Technology and Applications of cnc programming g code

CNC (Computer Numerical Control) programming using G-code is fundamental in modern manufacturing for controlling automated machine tools. G-code consists of commands that direct CNC machines, specifying coordinates, speeds, and movements required to manufacture parts accurately. It’s widely used across various industries including aerospace, automotive, and electronics.

Key applications of G-code include:

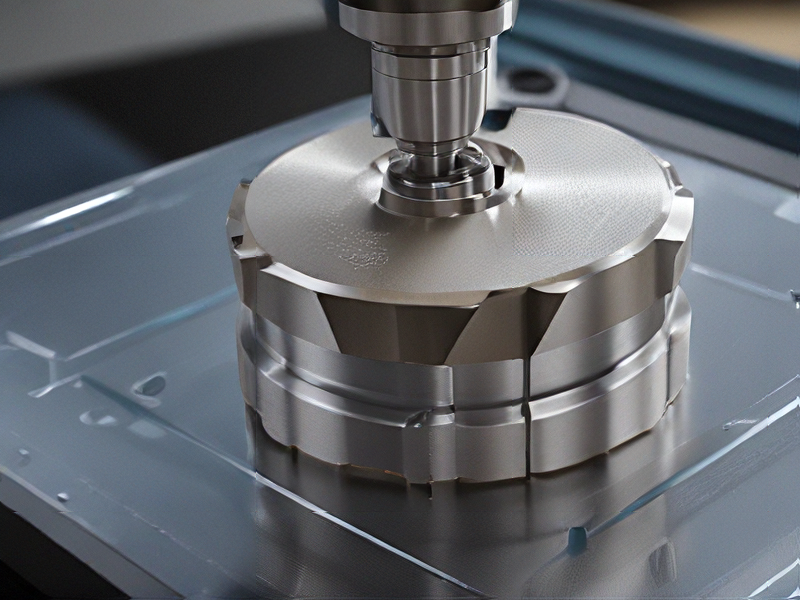

1. Machining Operations: G-code controls CNC machines to perform precise machining operations like milling, drilling, turning, and grinding. It specifies tool paths, tool changes, spindle speeds, and feed rates, ensuring high precision and repeatability.

2. Prototyping and Production: G-code is crucial in both prototyping and mass production. It allows manufacturers to quickly prototype new parts by programming specific tool movements and operations, facilitating efficient testing and refinement before full-scale production.

3. Complex Geometries: CNC machines using G-code can produce intricate and complex geometries that are difficult or impossible to achieve manually. This capability is essential in industries requiring high precision and tight tolerances.

4. Automation and Efficiency: By automating machining processes, G-code reduces human error and increases production efficiency. CNC machines can operate continuously, performing tasks with consistent accuracy and minimal downtime.

5. Customization and Flexibility: G-code programming enables customization of manufacturing processes. Manufacturers can tailor machining operations to specific requirements, adapting quickly to design changes or customer demands.

6. Integration with CAD/CAM: G-code works closely with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. CAD models are translated into G-code instructions by CAM software, ensuring seamless communication between design and manufacturing stages.

Overall, G-code programming is indispensable in modern manufacturing, offering precise control over CNC machines to produce complex parts efficiently and accurately. Its applications span from rapid prototyping to high-volume production across diverse industries, driving innovation and enhancing manufacturing capabilities worldwide.

Quality Testing Methods for cnc programming g code and how to control quality

Quality testing for CNC programming using G-code involves several methods and controls to ensure precision, accuracy, and adherence to design specifications. Here are key methods and controls:

1. Simulation and Verification:

– Software Simulation: Use simulation software to visualize and test the G-code before actual machining. This helps identify potential errors such as tool collisions, incorrect tool paths, and programming mistakes.

– Dry Run Testing: Conduct a dry run without material to ensure the tool paths and machine operations are correct. This helps in verifying the machine behavior as per the G-code.

2. Inspection and Measurement:

– First Article Inspection (FAI): Inspect the first produced part thoroughly against design specifications to ensure all dimensions and tolerances are met.

– In-Process Inspection: Use tools like dial indicators, coordinate measuring machines (CMM), and laser scanners to measure parts during production. This helps in catching deviations early in the process.

– Final Inspection: Perform a detailed inspection of the finished parts using CMM, calipers, micrometers, and other precision measurement tools to verify conformity with specifications.

3. Tool and Machine Calibration:

– Regularly calibrate tools and machines to maintain accuracy. Calibration ensures that any wear and tear or misalignment is corrected, reducing the risk of errors.

4. Standardized Procedures and Documentation:

– Develop and follow standardized procedures for CNC programming and operation. Proper documentation of G-code, tool selection, setup sheets, and machine settings helps in maintaining consistency and traceability.

5. Training and Skill Development:

– Ensure that CNC operators and programmers are well-trained. Skilled personnel can better understand and identify potential issues in G-code and machining processes.

6. Feedback and Continuous Improvement:

– Implement a feedback loop where operators, programmers, and quality inspectors share insights and suggestions for improving processes. Continuous improvement practices help in refining both programming and operational methods.

By incorporating these quality testing methods and controls, CNC programming using G-code can achieve high levels of precision, reliability, and adherence to design specifications.

Tips for Procurement and Considerations when Purchasing from cnc programming g code

When procuring CNC programming services or purchasing CNC G-code, several considerations ensure you obtain high-quality, cost-effective, and reliable outputs.

Tips for Procurement:

1. Vendor Evaluation:

– Experience and Expertise: Choose vendors with proven experience in CNC programming. Check their portfolio and client testimonials.

– Technical Capabilities: Ensure they possess the necessary software tools and technical knowledge for your specific requirements.

– Quality Assurance: Verify their quality control processes to ensure precision and accuracy.

2. Specification Clarity:

– Detailed Requirements: Provide clear, detailed specifications including material types, tolerances, and finish requirements.

– Communication: Maintain open and frequent communication with the vendor to address any questions or changes in specifications.

3. Cost and Value:

– Cost Analysis: Obtain detailed quotes and compare costs. Consider not just the price but the value offered in terms of quality and service.

– Hidden Costs: Be aware of potential hidden costs such as setup fees, tool wear, and shipping.

Considerations when Purchasing G-Code:

1. Compatibility:

– Machine Compatibility: Ensure the G-code is compatible with your CNC machine’s controller. Different machines may require different code syntax.

– Software Compatibility: Verify that the G-code is compatible with your CAD/CAM software to avoid translation errors.

2. Validation and Testing:

– Simulation: Run simulations to validate the G-code before actual production. This helps in identifying potential errors and optimizing tool paths.

– Prototype Testing: If possible, test the G-code on a prototype to ensure it meets all requirements before full-scale production.

3. Documentation and Support:

– Detailed Documentation: Ensure the G-code comes with comprehensive documentation, including tool lists, setup sheets, and operation instructions.

– Technical Support: Choose vendors that offer robust technical support to assist with troubleshooting and adjustments.

By meticulously evaluating vendors, ensuring detailed specifications, analyzing costs, verifying compatibility, and prioritizing thorough validation and support, you can streamline the procurement process and achieve optimal results in CNC programming and G-code purchases.

FAQs on Sourcing and Manufacturing from cnc programming g code in China

When sourcing and manufacturing CNC programming G code in China, consider these FAQs:

1. How do I find reliable CNC programming services in China?

– Look for experienced providers with a track record of quality and timely delivery. Online platforms, trade shows, and referrals are effective ways to find credible options.

2. What are the typical costs involved?

– Costs vary based on complexity, quantity, and provider. Chinese manufacturers often offer competitive pricing, but ensure clarity on additional fees like setup and shipping.

3. How can I ensure quality control?

– Specify quality standards and inspect samples before production. Regular communication and factory visits help maintain product consistency.

4. What are the advantages of manufacturing in China?

– Lower labor costs, a wide range of capabilities, and scalability are primary advantages. China’s robust manufacturing infrastructure supports large-scale production.

5. What are the challenges to be aware of?

– Language barriers, intellectual property protection, and cultural differences may pose challenges. Clear contracts and legal support mitigate risks.

6. How can I protect my designs and intellectual property?

– Use non-disclosure agreements (NDAs), trademarks, and patents. Working with reputable manufacturers and legal professionals adds layers of protection.

7. What are the shipping and logistics considerations?

– Plan for lead times, customs procedures, and transportation options. Choose reliable freight forwarders to ensure timely delivery.

Navigating these considerations ensures a smoother CNC programming G code sourcing and manufacturing experience in China.