Technology and Applications of cnc wood carving machines

CNC wood carving machines utilize computer numerical control to automate the carving and shaping of wood, offering precision and efficiency in manufacturing processes. These machines operate based on digital designs, interpreting instructions from CAD (Computer-Aided Design) software to execute complex carving patterns and cuts with high accuracy.

Key applications of CNC wood carving machines include:

1. Furniture Manufacturing: CNC machines can produce intricate designs for furniture components like table legs, chair backs, and decorative elements. This technology allows for consistent quality and customization.

2. Cabinetry and Joinery: Woodworkers use CNC carving machines to create precise joints, detailed panels, and custom moldings for cabinets and joinery projects, reducing production time and minimizing errors.

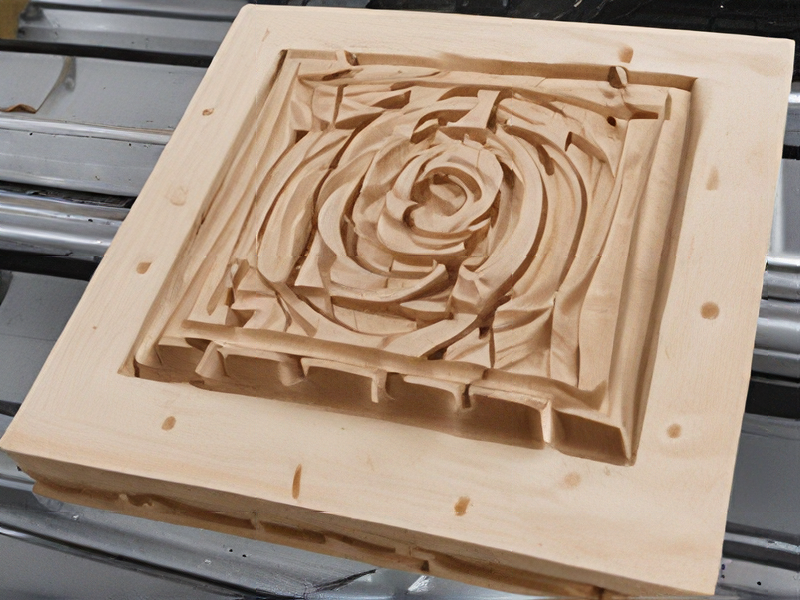

3. Artistic Woodworking: Artists and sculptors leverage CNC technology to bring intricate designs and artistic visions to life in wood, enabling detailed sculptures, wall art, and decorative pieces.

4. Sign Making: CNC routers are widely used in sign making industry to create customized signs with intricate lettering, logos, and designs on various types of wood.

5. Prototype Development: Designers and engineers use CNC wood carving machines to quickly produce prototypes of new products, allowing for iterative design improvements and cost-effective testing.

Technologically, modern CNC wood carving machines feature:

– Automatic Tool Changers: Enabling the machine to switch between different cutting tools without manual intervention, increasing efficiency.

– High-speed Spindles: Capable of rotating at varying speeds to accommodate different cutting requirements and materials.

– Precision Controls: Ensuring accuracy down to fractions of millimeters, crucial for intricate designs and complex cuts.

Overall, CNC wood carving machines revolutionize woodworking by enhancing precision, enabling complex designs, and improving productivity across various applications from furniture making to artistic creations and beyond.

Quality Testing Methods for cnc wood carving machines and how to control quality

Quality testing methods for CNC wood carving machines typically involve both process controls and final product inspections. Here are some key methods:

1. Dimensional Accuracy Check: Measure the carved dimensions against the CAD/CAM specifications using precision instruments like calipers or coordinate measuring machines (CMM).

2. Surface Quality Inspection: Assess the surface finish for smoothness, tool marks, and imperfections. This can be done visually or using surface roughness measurement tools.

3. Edge Quality Evaluation: Examine the edges of the carved wood pieces for burrs, tear-outs, or rough edges that don’t meet standards.

4. Tool Wear Monitoring: Regularly inspect cutting tools for signs of wear such as edge dullness or breakage. This ensures consistent carving quality and prevents defects.

5. Prototype Testing: Before full production, test a prototype to validate the CNC program’s accuracy and the machine’s capability to produce the desired designs.

6. Material Inspection: Check the wood material for defects like knots, warping, or moisture content, as these can affect carving quality.

To control quality effectively:

– Establish Standard Operating Procedures (SOPs): Document procedures for machine setup, tool calibration, and quality checks to ensure consistency.

– Regular Maintenance: Schedule routine maintenance for CNC machines to keep them in optimal condition and prevent unexpected defects.

– Training Programs: Train operators on machine operation, quality standards, and troubleshooting to minimize human errors.

– Data Collection and Analysis: Use software to collect data on machine performance and product quality. Analyze this data to identify trends and areas for improvement.

By implementing these methods and controls, manufacturers can ensure that CNC wood carving machines consistently produce high-quality products that meet customer expectations.

Tips for Procurement and Considerations when Purchasing from cnc wood carving machines

When purchasing CNC wood carving machines, several key considerations can streamline your procurement process:

1. Machine Specifications: Evaluate the machine’s specifications such as bed size, spindle power, and axis configuration to ensure they meet your production needs. Consider the type of materials you’ll be working with and the intricacy of designs required.

2. Accuracy and Precision: Look for machines known for their accuracy and precision in carving wood. This ensures consistent quality in your finished products.

3. Ease of Use: User-friendly interfaces and software compatibility are crucial for smooth operation. Consider training requirements for your team and the availability of technical support.

4. Speed and Efficiency: Assess the machine’s speed in carving operations. Higher speeds can increase productivity but should be balanced with precision requirements.

5. Durability and Maintenance: Opt for machines made from durable materials with a reputation for reliability. Consider maintenance needs and the availability of spare parts.

6. Vendor Reputation: Research the reputation of the manufacturer or vendor. Reviews and customer feedback can provide insights into after-sales service and support.

7. Cost and Return on Investment: Compare prices against features and capabilities. Factor in long-term costs, including maintenance and upgrades, to determine the overall return on investment.

8. Safety Features: Ensure the machine meets safety standards and includes necessary safety features to protect operators.

9. Customization Options: Depending on your specific needs, consider whether the machine can be customized or expanded with additional features in the future.

10. Training and Support: Investigate the training and support offered by the vendor. Comprehensive training can maximize operational efficiency and minimize downtime.

By carefully considering these factors and conducting thorough research, you can select a CNC wood carving machine that aligns with your production goals and enhances your woodworking capabilities effectively.

FAQs on Sourcing and Manufacturing from cnc wood carving machines in China

FAQs on Sourcing and Manufacturing from CNC Wood Carving Machines in China

1. Why source CNC wood carving machines from China?

China offers a wide range of CNC wood carving machines at competitive prices due to its advanced manufacturing capabilities, abundant raw materials, and efficient supply chain infrastructure.

2. How to find reliable suppliers in China?

Use platforms like Alibaba, Made-in-China, and Global Sources. Check supplier credentials, reviews, and request product samples. Visiting trade shows and factories can also ensure supplier reliability.

3. What should I consider when choosing a CNC wood carving machine?

Consider the machine’s size, power, spindle type, software compatibility, precision, and the type of wood it can handle. Ensure it meets your specific production needs and quality standards.

4. Are there different types of CNC wood carving machines?

Yes, they include 3-axis, 4-axis, and 5-axis machines. Each type offers varying levels of complexity and capability in carving intricate designs.

5. What is the typical lead time for manufacturing and shipping?

Lead time varies but generally ranges from 30 to 60 days, including manufacturing and shipping. Custom orders or large quantities may extend this period.

6. How can I ensure the quality of the machines?

Request detailed product specifications, certifications, and testing reports. Arrange for third-party inspections or quality control services to verify the machine’s performance and compliance.

7. What are the payment terms usually offered?

Common payment terms include 30% deposit upfront and 70% balance before shipment. Letters of credit and trade assurance services on platforms like Alibaba provide additional security.

8. Are there warranties and after-sales support?

Most suppliers offer a one-year warranty and provide technical support. Verify the availability of spare parts and the supplier’s responsiveness to after-sales inquiries.

9. What about import duties and regulations?

Check the import duties and regulations of your country. Work with freight forwarders or customs brokers to navigate the import process smoothly.

10. How to manage language barriers and communication?

Use clear, concise language and confirm understanding through written agreements. Employ translators or local agents if necessary.

These guidelines can help streamline the sourcing and manufacturing process, ensuring you get high-quality CNC wood carving machines from China.