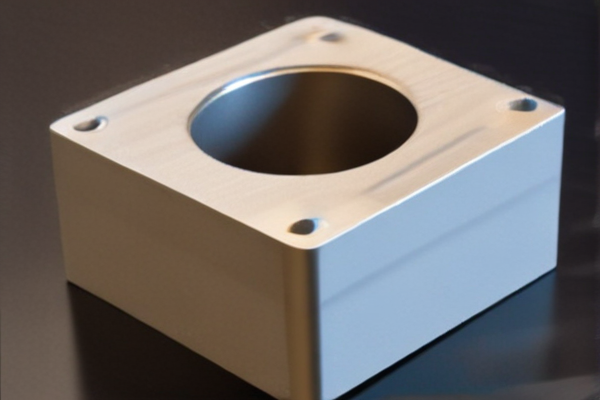

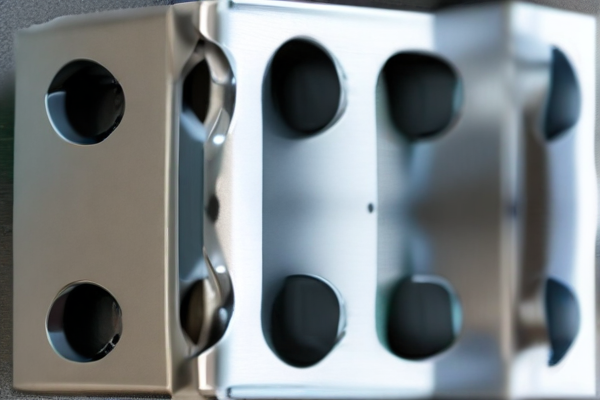

SourcifyChina Factory stands out in precision and efficiency, producing top-quality CNC milled parts tailored to client specifications. Their advanced machinery and skilled workforce ensure superior craftsmanship in every piece.

Customer satisfaction is paramount for SourcifyChina. Their dedicated team provides proactive communication, ensuring clients are well-informed throughout the production process. This commitment to transparency builds trust and fosters long-term partnerships.

Moreover, SourcifyChina offers competitive pricing without compromising quality. Leveraging economies of scale and efficient production techniques, they provide cost-effective solutions ideal for businesses aiming to reduce expenses while maintaining high standards.

On-time delivery is a cornerstone of SourcifyChina’s service. With meticulous planning and streamlined operations, they ensure timely completion and shipment of orders, helping clients meet their project deadlines with ease.

In addition to quality and efficiency, SourcifyChina prioritizes compliance with international standards and certifications. This adherence guarantees that products meet global quality and safety benchmarks, catering to diverse market needs.

To complete, choosing SourcifyChina Factory means selecting a partner committed to excellence in CNC milling. From superior craftsmanship and competitive pricing to on-time delivery and stringent quality controls, they offer a comprehensive solution tailored to meet and exceed your business requirements.

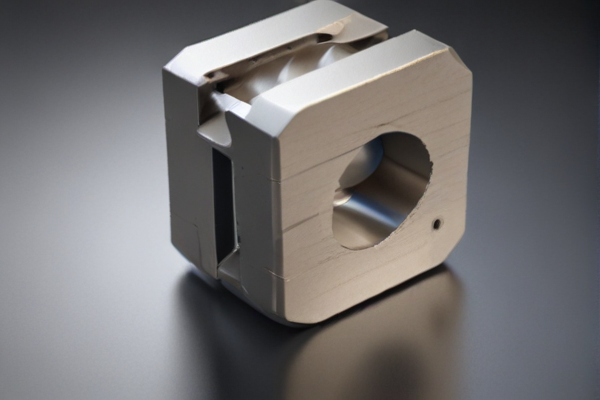

CNC milling, a subtractive manufacturing process, uses computerized controls to cut and shape various materials into precise components. Different types of CNC milling operations cater to varying specifications and complexities, offering versatile alternatives for diverse industrial applications.

– 2D milling: Basic operation, suitable for simple, flat-surfaced parts.

– 3-axis milling: Most common, handles various geometries by moving along X, Y, and Z axes.

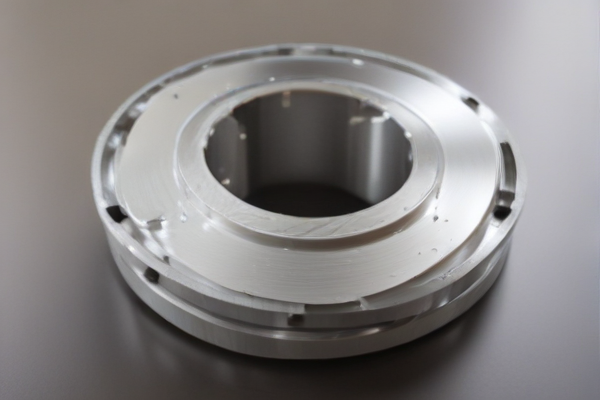

– 4-axis milling: Adds rotary motion along the X or Y axis, facilitating complex geometries.

– 5-axis milling: Offers highest precision, working simultaniously along X, Y, Z axes and rotating two additional axes, ideal for intricate designs.

– High-speed milling: Utilized for rapid material removal and reduced cycle times.

– Micro milling: Focuses on creating extremely small, detailed features.

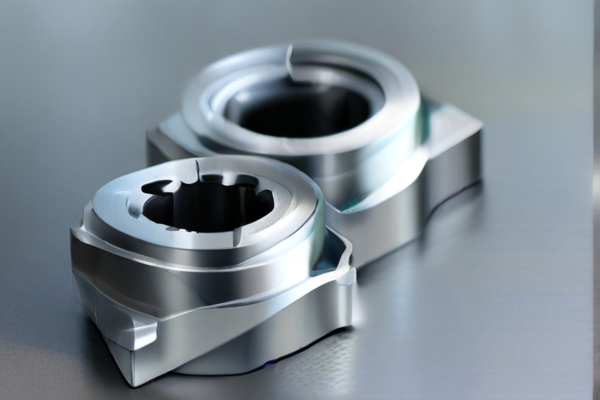

– Multitasking milling: Combines milling with turning or drilling to streamline production.

– Vertical milling machines (VMCs): Operate with a vertically oriented spindle.

– Horizontal milling machines (HMCs): Feature a horizontally oriented spindle, enhancing chip removal.

Options to consider in CNC milling:

– Material selection: Metals (aluminum, steel, titanium), plastics, composites.

– Tooling options: End mills, ball mills, chamfer mills for different finishes.

– Software compatibility: CAM software for design integration.

– Tolerances: Customizable based on project requirements.

– Surface finishes: Polishing, anodizing, coating, or plating for aesthetic/functional purposes.

– Batch sizes: Single prototypes to mass production flexibility.

– Customization: Tailored to specific industry needs such as automotive, aerospace, or medical devices.

CNC milled components offer high precision and repeatability, making them essential in various industries. These applications leverage the accuracy and efficiency of CNC milling for both complex and straightforward tasks.

– Aerospace: CNC milling ensures parts meet stringent specifications.

– Automotive: Precision milling for engine components and other critical parts.

– Medical: Manufacturing implants and surgical instruments with high accuracy.

– Electronics: Creating complex circuits and enclosures.

– Prototyping: Facilitates rapid development and iteration.

– Defense: Produces specialized equipment and weaponry.

– Consumer Goods: Designs of customized, intricate products.

– Construction: Producing machinery parts and tooling.

– Renewable Energy: Components for wind turbines and solar panels.

– Robotics: Precise machining for robot parts and assemblies.

CNC milling continues to revolutionize sectors by enabling the production of intricate, high-precision components efficiently.

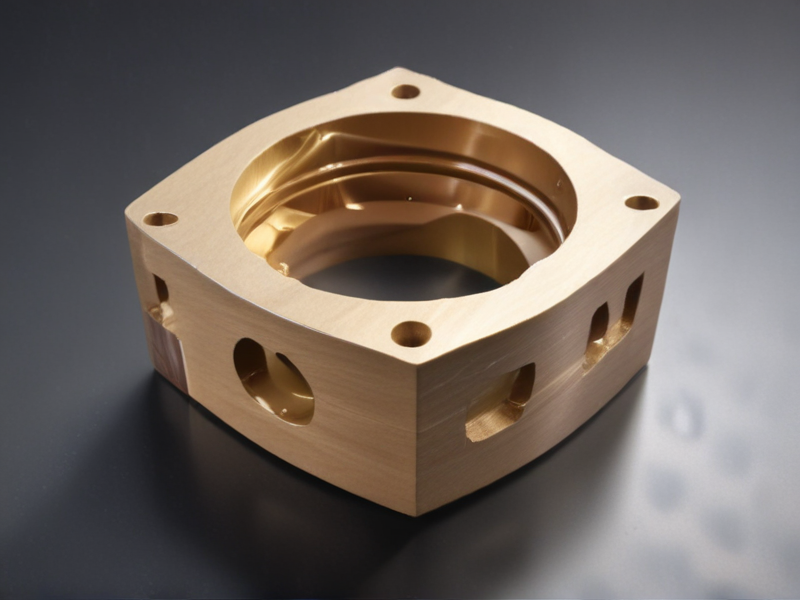

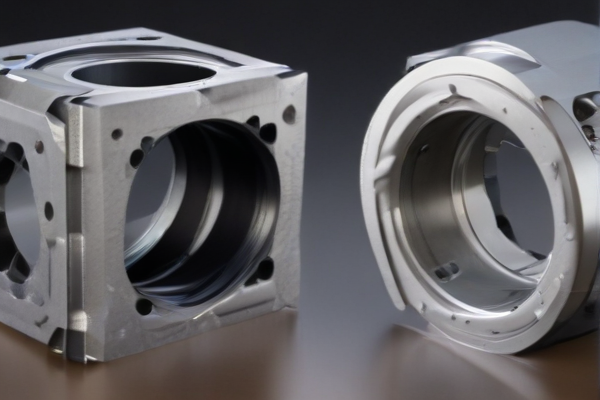

SourcifyChina excels in providing CNC milled parts made from various high-quality materials. These include metals such as aluminum, stainless steel, brass, and titanium. Each metal is chosen based on its unique properties and specific application requirements, ensuring optimal performance.

Aluminum is favored for its lightweight and excellent strength-to-weight ratio, making it ideal for aerospace and automotive industries. Stainless steel, known for its durability and corrosion resistance, is commonly used in medical devices and food processing equipment. Brass offers good machinability and aesthetic appeal, often utilized in decorative fixtures and plumbing parts.

Titanium is another critical material due to its exceptional strength and lightweight characteristics, preferred in aerospace and high-performance engineering projects. SourcifyChina also offers CNC milling services for various plastics including ABS, PEEK, and polycarbonate, ensuring a comprehensive material selection for diverse industrial needs.

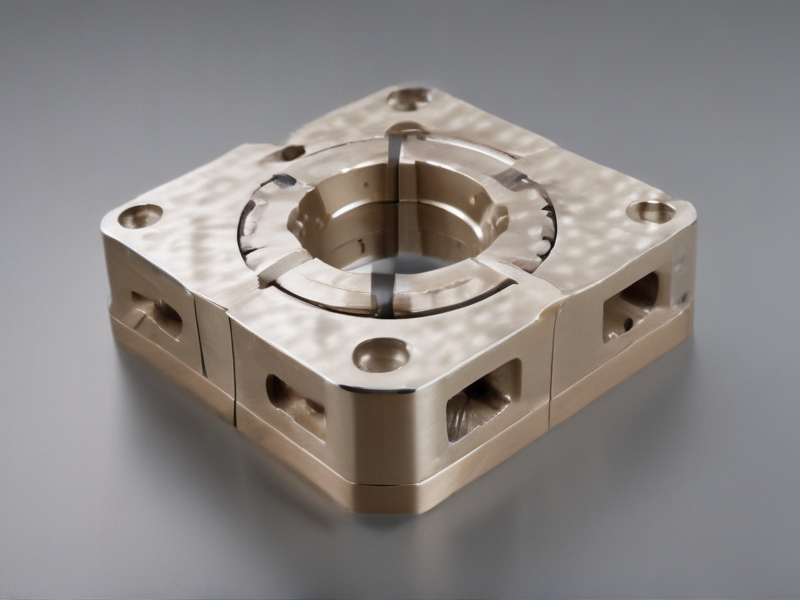

SourcifyChina employs advanced CNC milling machines to achieve precision and consistency across all materials. Regardless of the material, stringent quality control measures are applied at every stage of production to ensure high performance and reliability of the final product. With a team of experienced engineers, SourcifyChina brings technical expertise to each project, ensuring that every CNC milled component meets stringent specifications and quality standards.

SourcifyChina’s quality control process for CNC milled components begins with thorough material verification. Raw materials are inspected to ensure they meet the required specifications, which is fundamental for the final product’s integrity.

The next step involves precision machining. CNC mills are meticulously calibrated to adhere to exact design parameters. Regular maintenance and inspection of machines ensure consistent performance, reducing the likelihood of deviations.

Quality inspectors utilize advanced measuring tools such as coordinate measuring machines (CMM) and laser scanners to verify dimensional accuracy. Any deviations from the design specifications are immediately addressed, maintaining stringent quality standards.

Subsequent surface finishing and treatment processes are monitored to ensure compliance with customer requirements. This step includes checks on coating thickness, surface roughness, and overall aesthetic quality, contributing to the part’s functional and visual standards.

The final stage encompasses rigorous testing and a comprehensive inspection process. Components undergo stress tests, load tests, and other specific evaluations to confirm their durability and performance in real-world applications.

Overall, SourcifyChina ensures that each CNC milled product meets or exceeds client expectations. By integrating systematic checks at each stage of production, the company maintains high standards of quality, ensuring reliable and high-precision components.

SourcifyChina offers robust CNC milling capabilities, delivering precision parts with exceptional accuracy. Their state-of-the-art machinery handles complex geometries efficiently, making them ideal for various industries, including aerospace, automotive, and electronics.

Utilizing advanced CNC milling machines, SourcifyChina can work with an array of materials such as aluminum, steel, titanium, and plastic. This versatility ensures clients receive parts that meet their specific material requirements and performance standards.

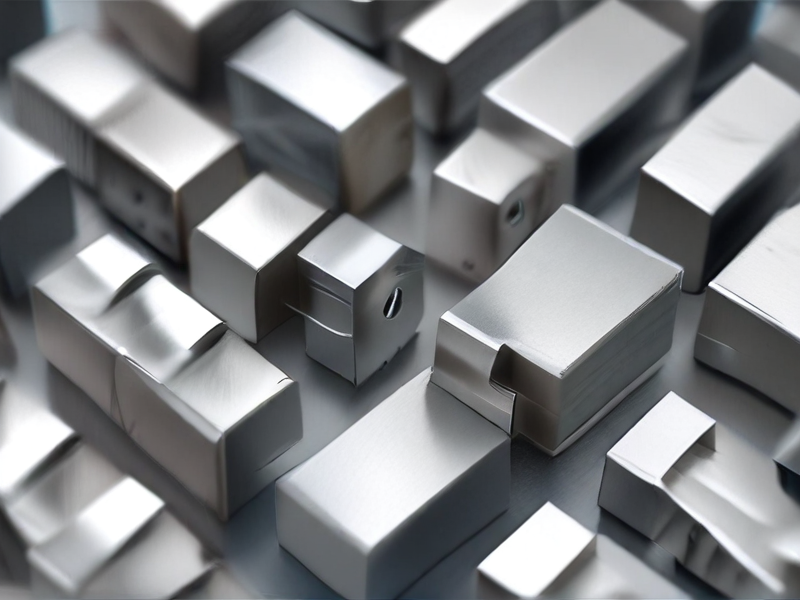

The company specializes in both prototyping and full-scale production runs. This flexibility allows businesses to test designs through rapid prototyping before committing to mass production, ensuring high-quality outcomes.

SourcifyChina’s team of experienced engineers and machinists ensures each project is executed with precision. Their expertise in CNC milling ensures every part meets exact specifications and tolerances, reducing the need for post-processing adjustments.

Adopting rigorous quality control measures, SourcifyChina guarantees consistent and reliable output. They utilize advanced inspection tools and techniques, such as coordinate measuring machines (CMM), to verify each part’s dimensions and quality.

By investing in the latest CNC milling technology and continuous staff training, SourcifyChina remains at the forefront of manufacturing innovation. This commitment to excellence ensures they can tackle even the most challenging projects with confidence.

Clients benefit from SourcifyChina’s efficient production processes and competitive pricing. Their streamlined operations reduce lead times and costs, offering businesses a cost-effective solution without compromising quality.

SourcifyChina’s comprehensive services also include design assistance and optimization. Their experienced team can provide valuable insights on improving manufacturability and performance, ensuring clients achieve the best possible results.

In summary, SourcifyChina’s CNC milling capabilities are marked by precision, versatility, and rigorous quality control. Their commitment to innovation and customer satisfaction makes them a trusted partner for businesses seeking high-quality, reliable CNC milled parts.

Benefits of CNC Milling

CNC milling offers unparalleled precision, efficiency, and versatility, making it an essential process in modern manufacturing.

– Precision: CNC milling machines provide highly accurate results, ensuring tight tolerances and consistent quality.

– Efficiency: Automated processes reduce human error and increase production speed, optimizing workflow and reducing costs.

– Versatility: Capable of machining a wide range of materials, including metals, plastics, and composites, CNC milling is suitable for various industries.

– Complex Geometries: Enables the creation of intricate and complex shapes that are difficult to achieve with manual machining.

– Scalability: Easily scalable from prototype to high-volume production, adapting to changing demands.

– Repeatability: Ensures repeatable outcomes, ideal for producing identical parts in large quantities.

– Less Waste: Precision cutting minimizes material waste, contributing to more sustainable manufacturing practices.

– Enhanced Safety: Reduced need for manual intervention minimizes the risk of injuries.

– Quick Turnaround: Faster setup and production times lead to quicker delivery of finished products.

– Cost-Effective: Lower labor costs and material waste translate to overall cost savings.

CNC (Computer Numerical Control) milling is a precision engineering process used to create complex parts with high accuracy and consistency. Here’s an overview of its features:

– High Precision: CNC milling machines can produce parts with excellent accuracy, often within micrometer tolerances.

– Consistency: The automated process ensures that every part produced is identical, reducing human error.

– Complex Geometry: Capable of creating intricate designs and complex geometries that are difficult or impossible with manual machining.

– Material Versatility: Can work with a wide range of materials, including metals, plastics, and composites.

– Multiple Operations: Able to perform various machining operations such as drilling, tapping, and cutting in one setup.

– Efficient Production: Faster production times due to automation and optimized tool paths.

– Scalability: Suitable for both prototyping and mass production, allowing easy scalability.

– Cost-Effective: Reduces labor costs and material waste, leading to overall cost efficiency.

– Enhanced Safety: Less manual intervention lowers the risk of workplace accidents.

– Advanced Software Integration: Uses CAD/CAM software for design and tool path programming, improving accuracy and efficiency.

– Surface Finish: Provides high-quality surface finishes that may require minimal post-processing.

– Flexibility: Easily adaptable to design changes without the need for significant retooling.

CNC milling stands out for its ability to produce detailed, high-quality parts efficiently and consistently, making it a preferred choice in various industries, from aerospace to automotive, medical, and more.

SourcifyChina is renowned for delivering high-quality CNC milled custom products. Utilizing advanced CNC milling technology, they create precise and intricate components tailored to specific customer requirements. Their expertise spans across various industries, ensuring reliability and accuracy in every project.

Clients benefit from SourcifyChina’s comprehensive design and engineering support. This collaboration fosters the development of innovative solutions, from prototyping to final production. Each step of the process is meticulously managed to guarantee top-tier results.

The company’s efficient manufacturing processes reduce lead times and costs without compromising on quality. SourcifyChina’s CNC milled products are celebrated for their durability and excellent craftsmanship. The firm’s commitment to continuous improvement keeps them at the cutting edge of technology and industry advancements.

Providing exceptional customer service is at the heart of SourcifyChina’s operations. Their dedicated team ensures seamless communication and punctual delivery. They prioritize customer satisfaction, offering customizable solutions to meet diverse project needs.

SourcifyChina’s commitment to sustainability is evident in their use of eco-friendly materials and practices. They strive to minimize environmental impact while maintaining high standards of production. This approach appeals to environmentally-conscious clients, aligning with modern sustainability goals.

Partner with SourcifyChina to experience unparalleled CNC milling solutions. Whether you’re seeking prototypes or mass-produced parts, their expertise and dedication promise exceptional outcomes for all your custom projects. Through innovation and precision, SourcifyChina continues to set the benchmark in CNC milled products.

SourcifyChina, a notable name in the field of CNC milling, stands as a premier manufacturing partner specializing in providing high-precision, custom-machined components to industries worldwide. Leveraging the latest advancements in CNC milling technology, SourcifyChina ensures a seamless blend of efficiency, accuracy, and scalability, catering to diverse sectors including aerospace, automotive, and medical. The company prides itself on its rigorous quality control processes, which are aligned with global standards, ensuring each product meets stringent customer specifications. With a dedicated team of skilled engineers and technicians, SourcifyChina also offers comprehensive end-to-end services—from initial design consultation to final production—delivering tailored solutions that bring innovative concepts to life. In an ever-evolving manufacturing landscape, the company’s commitment to innovation, excellence, and customer-centric approaches has solidified its reputation as a trusted and reliable outsourcing partner, making it a go-to choice for businesses seeking top-tier CNC milled components.

Computer Numerical Control (CNC) milling technology has revolutionized the Aerospace, Defense, and Marine industries by providing precision manufacturing capabilities that are critical to the performance and safety of these sectors. In aerospace applications, CNC milling is employed to create complex and intricate parts from high-strength materials like titanium and aluminum alloys. These parts range from structural components of airframes to highly precise turbine blades essential for jet engines. The accuracy, reliability, and repeatability that CNC milling offers ensure that components meet stringent specifications, which are vital for the demanding conditions of aerospace operations. Moreover, the ability to quickly prototype and produce lightweight, yet durable, parts helps drive innovation and enhances the aerodynamics, fuel efficiency, and overall performance of aircraft.

In the defense sector, CNC milling is crucial for the production of advanced weaponry, surveillance systems, and vehicular components. The defense industry often requires bespoke, high-tolerance parts made from tough materials that can withstand extreme environments and stresses. CNC milling allows for the efficient production of these components, ensuring that they meet exact performance and durability standards. For example, components for guided missile systems, armored vehicles, and advanced radar systems are frequently manufactured using CNC milling processes. Similarly, the marine industry benefits significantly from CNC milling, as it is used to produce a wide range of parts including propellers, hull components, and navigation instruments. Precision-milled components in marine applications reduce maintenance demands and enhance the durability and operational efficiency of vessels operating in harsh maritime environments. Thus, CNC milling stands as a cornerstone technology, driving advancements and ensuring high standards in Aerospace, Defense, and Marine applications.

CNC milling has become an essential technology in the automotive industry, significantly enhancing both the design and manufacturing processes. Automotive components demand high precision and durability, which CNC milling consistently delivers. From engine blocks to complex transmission components, CNC milling machines can fabricate intricate parts with remarkable accuracy and repeatability. The precision of CNC milled parts ensures optimal performance, which is critical for high-speed and high-stress automotive applications. Moreover, rapid prototyping and custom production capabilities enabled by CNC milling allow automotive engineers to swiftly iterate on designs, leading to faster time-to-market for new models and more efficient development cycles.

In the realm of electronics, CNC milling plays a pivotal role in producing highly precise and miniature components essential for modern devices. Printed circuit boards (PCBs), for instance, benefit greatly from CNC milling as it allows for the accurate cutting and drilling of intricate patterns and pathways required for electronic connections. Additionally, CNC milling is indispensable in fabricating custom enclosures for electronic devices, where precision and consistency are paramount to ensuring fit and function. The ability to rapidly prototype and produce small batches of components speeds up innovation cycles, fostering the development of cutting-edge technology in consumer electronics, medical devices, and aerospace applications. By leveraging CNC milling, the electronics industry can achieve the high standards required for both performance and reliability.

CNC milling, a precise and versatile manufacturing process, has found significant applications in the construction industry. By utilizing computer numerical control (CNC) technology, construction companies can fabricate complex architectural components with exceptional accuracy. CNC-milled parts are used in creating custom architectural elements such as intricate facades, metal frameworks, and detailed moldings. This process allows for the production of components that fit together perfectly, reducing the need for on-site adjustments and accelerating the construction timeline. Additionally, CNC milling enables the use of a wide range of materials, from metals to composite materials, enhancing the aesthetic and structural capabilities of modern buildings. The precision and efficiency of CNC milling thus contribute significantly to innovative design possibilities and improved construction methodologies.

In the energy sector, CNC milling technology plays a crucial role in the production and maintenance of various energy systems. For instance, the renewable energy industry benefits from CNC milled parts in the fabrication of wind turbine components, such as blades and hubs, which require intricate design and top-tier precision to maximize energy output and ensure long-term durability. CNC milling is also pivotal in the production of components for solar power systems, including mounting structures and intricate electrical connections. In the realm of traditional energy, CNC milled parts are essential for maintaining the efficiency and safety of machinery used in oil and gas extraction, as well as in the production of power generation equipment like turbines and generators. The precision of CNC milling ensures that these components meet stringent industry standards, ultimately contributing to the reliability and efficiency of energy systems worldwide.

The Industrial Equipment industry has seen a transformative shift with the application of CNC (Computer Numerical Control) milling technology. CNC milling is a precision-driven machining process that employs computer-aided design (CAD) to direct intricate cutting and shaping tasks on a variety of materials, such as metal, plastic, and wood. This automated approach enhances accuracy, repeatability, and efficiency compared to traditional manual labor, significantly reducing human error and production time. The ability to produce complex geometries and tight tolerances has made CNC milling indispensable for manufacturing critical components in heavy machinery, automotive parts, aerospace structures, and medical devices, ensuring consistency and superior quality in mass production.

Moreover, the flexibility and scalability brought by CNC milling are notable advantages in the Industrial Equipment sector. Companies can swiftly adapt to market demands by reprogramming CNC machines to accommodate new product designs or modifications without significant downtime. This agility supports rapid prototyping, allowing for faster product development cycles and more innovative solutions. Enhanced with advancements in software and tool development, CNC milling enables detailed customization and small-batch production, meeting bespoke industrial needs without sacrificing efficiency. Thus, the integration of CNC milling technology in industrial equipment manufacturing not only elevates the precision and quality of end products but also drives operational efficiency and responsiveness to evolving industry trends.

CNC (Computer Numerical Control) milling is extensively utilized in the production of medical devices due to its precision, efficiency, and ability to create complex geometries from various materials. Medical devices such as orthopedic implants, prosthetics, surgical instruments, and dental components require meticulous accuracy and consistency, which CNC milling can deliver. This technology allows manufacturers to produce components with tight tolerances and intricate features, ensuring that each piece meets stringent medical standards. CNC milled parts can be customized to fit individual patient needs, whether it’s a uniquely contoured bone plate or a bespoke dental crown, offering tailored solutions to improve patient outcomes and enhance the functionality of medical devices.

Moreover, CNC milling supports the use of biocompatible materials like titanium, stainless steel, and medical-grade polymers, which are essential in ensuring safety and performance in medical applications. The high-precision nature of CNC milling means that even the most delicate and intricate parts can be produced with a high degree of reproducibility, essentially minimizing the risk of defects and ensuring reliability and durability over time. This not only helps in meeting regulatory compliance but also significantly reduces the time and cost associated with medical device manufacturing. As a result, CNC milling becomes an indispensable technology in advancing medical care, offering the means to innovate and refine medical devices that are critical to modern healthcare.

CNC (Computer Numerical Control) milling is revolutionizing the realm of machining and manufacturing by providing unparalleled precision and efficiency in producing complex components. Unlike traditional manual milling, CNC milling relies on computerized controls to manage machining tools, ensuring consistently high accuracy and repeatability. This digital approach allows for intricate designs and specifications that manual methods might struggle to achieve. Industries ranging from aerospace to medical devices benefit tremendously, as CNC milling can craft components with tolerances within a few thousandths of an inch. The ability to produce complex geometries with minimal human intervention not only speeds up production but also reduces the risk of human error, leading to higher-quality end products.

In manufacturing applications, CNC milling is pivotal for both prototyping and mass production. During the prototyping phase, it enables rapid iterations and modifications of designs, allowing engineers to test and refine parts efficiently before committing to full-scale production. Once a design is validated, CNC milling machines can shift to high-volume production runs with ease. Their capability for continuous operation around the clock ensures that manufacturing demands can be met promptly without compromising on precision. The versatility of CNC milling machines also means they can handle a wide range of materials—from metals like aluminum and steel to plastics and composites—making them indispensable across various sectors. As a result, CNC milling not only enhances production agility but also propels innovation by enabling the realization of advanced, high-precision components.

Sure, here are some frequently asked questions (FAQs) about CNC milled quality work from SourcifyChina factory, along with their answers:

1. What is CNC milling and why is it beneficial?

CNC milling is a process where a computer-controlled machine cuts, drills, or grinds materials with high precision. It is beneficial because it ensures consistent, high-quality output and allows for complex designs that manual machining cannot achieve.

2. Why should I choose SourcifyChina for my CNC milling needs?

SourcifyChina offers competitive pricing, high-quality materials, state-of-the-art equipment, and a team of experienced engineers. We cater to a wide range of industries and ensure timely delivery schedules.

3. What materials can SourcifyChina CNC mill?

We work with a variety of materials including metals (aluminum, steel, brass, etc.), plastics (ABS, nylon, polycarbonate, etc.), and composites. Each material is chosen based on client requirements and project specifications.

4. What is the lead time for CNC milled parts?

The lead time depends on the complexity and quantity of the order. Standard lead times range from 2-4 weeks. Expedited services are available upon request.

5. How does SourcifyChina ensure quality in CNC milled components?

Quality is ensured through rigorous inspection processes including first article inspection (FAI), in-process inspections, and final inspection. We utilize advanced measuring equipment to maintain tight tolerances.

6. Can SourcifyChina handle large volume orders?

Yes, we can handle both small and large volume orders. Our scalable production capacity ensures that we meet the needs of both small startups and large corporations.

7. How do I get a quote for my CNC milling project?

You can get a quote by sending your project details, including CAD files and material specifications, to our sales team via email or through our website’s quote request form. We typically respond within 24 hours.

8. Does SourcifyChina provide design assistance?

Yes, we offer design assistance and review services to help optimize your designs for manufacturability and cost-efficiency. Our team of engineers can provide valuable feedback and suggestions.

9. What industries does SourcifyChina serve?

We serve a wide range of industries including automotive, aerospace, medical, electronics, and consumer goods, among others. Our versatile capabilities allow us to meet the diverse needs of different sectors.

SourcifyChina is a reputable factory known for high-quality CNC milled manufacturing. Here are some key tips to optimize your experience and results:

1. Detailed Specifications: Provide comprehensive design files, including CAD drawings and tolerances. This ensures precision and reduces misunderstandings.

2. Material Selection: Choose the right material for your project. SourcifyChina offers a range of materials like aluminum, brass, and stainless steel. Consult their experts for recommendations based on your application.

3. Prototyping First: Start with a prototype to test design and functionality before full-scale production. This helps in identifying any necessary modifications early on.

4. Communication: Maintain clear and frequent communication. Use visual aids like diagrams and photos to explain intricate details. Regularly check in on the manufacturing progress.

5. Quality Control: Emphasize the need for rigorous quality checks. SourcifyChina employs advanced QC processes, but additional third-party inspections can ensure standards are met.

6. Lead Times: Clarify lead times from the beginning and account for shipping duration. Building a buffer period can help mitigate unexpected delays.

7. Cost Efficiency: Balance cost with quality. While lower prices are attractive, ensure that the material and machining capabilities meet your project’s requirements.

8. Sample Approval: Request samples before full production to ensure the product meets your expectations. This step is crucial to avoid costly errors.

9. Compliance and Standards: Ensure compliance with relevant industry standards and certifications, which SourcifyChina typically adheres to, for assured product integrity.

10. After-Sales Support: Inquire about the after-sales support provided. Effective troubleshooting and issue resolution are vital for maintaining a successful partnership.

Following these tips can lead to a smoother, more efficient CNC milling collaboration with SourcifyChina, ensuring high-quality outcomes for your manufacturing needs.

Certainly! Here’s a concise FAQ for sourcing CNC milled parts from SourcifyChina factory:

1. What types of CNC milling services does SourcifyChina factory offer?

SourcifyChina provides a wide range of CNC milling services, including 3-axis, 4-axis, and 5-axis milling, which can handle diverse materials such as metals, plastics, and composites.

2. How can I request a quote for CNC milling services?

You can request a quote by filling out the online form on the SourcifyChina website or by emailing your project details, including specifications, drawings, and quantity required.

3. What information do I need to provide for a CNC milling quote?

To get an accurate quote, provide detailed CAD drawings or 3D models, material specifications, surface finish requirements, and the quantity of parts needed.

4. What is the typical lead time for CNC milling projects?

Lead times vary depending on the complexity and volume of your order, but typically range from 2 to 6 weeks. Expedited services are available upon request.

5. Can SourcifyChina handle custom and low-volume CNC milling orders?

Yes, SourcifyChina specializes in both custom and low-volume CNC milling orders, ensuring high-quality and precision for every project regardless of order size.

6. What quality control measures are in place at SourcifyChina?

SourcifyChina employs stringent quality control measures including ISO 9001 certification, in-process inspections, and final product inspections to ensure the highest standards.

7. Are there any minimum order quantities (MOQ) for CNC milled parts?

SourcifyChina does not enforce a strict MOQ, allowing flexibility for prototypes and small-batch productions as well as larger orders.

8. What materials can SourcifyChina mill?

SourcifyChina can mill a wide variety of materials including aluminum, stainless steel, brass, titanium, and engineering plastics like PEEK and ABS.

9. Does SourcifyChina provide secondary processes or finishing services?

Yes, SourcifyChina offers comprehensive finishing services such as anodizing, powder coating, polishing, and heat treatment to meet specific project requirements.

10. How can I track my order once it’s placed?

Once your order is confirmed, you will receive regular updates on the production status and tracking information once the order is shipped.

Sourcing CNC milled parts from SourcifyChina factory can be streamlined with these efficient tips:

1. Define Specifications Clearly:

– Detail material types (e.g., aluminum, steel).

– Specify tolerances, surface finishes, and dimensions.

2. Request Prototypes:

– Validate the factory’s capabilities by requesting an initial prototype before placing a bulk order.

3. Check Certifications:

– Ensure the factory has essential certifications like ISO for quality assurance.

4. Evaluate Experience:

– Look for factories with extensive experience in CNC milling and good client feedback.

5. Communication:

– Maintain clear and frequent communication through professional channels to avoid misunderstandings.

6. Site Visits:

– If feasible, visit the factory to assess their machinery, processes, and quality control firsthand.

7. Negotiate Terms:

– Discuss pricing, payment terms, lead times, and minimum order quantities upfront.

8. Use SourcifyChina’s Services:

– Utilize their resources for factory audits, logistics coordination, and dispute resolution.

By following these tips, you can ensure a smooth and productive sourcing experience with SourcifyChina factory for CNC milled parts.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.