“Reliable

SourcifyChina: Precision Laser Metal Cutting in China’s Leading Factories”

SourcifyChina stands out as a trusted partner for businesses seeking precision laser metal cutting services in China’s top factories. Utilizing advanced technology, SourcifyChina ensures high-quality, efficient, and cost-effective solutions for a wide range of industries. Their extensive network of vetted factories guarantees reliable and consistent results, making them a go-to source for companies worldwide. By leveraging SourcifyChina’s expertise, businesses can achieve superior product quality and faster turnaround times, essential for maintaining a competitive edge in today’s market. With a commitment to excellence and customer satisfaction, SourcifyChina is your dependable choice for precision laser metal cutting in China.

Choosing SourcifyChina Factory for purchasing cutting laser metal from China ensures high quality, competitive pricing, and efficient delivery. Their advanced technology guarantees precision and reliability, meeting international standards. SourcifyChina’s robust supply chain management and extensive industry experience provide seamless transactions, reducing risks and ensuring timely fulfillment.

Furthermore, SourcifyChina offers exceptional customer service, supporting clients throughout the purchasing process. Their team of experts assists with product selection, customization, and post-purchase support, ensuring customer satisfaction. Their commitment to quality control and continuous improvement results in superior products that meet diverse needs.

SourcifyChina’s strategic location and logistics expertise enable cost-effective and swift shipping solutions. They leverage strong partnerships with reputable carriers to ensure products reach clients promptly and in excellent condition. This efficiency reduces downtime and enhances business operations.

Lastly, SourcifyChina prioritizes sustainable and ethical manufacturing practices, aligning with global environmental standards. By choosing SourcifyChina, buyers contribute to responsible production and can confidently showcase their commitment to sustainability. This makes SourcifyChina a reliable partner for sourcing cutting laser metal products from China.

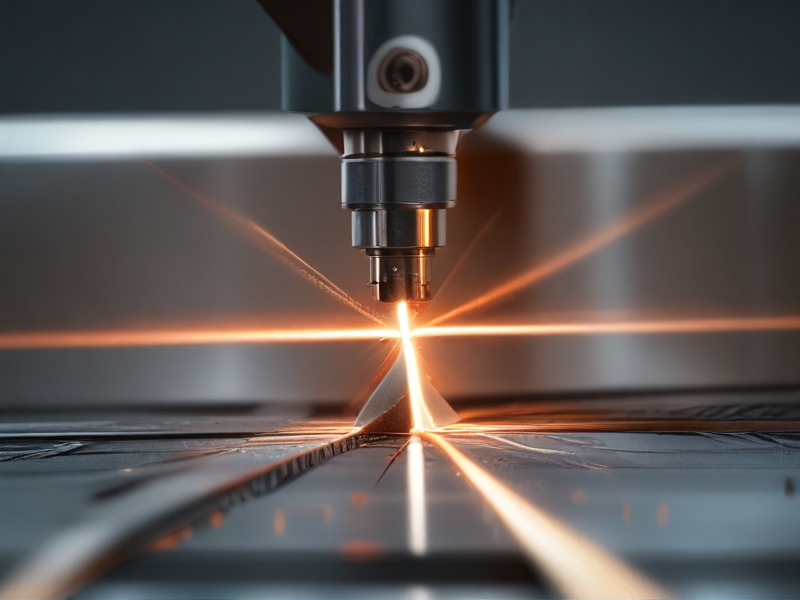

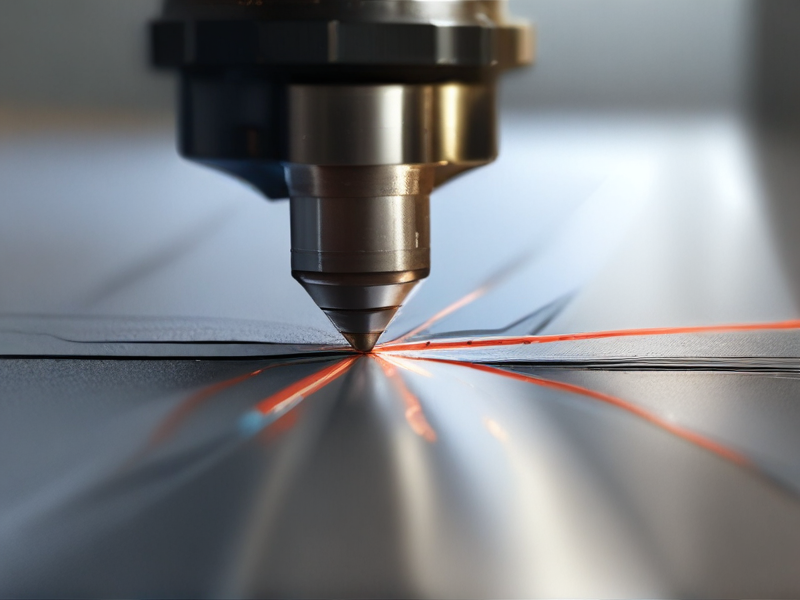

Cutting laser metal is a precise and efficient method used in various industries. It involves using a high-powered laser to cut materials like steel, aluminum, and titanium. There are several types and options available for cutting laser metal.

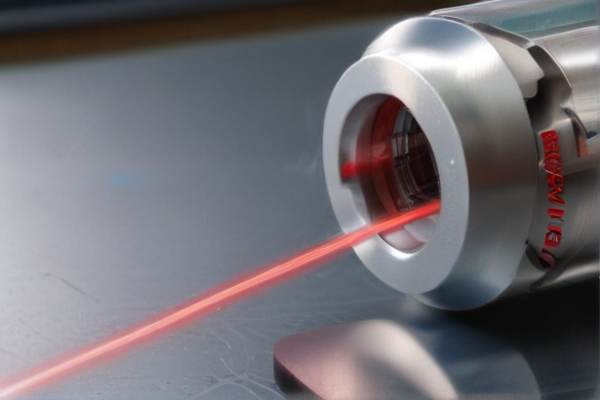

– CO2 Lasers: Suitable for cutting, boring, and engraving metals. High efficiency for thick materials.

– Fiber Lasers: Offer high power and precision, ideal for cutting thin metals with speed and accuracy.

– Nd:YAG Lasers: Suitable for high-precision applications, often used in the aerospace and medical industries.

– Disk Lasers: Provide excellent beam quality and high efficiency, used for both thick and thin materials.

– Diode Lasers: Primarily used for cutting thin metals, known for their energy efficiency and compact size.

Options for Cutting Laser Metal:

– Power Levels: Higher power levels for thicker materials and lower power levels for thinner materials.

– Beam Quality: Superior beam quality results in finer cuts and more intricate designs.

– Cooling Systems: Ensures consistent performance and prevents overheating during prolonged use.

– Cutting Speed: Adjustable speeds to balance precision and productivity based on material type and thickness.

– Automation and CNC Control: Enhances accuracy and repeatability, reducing manual intervention.

– Assist Gas: Gases like oxygen, nitrogen, or air are used to improve cutting quality and speed.

Each type and option of cutting laser metal offers unique advantages tailored to specific applications, ensuring the best fit for various industrial needs.

Cutting laser metal is a precise and efficient method used in various industries for manufacturing and fabrication. It offers high accuracy, speed, and versatility for cutting complex shapes and materials.

Applications include:

– Automotive parts production

– Aerospace component fabrication

– Medical device manufacturing

– Electronics and circuit board creation

– Construction and architectural designs

– Jewelry and decorative items

– Tool and die making

– Signage and advertising displays

– Metal furniture and fixtures

– Custom and prototype development

Overall, cutting laser metal technology is integral to many sectors due to its precision, efficiency, and ability to handle diverse materials.

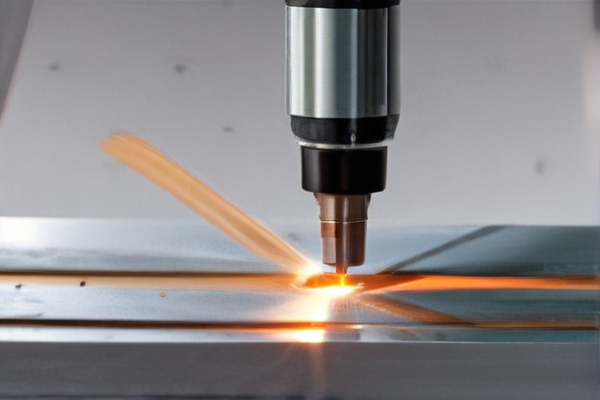

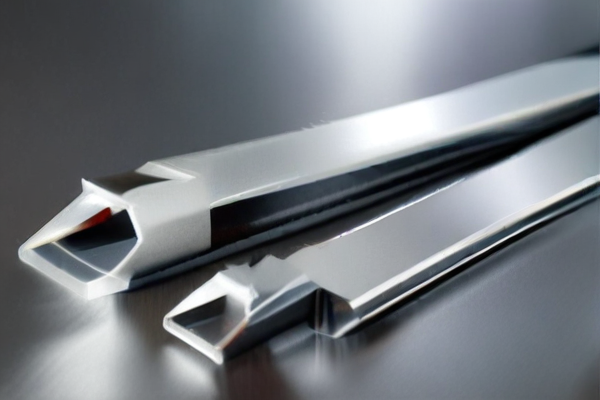

“SourcifyChina cutting laser metal” involves precision technology for cutting various metals using high-powered laser beams. This process is highly efficient and offers superior accuracy compared to traditional methods.

The laser cutting technique used by SourcifyChina is ideal for complex shapes and intricate designs. It provides a clean cut with minimal waste, making it a cost-effective solution for manufacturers.

Materials commonly cut with laser technology include stainless steel, aluminum, and copper. These metals are chosen for their durability, versatility, and resistance to corrosion, ensuring long-lasting and high-quality products.

SourcifyChina’s laser cutting services are widely utilized in industries such as automotive, aerospace, and electronics. Their advanced machinery and skilled technicians guarantee consistent results and high precision in every project.

The company emphasizes innovation and customer satisfaction. They continuously invest in the latest laser cutting technology to meet diverse client needs and maintain a competitive edge in the market.

In summary, SourcifyChina’s laser metal cutting services offer unparalleled precision, efficiency, and versatility. Their expertise and advanced technology make them a reliable partner for businesses requiring high-quality metal components.

SourcifyChina employs rigorous quality control measures in its laser metal cutting process to ensure precision and consistency. Each stage, from material selection to final inspection, adheres to strict standards to meet customer specifications.

The manufacturing process begins with high-quality raw materials, which undergo thorough inspection for defects. Only materials that pass this initial check are used in production, ensuring a strong foundation for further processing.

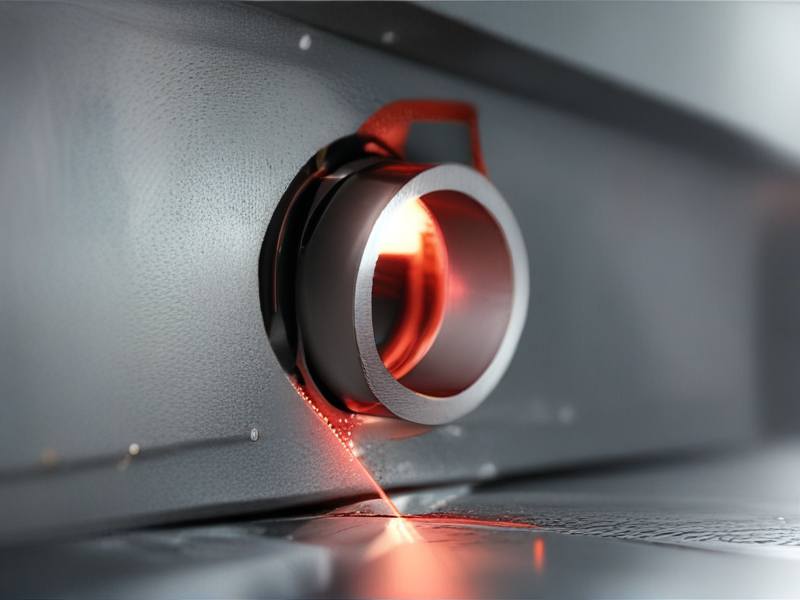

Advanced laser cutting machines are utilized, equipped with state-of-the-art technology to achieve precise cuts. These machines are regularly calibrated and maintained to ensure optimal performance and accuracy.

Throughout the cutting process, continuous monitoring is conducted using automated systems and manual inspections. This dual approach helps in detecting any deviations or imperfections early, allowing for immediate corrections.

Post-cutting, the products undergo a comprehensive quality assessment, including dimensional checks and surface finish evaluations. This step ensures that all components meet the stringent quality criteria set by SourcifyChina.

In the final stage, products are subjected to rigorous testing to verify their durability and performance under various conditions. This thorough testing guarantees that the end products are reliable and meet the highest industry standards.

SourcifyChina’s commitment to quality control in laser metal cutting is reflected in their consistent delivery of high-precision components. By maintaining a meticulous approach to each step, they ensure customer satisfaction and uphold their reputation for excellence.

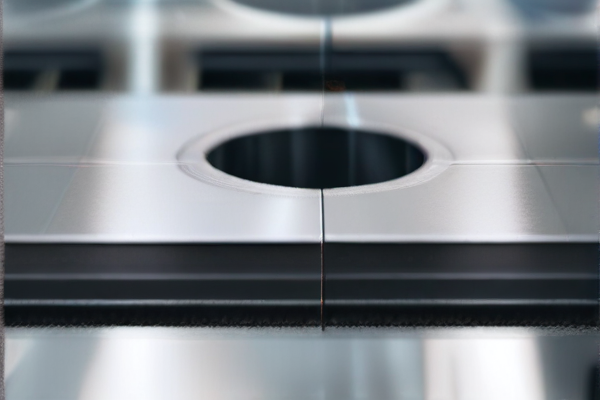

SourcifyChina offers advanced laser cutting capabilities for various metal types, providing high precision and clean cuts. Their state-of-the-art machinery ensures accuracy down to the millimeter, making it ideal for intricate designs and complex parts.

The company’s laser cutting technology is suitable for a wide range of metals, including steel, aluminum, and copper. This versatility allows them to cater to different industries, from automotive to electronics, ensuring robust and durable components.

SourcifyChina’s laser cutting process is efficient and cost-effective. It minimizes material waste and reduces production time, which translates into lower costs for clients and faster turnaround times.

Their expert team ensures every project meets stringent quality standards. By combining advanced technology with skilled craftsmanship, SourcifyChina delivers exceptional results that consistently exceed client expectations.

In conclusion, SourcifyChina’s cutting-edge laser metal cutting services provide precision, efficiency, and versatility, making them a top choice for industries requiring high-quality metal fabrication solutions.

Cutting metal with lasers offers unmatched precision and efficiency, revolutionizing the manufacturing industry with numerous benefits.

– Precision and Accuracy: Laser cutting provides highly precise cuts with minimal tolerance levels, ensuring exact specifications are met.

– Speed: Laser cutting is faster than traditional methods, significantly reducing production time.

– Versatility: Capable of cutting a wide range of metals, including steel, aluminum, and titanium.

– Quality: Produces clean edges and smooth finishes, reducing the need for further processing.

– Automation: Easily integrated with automated systems, enhancing productivity and reducing labor costs.

– Material Utilization: Minimizes waste by optimizing the cutting process.

– Consistency: Ensures uniformity in repeated cuts, crucial for mass production.

– Safety: Reduces risk of accidents associated with manual cutting tools.

– Reduced Contamination: Non-contact process limits contamination and damage to the metal.

– Energy Efficiency: More energy-efficient compared to other cutting methods, reducing operational costs.

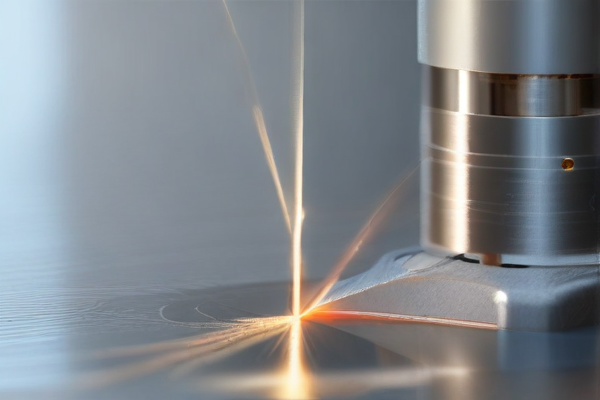

Cutting laser metal involves using a high-powered laser to cut through various metals with precision and speed. This method offers several advantages over traditional cutting techniques.

– High Precision: Laser cutting achieves extremely precise cuts, with minimal distortion, making it ideal for complex shapes and intricate designs.

– Speed: The process is much faster than traditional cutting methods, significantly reducing production time.

– Versatility: It can cut through a wide range of metals, including steel, aluminum, brass, and titanium.

– Clean Cuts: The high heat of the laser produces clean, smooth edges, often eliminating the need for further finishing.

– Automation: Laser cutting machines can be fully automated and integrated into production lines, enhancing efficiency.

– Reduced Waste: The precision of laser cutting minimizes material waste, making it a cost-effective option.

– Low Heat Affected Zone: The focused nature of the laser results in a smaller heat-affected zone, reducing the risk of warping or other heat-related damage to the material.

– Non-contact Process: As a non-contact cutting method, there is less wear and tear on the machinery, leading to lower maintenance costs and longer machine life.

– Ability to Cut Complex Geometries: The flexibility of laser cutting allows for the creation of complex geometries that would be difficult or impossible with other methods.

– High Reproducibility: Laser cutting ensures consistent quality and precision, ideal for mass production runs where uniformity is crucial.

– Environmental Benefits: With reduced material waste and no need for hazardous cutting fluids, laser cutting is more environmentally friendly.

In summary, laser metal cutting offers unparalleled precision, speed, and efficiency, making it an indispensable tool in modern manufacturing and metalworking industries.

SourcifyChina specializes in cutting-edge laser metal cutting services, delivering high-precision custom products tailored to various industries. Their advanced technology ensures accuracy and efficiency in every project.

From intricate designs to large-scale productions, SourcifyChina caters to a wide range of customer needs. They handle diverse materials and offer bespoke solutions, ensuring each piece meets exact specifications.

Their team of experts collaborates closely with clients to understand their requirements. This personalized approach guarantees that every project is executed flawlessly, maintaining high standards of quality and craftsmanship.

SourcifyChina’s commitment to innovation and excellence has made them a trusted partner for businesses seeking reliable laser metal cutting services. Their dedication to customer satisfaction is evident in every custom product they deliver. Whether it’s a small batch or a large order, SourcifyChina provides consistent quality, making them a go-to choice for custom metal cutting projects.

SourcifyChina is a leading company in the laser cutting metal industry, known for its precision and advanced technology. Specializing in high-quality metal cutting services, SourcifyChina utilizes state-of-the-art laser systems to deliver accurate and efficient solutions for a wide range of industrial applications. Their cutting-edge technology ensures minimal material waste and maximizes productivity, making them a preferred choice for businesses seeking reliable metal fabrication services. The company’s commitment to innovation and customer satisfaction is evident in their meticulous attention to detail and ability to handle complex cutting tasks with ease. SourcifyChina’s expertise spans various metals, including stainless steel, aluminum, and carbon steel, catering to diverse sectors such as automotive, aerospace, and construction. With a strong focus on quality and timely delivery, SourcifyChina continues to set benchmarks in the laser cutting industry, establishing itself as a trusted partner for precision metalwork.

Cutting laser metal technology has become integral to the Aerospace, Defense, and Marine sectors due to its precision, efficiency, and versatility. In aerospace, cutting lasers are used extensively to manufacture components from lightweight yet strong materials like titanium and aluminum. These materials are essential for creating aircraft that are both durable and fuel-efficient. The precision of laser cutting ensures that parts fit together with extreme accuracy, which is critical for maintaining the structural integrity and safety of aircraft. Additionally, laser cutting reduces material wastage and enhances production speed, helping manufacturers meet stringent industry deadlines and standards.

In the defense and marine industries, the application of laser cutting technology is equally significant. Defense applications include the fabrication of armored vehicle parts, weapons systems, and various other military hardware that require high precision and strength. Laser cutting allows for intricate designs and the production of complex shapes that traditional methods struggle to achieve. Similarly, in the marine industry, laser cutting is used to construct components for ships and submarines, ensuring that they can withstand harsh oceanic conditions. The technology also facilitates rapid prototyping and the production of custom parts, allowing for greater flexibility and responsiveness in design and manufacturing processes. Overall, laser cutting enhances the capability to produce high-quality, reliable components essential for aerospace, defense, and marine applications.

In the automotive industry, cutting laser metal has revolutionized manufacturing processes by providing precision, speed, and versatility. This technology is employed to cut various metal components used in car bodies, chassis, and intricate parts, ensuring high precision and clean edges that are essential for safety and performance. Laser cutting allows for the creation of complex shapes and detailed designs that would be difficult or impossible with traditional methods. Additionally, it reduces material wastage and shortens production times, enhancing efficiency and lowering costs. This innovation supports the production of lightweight, fuel-efficient vehicles, which is critical in meeting stringent environmental regulations and consumer demand for greener options.

In the electronics industry, cutting laser metal is pivotal in the fabrication of small, intricate parts used in devices such as smartphones, laptops, and medical equipment. The high precision of laser cutting is crucial for creating the minute components required in these devices, such as circuit boards, connectors, and enclosures. This method allows for the precise cutting of thin metals without causing deformation or heat damage, ensuring the integrity and functionality of the electronic components. Moreover, the flexibility of laser cutting supports rapid prototyping and custom production, enabling manufacturers to swiftly adapt to market changes and technological advancements. This capability is essential in the fast-paced electronics industry, where innovation and time-to-market are critical competitive factors.

Cutting laser metal technology has revolutionized the construction industry by enhancing precision, efficiency, and flexibility in material processing. In construction, laser cutting is used to fabricate structural components, including beams, columns, and intricate metal designs for facades and architectural elements. This method allows for precise cuts and intricate patterns that traditional cutting methods struggle to achieve, significantly reducing waste and improving material utilization. Additionally, the speed and accuracy of laser cutting contribute to shorter project timelines and lower labor costs, as it minimizes the need for manual adjustments and rework. The ability to quickly prototype and produce custom components also supports innovative architectural designs and adaptive reuse projects, further pushing the boundaries of modern construction.

In the energy sector, cutting laser metal technology plays a crucial role in the manufacturing and maintenance of equipment used in power generation and distribution. For instance, in the production of wind turbines, laser cutting ensures the precise fabrication of blades and other components, which is essential for optimal aerodynamic performance and efficiency. Similarly, in the oil and gas industry, laser cutting is used to produce complex piping systems and components with high precision, ensuring better fit and reducing the risk of leaks. Moreover, laser cutting is instrumental in the production of photovoltaic cells for solar panels, where it is used to create fine, precise cuts necessary for the efficient conversion of sunlight into electricity. The technology also supports the repair and retrofitting of existing infrastructure, enhancing the longevity and performance of energy systems. Overall, cutting laser metal technology contributes to increased reliability, efficiency, and sustainability in the energy sector.

The industrial equipment industry leverages cutting laser metal technology extensively due to its precision, efficiency, and versatility. Laser cutting involves using a high-powered laser beam to melt, burn, or vaporize metal, resulting in clean and precise cuts. This technology is crucial in manufacturing sectors such as automotive, aerospace, and construction, where intricate designs and tight tolerances are essential. The ability to cut through various metals, including steel, aluminum, and titanium, without direct contact minimizes material deformation and wear on the equipment, enhancing longevity and reducing maintenance costs.

Moreover, cutting laser metal technology supports rapid prototyping and mass production. Its programmable nature allows for quick adjustments to designs, facilitating customization and reducing lead times. The high speed and accuracy of laser cutters also contribute to increased production rates, meeting the demands of high-volume industries. Additionally, the automation capabilities of laser cutting systems integrate seamlessly with other industrial processes, enabling streamlined workflows and improved overall efficiency. This synergy between precision and productivity underscores the pivotal role of laser cutting in modern industrial equipment applications.

The application of cutting laser metal in the medical device industry has revolutionized the precision and efficiency with which complex components are manufactured. Laser cutting allows for incredibly precise and intricate designs that are crucial for medical devices, such as surgical instruments, implants, and diagnostic equipment. The high degree of accuracy afforded by laser technology ensures that each piece meets stringent medical standards, which is vital for patient safety and device reliability. Moreover, the ability to cut intricate patterns and shapes from various metals, including stainless steel and titanium, has expanded the possibilities for designing innovative medical solutions. The minimal thermal impact and clean edges produced by laser cutting reduce the need for further processing, streamlining production and reducing costs.

Additionally, laser cutting’s versatility and adaptability make it an indispensable tool in the rapid prototyping and manufacturing of custom medical devices. For personalized medical solutions, such as patient-specific implants and prosthetics, laser cutting enables quick and precise adjustments to designs based on individual patient anatomy. This technology supports the development of minimally invasive surgical tools, which require intricate designs to function within the body’s limited spaces. The ability to quickly iterate on prototypes accelerates the development process, bringing new and improved medical devices to market faster. In summary, laser cutting of metal in the medical device industry not only enhances the precision and quality of the devices but also significantly improves production efficiency and innovation capability.

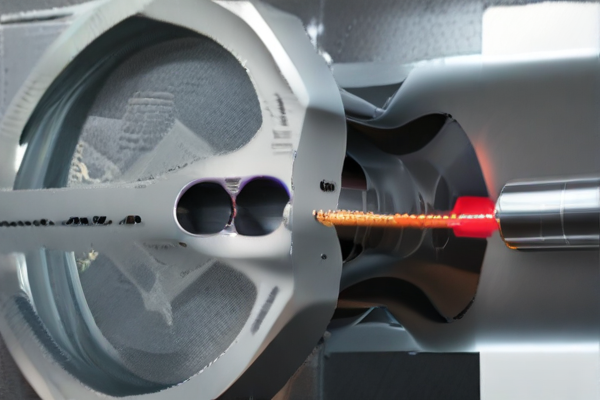

Laser cutting is a pivotal technology in the machining and manufacturing sectors, offering precision, speed, and versatility in metalworking. This process uses a high-powered laser beam directed through optics to cut, engrave, or mark metal surfaces. The intense heat generated by the laser causes the metal to melt, burn, or vaporize along a pre-determined path, resulting in clean, accurate cuts. This precision reduces the need for secondary finishing processes, saving time and cost. Furthermore, laser cutting supports complex geometries and tight tolerances, making it ideal for producing intricate parts and prototypes in industries ranging from aerospace to automotive and medical devices.

In manufacturing, laser cutting enhances efficiency and flexibility, accommodating a wide variety of metals including steel, aluminum, and titanium. The ability to quickly switch between different materials and thicknesses without significant downtime makes laser cutting an attractive option for both high-volume production runs and custom, low-volume projects. Advanced computer numerical control (CNC) systems further streamline operations, allowing for the automation of cutting processes and integration into larger manufacturing systems. As a result, manufacturers can achieve faster production cycles, reduce waste, and maintain high quality, ultimately improving competitiveness and innovation in the marketplace.

Q1: What types of metals can SourcifyChina’s laser cutting process handle?

A1: SourcifyChina’s laser cutting process can handle a variety of metals, including stainless steel, carbon steel, aluminum, brass, and copper.

Q2: What thickness of metal can SourcifyChina cut?

A2: Our laser cutting equipment can cut metal sheets up to 25mm thick, depending on the material and specific requirements of the project.

Q3: What is the maximum sheet size that can be cut?

A3: SourcifyChina’s laser cutting machines can accommodate metal sheets up to 3000mm x 1500mm in size.

Q4: What tolerances can be achieved with laser cutting?

A4: Our precision laser cutting technology ensures tight tolerances, typically within ±0.1mm, depending on the material and thickness.

Q5: How does SourcifyChina ensure the quality of the laser cutting work?

A5: Quality is ensured through stringent process controls, regular equipment maintenance, and thorough inspections at each stage of production.

Q6: Can SourcifyChina provide custom laser cutting designs?

A6: Yes, we offer custom laser cutting services based on your specific design files and requirements. We accept various file formats, including CAD and DXF.

Q7: What is the lead time for laser cutting orders?

A7: Lead times vary based on the complexity and volume of the order. Typically, small orders can be completed within a few days, while larger or more complex orders may take up to two weeks.

Q8: Does SourcifyChina offer any additional metal finishing services?

A8: Yes, we provide a range of additional services, including bending, welding, powder coating, and plating to meet your finished product needs.

Q9: How can I request a quote for laser cutting services?

A9: To request a quote, please contact us with your project details, including material type, thickness, dimensions, and design files. Our team will respond promptly with a detailed quotation.

Q10: What are the payment terms for orders placed with SourcifyChina?

A10: Our standard payment terms are 30% deposit upon order confirmation and the remaining balance before shipment. We accept various payment methods, including bank transfers and credit cards.

When considering cutting laser metal manufacturing from a SourcifyChina factory, here are some tips to ensure a successful partnership and high-quality output:

1. Understand Capabilities: Verify the factory’s laser cutting technology, including machine specifications, tolerance levels, and maximum material thickness they can handle. Modern CO2 and fiber laser machines offer different benefits and precision levels.

2. Material Quality: Confirm the types of metals they work with, such as stainless steel, aluminum, or brass. Ensure they source high-quality materials to avoid issues with durability and performance.

3. Design and Precision: Provide detailed CAD drawings and specifications. Accurate designs help in achieving precise cuts and reducing errors. Discuss the factory’s ability to handle complex geometries and intricate designs.

4. Prototyping: Start with a prototype to assess quality and precision before committing to large-scale production. This helps identify any potential issues early on and allows for adjustments.

5. Quality Control: Check their quality control processes. Ask about their inspection methods and standards for ensuring each piece meets the required specifications.

6. Lead Times: Clarify lead times for both prototypes and full production runs. Reliable lead times are crucial for planning and meeting your production schedules.

7. Communication: Maintain clear and consistent communication. Language barriers can lead to misunderstandings, so ensure that both parties are aligned on all aspects of the project.

8. Cost Transparency: Understand the cost structure, including any additional fees for setup, tooling, or materials. Request detailed quotes to avoid hidden charges.

9. Logistics and Shipping: Discuss logistics and shipping options. Ensure the factory has experience in exporting goods and can handle customs documentation efficiently.

10. Factory Visits: If possible, visit the factory to inspect their operations, meet the team, and see their equipment in action. This can build trust and provide a clearer picture of their capabilities.

Following these tips will help you establish a productive and efficient relationship with a laser metal cutting manufacturer from SourcifyChina.

1. What materials can SourcifyChina cut with their laser machines?

SourcifyChina can cut a variety of metals including steel, stainless steel, aluminum, copper, and brass. Their advanced laser cutting technology ensures precision and quality for all types of metal.

2. What is the maximum thickness of metal that SourcifyChina can cut?

The factory can cut metals up to 25mm in thickness, depending on the type of metal. Thicker metals can be cut with special arrangements.

3. What are the typical tolerances for laser-cut metal parts?

SourcifyChina maintains high precision with tolerances typically around ±0.1mm. This ensures that the parts meet strict quality standards and fit specifications.

4. What kind of laser cutting technology does SourcifyChina use?

SourcifyChina uses state-of-the-art fiber and CO2 laser cutting machines. These machines offer high speed, precision, and can handle complex cutting tasks efficiently.

5. How does SourcifyChina ensure the quality of laser-cut parts?

Quality is ensured through a rigorous inspection process that includes dimensional checks, surface finish inspections, and testing for material integrity. The factory is ISO certified, reflecting its commitment to quality.

6. Can SourcifyChina handle custom designs and large orders?

Yes, SourcifyChina is equipped to handle both custom designs and bulk orders. They offer flexible production capabilities to meet various client needs, from prototypes to large-scale manufacturing.

7. What is the lead time for orders from SourcifyChina?

Lead times vary based on the complexity and size of the order. Typically, small to medium-sized orders can be fulfilled within 1-2 weeks. Large or complex orders may require longer lead times.

8. How can I place an order with SourcifyChina?

Orders can be placed through their website, via email, or by contacting their customer service directly. Detailed specifications and drawings should be provided to ensure accurate production.

9. Does SourcifyChina offer international shipping?

Yes, SourcifyChina provides international shipping services. They work with reliable logistics partners to ensure timely and safe delivery of orders worldwide.

10. Are there any minimum order quantities (MOQ) required?

SourcifyChina is flexible with MOQs and can accommodate both small and large orders. Specific MOQs may vary depending on the project requirements and materials used.

When sourcing “cutting laser metal from SourcifyChina factory,” here are some tips to ensure you get the best quality and service:

1. Research the Supplier: Ensure that SourcifyChina factory has a good reputation. Look for reviews and ratings from other businesses that have sourced from them. Reliable suppliers often have positive feedback and a history of delivering quality products.

2. Verify Certifications: Check if the factory has relevant certifications such as ISO 9001 for quality management. This indicates that they adhere to international standards and practices.

3. Request Samples: Before placing a large order, ask for samples of the laser-cut metal. This allows you to assess the quality, precision, and finish of their work.

4. Evaluate Machinery and Technology: Inquire about the types of laser cutting machines they use. Modern, well-maintained equipment can produce more precise and consistent results.

5. Discuss Specifications: Clearly communicate your requirements, including material type, thickness, dimensions, and tolerances. Providing detailed specifications helps avoid misunderstandings and ensures you receive exactly what you need.

6. Check Lead Times: Understand their production and delivery timelines. Ensure that they can meet your deadlines without compromising on quality.

7. Negotiate Terms: Discuss payment terms, minimum order quantities, and pricing. Ensure that all terms are clear and agreed upon before proceeding.

8. Quality Control: Ask about their quality control processes. A good supplier will have stringent checks in place to ensure that each piece meets the required standards.

9. Shipping and Logistics: Confirm their shipping capabilities and costs. Ensure that they can handle the logistics of delivering the products to your location efficiently and safely.

10. After-Sales Support: Ensure that they offer good after-sales support in case you encounter any issues with the products.

By following these tips, you can effectively source high-quality laser-cut metal from SourcifyChina factory and build a successful partnership.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.