SourcifyChina Factory is a premier choice for purchasing custom enclosures from China due to its impeccable quality standards and excellent customer service. With years of expertise, they offer precision-engineered products that meet international manufacturing benchmarks.

Their reliable and efficient supply chain ensures timely delivery of custom enclosures, minimizing lead times and ensuring project timelines are met. This level of efficiency is critical for modern production environments where timing is everything.

Cost-effectiveness is another strong suit. SourcifyChina provides competitive pricing without compromising quality. This enables buyers to receive premium products while achieving significant cost savings, essential for maintaining budget constraints.

The factory’s robust quality control mechanisms involve stringent inspections at every production stage. These thorough checks ensure that each enclosure meets predefined specifications, eliminating the risk of substandard products reaching clients.

Customer-centered practices set SourcifyChina apart. They offer tailored solutions, addressing specific design and function requirements. This customization capability ensures that every product aligns perfectly with buyers’ needs, enhancing overall satisfaction.

Lastly, SourcifyChina excels in communication and support. Their multilingual team simplifies the purchasing process for international clients, providing clear and consistent updates. This reliable communication channel fosters trust and long-term partnerships.

In conclusion, choosing SourcifyChina Factory for custom enclosures means benefiting from unmatched quality, cost-efficiency, stringent quality control, tailored solutions, and excellent communication. These strengths collectively ensure a seamless procurement experience, making them a supplier of choice for discerning buyers.

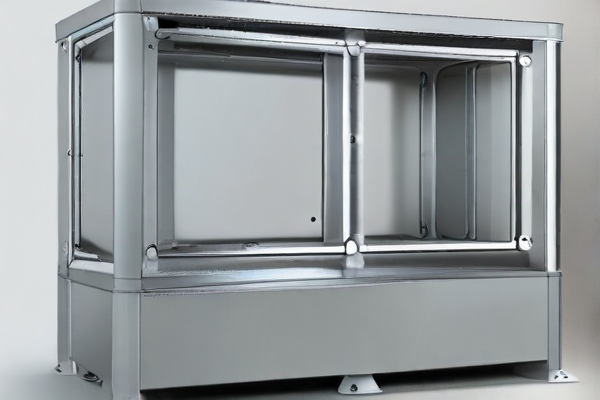

Custom enclosures are tailored solutions designed to house and protect electronic components, machinery, and other equipment. These can be created to meet specific dimensions, material requirements, and environmental conditions.

– Material Options: Aluminum, ABS plastic, polycarbonate, stainless steel

– Design Features: Ventilation, mounting provisions, access panels

– Environmental Ratings: IP ratings for dust and water resistance, NEMA standards

– Finish Options: Powder coating, anodizing, custom colors

– Size Customization: Variable dimensions, wall thickness

– Mounting Options: Wall-mounted, rack-mounted, free-standing

– Protection Requirements: EMI/RFI shielding, corrosion resistance

– Customization Services: CNC machining, laser cutting, silk screening

Custom enclosures are used to protect and house electronic components and systems, ensuring functionality and safety in various environments. They are tailored to meet specific requirements, offering flexibility in design and material choice.

Applications for custom enclosures include:

– Industrial Automation: Protecting control systems and machinery.

– Telecommunications: Housing for network equipment.

– Medical Devices: Enclosures for diagnostic and therapeutic devices.

– Consumer Electronics: Custom cases for gadgets and appliances.

– Automotive: Enclosures for vehicle electronics and sensors.

– Renewable Energy: Housing for solar and wind energy equipment.

– Aerospace: Protecting avionics and navigation systems.

– Marine: Waterproof enclosures for nautical electronics.

– Military: Rugged cases for defense electronics.

– Home Automation: Enclosures for smart home systems.

– Laboratory Equipment: Protective cases for sensitive instruments.

– Security Systems: Enclosures for surveillance and access control systems.

– Lighting: Custom housings for specialized lighting solutions.

SourcifyChina custom enclosures are meticulously designed to meet diverse industrial needs. They utilize high-grade materials that ensure durability and optimum protection for sensitive equipment. Quality is paramount, adhering to international standards.

The materials often include robust metals like aluminum and stainless steel. Aluminum offers excellent corrosion resistance, making it ideal for outdoor use. Stainless steel, known for its strength, is suitable for high-stress environments.

Additionally, certain applications may use advanced polymers. These polymers provide lighter weight while maintaining strength. They are perfect for settings where weight considerations are crucial without compromising on enclosure integrity.

Every enclosure undergoes rigorous testing to guarantee performance under various conditions. From extreme temperatures to physical impacts, SourcifyChina ensures that their custom enclosures can handle it all. The precise machining and finishing processes further enhance their reliability.

Customization options are vast, catering to specific customer requirements. Whether it’s distinct shapes, sizes, or unique features like specialized coatings and insulation, the materials used are always top-notch. This level of customization allows for tailored solutions that address unique challenges.

Cost efficiency paired with quality material selection makes SourcifyChina stand out. Their focus on durability, functionality, and customization results in products that offer long-term value. Choosing SourcifyChina means investing in enclosures that perform consistently, even in the most demanding environments.

SourcifyChina custom enclosures undergo a rigorous quality control manufacturing process to ensure exceptional product standards. This begins with thorough material selection to ensure durability and reliability.

Next, the manufacturing process incorporates precision engineering, employing advanced machinery and skilled technicians. Each enclosure is meticulously crafted to meet exact specifications and standards.

Post-production, each enclosure undergoes stringent testing procedures. This includes endurance tests, environmental resistance, and functionality checks to ensure they meet the required performance criteria.

Finally, before delivery, SourcifyChina conducts a comprehensive review and inspection. The enclosures are carefully packaged to prevent damage during transit, thereby ensuring customers receive a flawless product.

SourcifyChina specializes in crafting custom enclosures tailored to meet specific industry needs. Their advanced manufacturing facilities allow the production of high-quality, durable, and precise enclosures for various applications, including electronics, telecommunications, and industrial devices.

Utilizing state-of-the-art technology, SourcifyChina ensures each enclosure meets stringent quality standards. They employ advanced materials and techniques to offer products resistant to environmental stresses, enhancing longevity and performance. The company’s skilled workforce excels in delivering designs that combine functionality with aesthetics, ensuring user-friendly and visually appealing products.

Client collaboration is a cornerstone of SourcifyChina’s services. From the initial design phase to final production, they engage closely with clients to understand requirements and offer bespoke solutions. This consultative approach ensures that each enclosure not only meets specifications but also aligns with clients’ branding and operational goals.

SourcifyChina supports a diverse range of customization options, including size, material, color, and protective coatings. Whether for small batch prototypes or large-scale production runs, their flexible manufacturing processes can accommodate varying project scopes. This adaptability makes them a preferred partner for businesses seeking tailored enclosure solutions.

Their comprehensive service also includes post-production support, offering assembly, testing, and quality assurance. SourcifyChina understands the importance of timely delivery, adhering to strict deadlines without compromising on quality. This commitment to consistent excellence has earned them a reputation as a reliable supplier in the competitive custom enclosure market.

Innovation drives SourcifyChina, with continuous investment in research and development. They stay ahead of market trends and technological advancements, integrating new methodologies to enhance product offerings. Customers benefit from the latest in enclosure technology, ensuring their products remain competitive and forward-thinking.

In conclusion, SourcifyChina’s capabilities in custom enclosure manufacturing are extensive and versatile. From quality and customization to client collaboration and innovation, they provide end-to-end solutions. Businesses partnering with SourcifyChina can expect superior enclosures designed to elevate their product offerings, ensuring performance, durability, and aesthetic appeal.

Custom enclosures offer numerous advantages for businesses and individuals, enhancing both functionality and aesthetics in various applications. Here are some key benefits:

– Tailored Fit: Custom enclosures are designed to fit specific equipment perfectly, ensuring optimal protection and space utilization.

– Enhanced Protection: These enclosures can be built with materials and features tailored to environmental and security requirements, providing superior protection against dust, water, and physical damage.

– Improved Performance: By accommodating specific hardware needs, custom enclosures can improve cooling, airflow, and overall device performance.

– Aesthetic Appeal: Custom designs allow for branding and aesthetic enhancements, making the enclosures not only functional but also visually appealing.

– Compliance and Standards: Custom enclosures can be designed to meet industry-specific standards and regulatory requirements, ensuring compliance and safety.

– Versatility: They can be made for a wide range of applications, from industrial machinery to consumer electronics, offering flexibility in design and function.

– Cost Efficiency: Despite the initial investment, custom enclosures can reduce long-term costs by minimizing equipment damage and downtime.

– Ease of Maintenance: Tailored designs can include features that facilitate easier access for maintenance and repairs, saving time and effort.

– Scalability: Custom enclosures can be easily scaled or modified to accommodate future needs, providing long-term usability.

Overall, investing in custom enclosures can lead to significant improvements in equipment longevity, performance, and user satisfaction.

Custom enclosures offer tailored solutions to protect and house electronic devices or machinery. These enclosures can be designed to meet specific requirements related to size, shape, material, and functionality.

– Tailored Dimensions: Custom enclosures are built to match the exact dimensions needed for a project, ensuring a perfect fit.

– Material Selection: Choose from a variety of materials such as aluminum, plastic, or stainless steel to match the application’s environmental conditions.

– Enhanced Protection: Offer superior protection against dust, water, chemicals, and other environmental hazards, conforming to IP (Ingress Protection) standards.

– Design Flexibility: Various customization options, including mounting brackets, cutouts, and cable entry points, to suit specific application needs.

– Aesthetic Appeal: Possibility to match the design and finish to the company’s brand or product line, offering a professional appearance.

– Thermal Management: Custom enclosures can incorporate features such as heat sinks, ventilation slots, or cooling fans to manage heat dissipation effectively.

– EMI/RFI Shielding: Special coatings or materials can be used to provide shielding against electromagnetic and radio frequency interference.

– Ease of Assembly and Maintenance: Designed for easy assembly, disassembly, and maintenance, which reduces downtime and improves efficiency.

– Regulatory Compliance: Tailored to meet industry-specific standards and regulations, ensuring safety and reliability.

– Cost Efficiency: Although initially more expensive, the long-term benefits of reduced maintenance, downtime, and enhanced protection can result in overall cost savings.

Custom enclosures are an essential component for any application requiring robust, reliable, and tailor-made housing solutions, bringing a myriad of benefits tailored to specific needs.

SourcifyChina specializes in creating custom enclosures tailored to meet specific project requirements. Their expertise ranges from industrial to consumer applications, ensuring high-quality and durable solutions for any need.

Their team of skilled engineers collaborates closely with clients, offering personalized service and attention to detail. This collaborative approach leads to innovative, functional designs that cater to the unique requirements of each project.

By utilizing advanced manufacturing techniques and technologies, SourcifyChina maintains stringent quality control measures. These measures ensure that each custom enclosure meets the highest standards, offering both reliability and longevity.

Clients benefit from SourcifyChina’s comprehensive project management, from initial consultation to final delivery. This holistic service mitigates risks and ensures timely completion, making them a trusted partner in custom enclosure solutions.

In addition to their technical prowess, SourcifyChina prioritizes cost-effectiveness. By efficiently managing resources and optimizing production processes, they deliver top-quality enclosures without compromising budget constraints.

Their diverse portfolio exemplifies their versatility and commitment to excellence. From small-scale prototypes to large-volume orders, SourcifyChina delivers consistent performance across various industries, showcasing their adaptability and expertise.

In conclusion, SourcifyChina offers unparalleled custom enclosure solutions tailored to specific project needs. With a focus on quality, innovation, and cost-effectiveness, they are a reliable partner for any custom product project. Their end-to-end service and commitment to excellence ensure client satisfaction and project success, solidifying their reputation in the industry.

SourcifyChina Custom Enclosure is a specialized manufacturing company renowned for its expertise in producing tailored enclosure solutions for various industries. Leveraging cutting-edge technology and a highly skilled workforce, the company excels in delivering high-quality, durable enclosures that meet specific client requirements. SourcifyChina offers a comprehensive range of services, from initial design consultation to final production, ensuring that each enclosure is perfectly suited to its intended application. Their commitment to precision engineering and customer satisfaction has earned them a strong reputation in the global market. By providing cost-effective solutions without compromising on quality, SourcifyChina Custom Enclosure has positioned itself as a preferred partner for businesses seeking reliable and customized enclosure products.

Custom enclosures play a crucial role in the Aerospace, Defense, and Marine sectors, where they are essential for housing and protecting sophisticated electronic systems from harsh environmental conditions. In aerospace applications, custom enclosures must withstand extreme temperatures, high altitudes, and significant vibration. They are often designed using lightweight yet durable materials such as aluminum or advanced composites to ensure minimal weight addition without compromising on strength. These enclosures can house avionics systems, communication devices, and navigation instruments, ensuring they function reliably during flight. Precision engineering and stringent testing are paramount to ensure these enclosures meet rigorous industry standards such as those set by the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA).

In the defense and marine sectors, custom enclosures are equally vital for safeguarding critical equipment from moisture, saltwater corrosion, and physical impacts. For military applications, enclosures must be ruggedized to endure battlefield conditions, including exposure to dust, debris, and intense physical shock. They protect sensitive electronics like radar systems, communication gear, and tactical control systems. In marine applications, custom enclosures must be watertight and often utilize corrosion-resistant materials such as stainless steel or specialized polymers. These enclosures are vital for protecting navigation systems, sonar equipment, and other critical marine electronics that operate in submerged or humid conditions. By ensuring the integrity and functionality of these systems, custom enclosures enhance the operational readiness and reliability of aerospace, defense, and marine missions.

In the automotive industry, custom enclosures are pivotal in housing sensitive electronic components that control various vehicle functions. These enclosures provide essential protection against harsh environmental conditions such as extreme temperatures, moisture, dust, and vibrations. For instance, engine control units (ECUs) and advanced driver-assistance systems (ADAS) rely on custom enclosures to maintain optimal performance and ensure longevity. These enclosures are designed with specific materials and sealing mechanisms to prevent interference from electromagnetic waves, which can disrupt the delicate electronics inside. The bespoke nature of these enclosures allows for precise fitting within the limited and uniquely shaped spaces of modern vehicles, contributing to the overall efficiency and safety of automotive systems.

In the realm of electronics, custom enclosures are integral to the functionality and durability of various devices and systems. Whether for consumer electronics, industrial machinery, or medical equipment, these enclosures provide tailored protection against physical damage, dust, water ingress, and electromagnetic interference (EMI). For example, custom enclosures in medical devices must adhere to stringent hygiene and safety standards, often requiring materials that can withstand frequent sterilization processes. Similarly, in industrial applications, custom enclosures protect delicate sensors and control systems from harsh operational environments. The design flexibility of custom enclosures also facilitates better thermal management, ensuring that heat-sensitive components remain within safe operating temperatures. This level of customization helps optimize the performance, reliability, and longevity of electronic devices across various sectors.

Custom enclosures in the construction industry are vital for housing sensitive equipment and machinery that need to be protected from environmental hazards such as dust, moisture, and extreme temperatures. These enclosures are designed to fit specific dimensions and specifications, ensuring that construction tools, controls, and monitoring systems are securely encased. For example, customized electrical enclosures can protect wiring and circuit boards from harsh outdoor conditions, preventing malfunctions and extending the lifespan of the components. Additionally, these enclosures can be fabricated from various materials including metal, plastic, and composites, tailored to withstand the specific challenges of a given construction site, thus promoting safety and efficiency.

In the energy sector, custom enclosures play a crucial role in safeguarding critical infrastructure such as transformers, power distribution units, and renewable energy systems. These enclosures are engineered to provide robust protection against environmental factors, electromagnetic interference, and physical impacts, ensuring the uninterrupted operation of energy systems. For instance, in solar power installations, custom enclosures can house inverters and batteries, protecting them from weather elements and enhancing their performance and longevity. Similarly, in the wind energy sector, specially designed enclosures can shield electrical components from the corrosive effects of marine environments. By employing custom enclosures, energy companies can optimize the reliability and efficiency of their systems, contributing to more stable and sustainable energy production.

In the Industrial Equipment industry, custom enclosures play a pivotal role in enhancing operational efficiency and ensuring the safety and durability of sophisticated machinery. These tailored enclosures are designed to house sensitive electronic components, control panels, and intricate wiring systems, providing comprehensive protection against external factors such as dust, moisture, and corrosive materials. By confining these crucial elements within a custom enclosure, companies can significantly reduce the risk of equipment failure caused by environmental hazards, thereby minimizing downtime and maintenance costs. Moreover, these enclosures can be engineered to meet specific industry standards and certifications, ensuring compliance and bolstering the overall reliability of industrial operations.

Additionally, custom enclosures afford manufacturers the flexibility to optimize space and functionality according to unique application requirements. They can be designed with specific dimensions, access points, and mounting options to support various industrial processes seamlessly. For instance, in automation and control systems, enclosures can integrate advanced cooling solutions and cable management features, enhancing the performance and longevity of the equipment. Furthermore, aesthetically designed enclosures can contribute to a more organized and professional appearance of the plant floor, facilitating easier maintenance and upgrades. By leveraging the benefits of custom enclosures, the Industrial Equipment industry can achieve higher productivity levels and create safer working environments, ultimately driving innovation and growth.

Custom enclosures play a crucial role in the medical device industry by providing tailored protection and housing for sensitive equipment. These enclosures are designed to meet specific requirements such as size, shape, and material compatibility to ensure the safety and functionality of medical devices. For instance, devices like portable diagnostic tools, ventilators, and infusion pumps benefit from custom enclosures that offer precise fittings, which enhance device performance and reliability. Additionally, these enclosures can be manufactured from materials that are resistant to sterilization processes, chemicals, and other environmental factors typically encountered in medical settings, thereby ensuring longevity and consistent operation.

Beyond protection and durability, custom enclosures also contribute to regulatory compliance and patient safety. Medical devices must adhere to stringent standards set by regulatory bodies such as the FDA and ISO. Custom enclosures can be designed to comply with these regulations, incorporating features like secure closures, tamper-evident seals, and ergonomic designs that facilitate ease of use for healthcare professionals. Moreover, the ability to customize enclosures allows for the integration of advanced functionalities, such as built-in antimicrobial surfaces, which help reduce the risk of infection. Overall, custom enclosures not only protect the integrity of medical devices but also enhance their usability and compliance with health and safety standards.

In the realm of machining and manufacturing, custom enclosures play a pivotal role in various industries by providing tailored solutions for housing electronic components, mechanical parts, and other sensitive equipment. Unlike standard enclosures, custom enclosures are designed to meet specific requirements regarding dimensions, material properties, and functional features. Machining processes, such as CNC milling, turning, and drilling, allow for the precise fabrication of these custom enclosures from materials like aluminum, stainless steel, and plastic. The high precision and repeatability of machining ensure that each enclosure fits perfectly with the components it is designed to protect, offering superior durability and performance in demanding environments.

Manufacturing custom enclosures involves integrating advanced techniques and technologies to achieve optimal functionality and aesthetics. For instance, sheet metal fabrication processes can be employed to create enclosures with complex geometries and intricate designs. Additive manufacturing, or 3D printing, further expands the possibilities by enabling rapid prototyping and production of bespoke enclosures with unique shapes and features. These enclosures are crucial in sectors such as aerospace, medical devices, and telecommunications, where precise specifications and reliability are of utmost importance. By leveraging the capabilities of modern machining and manufacturing, businesses can create custom enclosures that not only protect critical components but also enhance the overall efficiency and performance of their products.

Sure! Here are some frequently asked questions (FAQs) with answers for manufacturing custom enclosure quality work from SourcifyChina factory:

Q1: What types of custom enclosures can SourcifyChina produce?

A1: SourcifyChina can produce a wide range of custom enclosures including electronic housings, industrial casings, and specialized containers made from materials like plastic, metal, and composite.

Q2: What is the lead time for manufacturing custom enclosures?

A2: The lead time typically ranges from 4 to 8 weeks, depending on the complexity of the design and material availability. Specific timelines will be provided after the design and specifications are finalized.

Q3: Can SourcifyChina assist with the design of custom enclosures?

A3: Yes, SourcifyChina offers comprehensive design assistance. Our team of experienced engineers can help transform your concepts into workable designs, ensuring functionality and manufacturability.

Q4: What quality control measures are in place for custom enclosures?

A4: SourcifyChina employs rigorous quality control measures including material verification, dimensional checks, and functional testing. We follow ISO standards to ensure each enclosure meets customer specifications and quality expectations.

Q5: Are there any minimum order quantities (MOQ) for custom enclosures?

A5: Yes, SourcifyChina typically requires a minimum order quantity, which can vary based on the type and complexity of the enclosure. Consult with our sales team for specific MOQ details for your project.

Q6: What materials are available for custom enclosures?

A6: SourcifyChina offers a variety of materials including ABS, polycarbonate, aluminum, stainless steel, and more. We can recommend the best material based on your specific requirements and application needs.

Q7: Can I get a prototype before full-scale production?

A7: Absolutely. SourcifyChina offers prototyping services to ensure the design meets your expectations before commencing full-scale production. This helps in fine-tuning the design and resolving any potential issues early on.

Q8: How can I get a quote for my custom enclosure project?

A8: To get a quote, provide detailed specifications including design drawings, material preferences, quantity, and any special requirements. Our team will review and provide a tailored quotation promptly.

Q9: Does SourcifyChina offer after-sales support?

Custom enclosure manufacturing with SourcifyChina involves several steps to ensure high-quality, tailored products for various applications. Here are some key tips:

1. Detailed Specifications:

– Provide precise measurements, materials, and design specifications. Use CAD files or detailed drawings to communicate your requirements clearly.

2. Material Selection:

– Choose materials based on the application of the enclosure. Common materials include metals (like aluminum or steel) and plastics (such as ABS or polycarbonate).

3. Prototype Development:

– Request a prototype before full-scale production. This allows you to check the fit, function, and finish of the enclosure and make necessary adjustments.

4. Customization Options:

– Take advantage of various customization options such as CNC machining, laser cutting, and surface treatments (painting, powder coating, anodizing).

5. Quality Control:

– Ensure the factory follows stringent quality control processes. Ask about their inspection methods and certifications like ISO 9001.

6. Communication:

– Maintain regular communication with the factory. Use project management tools or regular updates to track progress and address any issues promptly.

7. Lead Times and Shipping:

– Clarify lead times and shipping options. Plan for potential delays and understand the logistics to avoid last-minute surprises.

8. Cost Management:

– Get detailed quotations and understand the cost structure, including tooling, production, and shipping costs. Negotiate terms that include these elements to avoid hidden fees.

9. After-Sales Support:

– Ensure the factory offers good after-sales support for issues like defects or necessary modifications post-delivery.

10. Case Studies and References:

– Review case studies or ask for references to understand the factory’s experience and capability in producing similar enclosures.

By following these tips, you can effectively manage the custom enclosure manufacturing process with SourcifyChina, ensuring a high-quality product that meets your specific needs.

Sure, here’s a concise FAQ list for sourcing a custom enclosure from SourcifyChina factory:

Q: What is SourcifyChina Factory’s expertise in manufacturing custom enclosures?

A: SourcifyChina Factory specializes in producing high-quality custom enclosures tailored to meet specific design and functionality requirements, ensuring durability and precision.

Q: How can I request a quote for a custom enclosure?

A: You can request a quote by contacting SourcifyChina directly through their website, providing detailed specifications, quantities, and any special requirements for your custom enclosure.

Q: What materials can be used for custom enclosures?

A: SourcifyChina offers a variety of materials such as aluminum, stainless steel, plastic, and more. The material choice depends on your specific needs, such as durability, cost, and application environment.

Q: Can SourcifyChina create prototypes before mass production?

A: Yes, they offer prototyping services to ensure the design meets your expectations and functional requirements before commencing large-scale production.

Q: What are the lead times for custom enclosures?

A: Lead times vary based on the complexity of the design, material selection, and order size. Typically, prototyping takes a few weeks, and mass production can take several additional weeks.

Q: Are there minimum order quantities (MOQs) for custom enclosures?

A: Yes, MOQs may apply and vary depending on the complexity and material of the enclosure. Contact SourcifyChina for specific details related to your project.

Q: How does the design and approval process work?

A: Initially, you’ll provide design specifications or sketches. SourcifyChina will create detailed drawings or 3D models for your approval. Any necessary adjustments can be made before proceeding to prototyping and production.

Q: Is quality control included in the manufacturing process?

A: Absolutely, SourcifyChina employs stringent quality control measures throughout the manufacturing process to ensure each custom enclosure meets the required standards and specifications.

Q: Can SourcifyChina handle international shipping?

A: Yes, SourcifyChina provides international shipping services, ensuring your custom enclosures are delivered securely and efficiently to your location.

Q: What support is available after placing an order?

A: SourcifyChina offers continuous support, including updates on manufacturing progress, shipping details, and after-sales service to address any concerns or issues that may arise.

Sourcing custom enclosures from a factory like SourcifyChina requires a strategic approach to ensure quality, cost-effectiveness, and timely delivery. Here are some tips to guide you through the process:

1. Define Requirements Clearly:

– Specify dimensions, materials, design specifications, and any other essential features of the enclosure.

– Provide detailed drawings or CAD files to avoid any ambiguity.

2. Research and Select Suppliers:

– Look for suppliers with good reviews, proven track records, and relevant experience in manufacturing custom enclosures.

– SourcifyChina can help streamline this by connecting you with vetted suppliers.

3. Request for Quotation (RFQ):

– Send a comprehensive RFQ to multiple suppliers to compare prices, lead times, and capabilities.

– Include all specifications, quantities, and any special requirements.

4. Evaluate Quotes and Supplier Capabilities:

– Assess quotes not just on cost, but also on the quality of materials, production capabilities, and compliance with standards.

– Consider visiting the factory or requesting samples to verify quality.

5. Negotiate Terms:

– Discuss payment terms, delivery schedules, and any warranties or guarantees.

– Ensure all agreements are documented clearly in the contract.

6. Quality Control and Inspection:

– Set up a robust quality control process. This might include pre-production samples, in-process inspections, and final product checks.

– Consider third-party inspections for an unbiased assessment.

7. Logistics and Shipping:

– Plan the logistics, including packaging, shipping methods, and customs clearance.

– Factor in lead times for production and shipping to avoid delays.

8. Communication and Relationship Management:

– Maintain regular communication with the supplier to monitor progress and address any issues promptly.

– Building a strong relationship with the supplier can lead to better cooperation and possibly better terms in the future.

By following these steps, you can effectively source custom enclosures from SourcifyChina, ensuring they meet your specifications and quality standards.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.