Technology and Applications of do it yourself cnc router

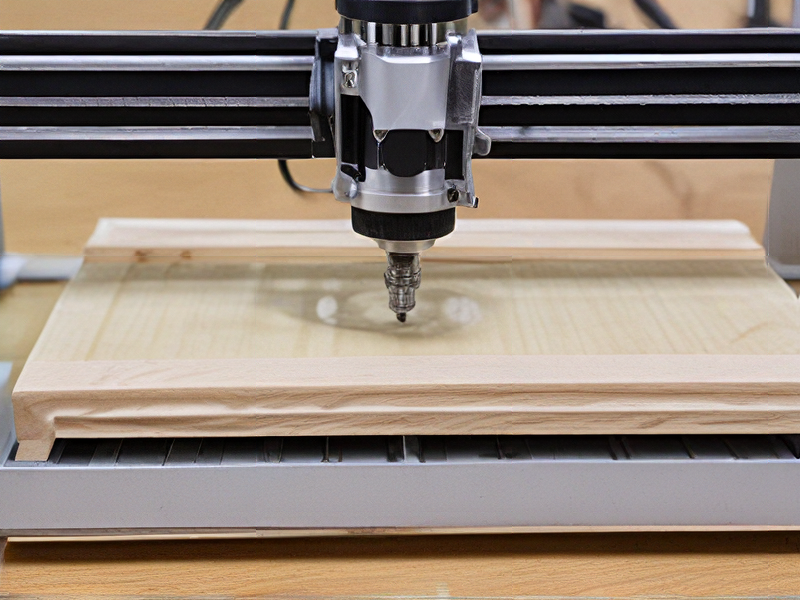

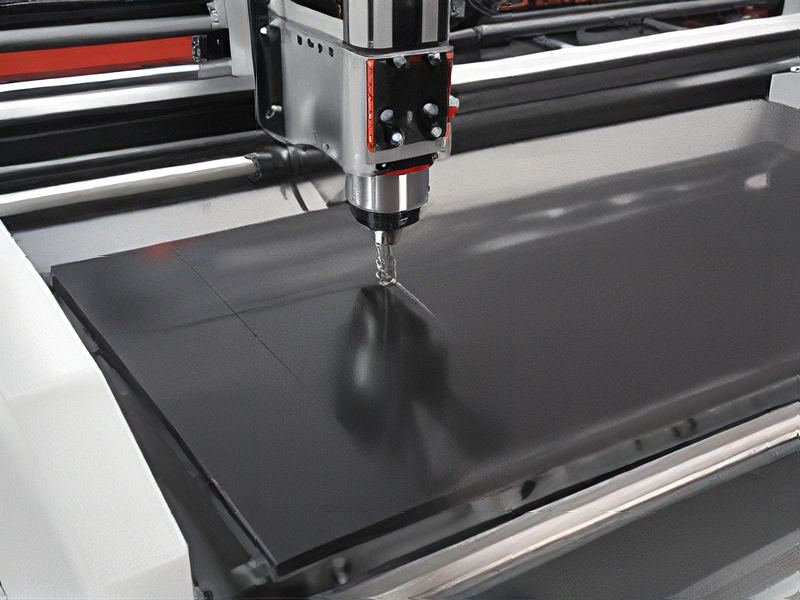

A DIY CNC router combines the precision of computer numerical control (CNC) with the flexibility of a homemade assembly. Typically constructed from readily available components like stepper motors, guide rails, and a controller board, DIY CNC routers allow hobbyists and small businesses to create intricate designs in various materials such as wood, plastics, and even metals.

Technology:

DIY CNC routers are driven by stepper motors that move the router bit along predefined paths programmed into the machine’s controller. This controller interprets instructions from computer-aided design (CAD) or computer-aided manufacturing (CAM) software, converting them into precise movements of the router. Most DIY setups utilize open-source software and controller boards like Arduino or Raspberry Pi, which are cost-effective and adaptable to different configurations.

Applications:

These routers find applications in woodworking, sign making, prototyping, and small-scale manufacturing. Woodworkers use them to carve intricate designs or cut out precise shapes and joints. In sign making, they create professional-grade lettering and logos. For prototyping, DIY CNC routers allow rapid iteration and testing of designs. Some enthusiasts even use them for engraving metal plates or creating molds for casting.

Advantages:

The primary advantage of DIY CNC routers lies in their affordability and customization. Hobbyists can tailor the machine to fit specific needs, upgrading components as skills and requirements grow. They also offer a learning opportunity in CNC technology, helping users understand machine mechanics, software integration, and material capabilities.

Challenges:

However, DIY CNC routers require assembly and calibration, which can be challenging without prior experience. Precision depends on component quality and setup accuracy, influencing final output quality. Moreover, while versatile, they may not match the speed and precision of commercial CNC machines designed for industrial use.

In conclusion, DIY CNC routers democratize CNC technology, making it accessible to enthusiasts and small businesses alike. They enable creativity and innovation in various fields while offering a hands-on learning experience in CNC machining and automation.

Quality Testing Methods for do it yourself cnc router and how to control quality

Quality testing for a DIY CNC router involves several methods to ensure precision, durability, and performance. Here’s a concise guide:

Methods for Quality Testing:

1. Calibration and Accuracy Testing:

– Dial Indicator: Attach a dial indicator to the spindle and measure deviations on the X, Y, and Z axes. Compare readings against expected values.

– Test Cuts: Perform cuts on various materials and measure the dimensions of the resulting parts using calipers or micrometers.

2. Repeatability Testing:

– G-Code Test: Run a specific G-code pattern multiple times and check for consistent results. Measure the final position to ensure the machine returns to the same coordinates accurately.

3. Rigidity and Vibration Testing:

– Force Application: Apply force to the machine structure and spindle, observing any deflections using a dial indicator.

– Vibration Analysis: Use a vibration meter to detect excessive vibrations during operation. Excessive vibrations can indicate issues with rigidity or component alignment.

4. Material and Component Inspection:

– Visual Inspection: Check for signs of wear, looseness, or damage on critical components such as rails, lead screws, and bearings.

– Material Testing: Verify the quality of materials used in construction, ensuring they meet specified standards.

Controlling Quality:

1. Regular Maintenance:

– Lubrication: Regularly lubricate moving parts to reduce wear and ensure smooth operation.

– Tightening: Periodically check and tighten all bolts and fasteners to maintain structural integrity.

2. Software Calibration:

– Firmware Updates: Keep firmware and control software up to date to benefit from improvements and bug fixes.

– Parameter Adjustment: Adjust and fine-tune machine parameters in the control software for optimal performance.

3. Documentation and Records:

– Log Keeping: Maintain detailed logs of all tests, adjustments, and maintenance activities to track performance over time and identify recurring issues.

4. Training and Best Practices:

– Operator Training: Ensure operators are trained in best practices for machine use and maintenance.

– Standard Operating Procedures: Develop and adhere to SOPs for setup, operation, and maintenance.

By systematically applying these methods, you can ensure the quality and reliability of your DIY CNC router, achieving consistent and precise results.

Tips for Procurement and Considerations when Purchasing from do it yourself cnc router

When procuring a DIY CNC router, several critical considerations can help ensure a successful purchase and optimal use. Here are key tips:

1. Define Your Needs:

– Assess your specific requirements, such as material types (wood, metal, plastic), project complexity, and precision needed. This helps in selecting a router with appropriate capabilities.

2. Budget:

– Establish a budget that includes not only the initial cost of the CNC router but also accessories, software, and potential maintenance costs.

3. Research Models:

– Compare different DIY CNC router models. Look for reputable brands and read reviews to understand the experiences of other users. Focus on build quality, ease of assembly, and customer support.

4. Specifications:

– Pay attention to key specifications like spindle power, working area, travel speed, and repeatability. Ensure these align with your project needs.

5. Software Compatibility:

– Check the software compatibility of the CNC router. Ensure it supports the CAD/CAM software you are familiar with or intend to use. Some routers come with proprietary software, which might have limitations.

6. Assembly and Setup:

– DIY routers often require assembly. Evaluate the complexity of the assembly process and ensure you have the necessary tools and skills. Look for routers with detailed manuals or online tutorials.

7. Support and Community:

– Opt for manufacturers that offer strong customer support and have an active user community. Forums and user groups can be invaluable for troubleshooting and advice.

8. Safety Features:

– Ensure the CNC router includes essential safety features such as emergency stop buttons and proper shielding to protect against debris and accidents.

9. Warranty and Return Policy:

– Review the warranty and return policies. A good warranty can provide peace of mind and protect your investment.

10. Future Upgrades:

– Consider the possibility of future upgrades. A modular design can allow for enhancements as your skills and project demands grow.

By carefully evaluating these factors, you can make an informed decision that aligns with your needs and ensures a smooth and productive experience with your DIY CNC router.

FAQs on Sourcing and Manufacturing from do it yourself cnc router in China

When sourcing and manufacturing a DIY CNC router from China, several FAQs arise:

1. What should I consider when sourcing a CNC router from China?

– Supplier Selection: Research suppliers thoroughly. Check reviews, ask for referrals, and ensure they have experience with CNC routers.

– Quality Assurance: Insist on product samples to assess build quality and performance.

– Communication: Clear and consistent communication is crucial. Ensure the supplier understands your specifications and requirements.

2. How can I ensure quality control during manufacturing?

– Detailed Specifications: Provide comprehensive design and performance specifications.

– Inspections: Regularly inspect manufacturing progress and final products. Consider hiring a third-party inspector if feasible.

– Quality Standards: Discuss and agree upon quality standards upfront to avoid misunderstandings.

3. What are the typical lead times and shipping considerations?

– Lead Times: Understand typical production lead times and factor in any delays for customization or quality checks.

– Shipping Options: Evaluate shipping methods (air, sea) based on cost and speed. Factor in customs clearance and potential import duties.

4. How do I handle customs, tariffs, and import regulations?

– Documentation: Ensure all necessary documentation (invoices, certificates) is accurate and complete.

– Tariffs and Duties: Research applicable tariffs and duties in your country and factor them into your budget.

5. What after-sales support can I expect?

– Warranty: Clarify warranty terms and conditions, including repair and replacement policies.

– Technical Support: Inquire about technical support availability and responsiveness post-purchase.

By addressing these FAQs and diligently managing the sourcing and manufacturing process, you can mitigate risks and ensure a smoother experience when procuring a DIY CNC router from China.