Technology and Applications of custom cars parts

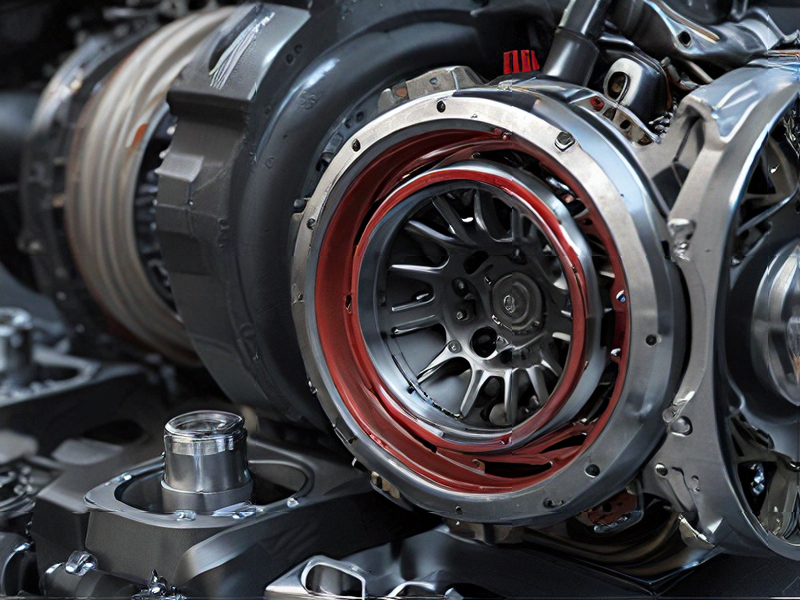

Custom car parts technology has significantly evolved, driven by advancements in materials science, manufacturing techniques, and digital technologies. Key developments include:

1. 3D Printing: Additive manufacturing allows for the creation of bespoke parts with complex geometries, reducing costs and production times. It enables enthusiasts and small manufacturers to produce unique components that are not available off the shelf.

2. CNC Machining: Computer Numerical Control (CNC) machining offers high precision in crafting custom parts from various materials, including metals and plastics. This technology is essential for producing engine components, suspension parts, and custom interior fittings.

3. Carbon Fiber and Advanced Composites: Lightweight and strong, carbon fiber and other advanced composites are increasingly used for custom car parts. These materials enhance performance by reducing weight while maintaining or increasing strength.

4. Electronics and Sensors: Modern custom parts often integrate advanced electronics, such as custom ECU (Engine Control Units) tuning, sensor integration for performance monitoring, and custom lighting systems. These enhance the vehicle’s performance, safety, and aesthetic appeal.

Applications of custom car parts are vast:

1. Performance Enhancement: Custom parts such as turbochargers, exhaust systems, and suspension components are tailored to improve vehicle performance, handling, and efficiency.

2. Aesthetic Customization: Body kits, custom paint jobs, and interior modifications allow car enthusiasts to personalize their vehicles, creating unique looks and styles.

3. Restorations and Replications: Custom parts are crucial in restoring vintage cars where original parts are no longer available. They also play a role in replicating classic cars with modern technology.

4. Specialized Uses: Custom parts are essential in motorsports, where vehicles need to meet specific performance and safety standards. Additionally, they are used in specialized vehicles like off-road trucks, where standard parts may not suffice.

Overall, the technology and application of custom car parts enable a high degree of personalization, improved performance, and the preservation of automotive heritage.

Quality Testing Methods for custom cars parts and how to control quality

Quality testing for custom car parts involves several methods to ensure parts meet specifications and perform reliably. Key methods include:

1. Material Testing: Verify materials meet required standards through tests like tensile strength, hardness, and corrosion resistance.

2. Dimensional Inspection: Use precision tools (calipers, micrometers) and techniques (CMM machines) to measure part dimensions against design specifications.

3. Non-Destructive Testing (NDT): Methods like ultrasonic testing, X-ray, and dye penetrant inspection identify internal and surface defects without damaging the parts.

4. Functional Testing: Simulate real-world conditions to test part performance, including stress tests, fatigue tests, and thermal cycling.

5. Fit and Assembly Testing: Ensure parts fit together correctly and work within the vehicle assembly, checking for issues like misalignment or improper fitting.

6. Performance Benchmarking: Compare custom parts against standard or high-performing benchmarks to evaluate improvements or areas needing refinement.

Quality Control Measures

1. Supplier Quality Assurance (SQA): Establish strict criteria for material and component suppliers, conduct regular audits, and ensure compliance with quality standards.

2. In-Process Quality Control (IPQC): Implement quality checks at various stages of manufacturing to detect and correct defects early. Use statistical process control (SPC) to monitor and control manufacturing processes.

3. Final Inspection: Conduct thorough inspections before parts are dispatched to ensure they meet all design and quality requirements.

4. Documentation and Traceability: Maintain detailed records of materials, processes, and inspections to trace issues back to their source and improve processes over time.

5. Continuous Improvement: Use feedback from testing and customer use to continuously improve parts and processes. Implement methodologies like Six Sigma or Lean Manufacturing to reduce defects and enhance quality.

By combining these testing methods and quality control measures, manufacturers can ensure custom car parts are reliable, safe, and meet the highest standards.

Tips for Procurement and Considerations when Purchasing from custom cars parts

Tips for Procurement and Considerations when Purchasing Custom Car Parts

#### 1. Understand Your Needs

– Identify Specific Requirements: Clearly define the car parts you need, including specifications, compatibility, and performance requirements.

– Budget Planning: Set a realistic budget considering the quality and rarity of custom parts.

#### 2. Research Suppliers

– Supplier Reputation: Choose reputable suppliers with positive reviews and reliable customer service.

– Certifications and Warranties: Ensure suppliers offer certified parts and warranties to guarantee quality and durability.

#### 3. Quality Over Cost

– Material and Build Quality: Prioritize high-quality materials and craftsmanship to ensure the longevity and performance of the parts.

– Comparative Analysis: Compare prices from different suppliers but be wary of deals that seem too good to be true, as they might compromise on quality.

#### 4. Check Compatibility

– Vehicle Specifications: Ensure the custom parts are compatible with your vehicle’s make, model, and year.

– Installation Requirements: Understand any specific installation needs and whether you’ll need professional help.

#### 5. Legal and Safety Considerations

– Regulations Compliance: Ensure the custom parts comply with local regulations and safety standards.

– Safety Testing: Verify if the parts have been tested for safety and performance.

#### 6. Order and Delivery Process

– Lead Times: Consider the lead time for custom parts, which can be longer than standard parts.

– Shipping and Handling: Review the supplier’s shipping policies, costs, and handling procedures to avoid delays or damage.

#### 7. After-Sales Support

– Customer Service: Ensure the supplier provides robust customer service for post-purchase support.

– Return Policies: Understand the return and exchange policies in case the parts do not meet your expectations or requirements.

By following these tips, you can make informed decisions when procuring custom car parts, ensuring you get high-quality components that meet your specific needs and enhance your vehicle’s performance.

FAQs on Sourcing and Manufacturing from custom cars parts in China

FAQs on Sourcing and Manufacturing Custom Car Parts in China

1. Why source custom car parts from China?

China offers a vast manufacturing base, cost-effective production, and a wide range of suppliers, making it ideal for custom car parts.

2. How do I find reliable manufacturers?

Use platforms like Alibaba, Made-in-China, and Global Sources. Verify suppliers through reviews, certifications, and by requesting samples.

3. What are the key factors to consider when choosing a manufacturer?

Look for experience in car parts, quality control processes, compliance with international standards, and good communication.

4. How can I ensure the quality of the parts?

Request samples, conduct factory audits, and use third-party inspection services to verify quality before mass production.

5. What is the typical production lead time?

Lead times vary but generally range from 30 to 60 days, depending on complexity and order size.

6. How can I protect my intellectual property (IP)?

Use non-disclosure agreements (NDAs), register your IP in China, and work with manufacturers who respect IP laws.

7. What payment terms are commonly accepted?

Common terms include a 30% deposit upfront and 70% upon shipment. Letters of Credit (LC) and Trade Assurance on Alibaba offer additional security.

8. How can I handle shipping and logistics?

Work with experienced freight forwarders, consider using DDP (Delivered Duty Paid) terms, and ensure compliance with international shipping regulations.

9. What are the import duties and taxes?

Import duties vary by country and product type. Check with local customs authorities or use an import duty calculator for estimates.

10. How do I manage communication and language barriers?

Hire bilingual staff, use professional translation services, and maintain clear and concise communication.

Sourcing custom car parts from China can be highly beneficial if done correctly, ensuring quality and cost-effectiveness.