“SourcifyChina: Reliable Custom Plastic Molds Factory for Precision Manufacturing Solutions”

Looking for high-quality, reliable custom plastic molds? Discover SourcifyChina, a leading factory known for precision manufacturing solutions tailored to your needs.

Choosing SourcifyChina Factory for custom plastic molds offers unmatched expertise and reliability. With years of experience in the industry, they ensure high-quality molds tailored to specific needs. Their advanced technology and skilled workforce guarantee precision and durability in every product.

SourcifyChina Factory provides competitive pricing without compromising on quality. Their streamlined processes and efficient production methods allow buyers to get the best value for their investment. Moreover, they offer flexible solutions to meet various budget requirements.

The factory’s commitment to customer satisfaction is evident in their excellent after-sales service. They provide comprehensive support, from initial consultation to post-delivery assistance, ensuring a smooth and hassle-free purchasing experience. Buyers can rely on their prompt responses and professional guidance.

SourcifyChina Factory’s strategic location in China offers logistical advantages. Proximity to major shipping ports and a well-established supply chain network enable faster delivery times and reduced shipping costs. This geographical benefit translates into timely project completion for buyers.

Furthermore, the factory adheres to stringent quality control standards. Each mold undergoes rigorous inspection to meet international quality benchmarks. This dedication to quality ensures that buyers receive molds that are both functional and reliable, minimizing the risk of defects and operational issues.

SourcifyChina Factory also values innovation and continuous improvement. They invest in the latest technologies and regularly update their manufacturing processes to stay ahead of industry trends. This proactive approach ensures that buyers receive cutting-edge solutions that enhance their competitiveness in the market.

In summary, SourcifyChina Factory stands out as a premier choice for custom plastic molds due to their expertise, competitive pricing, excellent customer service, logistical advantages, stringent quality control, and commitment to innovation. Buyers can trust them to deliver high-quality molds that meet their exact specifications and contribute to their business success.

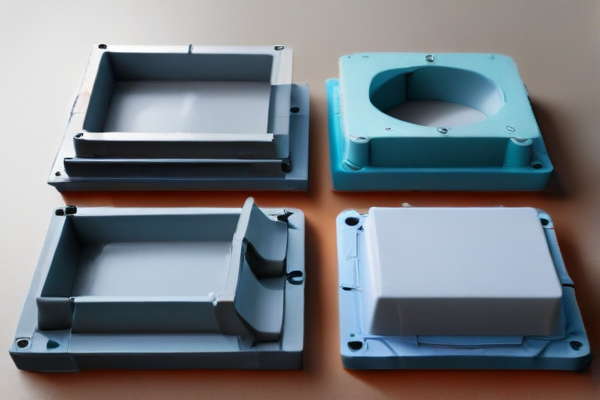

Custom plastic molds are essential in manufacturing a variety of products, offering precision and flexibility. They come in various types and can be tailored to specific requirements for different industries. Below are some common types and options for custom plastic molds:

– Injection Molds: Ideal for high-volume production, providing detailed and complex shapes.

– Blow Molds: Used for creating hollow plastic parts like bottles and containers.

– Compression Molds: Suitable for larger, simpler items, often used with thermosetting plastics.

– Rotational Molds: Perfect for producing large, hollow objects with uniform wall thickness.

– Thermoforming Molds: Used in creating shallow, detailed parts from plastic sheets.

Customization

Options:

– Material Selection: Choosing the right plastic (e.g., ABS, polycarbonate) based on product requirements.

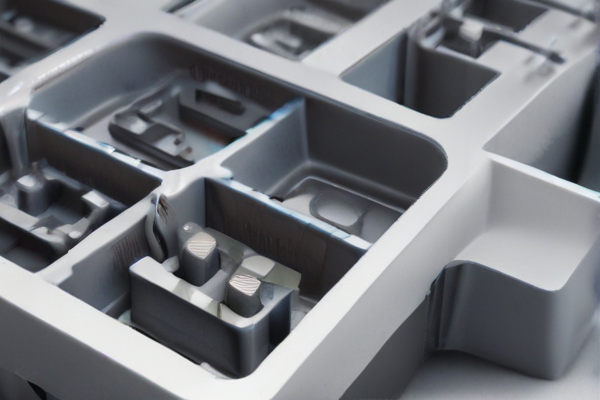

– Cavity Design: Single or multi-cavity molds for different production needs.

– Surface Finish: Options for textures, gloss, or matte finishes.

– Cooling Systems: Customized cooling channels for faster production cycles.

– Ejection Mechanisms: Tailored ejection systems to ensure smooth removal of parts.

– Tooling Durability: Hardening options for extended mold life and resistance to wear and tear.

Custom plastic molds are pivotal for efficient and effective manufacturing, offering a variety of options to meet specific production and design needs.

Custom plastic molds are essential in various industries for creating tailored plastic components, ensuring precision and efficiency in manufacturing processes.

– Automotive Industry: Production of specific car parts like dashboards, bumpers, and interior trims.

– Consumer Electronics: Manufacturing cases, buttons, and connectors for gadgets.

– Medical Devices: Crafting precise components for medical tools and equipment.

– Packaging: Customizing containers and packaging solutions for different products.

– Toy Manufacturing: Producing unique and intricate toy parts.

– Home Appliances: Creating durable parts for kitchen and home appliances.

– Construction: Molding components for tools and building materials.

– Aerospace: Developing lightweight and strong parts for aircraft.

– Prototyping: Rapid creation of prototypes for testing and development.

– Sports Equipment: Customizing parts for various sports gear and accessories.

Custom plastic molds enhance product quality, reduce production costs, and allow for innovative designs, making them indispensable in modern manufacturing.

SourcifyChina specializes in creating custom plastic molds with high precision and durability. They use top-grade materials to ensure the molds meet stringent quality standards. Each mold is crafted using advanced technology and expert craftsmanship, guaranteeing excellent performance and longevity.

The materials used in SourcifyChina’s custom plastic molds include high-quality steel and aluminum alloys. These materials are chosen for their strength, resistance to wear, and ability to withstand high temperatures, ensuring that the molds can produce consistent and high-quality plastic parts.

In addition to the robust materials, SourcifyChina also employs rigorous testing procedures. Each mold undergoes thorough inspection and testing to ensure it meets the client’s specifications and industry standards. This commitment to quality ensures reliable and efficient production processes for their customers.

Moreover, SourcifyChina offers a wide range of customization options. Whether it’s a specific design, size, or application, their team works closely with clients to develop molds that precisely fit their needs. This customer-centric approach helps businesses achieve their production goals more effectively.

Overall, SourcifyChina’s use of premium materials, combined with their expertise and dedication to quality, makes them a trusted partner for businesses seeking custom plastic molds. Their comprehensive approach to design, testing, and customization ensures that clients receive molds that are both durable and perfectly suited to their production requirements.

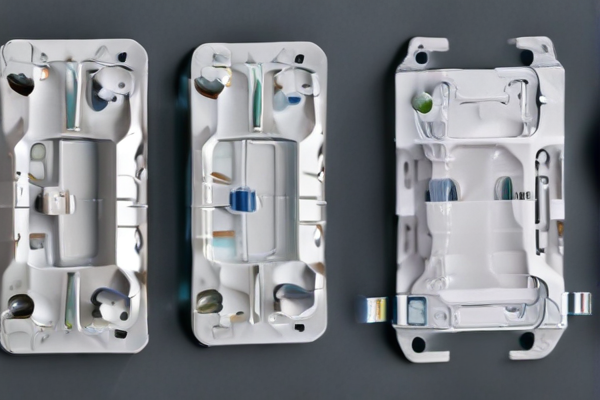

SourcifyChina’s custom plastic molds undergo a rigorous quality control manufacturing process. Every stage, from design to production, is meticulously monitored to ensure precision and consistency. Advanced CAD software is employed to create detailed mold designs, ensuring all specifications are met accurately.

Material selection is crucial, with SourcifyChina sourcing high-grade, durable materials to guarantee longevity and performance. Each material batch undergoes strict testing for quality and compliance with industry standards before being used in mold production.

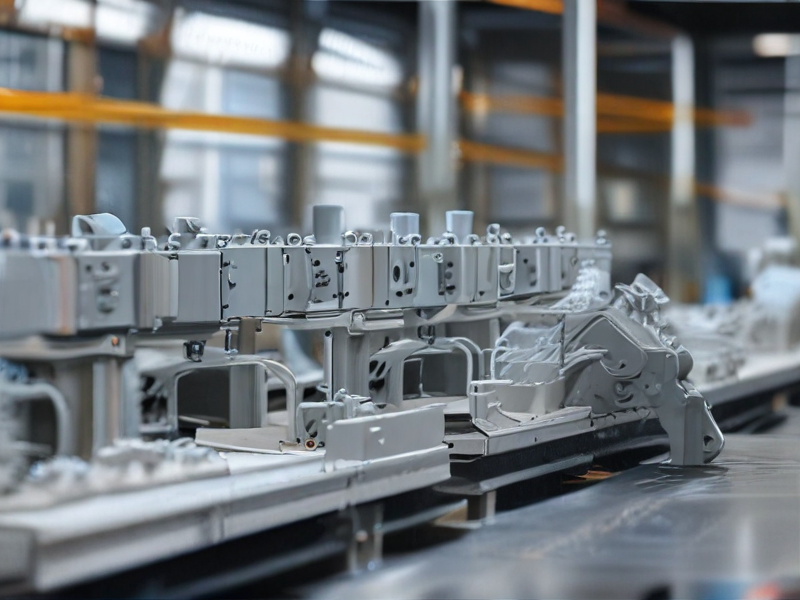

During the mold-making process, state-of-the-art CNC machines and EDM technology are utilized. This ensures high precision in shaping the molds, with tolerances maintained within extremely tight margins. Regular inspections and measurements are conducted to verify dimensional accuracy.

Post-production, each mold is subjected to comprehensive testing, including trial runs to assess functionality and durability. Any defects or deviations from the design specifications are promptly addressed. This iterative process ensures that the final product meets the highest quality standards.

SourcifyChina also implements continuous improvement practices, incorporating feedback from customers and advancements in technology. This proactive approach helps maintain their reputation for delivering reliable and high-quality custom plastic molds.

The company adheres to international quality management systems, such as ISO standards, ensuring all processes are documented, standardized, and regularly reviewed. This commitment to excellence is reflected in the consistent performance and reliability of their molds.

Customer satisfaction is paramount. SourcifyChina provides thorough documentation and support, ensuring clients receive molds that perfectly match their requirements. This comprehensive quality control process ensures that SourcifyChina’s custom plastic molds are synonymous with precision, durability, and exceptional performance in the manufacturing industry.

SourcifyChina excels in creating custom plastic molds tailored to diverse industry needs. Their expertise spans various sectors, ensuring precise and durable mold designs that meet stringent quality standards.

The company leverages advanced technology and high-precision equipment to deliver intricate and complex mold structures. Their skilled engineers work closely with clients to develop innovative solutions that enhance product functionality and aesthetics.

SourcifyChina’s capabilities include rapid prototyping, which accelerates the development process, allowing for quick adjustments and improvements. This agility ensures that clients can bring their products to market faster.

Furthermore, they offer comprehensive project management from initial concept to final production, ensuring seamless communication and project alignment. Their commitment to excellence is evident in their meticulous attention to detail and rigorous quality control measures.

In addition to custom plastic molds, SourcifyChina provides post-production support, including assembly, packaging, and logistics. This end-to-end service ensures a smooth transition from production to distribution.

Overall, SourcifyChina’s custom plastic molds capabilities reflect their dedication to innovation, quality, and customer satisfaction. Their holistic approach and state-of-the-art technology make them a reliable partner for any plastic molding project.

Custom plastic molds offer numerous advantages, making them an essential component in modern manufacturing. These molds provide precision, efficiency, and cost-effectiveness, catering to various industries.

– Precision and Consistency: Custom molds ensure high accuracy and uniformity in the produced parts, meeting strict specifications.

– Cost-Effectiveness: Once the mold is created, production costs per unit decrease significantly, making it economical for large-scale manufacturing.

– Flexibility in Design: They allow for intricate and complex designs, enabling the production of parts with unique features.

– Durability: Custom molds are made from robust materials, ensuring longevity and sustained performance over time.

– Speed of Production: These molds streamline the manufacturing process, significantly reducing production time.

– Reduced Waste: Precision in molding reduces material waste, promoting sustainable manufacturing practices.

– Versatility: Applicable across various industries such as automotive, medical, and consumer goods, custom molds cater to diverse needs.

– Enhanced Product Quality: High-quality molds result in superior finished products, enhancing brand reputation and customer satisfaction.

– Scalability: Easily scalable for different production volumes, they adapt to varying market demands.

– Improved Efficiency: Automation compatibility increases overall manufacturing efficiency, reducing manual labor requirements.

In summary, custom plastic molds are indispensable for achieving high-quality, efficient, and cost-effective production in various industries.

Custom plastic molds offer tailored solutions for manufacturing complex plastic components with high precision and efficiency. They are essential for various industries due to their adaptability and cost-effectiveness.

Key Features:

– Precision: Custom molds ensure precise dimensions and shapes, meeting exact specifications.

– Versatility: Suitable for various plastic materials, including thermoplastics and thermosets.

– Durability: Made from high-quality materials, providing long-lasting performance.

– Complex Geometries: Capable of producing intricate and detailed designs.

– Scalability: Supports both low and high-volume production runs.

– Efficiency: Reduces waste and speeds up the manufacturing process.

– Customization: Easily modified to accommodate design changes and specific requirements.

– Cost-effective: Lower production costs over time due to repeatable and consistent outputs.

– Consistency: Ensures uniformity in each produced part, maintaining quality standards.

– Speed: Accelerates the product development cycle, from prototype to final product.

SourcifyChina specializes in custom plastic molds, offering tailored solutions for diverse industries. Their expertise ensures high precision and quality in every mold, catering to both large-scale and small-scale production needs.

The company utilizes advanced technology to design and manufacture custom plastic products. Their state-of-the-art facilities and skilled team ensure efficient and cost-effective production, meeting the unique requirements of each client.

SourcifyChina’s custom projects range from automotive parts to consumer goods. They work closely with clients from concept to completion, ensuring the final product meets exact specifications and industry standards.

Their comprehensive services include prototyping, mold testing, and mass production. This holistic approach guarantees a seamless transition from design to manufacturing, minimizing delays and maximizing efficiency.

Clients appreciate SourcifyChina’s commitment to quality and innovation. Their attention to detail and customer-centric approach have earned them a reputation for excellence in custom plastic molding solutions.

By continuously investing in technology and training, SourcifyChina stays ahead of industry trends. This proactive approach ensures they can handle the most complex projects with ease, delivering superior results every time.

In summary, SourcifyChina is a leader in custom plastic mold manufacturing. Their dedication to quality, innovation, and customer satisfaction makes them the preferred partner for businesses seeking reliable and high-quality plastic molding solutions.

SourcifyChina, a prominent player in the custom plastic mold industry, is renowned for delivering high-quality, tailored molding solutions to a diverse clientele. Specializing in the design, manufacturing, and delivery of custom plastic molds, the company leverages cutting-edge technology and a team of skilled engineers to ensure precision and efficiency in every project. SourcifyChina’s expertise spans various sectors, including automotive, consumer electronics, medical devices, and household goods, providing innovative solutions that meet specific industry requirements. The company prides itself on its rigorous quality control processes and its ability to deliver cost-effective products without compromising on quality. By fostering strong partnerships with its clients, SourcifyChina not only meets but often exceeds customer expectations, making it a trusted name in the global market for custom plastic molds. With a commitment to continuous improvement and customer satisfaction, SourcifyChina remains at the forefront of the industry, adapting to new challenges and evolving market demands with agility and expertise.

Custom plastic molds are critical in the aerospace, defense, and marine industries due to their ability to meet stringent specifications and performance requirements. In aerospace applications, custom plastic molds are used to create lightweight and durable components that can withstand extreme temperatures and stresses. These components range from interior parts, like seat frames and overhead bins, to complex external structures such as aerodynamic fairings. The precision of custom molding ensures that each part meets the exact design specifications, which is crucial for maintaining safety and performance in aerospace environments. Additionally, the ability to produce parts with intricate geometries and tight tolerances enhances the overall efficiency and reliability of aerospace systems.

In the defense and marine sectors, custom plastic molds play a pivotal role in manufacturing equipment and components that must endure harsh conditions, such as high humidity, saltwater exposure, and significant mechanical stress. For defense applications, custom molds are used to create parts for weapons systems, communication devices, and protective gear, ensuring they are both lightweight and resilient. In marine applications, custom plastic molds are essential for producing watertight and corrosion-resistant components used in submarines, ships, and buoyancy devices. The versatility of plastic molding allows for the integration of features like complex shapes, embedded sensors, and modular designs, providing enhanced functionality and extended service life for defense and marine equipment. These industries benefit significantly from the cost-effective production and material properties offered by custom plastic molding, ensuring mission-critical performance in demanding environments.

Custom plastic molds play a crucial role in the automotive industry, enhancing the efficiency and precision of manufacturing processes. These molds enable the production of complex, high-quality components such as dashboards, bumpers, and various interior parts with consistent accuracy. Customization allows for the incorporation of specific design features, ensuring that each part fits seamlessly into the vehicle’s overall architecture. The use of custom plastic molds in automotive applications also supports lightweighting efforts, which are essential for improving fuel efficiency and reducing emissions. By using advanced materials and innovative molding techniques, manufacturers can create durable, lightweight parts that meet stringent safety and performance standards.

In the construction industry, custom plastic molds play a pivotal role in enhancing efficiency and precision. These molds are utilized to create components like concrete forms, decorative architectural elements, and insulation panels. The lightweight and durable nature of plastic molds allows for easy handling and reduces labor costs. Moreover, they can be designed to meet specific project requirements, ensuring consistent quality and fit. The ability to produce complex shapes with high accuracy also enables architects and builders to explore innovative designs. Additionally, plastic molds contribute to sustainability by being reusable and reducing waste associated with traditional construction materials.

In the energy sector, custom plastic molds are essential for manufacturing components used in renewable energy systems and infrastructure. For instance, they are used to produce parts for wind turbine blades, solar panel mounts, and battery casings. The precision of plastic molding ensures that these components meet strict performance and safety standards. Furthermore, the lightweight nature of plastic helps in reducing the overall weight of energy systems, enhancing efficiency and reducing transportation costs. Custom molds also facilitate the production of complex geometries that are necessary for optimizing the performance of energy devices, thereby supporting the development and deployment of sustainable energy technologies.

In the industrial equipment sector, custom plastic molds play a crucial role in manufacturing components with precise specifications and high durability. These molds allow for the creation of complex shapes and designs that are often required in industrial applications, such as housings for machinery, gears, and specialized tools. The use of custom plastic molds enhances production efficiency by enabling mass production of consistent and high-quality parts. This consistency is essential in maintaining the reliability and performance of industrial equipment, where even minor deviations can lead to significant operational issues.

Furthermore, custom plastic molds offer significant cost advantages. Traditional metal parts can be expensive and time-consuming to produce, especially when dealing with intricate designs or small production runs. Plastic molds, however, can be easily and quickly adapted to different shapes and sizes, reducing both material and labor costs. Additionally, plastics used in these molds can be engineered to meet specific requirements such as heat resistance, chemical stability, and mechanical strength, making them suitable for various industrial environments. By utilizing custom plastic molds, manufacturers can achieve greater flexibility, faster turnaround times, and reduced overall production costs, thereby enhancing their competitive edge in the market.

Custom plastic molds play a crucial role in the medical device industry, offering unparalleled precision and flexibility in manufacturing. These molds are specifically designed to meet the stringent requirements of medical applications, ensuring that each device produced is consistent in quality and performance. Custom molds are used to create a wide range of medical components, from simple tubing connectors to complex diagnostic tools and implantable devices. The ability to customize molds allows manufacturers to produce parts that are tailored to the specific needs of each application, enhancing the functionality and reliability of the final product. Moreover, the use of advanced plastic materials in these molds can provide additional benefits such as biocompatibility, chemical resistance, and sterilization capability, which are essential for medical applications.

The application of custom plastic molds in medical devices also supports rapid prototyping and scalability. With the advent of technologies like injection molding and 3D printing, custom molds can be quickly produced and modified, facilitating the development and testing of new medical devices. This accelerates the time-to-market for innovative products, allowing medical companies to respond swiftly to emerging healthcare needs. Additionally, the scalability of custom molds ensures that once a design is finalized, it can be mass-produced efficiently, maintaining high precision across large production runs. This combination of customization, rapid prototyping, and scalability makes custom plastic molds an invaluable asset in the medical device industry, driving advancements in medical technology and improving patient outcomes.

Custom plastic molds play a pivotal role in the machining and manufacturing sectors, particularly in the production of high-precision plastic components. These molds are crafted through advanced machining techniques, such as CNC machining and EDM (Electrical Discharge Machining), to achieve the exact specifications required for various applications. The process begins with the design phase, where detailed CAD models are created. These designs are then translated into physical molds using precise machining methods that ensure dimensional accuracy and surface finish. The resulting molds are used in injection molding machines, where molten plastic is injected into the mold cavities, cooled, and then ejected as finished parts. This method is highly efficient for mass production, offering consistency and reducing waste, which is essential for industries like automotive, consumer electronics, and medical devices.

In the manufacturing realm, custom plastic molds enable the creation of complex and intricate parts that would be difficult or impossible to produce using other methods. The versatility of plastic materials, combined with the precision of custom molds, allows manufacturers to produce parts with varied properties, such as flexibility, strength, and chemical resistance, tailored to specific needs. Moreover, the ability to produce large quantities of identical parts with tight tolerances ensures product reliability and quality. The use of custom plastic molds also reduces the need for secondary machining processes, thereby lowering production costs and shortening lead times. In summary, the application of custom plastic molds in machining and manufacturing not only enhances the efficiency and precision of production processes but also expands the possibilities for innovation in product design and functionality.

Here is a list of FAQs for manufacturing custom plastic molds at SourcifyChina factory, each with answers under 300 words:

Q: What materials can SourcifyChina use for custom plastic molds?

A: SourcifyChina offers a wide range of materials for custom plastic molds, including ABS, PC, PP, PS, PVC, POM, and more. We can help you choose the best material based on your product’s requirements for durability, flexibility, and appearance.

Q: What is the typical lead time for a custom plastic mold order?

A: The lead time for custom plastic mold orders at SourcifyChina typically ranges from 4 to 8 weeks, depending on the complexity of the design and the production volume. We strive to meet your deadlines and will provide a detailed timeline after reviewing your project specifications.

Q: How does SourcifyChina ensure the quality of custom plastic molds?

A: Quality is our top priority. SourcifyChina employs a rigorous quality control process, including material inspection, in-process checks, and final product testing. We utilize advanced machinery and experienced technicians to ensure every mold meets your exact specifications.

Q: Can SourcifyChina help with the design of custom plastic molds?

A: Yes, SourcifyChina provides comprehensive design support. Our team of skilled engineers can assist with product design, mold design, and optimization to ensure manufacturability and cost efficiency. We use advanced CAD software to create precise mold designs.

Q: What is the minimum order quantity for custom plastic molds at SourcifyChina?

A: We offer flexible order quantities to accommodate various project needs. While there is no strict minimum order quantity, smaller orders may incur higher per-unit costs due to setup and tooling expenses. Contact us to discuss your specific requirements.

Q: Does SourcifyChina offer prototyping services?

A: Yes, we provide prototyping services to help you validate your design before full-scale production. Our prototyping capabilities include 3D printing, CNC machining, and low-volume injection molding, allowing you to test and refine your product efficiently.

Q: How does SourcifyChina handle intellectual property protection?

A: We take IP protection seriously. SourcifyChina ensures confidentiality and security of your designs and specifications through non-disclosure agreements (NDAs) and secure data handling practices. Your intellectual property is safe with us.

Q: What are the payment terms for custom plastic molds?

A: Our standard payment terms are 50% deposit upon order confirmation and 50% balance before shipment. We accept various payment methods, including wire transfer, PayPal, and credit cards. Specific terms can be discussed based on your project.

For further inquiries, please contact our customer service team.

Manufacturing custom plastic molds at SourcifyChina factory involves a detailed process designed to meet specific client needs. Here are some essential tips to ensure a successful collaboration:

1. Define Requirements Clearly: Begin with a precise specification of your product requirements. Include detailed drawings, materials, tolerances, and any special features. This ensures that the factory understands exactly what you need.

2. Material Selection: Choose the right plastic material for your mold. Common options include ABS, PVC, PP, and PE, each with unique properties suited to different applications. Discuss the best material options with SourcifyChina’s experts to match your product’s requirements.

3. Design for Manufacturability (DFM): Work closely with the design team to ensure your product is optimized for manufacturing. This includes considering wall thickness, draft angles, and undercuts. A good DFM process minimizes production issues and reduces costs.

4. Prototype Testing: Before full-scale production, create prototypes. SourcifyChina offers rapid prototyping services to test and validate designs. This step helps identify and correct any design flaws early, saving time and money in the long run.

5. Tooling and Mold Fabrication: Invest in high-quality tooling. The mold’s precision and durability directly affect the quality and consistency of the final products. SourcifyChina uses advanced CNC machinery and skilled technicians to produce high-precision molds.

6. Quality Control: Implement stringent quality control measures throughout the production process. SourcifyChina utilizes various inspection techniques, such as dimensional checks and material testing, to ensure each product meets your specifications.

7. Project Management: Maintain clear and consistent communication with the project manager at SourcifyChina. Regular updates and feedback loops are crucial for addressing issues promptly and keeping the project on track.

8. Cost Considerations: Understand the cost structure, including mold fabrication, material costs, and production costs. SourcifyChina provides transparent pricing and can help optimize the cost without compromising on quality.

By following these tips, you can ensure a smooth and efficient manufacturing process for your custom plastic molds at SourcifyChina factory, resulting in high-quality, reliable products.

Sure, here’s a concise FAQ for sourcing custom plastic molds from SourcifyChina factory:

—

What types of custom plastic molds does SourcifyChina offer?

SourcifyChina specializes in a wide range of custom plastic molds, including injection molds, blow molds, and compression molds. They cater to various industries such as automotive, consumer goods, electronics, and medical devices.

What is the typical lead time for custom plastic molds?

The lead time for custom plastic molds generally ranges from 4 to 8 weeks, depending on the complexity and size of the mold. SourcifyChina ensures timely delivery without compromising quality.

How does SourcifyChina ensure mold quality?

SourcifyChina employs advanced CNC machining, precise quality control processes, and rigorous testing to ensure high-quality molds. They also use high-grade materials and have certifications like ISO 9001 to guarantee consistency and reliability.

Can SourcifyChina handle large production runs?

Yes, SourcifyChina is equipped to handle both small and large production runs. They have scalable manufacturing capabilities to meet the demands of various order sizes efficiently.

What materials can SourcifyChina use for mold production?

SourcifyChina works with a wide range of materials, including ABS, PC, PP, PE, PS, and more. They can also accommodate specific material requests based on the client’s project requirements.

Does SourcifyChina offer design assistance?

Yes, SourcifyChina provides design assistance, including CAD modeling and prototyping services. Their team of experienced engineers can help optimize designs for manufacturability and cost-effectiveness.

What are the payment terms for ordering custom molds?

Payment terms typically involve an initial deposit (usually 30-50%) with the balance due upon completion and approval of the mold. Specific terms can be discussed and tailored to the client’s needs.

How can I get a quote for a custom plastic mold?

To get a quote, you can contact SourcifyChina through their website, providing details such as design specifications, material preferences, and quantity requirements. They will respond with a detailed quote and timeline.

—

Sourcing custom plastic molds from SourcifyChina factory involves several key steps to ensure quality and efficiency. Here are some tips:

1. Company Verification: Start by verifying the legitimacy of SourcifyChina. Look for reviews, check their website, and ask for references.

2. Initial Contact: Reach out via email or phone. Clearly state your requirements and ask for a portfolio or examples of previous work.

3. Detailed Specifications: Provide detailed design files, materials specifications, and intended use of the molds. This includes CAD files, plastic type, and color.

4. Production Volume: Specify your expected production volume. This helps the factory determine the best manufacturing process.

5. Prototyping: Request a prototype before full production. This allows you to check the quality and make necessary adjustments.

6. Quality Standards: Ensure the factory adheres to international quality standards like ISO 9001. Ask about their quality control processes.

7. Quotes and Pricing: Obtain detailed quotes, including tooling costs, unit prices, and shipping. Compare with other suppliers to ensure competitive pricing.

8. Contracts: Draft a clear contract outlining terms, timelines, payment schedules, and penalties for delays or defects.

9. Regular Updates: Maintain regular communication to stay updated on production progress. Use video calls, emails, or project management tools.

10. Logistics Planning: Plan for shipping logistics. Decide on shipping methods, ensure customs clearance, and calculate total delivery time.

11. Post-Production Support: Ensure the factory offers post-production support. This includes assistance with any issues or defects that arise after delivery.

Following these tips can streamline the process of sourcing custom plastic molds from SourcifyChina, ensuring a high-quality outcome and a smooth business relationship.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.