Technology and Applications of custom sheet metal

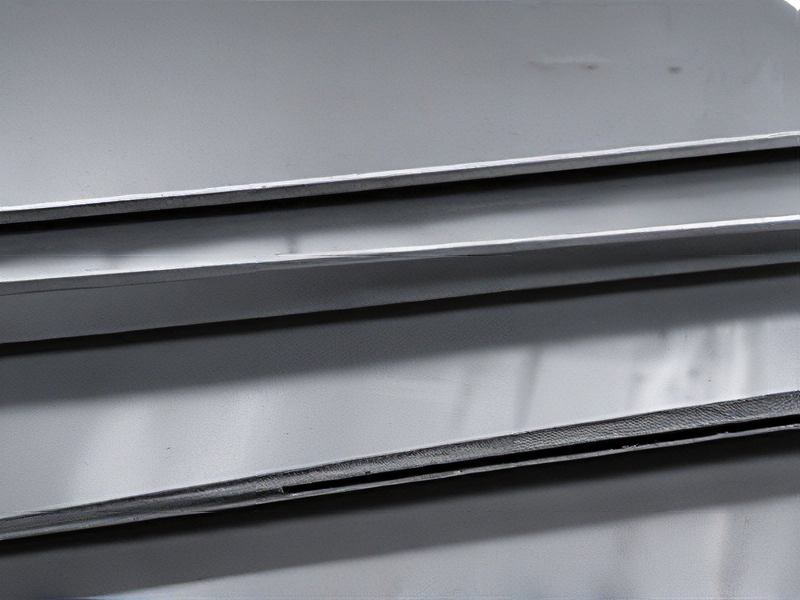

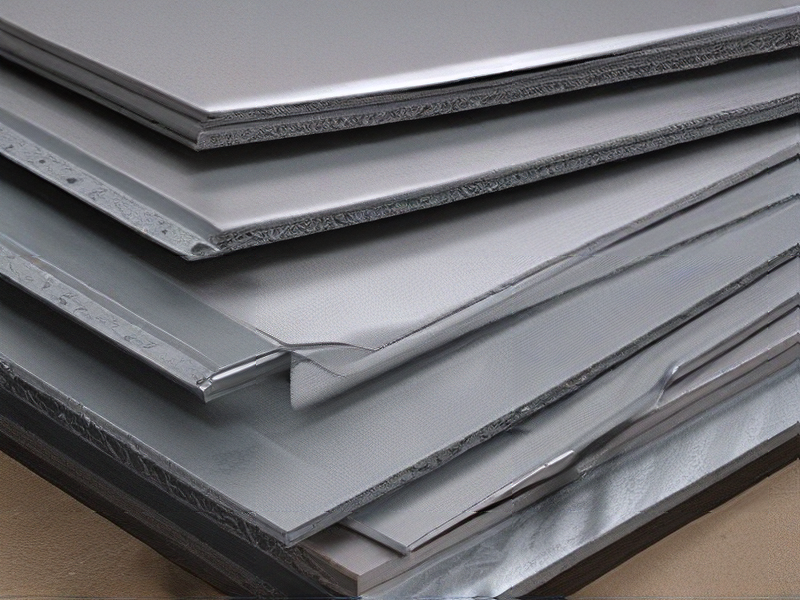

Custom sheet metal fabrication involves the manufacturing of metal components tailored to specific designs and requirements. This process utilizes various techniques such as cutting, bending, and assembling raw metal sheets to create final products.

Applications:

1. Industrial Machinery: Custom sheet metal parts are crucial in industrial equipment and machinery, providing structural support, housings for components, and enclosures for electronics.

2. Automotive Sector: Used extensively in vehicle manufacturing, including chassis components, panels, and decorative trim pieces.

3. Construction: Custom metal parts are employed in architectural applications like roofing, facade cladding, and structural elements.

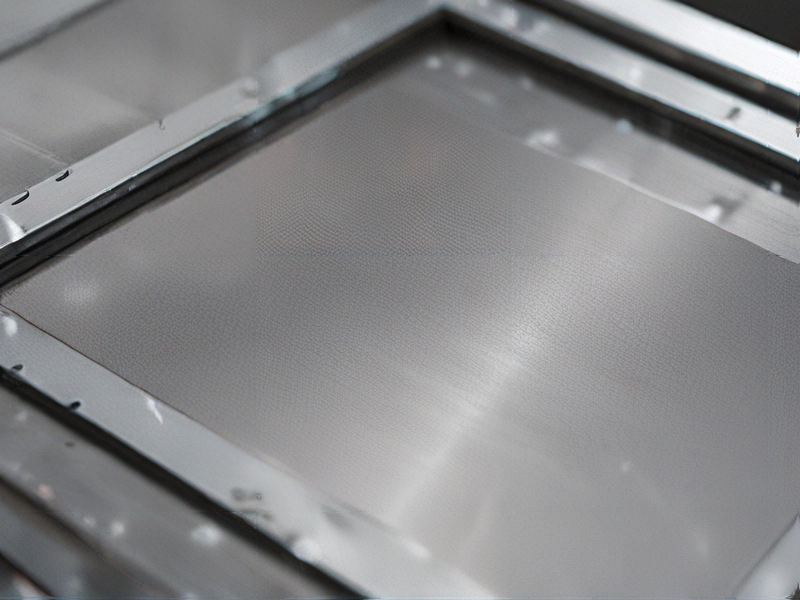

4. Electronics: Enclosures and brackets for electronic devices, ensuring protection and support.

5. Medical Equipment: Custom sheet metal is used for casings, trays, and structural components in medical devices.

6. Aerospace: Vital in aerospace applications, providing lightweight yet durable components for aircraft structures and interiors.

Technologies:

1. Computer-Aided Design (CAD): Designs are created and modified digitally, ensuring precision and efficiency in production.

2. CNC Machining: Computer-controlled machines accurately cut and shape metal sheets based on CAD designs.

3. Laser Cutting: High-precision lasers cut intricate patterns on metal sheets, allowing for complex designs and shapes.

4. Bending and Forming: Hydraulic or mechanical presses bend and form metal sheets into desired shapes and angles.

5. Welding and Assembly: Techniques like MIG and TIG welding are used to join metal parts together, followed by finishing processes such as polishing and painting.

Custom sheet metal fabrication offers versatility and precision, catering to diverse industries and applications with tailored solutions that meet specific functional and aesthetic requirements.

Quality Testing Methods for custom sheet metal and how to control quality

Quality testing methods for custom sheet metal typically involve several key approaches to ensure that the final products meet specified standards:

1. Dimensional Inspection: Utilizing precise measuring tools such as calipers, micrometers, or coordinate measuring machines (CMM) to verify dimensions and tolerances against engineering drawings.

2. Visual Inspection: Examining the surface for defects like scratches, dents, or surface finish inconsistencies that could affect appearance or functionality.

3. Material Testing: Conducting tests such as hardness tests (e.g., Rockwell or Brinell) to ensure the metal meets specified strength and durability requirements.

4. Welding Inspection: Assessing weld quality through visual inspection, dye penetrant testing, or ultrasonic testing to detect defects like cracks or incomplete weld penetration.

5. Corrosion Resistance Testing: Performing tests like salt spray testing to evaluate how well the sheet metal resists corrosion under simulated environmental conditions.

To control quality effectively:

– Establish Clear Standards: Define precise quality criteria and specifications for each component or product.

– Regular Inspections: Implement regular checks throughout the manufacturing process to identify and address issues early.

– Training and Qualification: Ensure that personnel involved in manufacturing and inspection are properly trained and qualified.

– Continuous Improvement: Use feedback from testing and inspection processes to continually improve processes and product quality.

– Supplier Quality Assurance: Collaborate closely with suppliers to maintain consistent material quality and adherence to specifications.

By integrating these methods and controls into the production process, manufacturers can uphold high standards of quality and reliability for custom sheet metal products.

Tips for Procurement and Considerations when Purchasing from custom sheet metal

When procuring custom sheet metal, several considerations ensure a successful purchase:

1. Specifications Clarity: Clearly define your requirements including dimensions, material type (aluminum, steel, etc.), thickness, finish, and tolerances. Detailed drawings or CAD files aid in accuracy.

2. Supplier Selection: Choose suppliers with proven expertise in custom sheet metal fabrication. Evaluate their experience, capabilities, and reviews from past clients.

3. Quality Assurance: Insist on quality certifications (ISO, AS9100, etc.) to ensure adherence to industry standards. Request samples or visit facilities if possible to assess quality firsthand.

4. Cost and Value: Compare quotes from multiple suppliers. Consider not only the initial cost but also factors like lead times, delivery terms, and potential for long-term partnerships.

5. Communication and Collaboration: Maintain clear communication throughout the procurement process. Ensure the supplier understands your expectations and timeline.

6. Logistics and Lead Times: Clarify shipping logistics, lead times, and production schedules upfront to prevent delays in your project timeline.

7. Prototype and Testing: If feasible, start with a prototype or small batch to verify specifications and quality before full-scale production.

8. Sustainability: Consider environmental factors such as material sourcing, waste management, and the supplier’s commitment to sustainable practices.

9. Contractual Agreements: Have a well-defined contract covering aspects like pricing, delivery schedules, quality standards, and dispute resolution mechanisms.

10. Feedback and Continuous Improvement: Provide feedback to suppliers post-purchase for continuous improvement and build lasting supplier relationships.

By adhering to these considerations, you can enhance the efficiency, reliability, and quality of your procurement process for custom sheet metal components.

FAQs on Sourcing and Manufacturing from custom sheet metal in China

Certainly! Here are some FAQs on sourcing and manufacturing custom sheet metal in China:

1. Why should I consider sourcing sheet metal from China?

China offers competitive pricing due to lower labor costs and established manufacturing infrastructure. This can result in cost savings for bulk orders.

2. How do I find a reliable sheet metal manufacturer in China?

Research online platforms and directories, verify certifications (ISO, QC standards), request client references, and consider visiting facilities if possible. Engage with multiple suppliers to compare capabilities and pricing.

3. What are the typical lead times for custom sheet metal orders?

Lead times can vary based on complexity and order size but generally range from 4 to 8 weeks. Larger orders or those requiring extensive customization may take longer.

4. What quality standards can I expect from Chinese manufacturers?

Reputable manufacturers adhere to international quality standards (ISO 9001, ISO 14001) and employ rigorous quality control measures. Request samples and conduct inspections to ensure compliance.

5. How can I manage quality control when manufacturing abroad?

Implement clear specifications and quality criteria in your contract. Conduct regular inspections during production and before shipment. Consider third-party inspection services for additional assurance.

6. What are the typical payment terms when dealing with Chinese manufacturers?

Payment terms often include an initial deposit (30-50%) with the balance due upon completion or shipment. Negotiate terms that align with your cash flow and risk tolerance.

7. Are there any potential challenges or risks in sourcing from China?

Challenges may include language barriers, cultural differences, intellectual property protection, and logistics. Mitigate risks by working with experienced agents or consultants familiar with the local market.

Navigating these considerations diligently can help ensure a successful partnership with a Chinese manufacturer for your custom sheet metal needs.