Technology and Applications of cost of sheet metal

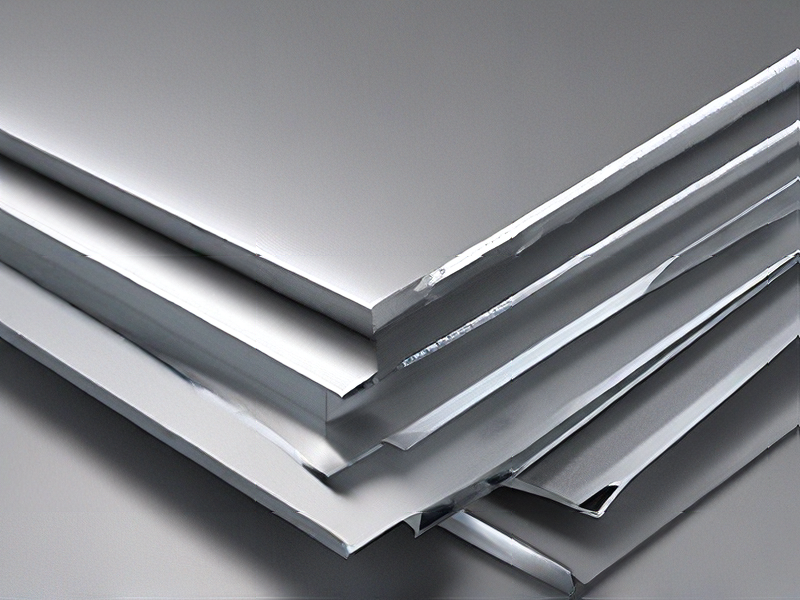

The cost of sheet metal is influenced by various factors, including material type, thickness, dimensions, and finishing processes. Common materials like steel, aluminum, and stainless steel each have distinct cost profiles, with steel generally being more affordable than stainless steel due to its composition. Aluminum, while lighter, tends to be more expensive than steel.

The thickness of the sheet metal also plays a significant role in cost, as thicker sheets require more material and energy for fabrication. Thinner sheets are cheaper but may lack strength for certain applications. Additionally, the size and dimensions of the sheets affect costs due to material usage and handling during production.

Production processes such as cutting, bending, welding, and finishing add to the overall cost. Precision cutting methods like laser cutting are more expensive but offer higher accuracy, while simpler methods like shearing are more cost-effective for basic shapes. Bending and forming operations also contribute to costs, especially for complex geometries.

Surface finishing, such as painting, powder coating, or anodizing, enhances aesthetics and durability but adds to the final cost. These finishes protect against corrosion and wear, making them essential for outdoor or high-visibility applications.

In summary, the cost of sheet metal is determined by material selection, thickness, size, fabrication processes, and finishing options. Each decision point involves trade-offs between cost, strength, and aesthetics, influencing the suitability of sheet metal for various industrial and commercial applications.

Quality Testing Methods for cost of sheet metal and how to control quality

Quality Testing Methods for Sheet Metal Costs

1. Material Certification and Verification:

– Supplier Certification: Ensure suppliers provide material certifications verifying the type, grade, and properties of the sheet metal.

– Incoming Inspection: Verify material specifications through random sampling and testing upon receipt.

2. Dimensional Inspection:

– Calipers and Micrometers: Measure thickness, length, and width to ensure compliance with specifications.

– Coordinate Measuring Machines (CMM): Provide high-precision measurements for complex geometries.

3. Visual Inspection:

– Surface Finish: Check for defects such as scratches, dents, and corrosion.

– Edges and Corners: Ensure edges are smooth and free of burrs or sharp edges that could affect quality.

4. Non-Destructive Testing (NDT):

– Ultrasonic Testing: Detect internal flaws or inconsistencies in the sheet metal without causing damage.

– Eddy Current Testing: Identify surface and near-surface defects.

5. Mechanical Testing:

– Tensile Testing: Assess the metal’s strength and ductility.

– Hardness Testing: Measure resistance to deformation using methods like Rockwell or Vickers hardness tests.

Quality Control Measures

1. Standard Operating Procedures (SOPs):

– Develop and follow detailed SOPs for each stage of production, from material selection to final product inspection.

2. Training and Certification:

– Ensure that personnel are properly trained and certified to perform quality inspections and tests.

3. Regular Audits and Reviews:

– Conduct regular audits of the manufacturing process and review quality control procedures to identify and rectify any deficiencies.

4. Statistical Process Control (SPC):

– Implement SPC to monitor and control the manufacturing process through statistical methods, ensuring consistent quality and identifying variations.

5. Continuous Improvement:

– Foster a culture of continuous improvement using methodologies such as Six Sigma or Lean Manufacturing to reduce defects and optimize processes.

By combining thorough testing methods with robust quality control measures, the cost and quality of sheet metal can be effectively managed and maintained.

Tips for Procurement and Considerations when Purchasing from cost of sheet metal

When procuring sheet metal, several considerations can optimize cost-effectiveness and quality:

1. Material Specifications: Understand the specific requirements of your project in terms of material type, thickness, and finish. Choosing the right grade of sheet metal ensures durability and performance.

2. Supplier Selection: Research and select suppliers based on reputation, reliability, and cost competitiveness. Consider their ability to meet deadlines and provide consistent quality.

3. Quantity and Lead Time: Bulk purchasing often reduces unit costs. However, balance this with storage capabilities and cash flow. Ensure suppliers can meet your required delivery schedules.

4. Quality Assurance: Insist on certifications and quality standards adherence from suppliers. This guarantees consistency and compliance with your project’s specifications.

5. Transportation and Logistics: Factor in shipping costs, especially for large or bulky orders. Optimize logistics to minimize transit times and potential damage.

6. Cost Transparency: Ensure clarity on pricing, including any additional fees or surcharges. Request detailed quotes and negotiate where possible to secure competitive pricing.

7. Supplier Relationships: Cultivate strong relationships with suppliers for potential discounts, improved service, and priority during high-demand periods.

8. Environmental Impact: Consider the environmental footprint of your procurement choices. Opt for suppliers with sustainable practices where feasible.

9. Risk Management: Have contingency plans for supply chain disruptions or quality issues. Diversify suppliers or maintain safety stock for critical projects.

10. Feedback and Improvement: Gather feedback post-purchase to refine procurement strategies continually. Learn from any challenges or successes encountered.

By integrating these considerations into your procurement strategy, you can effectively manage costs while ensuring high-quality sheet metal for your projects.

FAQs on Sourcing and Manufacturing from cost of sheet metal in China

FAQs on Sourcing and Manufacturing Sheet Metal in China

1. What are the typical costs of sheet metal in China?

The cost of sheet metal in China varies based on material type, thickness, and volume. Generally, prices range from $500 to $800 per ton for common materials like stainless steel, aluminum, and galvanized steel.

2. How do I find reliable suppliers?

To find reliable suppliers, use platforms like Alibaba, Made-in-China, or Global Sources. Look for verified suppliers, check reviews, request samples, and perform factory audits if possible.

3. What are the benefits of sourcing sheet metal from China?

China offers competitive pricing, a wide range of material options, advanced manufacturing capabilities, and large-scale production facilities, which can lead to cost savings and high-quality products.

4. What are the challenges of sourcing from China?

Challenges include language barriers, quality control issues, longer lead times, and potential trade tensions. Effective communication and robust quality assurance processes are essential to mitigate these risks.

5. How can I ensure the quality of the sheet metal?

Ensure quality by requesting material certificates, performing third-party inspections, visiting factories, and setting clear specifications and quality standards in purchase agreements.

6. What are the shipping options and costs?

Shipping options include sea freight (most cost-effective for large volumes) and air freight (faster but more expensive). Shipping costs depend on the shipment size, weight, and destination. Sea freight can range from $50 to $200 per cubic meter.

7. What are the import duties and taxes?

Import duties and taxes vary by country. In the U.S., for example, tariffs on sheet metal products can range from 0% to 25%, depending on the material and product classification. Check with a customs broker for specific rates.

8. How long does it take to receive an order?

Lead times vary but typically range from 30 to 60 days, including production and shipping. Expedited production and shipping can reduce this time but will increase costs.

9. What payment methods are accepted?

Common payment methods include T/T (bank transfer), L/C (letter of credit), and PayPal. Terms usually involve a deposit (30-50%) with the balance paid upon shipment.

10. How do I handle logistics and customs clearance?

Hiring a freight forwarder can simplify logistics and customs clearance. They handle shipping, documentation, and coordination with customs authorities to ensure smooth delivery.

By considering these FAQs, you can make informed decisions when sourcing and manufacturing sheet metal from China.