Technology and Applications of diy cnc router

Technology and Applications of DIY CNC Routers

#### Technology

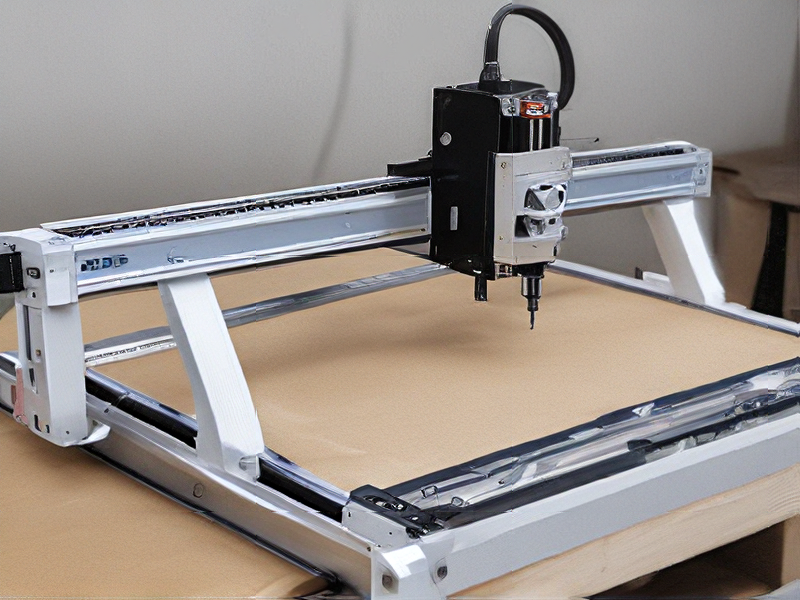

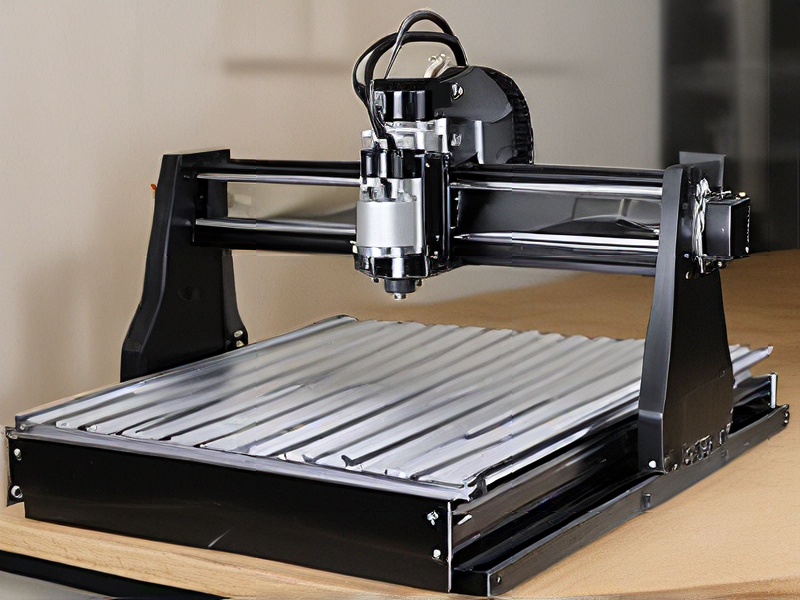

DIY CNC (Computer Numerical Control) routers are automated cutting machines that follow programmed paths to shape materials like wood, plastic, and metal. These routers consist of:

1. Frame: Typically made from aluminum or steel, providing structural support.

2. Motors: Stepper or servo motors drive the cutting tool along the X, Y, and Z axes.

3. Control System: A computer with CNC software (such as GRBL or Mach3) controls the router’s movements, translating digital designs into precise tool paths.

4. Spindle: The cutting tool, powered by an electric motor, which spins at high speeds to carve the material.

5. Drive System: Components like lead screws, ball screws, or belts that convert motor rotations into linear movements.

6. Power Supply: Supplies consistent power to the motors and control system.

#### Applications

1. Prototyping: DIY CNC routers are invaluable for creating prototypes, allowing makers and engineers to produce precise models quickly.

2. Furniture Making: Custom furniture pieces can be designed and produced with intricate details, enabling personalized and unique designs.

3. Sign Making: CNC routers are used to create detailed signs and engravings, useful for businesses and personal projects.

4. Art and Craft: Artists and hobbyists utilize CNC routers to craft detailed sculptures, decorations, and other artistic items.

5. PCBs (Printed Circuit Boards): They can mill PCBs for electronics projects, offering a cost-effective way to produce custom circuit boards.

6. Automotive and Aerospace: DIY CNC routers can manufacture small, precise parts needed in these industries, supporting innovation and repair.

Conclusion

DIY CNC routers combine precision, flexibility, and affordability, making them a popular choice for hobbyists, small businesses, and educational institutions. Their versatility allows for a wide range of applications, from intricate art to functional engineering components.

Quality Testing Methods for diy cnc router and how to control quality

Quality testing for a DIY CNC router involves several methods to ensure precision, durability, and performance. Here are key testing methods and quality control measures:

Testing Methods

1. Alignment and Calibration:

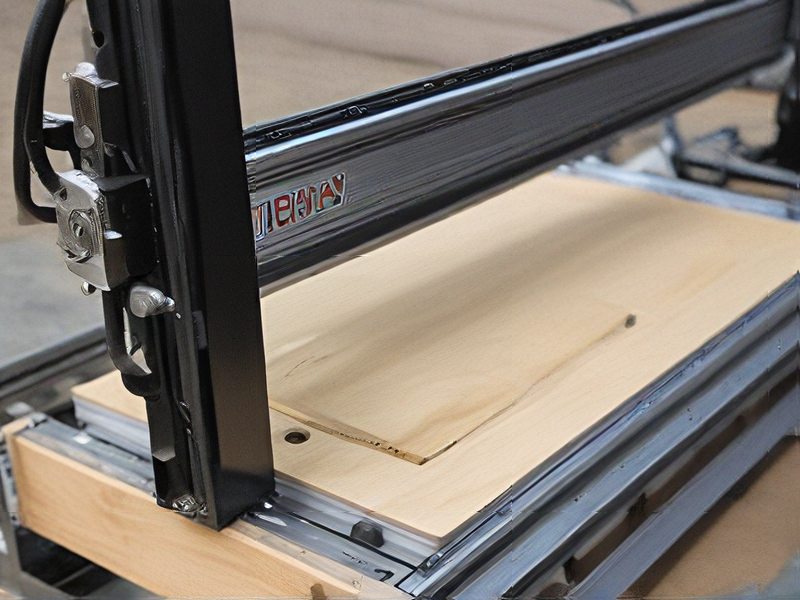

– Bed Leveling: Ensure the CNC bed is perfectly level to avoid discrepancies in cutting depth.

– Axis Alignment: Use dial indicators or laser alignment tools to check the straightness of X, Y, and Z axes.

2. Accuracy and Precision Testing:

– Test Cuts: Perform test cuts on various materials to check the accuracy of dimensions and repeatability.

– Backlash Test: Measure the amount of play or movement in the machine when reversing direction to ensure minimal backlash.

3. Speed and Feed Rate Testing:

– Optimal Settings: Experiment with different speeds and feed rates to determine the optimal settings for various materials.

– Vibration Analysis: Monitor and reduce vibrations to enhance cutting precision and prolong tool life.

4. Software and Control Systems:

– G-Code Validation: Verify the accuracy of G-code generated by CAM software.

– Controller Testing: Ensure the CNC controller responds correctly to commands without delays or errors.

Quality Control Measures

1. Material Selection:

– High-Quality Components: Use high-grade materials for the frame, screws, and motors to enhance durability and performance.

– Tool Inspection: Regularly check cutting tools for wear and replace them as needed to maintain cut quality.

2. Routine Maintenance:

– Lubrication: Keep moving parts well-lubricated to prevent wear and tear.

– Cleaning: Regularly clean the machine to avoid dust and debris buildup that can affect performance.

3. Documentation and Training:

– User Manuals: Provide comprehensive manuals for assembly, calibration, and maintenance.

– Training: Educate users on proper operation and troubleshooting techniques.

4. Feedback and Iteration:

– User Feedback: Collect feedback from users to identify common issues and areas for improvement.

– Continuous Improvement: Regularly update the design and software based on user feedback and technological advancements.

Implementing these methods and measures ensures a high-quality DIY CNC router that performs reliably and accurately.

Tips for Procurement and Considerations when Purchasing from diy cnc router

When purchasing a DIY CNC router, consider these key tips and considerations to ensure you make an informed decision:

1. Purpose and Requirements: Define your specific needs and goals. Consider factors like the size of materials you’ll be working with, the complexity of projects, and whether you need additional features like laser engraving or a specific bed size.

2. Budget: Determine your budget range early on. DIY CNC routers can vary widely in price depending on size, capability, and build quality. Balance your budget with the features and performance you require.

3. Kit vs. Ready-Made: Decide whether you want a kit (which requires assembly) or a pre-assembled machine. Kits are often more affordable but require technical know-how, while pre-assembled machines offer convenience but may cost more.

4. Accuracy and Precision: Look for reviews or specifications that indicate the machine’s accuracy and precision. This is crucial for ensuring your projects are executed correctly.

5. Support and Community: Check if there’s a supportive user community or manufacturer support available. This can be invaluable for troubleshooting issues and learning best practices.

6. Software Compatibility: Ensure the CNC router is compatible with the software you plan to use for designing and controlling your projects (e.g., CAD/CAM software).

7. Build Quality and Materials: Assess the materials used in construction and read reviews for insights into durability and longevity. A sturdy frame and quality components are essential for reliable performance.

8. Expansion and Upgradability: Consider whether the machine allows for future upgrades or modifications as your skills and needs evolve. This can extend the lifespan and functionality of your CNC router.

9. Safety Features: Check for safety features such as emergency stop buttons, enclosure options, and protective shields, especially if you’ll be working in a home workshop environment.

10. Shipping and Delivery: Factor in shipping costs and delivery times, especially if ordering internationally or from a remote location.

By carefully evaluating these factors, you can choose a DIY CNC router that meets your specific requirements, fits your budget, and provides reliable performance for your projects.

FAQs on Sourcing and Manufacturing from diy cnc router in China

Certainly! Here are some FAQs regarding sourcing and manufacturing DIY CNC routers from China:

1. What are the advantages of sourcing a DIY CNC router from China?

Sourcing from China often offers cost advantages due to lower labor and manufacturing costs. Chinese manufacturers also have extensive experience in producing CNC machinery.

2. How can I ensure quality when sourcing from China?

Conduct thorough research on manufacturers, read reviews, and ask for samples or visit the factory if possible. Implementing a quality control process with clear specifications is crucial.

3. What are the typical lead times for manufacturing a DIY CNC router in China?

Lead times can vary based on complexity and order size, but generally range from a few weeks to a couple of months. Communication and clarity in requirements help in meeting timelines.

4. Are there any challenges in sourcing DIY CNC routers from China?

Challenges may include language barriers, cultural differences, and potential logistical issues. Working with a reputable sourcing agent or partner can mitigate these challenges.

5. Can I customize the design of the CNC router when sourcing from China?

Yes, many Chinese manufacturers offer customization options. It’s essential to provide detailed specifications and have clear communication throughout the design process.

6. What are the payment terms typically used when sourcing from China?

Payment terms vary but often include options like T/T (Telegraphic Transfer), L/C (Letter of Credit), or Alibaba’s Trade Assurance. Negotiating favorable terms and ensuring payment security is crucial.

7. How do I handle shipping and logistics when sourcing from China?

Manufacturers often assist with shipping arrangements. Factors like shipping method, customs clearance, and import duties should be considered and planned for in advance.

8. What support can I expect post-purchase from Chinese manufacturers?

Reputable manufacturers provide warranties, technical support, and spare parts. Clarifying these details before purchase ensures ongoing support and maintenance.

Navigating sourcing and manufacturing from China requires diligence, clear communication, and understanding of both the process and potential challenges.