When selecting a supplier for custom bolts from China, choosing SourcifyChina Factory ensures access to high-quality products. With a rigorous quality control process, they guarantee bolts that meet international standards, reducing the risk of defects.

SourcifyChina Factory offers competitive pricing without sacrificing quality. Their large-scale production capacity allows them to provide cost-effective solutions for custom bolt manufacturing, ensuring affordability for clients worldwide.

Customer service is a priority at SourcifyChina Factory. They offer personalized support throughout the purchasing process, from initial consultation to post-purchase services. This dedication to customer satisfaction sets them apart in the industry.

Timely delivery is another advantage of partnering with SourcifyChina Factory. Their efficient production and logistics operations ensure that orders are fulfilled on schedule, helping clients meet project deadlines without stress.

Sustainability is embedded in SourcifyChina Factory’s operations. They employ eco-friendly manufacturing practices to minimize their environmental impact, giving buyers confidence that their purchase decisions support responsible business practices.

In conclusion, choosing SourcifyChina Factory for purchasing custom bolts from China combines quality, affordability, exceptional customer service, timely delivery, and sustainability. These factors make them a reliable and attractive option for buyers looking for customized manufacturing solutions in a competitive market.

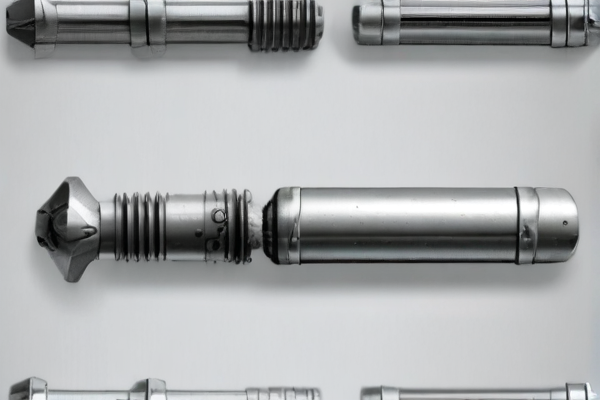

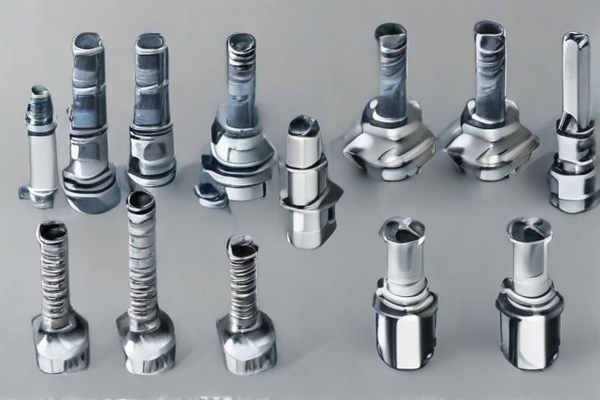

Custom bolts come in various types and options to suit specific applications, ensuring optimal performance and compatibility. They are tailored in terms of material, size, threading, and coating to meet unique requirements.

– Materials: Stainless steel, titanium, aluminum, alloy steel.

– Sizes: Custom lengths, diameters, and head sizes.

– Threading: Coarse, fine, or custom thread patterns.

– Coatings: Zinc plating, hot-dip galvanizing, anodizing, powder coating.

– Head Types: Hex, socket, square, round, countersunk.

– Grades: Varied strength levels, such as Grade 5, Grade 8, and others.

– Applications: Automotive, aerospace, construction, machinery, marine.

– Special Features: Locking mechanisms, tamper-proof designs, high-temperature resistance.

– Manufacturing Methods: Cold heading, hot forging, CNC machining.

Custom bolts are specifically designed to meet unique requirements that standard bolts cannot fulfill. They are utilized in various industries where precision, strength, and specific material properties are critical.

– Automotive Industry: Custom bolts ensure high performance and reliability in engines and other mechanical components.

– Aerospace: Vital for aircraft construction, custom bolts must withstand extreme conditions and stress.

– Construction: Tailored bolts provide enhanced stability and safety for buildings and infrastructural projects.

– Marine Engineering: Custom bolts resist corrosion and maintain integrity in harsh, salty environments.

– Heavy Machinery: Ensure robust connectivity in high-load and high-vibration conditions.

– Energy Sector: Used in wind turbines, solar panels, and oil rigs for sustainable and secure installations.

– Medical Devices: Precision engineering of bolts is crucial for reliable and safe medical equipment.

– Electronics Manufacturing: Custom bolts fit into compact and uniquely-shaped electronic components.

– Railway Systems: Essential for the construction and maintenance of track infrastructure.

– Military Applications: Custom bolts enhance performance and safety in defense equipment and vehicles.

– Architectural Designs: Allow for innovative structural and aesthetic solutions in modern architecture.

– Mining Operations: Custom bolts withstand abrasive and high-pressure environments underground.

– Renewable Energy Projects: Integral to the assembly and operation of various green energy technologies.

– Sports Equipment: Used in the manufacturing of high-performance, specialized sports gear.

– Agricultural Machinery: Enhance the durability and functionality of farming equipment.

– Robotics: Support the intricate assembly and operation of advanced robotic systems.

– Hydraulics and Pneumatics: Essential for leak-proof and high-strength connections.

– Space Exploration: Custom bolts are designed for the extreme conditions of outer space missions.

– Oil and Gas Industry: Provide secure and durable fittings essential for pipeline and platform integrity.

With these diverse applications, custom bolts play a quintessential role across multiple fields, ensuring that both performance and safety standards are upheld.

SourcifyChina custom bolts are manufactured using high-grade stainless steel, ensuring excellent resistance to corrosion and wear. Stainless steel is a preferred material for bolts due to its durability and longevity, making it ideal for various applications.

Additionally, SourcifyChina offers carbon steel custom bolts, known for their strength and cost-effectiveness. Carbon steel bolts are suitable for heavy-duty applications where high tensile strength is required, providing reliable performance in demanding environments.

For specialized needs, SourcifyChina also provides custom bolts made of alloy steel. This material combines the best properties of multiple metals, resulting in enhanced strength, toughness, and resistance to fatigue and impact.

Titanium is another material option available for custom bolts. Lightweight yet incredibly strong, titanium bolts offer exceptional performance in aerospace and automotive industries where weight reduction is crucial without compromising on strength.

Finally, SourcifyChina’s custom bolts can be crafted from brass, an alloy of copper and zinc. Brass bolts are highly resistant to corrosion and have excellent machinability, making them suitable for both industrial and decorative applications.

In conclusion, SourcifyChina offers a diverse range of materials for custom bolts, including stainless steel, carbon steel, alloy steel, titanium, and brass. Each material choice is tailored to meet the specific requirements of various industries, ensuring optimal performance and reliability.

SourcifyChina’s custom bolts undergo stringent quality control processes to ensure superior durability and reliability. Initially, raw materials are meticulously inspected to comply with industry standards.

During production, advanced machinery and skilled technicians work together to manufacture bolts precisely meeting required specifications. Continuous in-line inspections are performed to detect any deviations early.

Post-manufacturing, each batch of bolts is subjected to rigorous testing. Tests include tensile strength, hardness, and corrosion resistance, ensuring the bolts can withstand demanding environments.

Final inspections involve a thorough visual check and dimensional verification. Each bolt is then serialized for traceability. SourcifyChina’s unwavering commitment to quality guarantees top-notch bolts for various applications.

SourcifyChina specializes in providing custom bolts tailored to meet precise specifications for various industries, including automotive, construction, and aerospace. Their products adhere to strict quality standards, ensuring reliability and durability in critical applications.

Utilizing advanced manufacturing techniques, SourcifyChina produces bolts in an extensive range of materials such as stainless steel, titanium, and specialized alloys. This variety allows for optimal performance in diverse environmental conditions and ensures compatibility with different mechanical requirements.

In addition to material versatility, SourcifyChina offers custom finishes and coatings that enhance corrosion resistance and aesthetic appeal. Clients can select from various plating options, including zinc, chrome, and nickel, ensuring that the bolts meet specific functional and visual criteria.

A key strength of SourcifyChina is its emphasis on precision engineering. The use of state-of-the-art CNC machinery and rigorous quality control processes ensures that each custom bolt meets exacting tolerances and customer specifications. The company also provides full traceability and certification for their products, adding an extra layer of trust and reliability.

Collaborative customer service is another hallmark of SourcifyChina. Their engineering team works closely with clients to understand their unique requirements and provide tailored solutions. This client-focused approach ensures that each project benefits from expert guidance from initial design to final delivery.

Ultimately, SourcifyChina’s custom bolt capabilities are a blend of robust materials, advanced manufacturing, and exceptional customer service. Their ability to deliver high-quality, precisely engineered bolts makes them a trusted partner for businesses seeking reliable fastening solutions.

Custom bolts offer numerous advantages, enhancing the efficiency and reliability of various applications. Below are some key benefits of using custom bolts in different industries.

– Precision Fit: Custom bolts are designed to match specific requirements, ensuring a perfect fit and reducing the likelihood of mechanical failures.

– Enhanced Durability: Made from high-quality materials, custom bolts can withstand extreme conditions, leading to longer-lasting assemblies.

– Optimized Performance: Tailored bolts improve overall system performance by aligning with precise engineering demands.

– Increased Safety: By meeting exact specifications, custom bolts minimize the risk of malfunction or breakdown, promoting a safer operational environment.

– Versatility: Custom options are available for a wide range of applications, making them suitable for diverse industries including automotive, aerospace, and construction.

– Cost-Effective: Although initial costs might be higher, custom bolts reduce maintenance and replacement expenses in the long run.

– Streamlined Production: Using bolts that perfectly fit their applications can speed up the assembly process, reducing downtime and improving productivity.

– Consistency: Custom bolts provide a uniform solution tailored to specific needs, ensuring consistent quality across all units.

– Reduced Inventory: Companies can minimize the stock of different fasteners by using versatile custom bolts, simplifying inventory management.

By opting for custom bolts, businesses can achieve a level of precision and efficiency that standard bolts often fail to deliver, making them a worthy investment for high-quality applications.

Custom bolts are essential components tailored to specific applications, offering unique features that standard bolts may not provide. These features ensure optimal performance, durability, and compatibility with various projects.

– Material Variety: Custom bolts can be made from a wide range of materials, including stainless steel, titanium, and specialized alloys, catering to different environmental and mechanical requirements.

– Precision Engineering: Designed with precise tolerances, custom bolts provide excellent fit and function, reducing the risk of mechanical failures.

– Corrosion Resistance: Special coatings and finishes, such as galvanization or anodization, enhance the longevity of custom bolts by providing superior protection against corrosion.

– Unique Head Styles: Custom bolts can feature various head styles, such as hex, socket, or Torx, to meet specific installation and removal needs.

– Thread Customization: The threads on custom bolts can be tailored to specific applications, including options for coarse, fine, or custom thread patterns.

– Strength Specifications: Custom bolts can be engineered to meet specific strength requirements, ensuring they can withstand the demands of high-stress environments.

– Dimensional Flexibility: They can be produced in various sizes and shapes, fitting into unique geometries and meeting precise dimensional specifications.

– Special Features: Custom bolts can include additional features such as self-locking mechanisms, anti-vibration properties, or custom branding for easy identification.

– Quality Assurance: Custom bolts often undergo rigorous testing and quality control processes to ensure they meet exact standards and specifications.

These tailored features make custom bolts an indispensable choice for industries requiring specific fastening solutions, from aerospace to automotive to heavy machinery. The customization ensures that each bolt performs optimally in its intended application, enhancing overall system reliability and efficiency.

SourcifyChina custom bolts provide unparalleled precision and durability, tailored specifically to meet the diverse needs of various industries. Their extensive range ensures clients can find the perfect fit for any application.

Collaborating with SourcifyChina means leveraging advanced manufacturing techniques and high-quality materials. This guarantees reliable and long-lasting custom bolts that outperform standard options and enhance overall project efficiency.

With a commitment to excellence, SourcifyChina prioritizes client satisfaction through rigorous quality control and exceptional customer service. Their custom bolts are designed to meet strict specifications and withstand demanding conditions.

The versatility of SourcifyChina custom bolts makes them ideal for construction, automotive, and industrial projects. They are crafted to handle specific requirements, ensuring optimal performance and safety.

SourcifyChina also offers comprehensive project management support, from initial design consultation to final production. Clients can rely on their expertise to deliver solutions that are both cost-effective and timely, making them a trusted partner in any endeavor.

In competitive markets, having a partner like SourcifyChina is invaluable. Their custom bolts not only meet industry standards but also surpass expectations, ensuring that project goals are consistently achieved.

SourcifyChina Custom Bolts stands as a premier tailor-made bolt manufacturing company grounded in the industrious landscape of China. Renowned for its precision engineering and unparalleled quality, the company specializes in the production of custom bolts that cater to a diverse array of industries, from construction and automotive to aerospace and heavy machinery. By leveraging advanced manufacturing technologies and stringent quality control processes, SourcifyChina ensures that each bolt not only meets but exceeds global industry standards. Their dedicated team of engineers and industry experts works closely with clients to provide bespoke solutions that align perfectly with specific requirements, ensuring reliability, durability, and peak performance in every application. Additionally, the company’s commitment to sustainable practices and prompt delivery has earned it a reputation as a dependable partner in the global supply chain. Through continuous innovation and customer-focused service, SourcifyChina Custom Bolts remains at the forefront of the bolt manufacturing sector, driving advancements and fostering long-term client relationships around the world.

Custom bolts are crucial in the Aerospace industry, where precision, reliability, and safety are paramount. Aircraft structures, jet engines, and avionics systems all demand fasteners that meet stringent specifications for performance under extreme conditions. Custom bolts can be engineered to withstand high levels of stress, temperature variations, and even corrosion resulting from exposure to various environments. The utilization of materials such as titanium, Inconel, and other high-strength alloys ensures that these bolts can endure the mechanical demands and corrosive atmospheres encountered at high altitudes. Additionally, custom bolts often incorporate unique thread designs and locking mechanisms to prevent loosening due to vibration, a common issue in aviation.

In the Defense and Marine sectors, custom bolts are equally vital for maintaining the structural integrity and operational effectiveness of vehicles, equipment, and vessels. Defense applications span from armored vehicles to missile systems, where the need for bolts that can handle explosive forces and high levels of wear and tear is critical. Custom bolts designed for these purposes often feature specialized coatings or treatments that enhance their durability and resistance to elements such as saltwater, sand, and other harsh conditions encountered in combat environments. In Marine applications, custom bolts are used extensively in submarines, ships, and offshore structures where resistance to corrosion from seawater and biofouling is incredibly important. These bolts are engineered to provide a secure and reliable fastening solution, ensuring the long-term stability and safety of marine constructions and vehicles amid challenging and variable maritime conditions.

Custom bolts serve an indispensable role in the automotive industry, providing the necessary strength and precision needed for the assembly and performance of vehicles. From securing the engine components to fastening chassis parts, these specialized bolts are designed to meet exact specifications, ensuring safety and reliability. Automotive applications often demand bolts that can withstand high torque, vibration, and extreme temperatures. Custom bolts are engineered to address these challenges by using advanced materials such as high-tensile steel or titanium alloys and incorporating unique threads or head designs. This customization not only enhances the durability of the vehicle components but also contributes significantly to the efficiency and longevity of the automotive system.

In the realm of electronics, custom bolts are equally crucial, especially in securing delicate and sensitive devices. Given the intricate nature of electronic assemblies, these bolts are designed with precision to avoid damaging circuit boards or other critical components. Applications range from securing printed circuit boards (PCBs) in computing devices to fastening intricate parts in home electronics and industrial machinery. Custom bolts in electronics often feature coatings and materials that provide insulation and corrosion resistance, ensuring that the electrical conductivity or performance is not compromised. Additionally, the miniaturization trend in electronics demands bolts with smaller dimensions but higher strength and reliability, a requirement that custom bolts are adept at fulfilling. By fitting snugly and securely, custom bolts help in maintaining the integrity and functionality of electronic devices across a wide array of applications.

Custom bolts play an indispensable role in the construction industry, providing tailored solutions that meet specific structural requirements and ensuring the durability and safety of buildings. In construction, standard bolts might not always fit the unique needs of a particular project, such as connecting steel beams in a high-rise building or securing the joints in bridges. Custom bolts offer the flexibility to specify exact dimensions, materials, and thread types, thereby enhancing the integrity of critical connections. For example, in seismic retrofit projects, custom bolts can be designed to withstand substantial stress and resist corrosion, ensuring that structures remain secure even during earthquakes. Furthermore, the use of custom bolts in construction can streamline the assembly process, reducing the need for on-site modifications and leading to faster project completion times.

In the energy sector, custom bolts are crucial for ensuring the reliability and efficiency of various applications, from wind turbines to oil rigs. For instance, in renewable energy installations like wind farms, the bolts must endure extreme weather conditions and significant mechanical loads. Custom bolts can be engineered from high-strength alloys to provide the necessary durability, preventing mechanical failure that could lead to costly downtime or catastrophic damage. Additionally, in the oil and gas industry, where equipment often operates under high pressure and corrosive environments, custom bolts can be fabricated to meet stringent specifications for safety and performance. These bolts are integral in assembling and maintaining critical infrastructure such as pipelines, drilling rigs, and refineries, ensuring continuous and safe energy production. Overall, the adaptability and precision of custom bolts make them an essential component in optimizing both the performance and longevity of energy systems.

Custom bolts play a critical role in the industrial equipment industry by providing tailored solutions that standard bolts cannot offer. These bolts are engineered to meet specific requirements regarding size, material, strength, and threading to ensure optimal performance and safety in demanding applications. For instance, in heavy machinery and construction equipment, custom bolts are designed to withstand extreme stresses and harsh environments, thereby enhancing the reliability and longevity of the equipment. The customization process can include selecting materials that resist corrosion, high temperatures, or other environmental factors, making these bolts indispensable for industries such as oil and gas, mining, and aerospace.

Moreover, the use of custom bolts in the industrial equipment sector facilitates the design and manufacture of innovative machinery and structures. Engineers can specify bolts that precisely fit the unique dimensions and load-bearing requirements of their projects, leading to improved efficiency and functionality. This level of customization also helps in maintaining equipment, as custom bolts can be designed for easy installation and removal, reducing downtime during repairs and maintenance. By aligning bolt specifications with the exact needs of industrial applications, custom bolts not only enhance performance but also contribute to cost savings by reducing the frequency of part replacements and minimizing the risk of equipment failure.

Custom bolts are integral to the medical devices industry, serving as critical components that facilitate the assembly and functionality of numerous medical instruments and equipment. Unlike standard bolts, custom bolts are meticulously designed and manufactured to meet the specific requirements of medical devices, ensuring enhanced precision, reliability, and performance. They are often used in complex medical apparatus such as surgical robots, MRI machines, and prosthetic devices, where exact tolerances and material compatibility are paramount. For instance, in surgical robots, the custom bolts must withstand repeated sterilization processes and maintain their structural integrity under high-stress conditions. Their unique specifications help in minimizing microbial contamination and ensuring that the devices operate flawlessly, which is crucial for patient safety and successful medical outcomes.

Furthermore, custom bolts in medical devices are frequently made from biocompatible materials such as titanium and stainless steel, which are essential for preventing adverse reactions in patients. In the realm of prosthetics, for example, custom bolts play a significant role in affixing components securely without compromising the comfort and mobility of the user. They are engineered to provide a seamless integration with the prosthetic structure, ensuring durability and adaptability to the user’s movements. Moreover, custom bolts can be tailored to incorporate anti-tamper features, which are vital in preventing unauthorized adjustments or disassembly of medical devices. This enhanced security is crucial for maintaining the integrity and dependability of life-sustaining equipment, ultimately contributing to the overall efficiency and safety of healthcare services.

Custom bolts play a critical role in the machining and manufacturing industries, providing tailored solutions to meet specific engineering requirements. These bolts are designed and fabricated to exact specifications, ensuring compatibility with unique assemblies and structures. In machining, custom bolts are often required for securing components in specialized machinery, where standard bolts might not fit due to non-standard sizes, unique shapes, or specific material requirements. The precision and durability of custom bolts are paramount, as they must withstand the operational stresses and strains of high-performance machinery. Advanced machining techniques such as CNC machining and precision grinding are typically employed to manufacture these bolts, ensuring high accuracy and quality.

In the broader manufacturing context, custom bolts are indispensable in industries ranging from aerospace to automotive, where they must meet rigorous standards for strength, reliability, and resistance to extreme conditions. For instance, aerospace applications often require bolts made from high-strength alloys that can endure the harsh environments of space or high-altitude flight. In the automotive industry, custom bolts are used in engine assembly, suspension systems, and other critical components where precision and performance are vital. Additionally, custom bolts enable manufacturers to innovate and optimize their designs, allowing for enhanced functionality and efficiency in their products. The ability to produce bolts tailored to specific applications not only enhances the safety and reliability of manufactured goods but also supports advancements in technology and engineering solutions.

Q: What is SourcifyChina factory’s expertise in manufacturing custom bolts?

A: SourcifyChina factory specializes in producing high-quality custom bolts tailored to your specific requirements, providing exceptional craftsmanship and precision to meet industry standards.

Q: How do I place an order for custom bolts with SourcifyChina factory?

A: To place an order, please contact our sales team with your detailed specifications, including material, size, design, and quantity. We will provide a quotation and guide you through the ordering process.

Q: What materials are available for custom bolt manufacturing?

A: We offer a wide range of materials including stainless steel, carbon steel, alloy steel, and other specialty materials to meet diverse application requirements.

Q: Can SourcifyChina factory provide prototypes before mass production?

A: Yes, we can produce prototypes for your custom bolts to ensure they meet your specifications and quality standards before initiating mass production.

Q: What quality assurance measures are in place for custom bolts?

A: SourcifyChina factory implements strict quality control procedures, including material inspection, dimensional checks, and performance testing, to ensure each bolt meets our high quality standards.

Q: What is the typical lead time for manufacturing custom bolts?

A: The lead time varies depending on the complexity and quantity of your order. Generally, it ranges from 2 to 6 weeks. We will provide an estimated lead time upon receiving your order details.

Q: Does SourcifyChina factory offer international shipping?

A: Yes, we provide international shipping services. We work with reliable logistics partners to ensure timely and safe delivery of your custom bolts worldwide.

Q: Are there minimum order quantities for custom bolts?

A: Yes, there is a minimum order quantity which depends on the project’s specific requirements. Please contact us to discuss your needs and get accurate details.

Q: Can SourcifyChina factory handle large-scale production runs?

A: Absolutely, SourcifyChina factory is equipped with advanced machinery and skilled workforce to handle both small and large-scale production runs efficiently.

Q: Do you offer post-manufacturing services like threading or coating?

A: Yes, we provide additional services such as threading, coating, plating, and heat treatment to meet your specific requirements and enhance the performance of your custom bolts.

When considering custom bolts manufacturing from SourcifyChina factory, take note of the following tips to ensure a smooth and efficient process:

1. Define Specifications Clearly:

– Provide detailed drawings and specifications, including material type, dimensions, thread type, tensile strength, finish, and any other special requirements.

2. Material Selection:

– Choose the right material based on the application. Common materials include stainless steel, carbon steel, and various alloys. Discuss with SourcifyChina for recommendations suited to your needs.

3. Quality Assurance:

– Inquire about the factory’s quality control processes. Ensure they have certifications like ISO 9001. Request material certificates and testing reports for each batch.

4. Minimum Order Quantity (MOQ):

– Understand the MOQ requirements. Custom manufacturing may involve higher MOQs to justify the setup costs.

5. Lead Time and Production Schedule:

– Discuss lead times and ensure they can meet your deadlines. Factor in time for production, quality checks, and shipping.

6. Prototyping:

– If possible, request prototypes before full production. This allows you to verify specifications and quality.

7. Cost Considerations:

– Obtain a detailed quote that includes all costs: material, labor, tooling, and shipping. Consider potential hidden costs like tariffs and customs fees.

8. Communication:

– Maintain clear and regular communication with the SourcifyChina team. Use detailed and unambiguous terminologies to avoid misunderstandings.

9. Logistics and Shipping:

– Plan logistics carefully. Choose reliable shipping partners and consider the implications of shipping methods on lead time and costs.

10. After-Sales Support:

– Ensure SourcifyChina provides robust after-sales support for any issues that might arise post-delivery.

By following these tips, you can ensure a successful partnership with SourcifyChina for high-quality custom bolt manufacturing.

FAQs for Sourcing Custom Bolts from SourcifyChina Factory

1. How do I request a quote for custom bolts?

To request a quote, visit SourcifyChina’s website and fill out the quote request form with detailed specifications of your custom bolts, including material, dimensions, quantity, and any special requirements.

2. What materials are available for custom bolts?

SourcifyChina offers a wide range of materials including stainless steel, carbon steel, alloy steel, brass, and more. Specify your preferred material when requesting a quote.

3. Can I order bolts in small quantities?

Yes, SourcifyChina accommodates both small and large quantity orders. Minimum order quantities (MOQs) may apply depending on the specifications of the bolts.

4. What is the typical lead time for custom bolts?

Lead times vary based on the complexity of the order and current production capacity. Generally, it ranges from 2 to 6 weeks. Contact customer service for a more accurate estimate.

5. Do you provide samples before full production?

Yes, SourcifyChina can provide samples for approval before commencing full-scale production. Sample fees and lead times will be discussed during the quote process.

6. What quality control measures are in place?

SourcifyChina employs rigorous quality control measures including material verification, dimensional inspections, and performance testing to ensure the highest quality standards.

7. How are the bolts packaged and shipped?

Custom bolts are packaged according to international shipping standards to prevent damage. Packaging options include cartons, pallets, or custom packaging as requested. Shipping can be arranged via air, sea, or courier.

8. Can I track my order status?

Yes, SourcifyChina provides regular updates on order status and shipment tracking information once the order is dispatched.

9. What payment methods are accepted?

SourcifyChina accepts various payment methods including wire transfer, PayPal, and credit cards. Payment terms will be detailed in the quote.

10. Who do I contact for support or additional questions?

For support or additional questions, contact SourcifyChina’s customer service team via email, phone, or the contact form on their website.

Sourcing custom bolts from a reputable factory like SourcifyChina can be streamlined by following these tips:

1. Define Specifications: Clearly outline your bolt requirements, including material, size, tolerance, coating, and any custom features. Detailed specifications ensure the factory can meet your exact needs.

2. Quality Assurance: Verify the factory’s quality control measures. Request certificates like ISO 9001 and check if they conduct inspections and tests on materials and finished products.

3. Samples and Prototypes: Always request samples or prototypes before placing a large order. This allows you to inspect the quality and ensure the bolts meet your standards.

4. Communication: Maintain clear and consistent communication with the factory. Use video calls, emails, and messaging apps to discuss details and address any concerns promptly.

5. Lead Time and Logistics: Clarify the production lead time and delivery schedule. Factor in additional time for shipping and potential customs delays to avoid disruptions in your supply chain.

6. Payment Terms: Negotiate favorable payment terms. Consider using a letter of credit or escrow service to protect your payment until the goods are inspected and verified.

7. Supplier Background Check: Conduct a thorough background check on SourcifyChina, including customer reviews, case studies, and possibly a factory audit, to ensure reliability and trustworthiness.

8. Contract Agreement: Draft a comprehensive contract detailing specifications, delivery timelines, payment terms, and penalties for non-compliance to safeguard both parties.

By defining your specifications, ensuring quality, and maintaining clear communication, you can effectively source custom bolts from SourcifyChina while mitigating risks.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.