Technology and Applications of cnc router kits

Technology and Applications of CNC Router Kits

Technology:

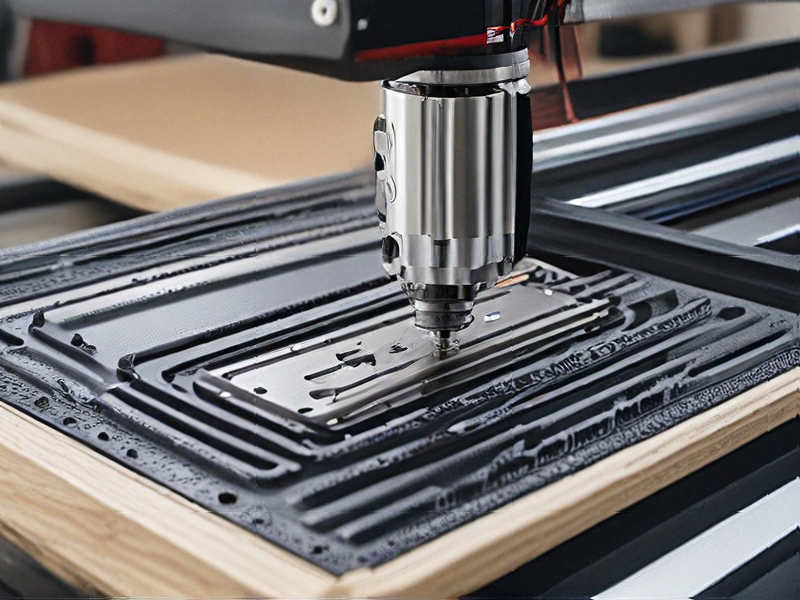

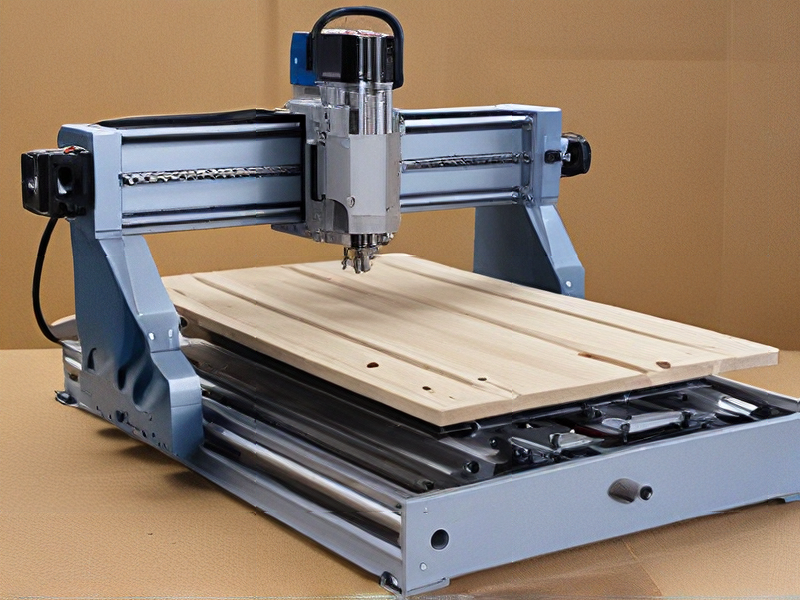

CNC (Computer Numerical Control) router kits utilize computer-controlled systems to automate the cutting, shaping, and carving of materials. These kits typically include a router, a control unit, and software for design and control. The technology relies on stepper or servo motors to precisely move the router along the X, Y, and Z axes, following a programmed path. The software converts digital designs into G-code, which directs the machine’s movements. CNC routers can work with various materials, including wood, plastics, metals, and composites.

Applications:

1. Woodworking:

CNC routers are extensively used in woodworking for making furniture, cabinetry, and decorative items. They enable intricate designs, precise cuts, and efficient production, which are difficult to achieve manually.

2. Sign Making:

The ability to cut and engrave various materials makes CNC routers ideal for creating detailed and customized signs. They can produce professional-quality signage with intricate fonts and logos.

3. Prototyping:

In manufacturing and product development, CNC routers are used to create prototypes. Their precision allows for the rapid development of parts and components, speeding up the design process.

4. Arts and Crafts:

Artists and hobbyists use CNC routers for creating sculptures, models, and detailed craft projects. The technology offers precision and repeatability, making complex designs more accessible.

5. Educational Purposes:

Educational institutions use CNC router kits to teach students about manufacturing, design, and engineering principles. These kits provide hands-on experience with advanced technology.

6. Aerospace and Automotive Industries:

CNC routers play a role in the aerospace and automotive sectors for fabricating components, molds, and fixtures. Their precision and repeatability are crucial for maintaining high standards.

Overall, CNC router kits enhance productivity, precision, and versatility across various industries, making complex and high-quality production more accessible.

Quality Testing Methods for cnc router kits and how to control quality

Quality testing methods for CNC router kits involve a series of inspections and tests to ensure the components meet the required standards and performance expectations. Here are some key methods:

1. Visual Inspection: Check for any visible defects or inconsistencies in components such as misalignment, surface finish issues, and damage during transport.

2. Dimensional Accuracy: Use calipers, micrometers, and other precision measurement tools to ensure parts meet specified dimensions and tolerances.

3. Material Verification: Confirm that the materials used match the specified requirements, which can include hardness tests, chemical composition analysis, and tensile strength tests.

4. Assembly Testing: Assemble the kit to verify that all parts fit together correctly and function as intended. This includes checking the alignment of guide rails, smooth operation of bearings, and proper mounting of motors.

5. Functionality Testing: Run the CNC router through a series of test cuts to evaluate its performance. This includes checking the accuracy of cuts, repeatability, spindle speed, and overall operation.

6. Electrical Testing: Inspect wiring and connections to ensure they are secure and meet safety standards. This includes checking the power supply, stepper motors, and control units.

7. Software Testing: Test the control software for bugs and ensure it communicates effectively with the hardware. Verify the accuracy of the machine’s response to programmed commands.

To control quality effectively, follow these strategies:

– Standard Operating Procedures (SOPs): Develop and adhere to detailed SOPs for each stage of production and assembly.

– Quality Control Checkpoints: Implement checkpoints throughout the manufacturing process where specific tests and inspections are conducted.

– Training: Ensure all personnel are adequately trained in both the use of quality control tools and the SOPs.

– Supplier Quality Management: Regularly audit and assess suppliers to ensure they provide high-quality materials and components.

– Continuous Improvement: Collect data from testing and inspections to identify trends and areas for improvement, and implement corrective actions as needed.

By systematically applying these methods and controls, you can ensure the consistent quality and reliability of CNC router kits.

Tips for Procurement and Considerations when Purchasing from cnc router kits

When purchasing CNC router kits, several key considerations can enhance the procurement process:

1. Technical Specifications: Evaluate the kit’s technical specifications such as the working area dimensions, spindle power, and precision (measured in terms of resolution and repeatability). Ensure these match your project requirements.

2. Kit Completeness: Verify that the kit includes all necessary components for assembly and operation, including the frame, motors, controller, power supply, and software. Check for any optional or recommended accessories.

3. Ease of Assembly: Assess the complexity of assembly instructions and the availability of online support or community forums for troubleshooting. Kits with clear documentation and user-friendly assembly processes can save time and reduce frustration.

4. Software Compatibility: Ensure compatibility between the CNC kit and the CAD/CAM software you intend to use. Some kits may come with proprietary software, while others are compatible with a range of third-party applications.

5. Build Quality and Material: Consider the materials used in the kit components, particularly the frame and linear motion systems (rails, bearings). Higher quality materials often result in better durability and smoother operation.

6. Support and Warranty: Research the manufacturer’s reputation for customer support and the warranty offered on the kit. Reliable support can be crucial for resolving technical issues and obtaining replacement parts if needed.

7. Cost and Budget: Compare the cost of the kit against your budget and evaluate the value proposition in terms of features, quality, and support offered.

8. User Reviews and Feedback: Look for reviews and testimonials from other users who have assembled and used the same or similar kits. Their experiences can provide valuable insights into reliability and performance.

By carefully considering these factors, you can make a more informed decision when purchasing a CNC router kit that aligns with your specific needs and ensures a smoother integration into your workshop or production environment.

FAQs on Sourcing and Manufacturing from cnc router kits in China

When sourcing CNC router kits from China, there are several common FAQs to consider:

1. Quality Assurance: How can I ensure the quality of CNC router kits from Chinese manufacturers?

– Answer: Research manufacturers thoroughly, request samples, and consider third-party inspections to verify quality standards.

2. Costs and Pricing: What factors influence the pricing of CNC router kits?

– Answer: Factors include materials used, complexity of design, customization, and order quantity. Negotiating prices based on these factors is common practice.

3. Lead Times: How long does it take to manufacture and deliver CNC router kits from China?

– Answer: Lead times vary based on order specifics and manufacturer capacity. Clarify production timelines and shipping arrangements before placing orders.

4. Customization Options: Can I request customizations to CNC router kits?

– Answer: Many Chinese manufacturers offer customization options. Clearly communicate your requirements and discuss feasibility with potential suppliers.

5. Payment Terms and Logistics: What are typical payment terms, and how is shipping handled?

– Answer: Payment terms often involve a deposit and balance upon completion. Shipping methods vary; clarify responsibilities for shipping, insurance, and customs.

6. After-Sales Support: What kind of after-sales support is provided?

– Answer: Inquire about warranties, technical support, and availability of spare parts to ensure ongoing operational support.

7. Compliance and Certification: What certifications do CNC router kits from China adhere to?

– Answer: Ensure products meet relevant safety and quality standards (e.g., CE, RoHS). Request documentation from manufacturers to confirm compliance.

Navigating these FAQs when sourcing CNC router kits from China can help ensure a smoother manufacturing process and satisfactory outcomes.