SourcifyChina Factory is a trusted partner for buyers seeking custom fabricators in China. With extensive industry experience, they offer unparalleled quality and reliability, ensuring your products meet the highest standards.

Their team streamlines the purchasing process, from initial consultation to final delivery, providing seamless communication and timely updates. This minimizes delays and keeps your project on track.

SourcifyChina emphasizes stringent quality control measures, ensuring every item meets rigorous international standards. By leveraging their network of reputable suppliers, they deliver consistent, high-quality products.

Competitive pricing at SourcifyChina allows buyers to maximize value without compromising quality. Their efficient operations and strategic sourcing translate into significant cost savings for your business.

With SourcifyChina, you benefit from comprehensive logistics support, including shipping and customs clearance. Their expertise ensures your products arrive safely and promptly, regardless of destination.

Customer satisfaction is paramount at SourcifyChina. They build strong relationships by offering responsive support and tailored solutions, making them the preferred choice for buyers seeking custom fabricators in China.

Custom

Fabricators: Types and Options

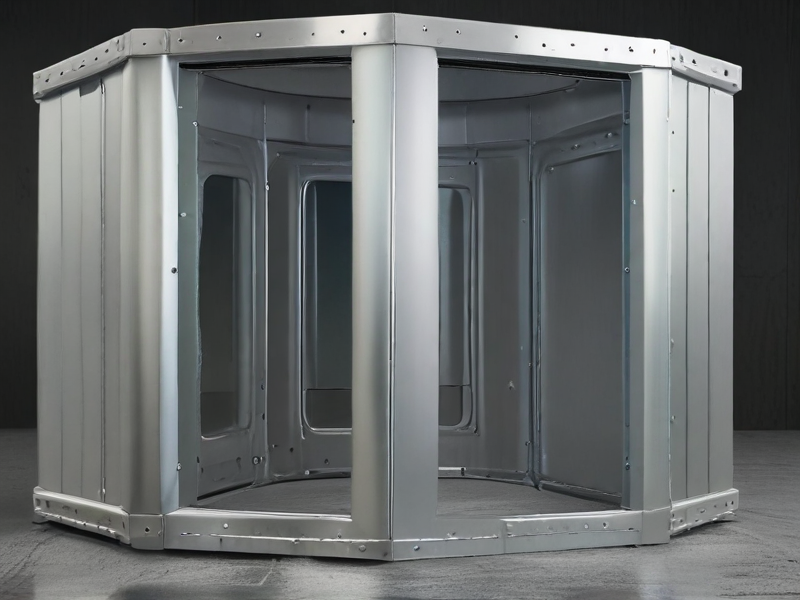

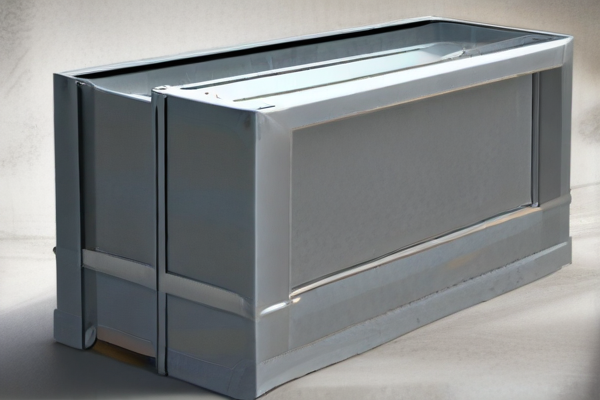

Custom fabricators specialize in creating unique products tailored to specific requirements. They cater to various industries, including construction, automotive, and aerospace, using diverse materials and advanced technologies.

– Metal Fabrication

– Steel, aluminum, copper

– Welding, cutting, bending

– Plastic Fabrication

– Acrylic, PVC, polycarbonate

– Injection molding, extrusion, thermoforming

– Wood Fabrication

– Hardwood, plywood, MDF

– CNC routing, lathing, joinery

– Glass Fabrication

– Tempered, laminated, tinted

– Cutting, polishing, beveling

– Composite Fabrication

– Fiberglass, carbon fiber, Kevlar

– Lamination, molding, bonding

– Stone Fabrication

– Granite, marble, limestone

– Cutting, shaping, engraving

– Textile Fabrication

– Cotton, wool, synthetic blends

– Weaving, knitting, dyeing

– Custom Solutions

– Prototyping

– Design and engineering services

– Assembly and finishing

Each type of custom fabrication offers unique benefits and is chosen based on the project requirements. Services may include prototyping, detailed design assistance, and end-to-end project management, ensuring high-quality, precise, and functional products tailored to client needs.

Custom fabricators offer tailored solutions for various industries, creating specialized components and structures. Their expertise ensures high-quality, unique products that meet specific requirements for function and design.

– Manufacturing: Custom parts and machinery for specific production needs.

– Construction: Unique architectural elements, bespoke structures, and fittings.

– Automotive: Custom car parts, modifications, and performance enhancements.

– Marine: Specialized boat components and custom-built vessels.

– Aerospace: Precision-engineered parts and prototypes.

– Medical: Custom surgical instruments and medical devices.

– Signage: Tailor-made signs and displays for businesses.

– Art and Design: Custom sculptures and artistic structures.

– Food Processing: Specialized equipment for unique food production processes.

– Renewable Energy: Custom components for solar panels and wind turbines.

– Telecommunications: Special enclosures and mounts for equipment.

– Furniture: One-of-a-kind pieces tailored to client specifications.

– Agriculture: Custom machinery and parts for farming needs.

– Defense: Specialized equipment and armaments.

– Robotics: Custom-built robots and robotic components.

– Exhibition Displays: Unique, custom-built trade show displays.

– Greenhouses: Tailored structures for specific horticultural requirements.

– Mining: Custom tools and machinery for mining operations.

– Textile Industry: Specialized equipment for fabric production and processing.

With diverse capabilities, custom fabricators can transform any specific need into a tangible, functional product, driving innovation across multiple sectors. Their ability to create unique and precise solutions underscores their importance in modern industry.

SourcifyChina custom fabricators utilize a wide range of materials to cater to various industry needs. Their selection includes metals, plastics, and composites, ensuring high durability and adaptability for numerous applications.

Their metallic offerings encompass stainless steel, aluminum, and brass. These materials are chosen for their strength, corrosion resistance, and suitability for mechanical and structural applications.

In the realm of plastics, SourcifyChina offers products crafted from ABS, PVC, and polycarbonate. These materials are ideal for custom parts requiring flexibility, weather resistance, and ease of manufacturing.

Composites, blending materials like carbon fiber with resins, offer unique benefits such as lightweight strength and high impact resistance. These are particularly used in aerospace, automotive, and sports equipment industries.

SourcifyChina ensures every material meets stringent quality controls, guaranteeing products that stand the test of time. Their diverse material options and commitment to excellence make them a preferred choice for custom fabrication solutions.

SourcifyChina custom fabricators prioritize rigorous quality control in their manufacturing process to ensure top-notch products. Starting from material selection, only premium raw materials undergo stringent checks to meet industry standards.

During production, advanced machinery and skilled technicians enforce meticulous standards. Each stage of the manufacturing process is monitored to maintain consistency and precision, leading to superior quality outputs.

Post-production, thorough inspections are conducted. Products are scrutinized for any defects or deviations from design specifications. This ensures that only flawless items are packaged and dispatched.

Finally, feedback loops from clients are integrated into the quality control process. Continual assessment and improvement of protocols guarantee that SourcifyChina custom fabricators consistently deliver excellence.

SourcifyChina custom fabricators excel in producing high-quality, tailor-made components for various industries. With advanced machinery and technologies, they ensure precise, durable fabrications in metal, plastic, and other materials.

Their skilled team of engineers and technicians collaborate closely with clients to understand unique requirements, ensuring each project meets exact specifications. This personalized approach fosters innovation and efficiency, resulting in optimal product performance.

Equipped to handle both small and large-scale production runs, SourcifyChina offers flexibility and scalability. This adaptability allows them to cater to diverse market needs, from prototyping to full-scale manufacturing.

SourcifyChina’s commitment to quality is evident in their rigorous testing and inspection processes. Adhering to international standards, they guarantee the reliability and safety of each fabricated product.

Furthermore, their comprehensive supply chain management ensures timely delivery and cost-effectiveness. By optimizing logistics and employing strategic partnerships, they streamline the entire production cycle, benefiting clients worldwide.

Overall, SourcifyChina custom fabricators demonstrate robust capabilities in delivering exceptional, bespoke fabrications. Their expertise, quality assurance, and efficient supply chain make them a trusted partner in various industrial projects.

Custom fabricators offer tailored solutions for your specific needs, ensuring precision, quality, and efficiency. They cater to a diverse range of industries, providing numerous benefits.

– Customization: Tailor-made designs to match unique project specifications.

– Quality: High-quality materials and craftsmanship for durable products.

– Innovation: Ability to implement cutting-edge technology and design.

– Efficiency: Streamlined processes reduce waste and improve productivity.

– Support: Expert guidance and problem-solving from experienced professionals.

– Versatility: Services for a variety of industries, including automotive, aerospace, and construction.

– Flexibility: Adaptable solutions to accommodate changes in project scope or requirements.

– Cost-Effective Solutions: Competitive pricing through efficient resource management.

– Timely Delivery: Effective project management ensures deadlines are met.

– Safety: Adherence to industry standards and regulations for safe, reliable products.

Custom fabricators are specialized manufacturers that create tailored metal, plastic, or composite structures and components based on specific client requirements. Here are key features of custom fabricators:

– Expertise in Multiple Materials: Whether working with metals, plastics, composites, or other materials, custom fabricators possess diverse knowledge to handle different substances.

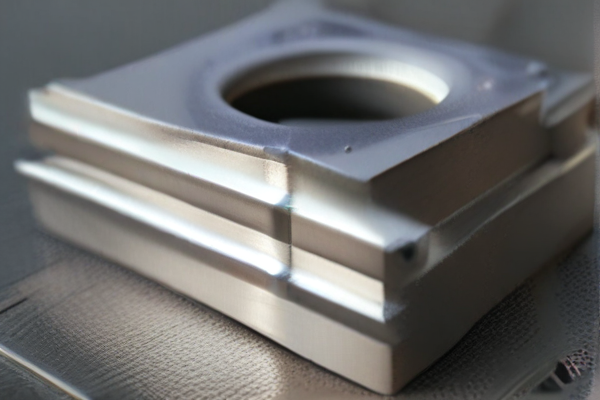

– Precision Engineering: Utilizing advanced machinery and technology such as CNC machines, 3D printers, and laser cutters to achieve high-precision results.

– Customization and Flexibility: Ability to adapt designs to client specifications, offering bespoke solutions rather than off-the-shelf products.

– Design Assistance: Providing support in drafting, designing, and engineering drawings to ensure feasibility and functionality.

– Prototyping and Testing: Creating prototypes and conducting rigorous testing to validate the design before full-scale production.

– Quality Assurance: Implementing stringent quality control processes to ensure the final product meets all standards and customer expectations.

– Scalability: Capability to handle both small-scale custom orders and larger, more complex production runs.

– Innovative Solutions: Leveraging cutting-edge technologies and novel approaches to solve complex fabrication challenges.

– Collaboration Across Industries: Serving various sectors including aerospace, automotive, medical, construction, and more.

– Customer Support: Offering excellent post-production support, including maintenance and repair services.

– Sustainability Practices: Implementing eco-friendly practices such as recycling materials and reducing waste during the fabrication process.

Custom fabricators are essential for industries requiring unique, precise, and adaptive manufacturing solutions, thereby playing a crucial role in advancing modern engineering and design.

SourcifyChina Custom Fabricators specialize in delivering tailored manufacturing solutions. Their wide range of custom products includes bespoke machinery parts, bespoke electronics, and specialized industrial tools. Clients benefit greatly from their commitment to quality, precision, and innovation.

One of their standout projects involved designing specialized medical equipment for a leading healthcare provider. This project required stringent adherence to health and safety standards, showcasing the company’s meticulous craftsmanship and expertise.

In the aerospace sector, SourcifyChina provided custom components that meet stringent regulatory requirements. They successfully delivered on tight timelines without compromising on product quality or reliability.

SourcifyChina’s innovative approach was also evident in a recent renewable energy project. They manufactured custom solar panel mounts that improved efficiency and reduced installation times, playing a crucial role in advancing sustainable energy solutions.

Their customer-centric approach ensures that each project receives individual attention. From initial concept consultation to final product delivery, SourcifyChina maintains transparent communication, ensuring that client specifications and expectations are met or exceeded.

Overall, SourcifyChina Custom Fabricators are a trusted partner for bespoke manufacturing needs. Their breadth of expertise, commitment to quality, and customer-centric service make them an ideal choice for companies requiring specialized products and solutions.

SourcifyChina Custom Fabricators is a distinguished company renowned for its adeptness in delivering bespoke manufacturing solutions across an array of industries. Based in China, SourcifyChina leverages the country’s extensive industrial capabilities to provide high-quality, custom-engineered products tailored to meet the unique needs of their clients. The company stands out for its commitment to precision, innovation, and excellence, adhering to stringent quality standards that ensure the end product not only meets but often exceeds expectations. By integrating advanced technologies with skilled craftsmanship, SourcifyChina efficiently caters to diverse sectors including automotive, aerospace, consumer electronics, and heavy machinery. They prioritize strong client partnerships, offering end-to-end services from initial design consultation and prototyping to full-scale production and logistics support. This comprehensive approach allows them to deliver solutions that are not only cost-effective but also optimized for performance and durability. SourcifyChina’s dedication to continuous improvement and customer-centric values has cemented its reputation as a reliable, go-to partner for custom fabrication needs on a global scale.

Custom fabricators play a critical role in the aerospace, defense, and marine industries by providing tailored solutions that meet the stringent performance, safety, and durability requirements of these sectors. In aerospace applications, custom fabricators produce highly specialized components such as structural frames, fuel tanks, and engine parts, often utilizing advanced materials like titanium and carbon fiber composites. These bespoke parts are designed to withstand extreme conditions, such as high temperatures, intense pressure, and significant mechanical stress, ensuring the safety and efficiency of aircraft. By combining precision engineering with rigorous testing protocols, custom fabricators help aerospace manufacturers achieve optimal weight-to-strength ratios and enhance overall aircraft performance.

In the defense and marine sectors, the demand for custom fabrication is equally significant. Defense applications often require bespoke solutions for armored vehicles, weapon systems, and surveillance equipment, where reliability and robustness are critical. Custom fabricators deliver components that meet specific ballistic, thermal, and electromagnetic requirements, thereby ensuring operational readiness and mission success. In the marine industry, custom fabricators contribute to the construction and maintenance of ships and submarines by providing components like hull sections, propulsion systems, and underwater sensors. These parts must endure harsh marine conditions, such as corrosion, high pressure, and varying temperatures. By leveraging advanced fabrication techniques and materials, custom fabricators enhance the safety, longevity, and performance of marine vessels, supporting both commercial and military maritime operations.

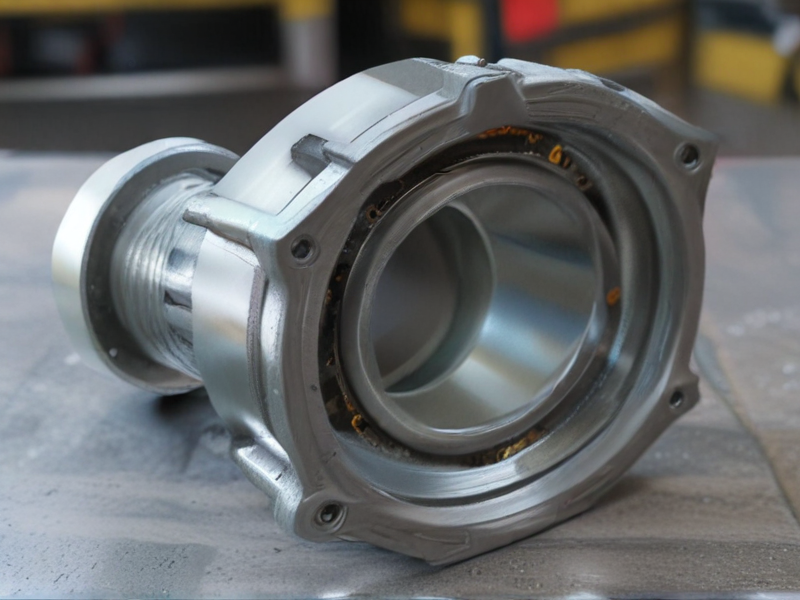

Custom fabricators play a pivotal role in the automotive industry by providing tailored solutions for a variety of vehicle components. These fabricators specialize in creating bespoke parts and systems that meet the specific requirements of automotive manufacturers, enhancing both performance and aesthetic appeal. For instance, custom fabricators can design and produce specialized exhaust systems, unique body panels, and advanced suspension components that cater to high-performance or luxury vehicles. They also contribute to the prototype and development stages of new models by producing custom molds, jigs, and fixtures, ensuring that each component aligns perfectly with the vehicle’s design and engineering specifications. The integration of these custom elements can lead to significant improvements in vehicle efficiency, safety, and overall driving experience.

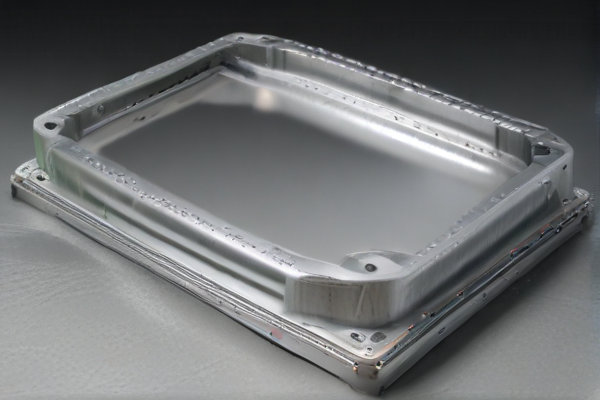

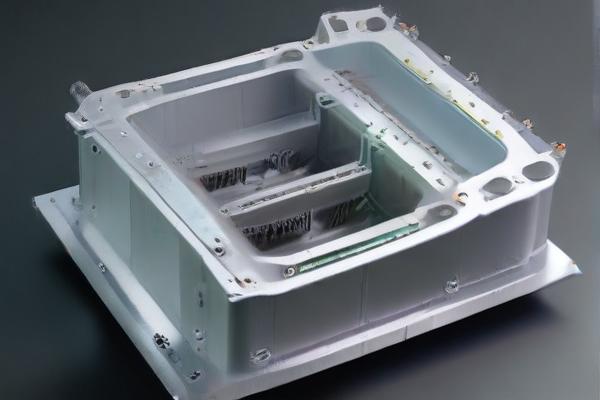

In the realm of electronics, custom fabricators are essential for the development of specialized enclosures, circuit boards, and components tailored to the precise needs of electronic devices and systems. They collaborate closely with designers and engineers to fabricate parts that meet exacting standards for size, shape, and material properties, ensuring optimal functionality and durability. Custom fabricators are particularly valuable in the production of devices that require unique or non-standard configurations, such as medical equipment, industrial controls, and consumer electronics. By providing custom solutions, fabricators help innovators bring complex and highly personalized electronic products to market more efficiently. Their expertise in materials and advanced manufacturing techniques, such as CNC machining and additive manufacturing, enables the creation of intricate, high-precision components that are essential for the reliability and performance of modern electronic devices.

Custom fabricators play a pivotal role in the construction industry, enabling the creation of specialized components that adhere to precise architectural specifications and structural demands. These expert craftsmen design and manufacture bespoke structural elements such as steel beams, trusses, and cladding systems that are integral to building frameworks. With the advent of advanced technologies like Computer-Aided Design (CAD) and Computer Numerical Control (CNC) machining, custom fabricators can produce complex shapes and structures that improve both the aesthetics and functionality of construction projects. Whether it is the development of unique curtain walls for skyscrapers or intricate metalwork for bridges and arenas, custom fabrication ensures that each piece fits seamlessly into the larger construction blueprint, enhancing both project efficiency and structural integrity.

In the energy sector, custom fabricators are indispensable in the development and maintenance of specialized equipment required for energy production and distribution. From the fabrication of bespoke components for wind turbines to the construction of custom piping systems for oil and gas refineries, these experts ensure that all parts meet stringent industry standards and performance criteria. The precision and quality provided by custom fabricators are critical, especially given the harsh operational environments often encountered in energy production. For instance, in the renewable energy sector, custom-fabricated mounting systems for solar panels or structural supports for offshore wind farms are engineered to withstand corrosive conditions and extreme weather, thereby extending the lifecycle and efficiency of the installations. Their contribution is not just limited to new projects; they also manufacture replacement parts tailored to existing systems, ensuring minimal downtime and optimal performance across energy infrastructures.

The industrial equipment industry heavily relies on custom fabricators to produce specialized components and machinery tailored to specific operational needs. Custom fabrication allows for the creation of unique parts that meet exact specifications, ensuring optimal performance and compatibility with existing systems. For example, in a production facility, custom-fabricated conveyor systems can be designed to fit precise dimensions and handle unique materials, enhancing workflow efficiency and reducing downtime. This bespoke approach is crucial for industries like aerospace, pharmaceuticals, and automotive manufacturing, where standard, off-the-shelf solutions might not meet stringent regulatory or operational requirements. By leveraging the expertise of custom fabricators, these industries can achieve greater precision in their operations, leading to improved product quality and overall productivity.

Additionally, custom fabricators play a pivotal role in the maintenance and upgrading of industrial equipment. Over time, machinery may require modifications or enhancements to adapt to new production processes or to integrate advanced technologies. Custom fabricators can design and produce necessary components, such as specialized brackets, supports, or enclosures, facilitating seamless upgrades and ensuring that equipment remains up-to-date. This versatility extends the lifespan of industrial machinery and reduces the need for substantial capital investments in entirely new equipment. Furthermore, custom fabrication allows for the swift replacement of worn or damaged parts, minimizing operational interruptions. By providing tailored solutions that precisely meet the unique demands of various industrial applications, custom fabricators enable companies to maintain a competitive edge in an ever-evolving market landscape.

Custom fabricators in the realm of medical devices play an indispensable role in enhancing patient care and treatment outcomes. Utilizing advanced materials and innovative manufacturing techniques, these fabricators create tailored solutions that cater to unique medical needs. For instance, prosthetics and orthotics can be customized to perfectly fit the anatomical requirements of individual patients, thereby improving both comfort and functionality. Custom fabricators can also design patient-specific surgical instruments and implants, which significantly increase the precision and efficacy of surgical procedures. By leveraging cutting-edge technologies like 3D printing and computer-aided design (CAD), custom fabricators can rapidly produce prototypes and final devices, making personalized medical care more accessible and efficient.

Moreover, the application of custom fabricators extends to the development of specialized medical equipment and diagnostic tools. Fabricators can produce customized housings for medical devices that not only protect the internal components but also ensure ergonomic handling by healthcare professionals. For instance, custom-designed enclosures for portable ultrasound machines can enhance their usability in diverse medical settings, from remote clinics to modern hospitals. Additionally, patient monitoring systems can be tailored to suit specific clinical environments, enabling more precise and real-time data collection. Custom fabricators are pivotal in enhancing the functionality, reliability, and user experience of medical devices, ultimately driving forward innovations that meet the evolving challenges of the healthcare industry.

Custom fabricators play a pivotal role in the realm of machining and manufacturing, providing bespoke solutions that cater to the diverse needs of industries such as aerospace, automotive, medical, and consumer products. Utilizing advanced computer-aided design (CAD) software and precise computer numerical control (CNC) machinery, custom fabricators can produce high-precision components with complex geometries that standard manufacturing processes cannot achieve. Their expertise in material selection, heat treatment, and surface finishing ensures that each part not only conforms to stringent quality standards but also meets the specific functional requirements of the end application. Custom fabricators excel in creating prototypes, small-batch productions, and specialty parts, allowing manufacturers to bring innovative products to market rapidly and efficiently.

In addition to their technical capabilities, custom fabricators offer a high degree of flexibility and customization, which is essential for specialized applications that require unique solutions. They often collaborate closely with engineers and designers to iterate and refine designs, making adjustments that can enhance performance, reduce weight, or improve manufacturability. This collaborative approach is particularly beneficial in industries where precision and reliability are paramount, such as in the production of medical implants or aerospace components, where failure is not an option. By leveraging their deep expertise and state-of-the-art equipment, custom fabricators serve as indispensable partners in the manufacturing ecosystem, helping companies overcome production challenges and achieve their innovation goals.

Sure! Here is a list of FAQs for manufacturing “custom fabricators quality work from SourcifyChina factory”:

Q: What is SourcifyChina?

A: SourcifyChina is a manufacturing and sourcing company that specializes in providing high-quality custom fabrication services from reputable factories in China. They streamline the production process, ensuring efficient and cost-effective solutions for your manufacturing needs.

Q: What types of custom fabrication services do you offer?

A: SourcifyChina offers a wide range of custom fabrication services including metalworking, plastic injection molding, CNC machining, laser cutting, welding, and assembly services. They cater to various industries such as automotive, aerospace, consumer goods, and electronics.

Q: How do you ensure quality in your custom fabrication work?

A: Quality assurance is a top priority. SourcifyChina employs strict quality control measures, including rigorous inspections, certifications, and testing protocols. They work with ISO-certified factories and conduct regular audits to maintain high standards.

Q: Can I get design assistance for my project?

A: Yes, SourcifyChina offers design assistance and engineering support to help refine your product ideas and ensure they are manufacturable. Their team of experts can work with your CAD files or help create new designs from scratch.

Q: What is the typical lead time for an order?

A: Lead times vary depending on the complexity and size of the project. Generally, it ranges from 2-8 weeks. SourcifyChina strives to deliver products within the agreed timeframe and provides regular updates throughout the production process.

Q: How can I get a quote for my custom fabrication project?

A: To get a quote, you can submit your project details, including design files, materials, quantities, and any specific requirements, through their online form or contact their sales team directly. They will provide a detailed quotation and timeline based on your specifications.

Q: Do you offer international shipping?

A: Yes, SourcifyChina offers international shipping. They can handle all logistics, including customs clearance and delivery to your preferred location. They work with reliable shipping partners to ensure timely and safe delivery of your products.

Q: What payment methods do you accept?

A: SourcifyChina accepts various payment methods, including bank transfers, PayPal, and credit cards. Payment terms can be discussed and agreed upon based on the project scope and client requirements.

Q: How do I start working with SourcifyChina?

When considering custom fabricators manufacturing from SourcifyChina factory, keeping a few critical tips in mind can make your experience seamless and effective.

1. Clear Specifications: Communicate your requirements in detail, including materials, dimensions, and tolerances. Precise CAD drawings and technical specifications help prevent misunderstandings.

2. Prototype Testing: Before mass production, request prototypes to ensure the product meets your standards. It’s a necessary step to verify design and functionality.

3. Quality Standards: Verify the factory’s adherence to quality control standards such as ISO 9001. A quality-focused manufacturer ensures consistent product output.

4. Material Sourcing: Discuss material options to find the best balance of cost and quality. SourcifyChina’s broad network helps source the most suitable materials.

5. Production Timeline: Establish clear timelines for production and shipping. Delays can impact project deadlines, so having a realistic schedule is crucial.

6. Communication: Maintain regular communication. Language barriers can cause issues, so make sure you are on the same page regarding project updates and changes.

7. Cost Efficiency: Understand the cost structure, including production, shipping, and potential tariffs. Request detailed quotes to avoid hidden costs.

8. Scalability: Ensure the factory can scale production if required. Flexibility in order volume can be crucial for growing businesses.

9. Cultural Considerations: Respect and understand cultural nuances. Building a positive relationship can enhance cooperation and project success.

10. Legal Safeguards: Have a contract in place that outlines all terms, including IP protection, to safeguard your designs and interests.

By following these tips, you can leverage SourcifyChina’s manufacturing capabilities to produce high-quality custom fabrications efficiently and cost-effectively.

Certainly! Here are some frequently asked questions (FAQ) about sourcing custom fabricators from SourcifyChina factory:

1. What types of custom fabrications can SourcifyChina handle?

SourcifyChina specializes in a wide range of custom fabrication services, including metalworks, plastic components, composite materials, and electronic components. They cater to various industries such as automotive, aerospace, consumer electronics, and more.

2. How can I start a project with SourcifyChina?

To start a project, you can contact SourcifyChina through their website’s inquiry form or via email. Provide detailed specifications, including design files, material requirements, and any other pertinent details to receive an accurate quote.

3. What is the lead time for custom fabrications?

Lead times vary based on the complexity and size of the project. Typically, the design and prototyping phase can take 2-4 weeks, while full-scale production might range from 6-12 weeks. SourcifyChina will provide a more accurate timeline once your project details are reviewed.

4. Can SourcifyChina assist with design and prototyping?

Yes, SourcifyChina offers design and prototyping services to ensure your custom fabrication meets your specifications. Their team of engineers and designers can assist in refining your designs and creating prototypes before moving to full production.

5. How does SourcifyChina ensure quality for custom fabrications?

SourcifyChina utilizes rigorous quality control measures including material verification, precision testing, and final inspections. They comply with international standards to ensure every product meets your quality requirements.

6. What are the payment terms?

Payment terms typically involve an initial deposit with the balance due upon completion or prior to shipment. SourcifyChina accepts various payment methods including wire transfers and letters of credit. Specific terms will be discussed during the quotation process.

7. Can I visit the SourcifyChina factory?

Yes, visits can be arranged by appointment. SourcifyChina welcomes clients to tour their facilities, meet the team, and discuss project details in person.

8. How does SourcifyChina handle shipping and customs?

SourcifyChina coordinates with trusted logistics partners to handle shipping and customs clearance. They provide door-to-door services and manage all necessary documentation to ensure smooth delivery.

Sourcing custom fabricators from a factory like SourcifyChina requires careful planning and strategic steps to ensure you get high-quality products at competitive prices. Here are some actionable tips:

1. Define Your Requirements: Clearly outline your product specifications, including material, dimensions, and any custom features. Precise requirements help avoid misunderstandings and ensure the fabricator understands your needs.

2. Research and Vet Factories: Use platforms like Alibaba, Global Sources, or Sourcify’s own database to find potential factories. Look for those that specialize in your product category and have a proven track record.

3. Request Samples: Before committing to a large order, always request samples. This step allows you to inspect the quality and ensure the fabricator can meet your standards.

4. Evaluate Communication: Effective communication is crucial. Choose a fabricator that responds promptly and clearly. Good communication can mitigate risks and streamline the manufacturing process.

5. Check Certifications and Compliance: Ensure the factory complies with industry standards and holds relevant certifications. This step is vital for maintaining product quality and meeting regulatory requirements.

6. Visit the Factory: If possible, visit the factory to assess their production capabilities, quality control processes, and working conditions. This firsthand visit can provide valuable insights that remote communication cannot.

7. Negotiate Terms: Discuss pricing, payment terms, lead times, and minimum order quantities. Having these terms clear in writing can prevent disputes later on.

8. Monitor Production: Regularly check in on the production process to catch and correct any issues early. Some businesses hire third-party quality control inspectors for this task.

9. Review Samples Post-Production: Inspect the first batch of the production run before the entire order is completed. This step ensures consistency and adherence to your specifications.

10. Build a Long-term Relationship: Developing strong relationships with your fabricators can lead to better prices, priority treatment, and smoother negotiations in the future.

By following these tips, you can effectively source custom fabricators from SourcifyChina and ensure a successful partnership.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.