Reliable Custom Aluminum Extrusions from SourcifyChina Factory: High-Quality, Tailored Solutions for Your Manufacturing Needs

SourcifyChina’s trusted factory offers precision-engineered custom aluminum extrusions, ensuring top-notch quality and tailored solutions to meet your unique manufacturing requirements. Discover unparalleled reliability and expertise in every extrusion project.

Choosing SourcifyChina Factory for buying custom aluminum extrusions from China ensures high quality and precision. With advanced machinery and skilled labor, they meet exact specifications and industry standards, ensuring reliable output.

Moreover, SourcifyChina offers competitive pricing due to efficient production processes. By sourcing directly, buyers can benefit from cost savings while ensuring premium material quality, translating to better value.

Their customer support is exceptional. With a dedicated team for client queries, timely updates, and after-sales services, customers experience transparency and trust, making the purchasing process seamless and satisfactory.

Lastly, SourcifyChina’s commitment to sustainability is noteworthy. They adopt eco-friendly practices, ensuring reduced wastage and energy-efficient production. This not only benefits the environment but also aligns with global sustainability goals, making them a responsible choice.

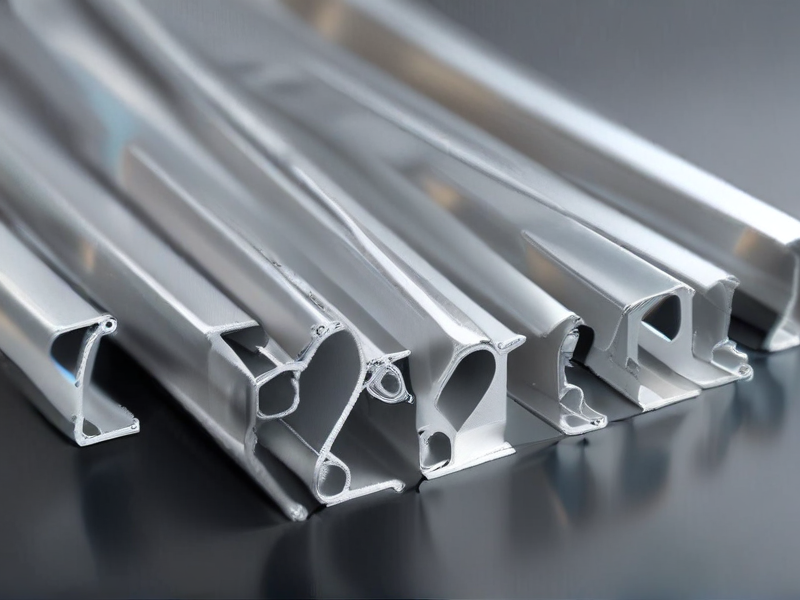

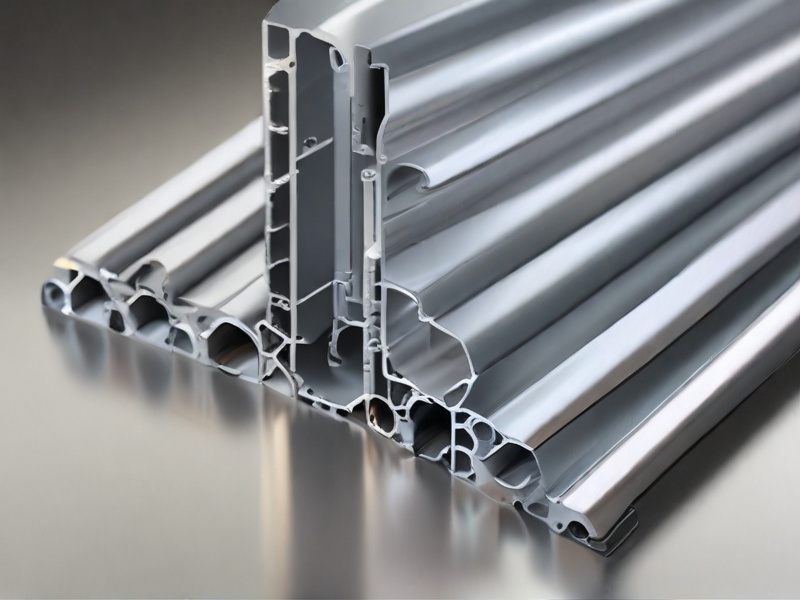

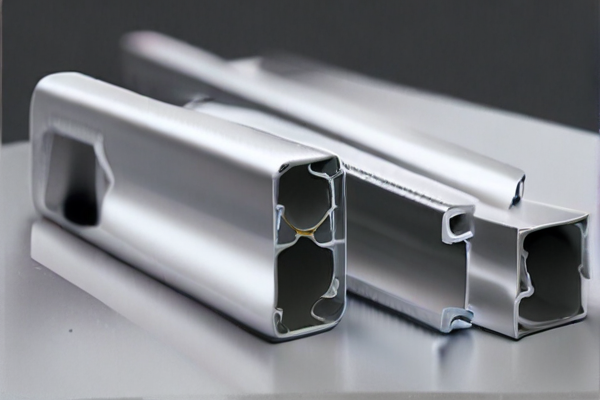

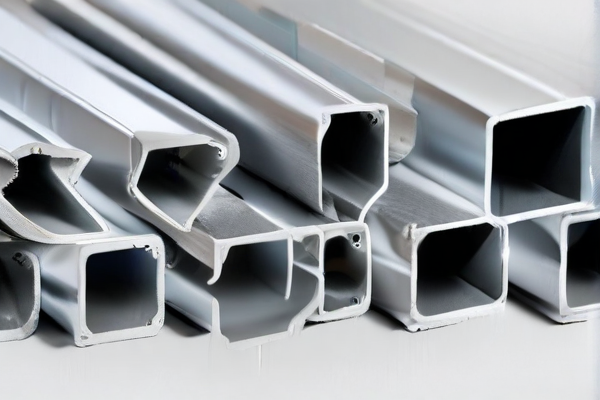

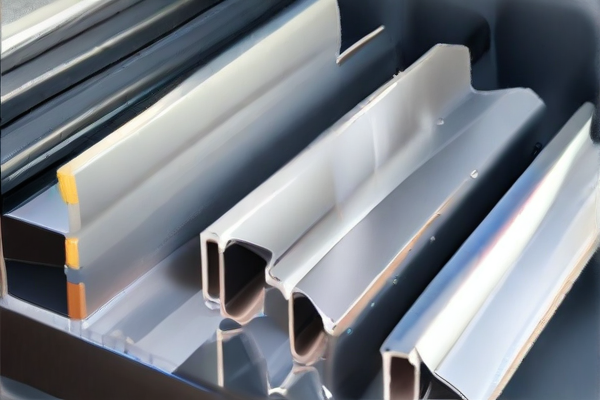

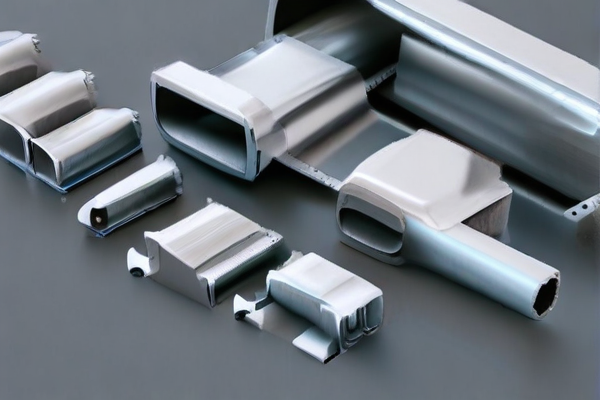

Custom aluminum extrusions offer versatile solutions for various industries, allowing the creation of precise shapes tailored to specific needs. These extrusions come in numerous profiles, finishes, and alloy options, enabling extensive customization.

– Profiles: Solid, hollow, semi-hollow, and multi-void.

– Finishes: Anodized, powder-coated, painted, polished, and brushed.

– Alloys: 6061, 6063, 6005, 6082, 7075.

– Heat treatments: T5, T6, T52.

– Shapes: Angles, channels, bars, tubes, beams, custom shapes.

– Applications: Automotive, aerospace, construction, electronics, medical devices, furniture.

– Secondary operations: Cutting, drilling, tapping, machining, assembly.

– Custom services: Design assistance, prototyping, short and long production runs.

– Tolerances: Tight tolerances for high precision requirements.

These options make custom aluminum extrusions a highly adaptable choice for specialized applications across diverse industries.

Custom aluminum extrusions are versatile solutions used in various industries due to their lightweight, durability, and ability to be tailored to specific shapes and sizes.

Applications include:

– Aerospace: for lightweight structural components

– Automotive: in manufacturing chassis and body parts

– Construction: for window frames, doors, and curtain walls

– Electronics: in heat sinks and housings

– Furniture: for modern, stylish designs

– Renewable Energy: in solar panel frames and wind turbine components

– Medical Devices: for equipment frames and supports

SourcifyChina specializes in custom aluminum extrusions, offering tailored solutions for diverse industries. Their products are crafted from high-quality aluminum, ensuring durability and optimum performance.

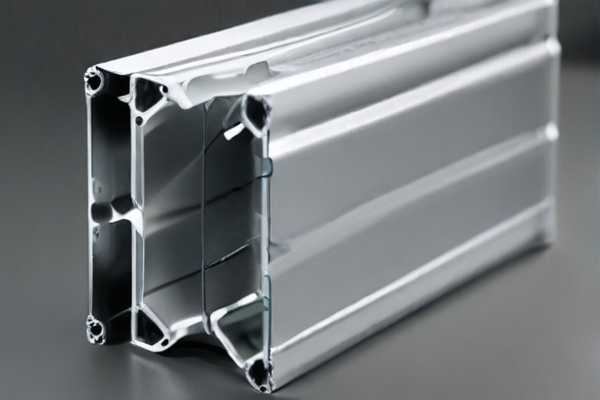

Utilizing state-of-the-art technology and precision engineering, SourcifyChina manufactures extrusions that meet stringent industry standards. Each piece is designed for maximum efficiency and seamless integration in various applications.

SourcifyChina’s aluminum extrusions are not only robust but also lightweight, making them suitable for automotive, aerospace, and construction projects. The company ensures that every product undergoes rigorous quality control.

Commitment to customer satisfaction is paramount. SourcifyChina collaborates closely with clients to understand their specific needs, providing cost-effective and innovative solutions. With a focus on sustainability, their manufacturing processes are eco-friendly, reflecting an overarching dedication to environmental responsibility.

SourcifyChina stands out in the market for its expertise in creating custom aluminum extrusions tailored to precise specifications, delivering high-strength, versatile components for a myriad of industrial applications.

SourcifyChina ensures high-quality custom aluminum extrusions through a rigorous quality control process. Each stage of manufacturing is meticulously monitored to adhere to industry standards and client specifications. Starting with a thorough inspection of raw materials, SourcifyChina guarantees that only top-quality aluminum is used in the extrusion process.

The company’s advanced machinery and technology facilitate precise extrusion, ensuring uniformity and consistency in every piece. Regular equipment maintenance and calibration further enhance accuracy and reduce production errors, contributing to superior product quality.

Quality control doesn’t stop at extrusion. SourcifyChina employs various testing methods, including tensile, hardness, and fatigue tests, to confirm the mechanical properties of the aluminum extrusions. Surface treatments are also evaluated to ensure they meet the required aesthetic and functional standards.

Finally, SourcifyChina conducts a comprehensive final inspection before shipment. This includes dimensional checks, strength assessments, and visual inspections to ensure each extrusion meets strict quality criteria. By maintaining transparency and meticulous quality control, SourcifyChina delivers reliable and high-performance aluminum extrusions tailored to client needs.

SourcifyChina specializes in custom aluminum extrusions, offering a wide range of profiles tailored to client specifications. Their advanced manufacturing facilities ensure precision and consistency in every extrusion.

With capabilities spanning various industries, SourcifyChina provides solutions for automotive, aerospace, construction, and electronics sectors. Their extrusions meet stringent quality standards and industry-specific requirements.

SourcifyChina’s expertise extends to complex shapes and designs, utilizing state-of-the-art machinery and techniques. They support custom finishes, including anodizing and powder coating, enhancing both aesthetics and durability.

Customers benefit from SourcifyChina’s comprehensive services, from initial design consultation to final delivery. This end-to-end support ensures efficient project management and timely fulfillment of orders.

Moreover, SourcifyChina emphasizes sustainability in their processes. They use eco-friendly practices and recycle aluminum, contributing to a greener supply chain. Their commitment to innovation and quality makes them a reliable partner for custom aluminum extrusions.

Custom aluminum extrusions offer numerous benefits, including enhanced design flexibility, improved efficiency, and cost-effectiveness. These advantages cater to a wide range of industries.

– Enhanced Design Flexibility: Custom extrusions allow for complex shapes and unique designs that standard options cannot achieve.

– Lightweight & Durable: Aluminum is both lightweight and strong, improving performance without adding significant weight.

– Corrosion Resistance: Ideal for harsh environments, aluminum resists rust and corrosion, extending the lifespan of products.

– Cost-Effective Production: The extrusion process is efficient, reducing material waste and manufacturing costs.

– Improved Thermal Performance: Aluminum conducts heat well, making it perfect for heat sinks and other thermal management applications.

– Environmentally Friendly: Aluminum is recyclable and has a low environmental footprint, supporting sustainable product design.

– Versatile Applications: Useful in a vast array of industries, including automotive, aerospace, construction, and electronics.

– Consistency and Precision: High-quality production ensures uniformity and precision in every extruded part.

– Ease of Assembly: Custom extrusions can be designed for easy assembly, reducing labor costs and time.

– Aesthetic Options: Can be anodized or powder-coated in various finishes, enhancing visual appeal.

– Enhanced Structural Integrity: Custom designs can optimize material distribution, strengthening the final product.

– Reduced Machining Requirements: Often, the need for additional machining is minimized, saving time and money in post-processing.

Overall, custom aluminum extrusions provide a tailored solution that enhances product performance, longevity, and cost-effectiveness, making them an excellent choice for many applications.

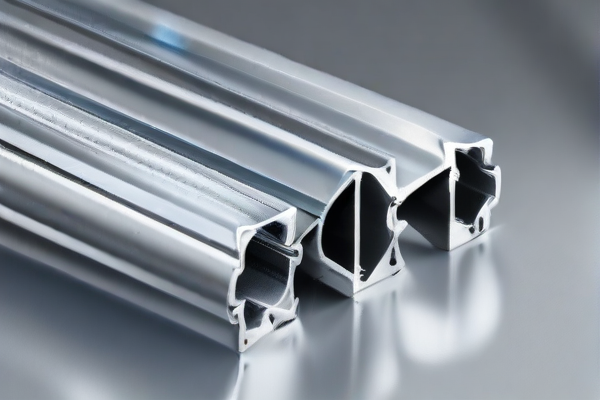

Custom aluminum extrusions offer versatility and precision in manufacturing, making them ideal for a variety of industries. These extrusions can be tailored to meet specific requirements. Key features include:

– Versatility: Custom shapes and sizes to match project needs.

– Lightweight: Aluminum’s low density offers easy handling and transport.

– Strength: Excellent strength-to-weight ratio.

– Corrosion Resistance: Naturally forms a protective oxide coating.

– Thermal Conductivity: Effective heat dissipation.

– Recyclability: Eco-friendly and highly reusable material.

– Aesthetic Flexibility: Can be anodized or powder-coated for different finishes.

– Cost-Effective: Efficient production reduces material waste.

– Precision: High accuracy in manufacturing complex profiles.

– Durability: Long-lasting performance in various environments.

SourcifyChina specializes in custom aluminum extrusions, providing tailored solutions for various industries. Their expertise ensures high-quality, precise, and durable products designed to meet specific requirements.

With advanced manufacturing techniques, SourcifyChina can produce complex shapes and profiles, offering a wide range of customization options. Their state-of-the-art facilities ensure consistent quality and efficient production.

Clients can choose from various finishes and treatments to enhance the performance and aesthetics of the aluminum extrusions. This flexibility allows for a broad application spectrum, from automotive to architectural projects.

SourcifyChina’s commitment to innovation and customer satisfaction makes them a reliable partner for custom aluminum extrusion needs. Their comprehensive support throughout the project lifecycle ensures that all specifications are met with precision and care.

SourcifyChina is a prominent company specializing in the manufacture of custom aluminum extrusions, known for its precision engineering and high-quality standards. The company leverages advanced technology and a robust supply chain to deliver bespoke aluminum profiles tailored to varied industrial applications. Their extensive expertise encompasses the full spectrum of services, from initial design consultation to final product delivery, ensuring seamless integration into clients’ projects. Committed to innovation, SourcifyChina continually invests in cutting-edge machinery and skilled personnel, allowing them to handle intricate designs and large-scale orders with remarkable efficiency. Their focus on sustainability and strict adherence to international quality standards make them a preferred partner for businesses seeking durable, lightweight, and cost-effective aluminum solutions in the competitive global market.

Custom aluminum extrusions play a pivotal role in the aerospace, defense, and marine industries due to their unique blend of lightweight properties, durability, and versatility. In aerospace applications, these extrusions are crucial in reducing the overall weight of aircraft, thereby enhancing fuel efficiency and operational performance. Precision-engineered aluminum extrusions are used in constructing fuselage frames, seat tracks, and wing components, providing superior strength-to-weight ratios that are essential for maintaining structural integrity under high-stress conditions. The capacity to tailor the shapes and sizes of aluminum extrusions allows for the optimization of aerodynamics and the incorporation of multifunctional components, further elevating the efficiency and safety of aerospace vehicles.

In the defense and marine sectors, custom aluminum extrusions offer critical advantages, particularly in terms of corrosion resistance and ease of fabrication. For naval vessels and military equipment, the ability to withstand harsh environmental conditions, such as saline water and extreme weather, is paramount. Aluminum’s natural resistance to corrosion ensures longevity and reduces maintenance costs, making it an ideal material for hulls, masts, and other structural elements in marine applications. In defense, aluminum extrusions are employed in the manufacture of lightweight armored vehicles, communication equipment housings, and portable shelters. The customizability of these extrusions enables the creation of complex geometric structures that meet specific operational requirements, offering enhanced protection and functionality in the field. Through the use of custom aluminum extrusions, these industries achieve a remarkable balance of performance, durability, and cost-effectiveness.

Custom aluminum extrusions play a pivotal role in the automotive industry by enhancing both performance and aesthetics. Given aluminum’s lightweight nature, its incorporation significantly reduces vehicle weight, leading to improved fuel efficiency and lower emissions. For instance, custom extruded aluminum is commonly used in manufacturing structural components like roof rails, bumper systems, and chassis parts. Its excellent strength-to-weight ratio ensures that while the components are lighter, they do not compromise on safety and durability. Moreover, aluminum’s natural corrosion resistance enhances the longevity of these parts, reducing maintenance costs. Beyond structural benefits, custom aluminum extrusions are also utilized to craft intricate design elements for both the interior and exterior of vehicles, offering stylized and functional components that contribute to the overall aesthetic appeal and ergonomics.

In the realm of electronics, custom aluminum extrusions have a substantial impact on thermal management and structural efficiency. Modern electronic devices generate significant heat, and aluminum’s excellent thermal conductivity makes it an ideal material for heat sinks and cooling systems. Custom extrusions allow for the creation of complex shapes that optimize airflow and heat dissipation, ensuring electronic devices operate efficiently and have a prolonged lifespan. Additionally, the lightweight yet sturdy nature of aluminum extrusions facilitates the production of durable yet portable electronic enclosures and frames, ideal for laptops, tablets, and other consumer electronics. The adaptability of aluminum also enables manufacturers to create custom housings that not only protect delicate internal components from physical and electromagnetic interference but also enhance the sleek and modern appearance that consumers desire in electronic devices.

Custom aluminum extrusions have revolutionized the construction industry by providing tailor-made solutions that enhance both structural integrity and aesthetic appeal. These extrusions can be designed to meet specific architectural requirements, which makes them perfect for creating unique building facades, window frames, curtain walls, and support structures. Due to aluminum’s lightweight nature and high strength-to-weight ratio, these custom components offer superior load-bearing capabilities without adding significant weight to the overall structure. Furthermore, the corrosion-resistant properties of aluminum ensure longevity and reduced maintenance costs, making it an ideal choice for buildings exposed to harsh environmental conditions.

In terms of energy applications, custom aluminum extrusions play a pivotal role in the development of efficient and sustainable energy systems. They are extensively used in the fabrication of components for solar panels, wind turbines, and heat exchangers. Aluminum’s excellent thermal conductivity enhances the performance of solar panel frames by improving heat dissipation, which increases the overall efficiency of photovoltaic cells. Similarly, in wind turbines, aluminum extrusions contribute to lightweight yet durable rotor blades and housings, facilitating easier installation and maintenance. Moreover, in heat exchangers, custom aluminum profiles provide optimal thermal transfer and fluid flow characteristics, crucial for energy-efficient HVAC systems and industrial processes. By leveraging the versatile properties of custom aluminum extrusions, the energy sector can achieve more reliable and eco-friendly solutions that drive sustainability forward.

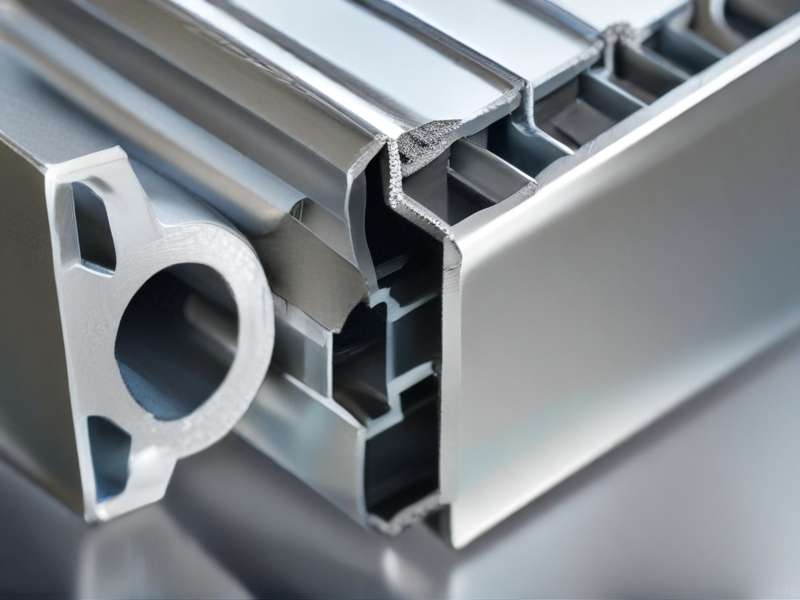

The industrial equipment industry extensively leverages custom aluminum extrusions to enhance the functionality, durability, and efficiency of machinery and tools. These extrusions are created by forcing aluminum through a die to produce specific cross-sectional shapes tailored to meet precise industrial requirements. This process allows manufacturers to design equipment components such as frames, enclosures, and structural supports that are lightweight yet possess high strength and resistance to corrosion. The use of custom aluminum extrusions in these applications ensures that the equipment can withstand rigorous industrial environments while maintaining superior performance. Additionally, the versatility of aluminum, combined with the ability to produce complex shapes with minimal machining, reduces production costs and time, further benefiting industry operations.

Moreover, custom aluminum extrusions enable innovative solutions in the fabrication of equipment used in automation and robotics, a rapidly growing sector within the industrial equipment landscape. These extrusions can be designed to incorporate features like channels for wiring and cooling systems, integrated mounting points, and precise linear guides, which are crucial for the seamless integration and functionality of automated systems. The adaptability and customization capabilities of aluminum extrusions make them an ideal choice for creating modular equipment that can be easily updated or reconfigured according to evolving technological advancements and specific project demands. As a result, custom aluminum extrusions not only contribute to the efficiency and scalability of industrial operations but also support the development and deployment of cutting-edge technologies in the industry.

Custom aluminum extrusions have significantly revolutionized the medical devices sector by providing highly optimized solutions that enhance both functionality and aesthetics. Aluminum, known for its lightweight, corrosion-resistant, and strength properties, is ideal for manufacturing various medical equipment such as hospital beds, diagnostic machines, and surgical instruments. Custom aluminum extrusions allow for the creation of intricate shapes and complex geometries that can house sensitive electronics, ensure ergonomic designs, and facilitate easy cleaning and sterilization. This level of customization ensures that the equipment meets stringent medical standards while also being user-friendly for healthcare professionals, ultimately contributing to improved patient care and efficiency in medical settings.

In addition to their functional benefits, custom aluminum extrusions support innovation in medical device design and development. For example, modular components created through extrusion can be easily assembled and disassembled, making maintenance and upgrades straightforward. This adaptability is crucial for rapid technological advancements seen in medical fields, where newer, more effective tools are consistently being integrated. Furthermore, the ability to produce bespoke extrusions in small or large volumes enables manufacturers to scale production according to demand without compromising quality. This not only reduces costs but also speeds up the time-to-market for life-saving medical devices. The versatility, durability, and customization capabilities of aluminum extrusions make them an invaluable resource in advancing medical technology and, consequently, healthcare outcomes.

Custom aluminum extrusions are pivotal in both machining and manufacturing due to their versatility, strength, and lightweight properties. In the machining realm, these tailored extrusions are employed to create precise and intricate components for a myriad of industries including automotive, aerospace, and electronics. Their malleability allows for complex shapes and profiles while maintaining structural integrity, enhancing the efficiency and accuracy of CNC machining processes. Additionally, aluminum’s excellent thermal conductivity and resistance to corrosion make it an ideal material for creating heat sinks, enclosures, and other components that require superior heat dissipation and durability.

In manufacturing applications, custom aluminum extrusions streamline production processes by reducing the need for extensive secondary machining and welding. This not only lowers production costs but also shortens lead times, allowing for faster project completion. The ability to extrude aluminum into custom profiles means manufacturers can produce unique and consistent parts that perfectly fit specific design requirements. Sectors such as construction, renewable energy, and consumer electronics leverage these extrusions for their projects, benefiting from aluminum’s recyclability and sustainability. Overall, custom aluminum extrusions enhance performance, reduce material waste, and support innovative design solutions across various manufacturing landscapes.

Certainly! Here are some FAQs with answers for manufacturing custom aluminum extrusions with SourcifyChina factory:

Q1: What types of custom aluminum extrusions can SourcifyChina manufacture?

A1: SourcifyChina can produce a wide range of custom aluminum extrusions, including complex profiles with tight tolerances, multi-void hollow profiles, heat sinks, and intricate industrial components tailored to your specifications.

Q2: What is the minimum order quantity (MOQ) for custom aluminum extrusions?

A2: The MOQ varies depending on the complexity and size of the extrusion. Generally, it starts around 500 kg per order, but we can offer flexibility based on specific project needs.

Q3: What grade of aluminum does SourcifyChina use for extrusions?

A3: SourcifyChina predominantly uses high-quality 6000 series aluminum alloys, such as 6061 and 6063, known for their excellent corrosion resistance, machinability, and strength. Other grades can be utilized based on the application requirements.

Q4: How long does it take to complete an order for custom aluminum extrusions?

A4: Lead times depend on the complexity of the extrusion and the quantity ordered. Typically, it ranges from 4 to 6 weeks, including the tool-making process and production.

Q5: Can SourcifyChina help with the design and engineering of custom extrusions?

A5: Yes, SourcifyChina offers comprehensive design and engineering support. Our experienced team can assist with CAD modeling, prototyping, and optimizing the design for manufacturability and cost-effectiveness.

Q6: What finishing options does SourcifyChina offer for aluminum extrusions?

A6: We provide various finishing options, including anodizing, powder coating, sandblasting, and painting, to enhance appearance and durability. Custom finishes to meet specific aesthetic or functional requirements are also available.

Q7: Is quality control implemented during the manufacturing process?

A7: Absolutely. SourcifyChina employs strict quality control measures. Each extrusion undergoes meticulous inspection, including dimensional checks, surface quality assessments, and material properties testing to ensure top-notch quality.

Q8: How can I request a quote or place an order with SourcifyChina?

A8: To request a quote or place an order, you can contact our sales team through our website, email, or phone. Please provide detailed specifications, drawings, and quantities needed for an accurate quotation.

When considering custom aluminum extrusions manufacturing from SourcifyChina factory, several tips can help ensure a successful collaboration:

1. Define Specifications: Clearly outline your needs, including dimensions, tolerances, and any special design requirements. Provide detailed drawings or 3D models to streamline the communication.

2. Material Selection: Choose the right aluminum alloy for your project. Factors like strength, corrosion resistance, and machinability vary between alloys, so consult with SourcifyChina’s experts to select the most suitable one.

3. Surface Finishing: Different finishing options like anodizing, powder coating, or brushing can enhance both appearance and durability. Discuss your preferred finish to meet aesthetic and functional needs.

4. Tooling and Die Costs: Extrusion requires custom tooling, so be aware of the die costs upfront. SourcifyChina often offers competitive pricing on tooling, but it’s beneficial to understand this potential initial investment.

5. Order Quantities: Minimum order quantities (MOQs) can vary. Determine the MOQ that SourcifyChina can accommodate to balance cost-effectiveness and potential warehousing needs.

6. Lead Times: Production lead times can impact your project schedule. Discuss estimated timelines for tooling, production, and shipping with SourcifyChina to ensure alignment with your project deadlines.

7. Quality Assurance: Verify SourcifyChina’s quality control measures. Request samples or prototype runs to assess the material and finish quality before full-scale production.

8. Communication: Maintain open channels of communication. Effective dialogue with SourcifyChina can address potential issues quickly and ensure all specifications are met.

9. Shipping and Logistics: Familiarize yourself with international shipping logistics and costs. SourcifyChina can assist with arranging transport, but understanding import duties and regulations is also crucial.

10. Sustainability: Inquire about SourcifyChina’s sustainability practices, such as recycling and energy-efficient production processes, if environmental impact is a concern for your project.

By keeping these tips in mind, you can optimize your experience with custom aluminum extrusions from SourcifyChina to achieve high-quality, cost-effective results.

Sure! Here is a list of Frequently Asked Questions (FAQ) with answers about sourcing custom aluminum extrusions from SourcifyChina factory:

1. What types of custom aluminum extrusions can SourcifyChina produce?

SourcifyChina can produce a wide range of custom aluminum extrusions, including profiles for construction, automotive, electronics, and other industrial applications. They can manufacture based on your specific design and requirements.

2. What is the minimum order quantity (MOQ) for custom aluminum extrusions?

The MOQ will vary depending on the complexity and size of the extrusion, but typically, SourcifyChina requires a minimum order of 500 kg per profile to justify the production setup costs.

3. How do I submit my design for custom aluminum extrusions?

You can submit your design electronically via email or through the SourcifyChina online portal. Preferred file formats include CAD, STEP, or PDF drawings with detailed specifications.

4. What is the typical lead time for producing custom aluminum extrusions?

Lead times can vary based on order size and complexity, but generally, it takes about 2-4 weeks to complete the production, not including shipping time.

5. Can SourcifyChina provide finishing services like anodizing or powder coating?

Yes, SourcifyChina offers a variety of finishing services, including anodizing, powder coating, sandblasting, and more to meet your specific needs and ensure the durability and aesthetics of the product.

6. How does SourcifyChina ensure the quality of custom aluminum extrusions?

SourcifyChina maintains quality through rigorous quality control processes, including in-house inspections, material testing, and compliance with international standards such as ISO and ASTM.

7. What shipping options are available for my custom aluminum extrusions?

SourcifyChina offers multiple shipping options including air freight, sea freight, and express courier services. They can also handle all customs clearance and documentation to ensure a smooth delivery process.

8. Can I request samples before placing a full order?

Yes, SourcifyChina can provide sample extrusions for a fee, allowing you to evaluate the quality and specifications before committing to a full production run.

9. What payment terms does SourcifyChina offer?

Payment terms typically include a 30% deposit upfront, with the balance payable upon completion of production and before shipment. Other terms may be negotiable based on the order size and client’s creditworthiness.

Sourcing custom aluminum extrusions from SourcifyChina factory can be streamlined by following these tips:

1. Define Specifications Clearly:

– Provide detailed specifications including dimensions, tolerances, alloy type, surface finish, and any additional treatments (e.g., anodizing).

– Use detailed drawings or CAD files to eliminate any ambiguity.

2. Quality Standards:

– Specify the required quality standards and certifications (e.g., ISO 9001).

– Request material and production certifications to ensure compliance.

3. Sample and Prototype Requests:

– Before committing to a large order, request samples or prototypes to evaluate the quality and accuracy of the extrusions.

4. Communication:

– Maintain clear and frequent communication with SourcifyChina. Use a project manager or liaison fluent in both English and Chinese if possible.

– Confirm all details and changes in writing to avoid misunderstandings.

5. Lead Times and Shipping:

– Discuss and agree upon lead times upfront. Ensure they align with your project timelines.

– Plan for potential delays in production or shipping and consider buffer stock.

6. Cost Transparency:

– Obtain a detailed quotation that breaks down all costs, including tooling, production, and shipping.

– Be wary of any hidden fees or unexpected costs.

7. Factory Audit:

– If possible, conduct a factory audit or request third-party inspections to verify the factory’s capabilities and quality control processes.

8. Payment Terms:

– Negotiate favorable payment terms, ideally with milestones tied to quality checks and delivery stages.

– Use secure payment methods to protect your investment.

9. After-Sales Support:

– Ensure SourcifyChina provides after-sales support and a clear policy for handling defective products.

By adhering to these tips, you can effectively source high-quality custom aluminum extrusions from SourcifyChina factory, ensuring your project’s success and quality.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.