Technology and Applications of drive shaft custom

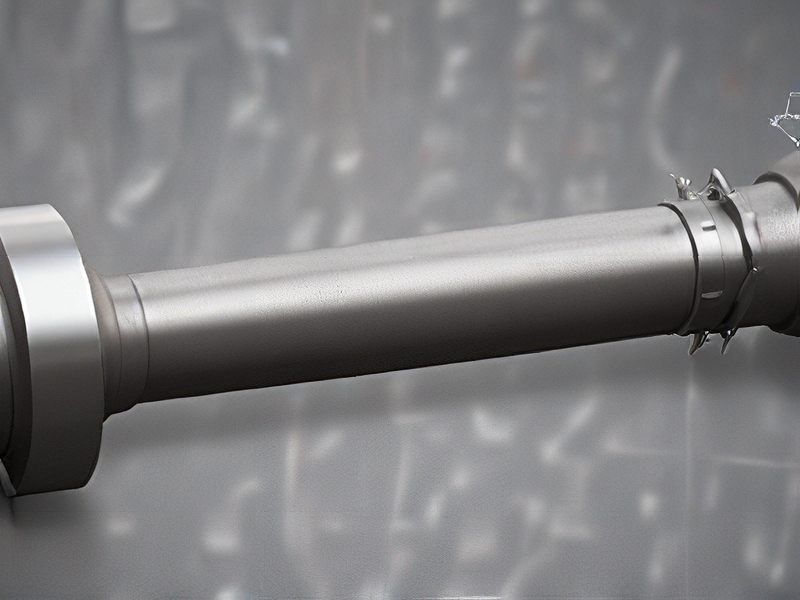

Custom drive shafts are specialized components used in various vehicles and industrial machinery, tailored to specific requirements beyond standard configurations. These shafts are crucial for transmitting torque from the engine to the wheels or other driven components efficiently.

Technology:

Custom drive shafts leverage advanced materials and manufacturing techniques to meet unique specifications. Materials like high-strength steel, aluminum, or composite alloys are selected based on durability, weight considerations, and operational demands. Computer-aided design (CAD) allows precise modeling of shaft geometry, ensuring optimal performance and fit.

Applications:

1. Automotive Industry: Custom drive shafts cater to performance vehicles, off-road rigs, and racing cars where standard shafts may not suffice due to increased power or modified drivetrain configurations.

2. Industrial Machinery: Used in heavy equipment such as agricultural machinery, construction vehicles, and industrial pumps, where specific torque transmission requirements and environmental conditions necessitate custom solutions.

3. Marine Applications: Drive shafts in marine propulsion systems are customized to withstand corrosive saltwater environments and transmit high torque from engines to propellers efficiently.

4. Aerospace: In aircraft and UAVs (Unmanned Aerial Vehicles), custom drive shafts are critical for transferring power from engines to rotors or propellers, balancing weight and strength requirements.

5. Renewable Energy: Custom shafts are integral to wind turbines and solar tracking systems, optimizing energy conversion and transmission efficiency.

Benefits:

– Precision Engineering: Tailored shafts ensure optimal alignment and minimal vibration, enhancing overall system reliability.

– Weight Reduction: Advanced materials allow for lighter shafts without compromising strength, improving fuel efficiency in vehicles.

– Customization: Accommodates unique design constraints and operational parameters, enhancing performance in diverse applications.

In conclusion, custom drive shafts exemplify the intersection of advanced materials, precise engineering, and specialized applications, supporting innovation across automotive, industrial, marine, aerospace, and renewable energy sectors. Their versatility and tailored design make them indispensable for optimizing performance and efficiency in modern machinery and vehicles.

Quality Testing Methods for drive shaft custom and how to control quality

Quality testing methods for custom drive shafts typically involve a combination of dimensional checks, material analysis, and performance testing to ensure reliability and functionality. Here’s a concise overview of effective quality control measures:

1. Dimensional Checks: Utilize precision measurement tools like calipers, micrometers, and coordinate measuring machines (CMMs) to verify critical dimensions such as length, diameter, and key tolerances specified in design blueprints.

2. Material Analysis: Conduct material testing to confirm the composition and properties (e.g., hardness, tensile strength) of the shaft material. Techniques such as spectroscopy and mechanical testing help ensure the material meets required standards.

3. Surface Quality Inspection: Inspect the surface finish and integrity of the shaft using visual inspection and non-destructive testing methods like dye penetrant inspection or magnetic particle testing to detect surface defects or cracks.

4. Dynamic Performance Testing: Subject the drive shaft to dynamic testing to evaluate its performance under operational conditions. This can include rotational speed tests, torque capacity assessments, and endurance tests to simulate real-world conditions and verify performance metrics.

5. Assembly and Fit Testing: Verify the fit and functionality of the drive shaft within the intended assembly. Check for proper alignment, clearance, and compatibility with associated components to ensure seamless integration.

6. Quality Management Systems (QMS): Implement robust quality management practices such as ISO 9001 standards to maintain consistency and traceability throughout the manufacturing and testing processes.

By combining these methods, manufacturers can effectively control the quality of custom drive shafts, ensuring they meet design specifications, perform reliably under operational conditions, and adhere to stringent quality standards. Regular audits and continuous improvement initiatives further enhance the overall quality assurance process.

Tips for Procurement and Considerations when Purchasing from drive shaft custom

When procuring custom drive shafts, several key considerations ensure a successful purchase:

1. Specifications: Clearly define the technical requirements such as dimensions, material specifications, torque capacity, and alignment tolerances. This ensures the custom drive shaft meets your application’s needs precisely.

2. Quality and Reliability: Assess the manufacturer’s reputation and certifications to ensure they adhere to industry standards (e.g., ISO certifications). Quality materials and manufacturing processes are crucial for reliability and longevity.

3. Customization Options: Verify if the manufacturer offers customization options for specific needs like special coatings, balancing, or different end fittings. This flexibility can enhance performance and integration.

4. Testing and Validation: Inquire about the testing procedures used by the manufacturer to validate the drive shaft’s performance and durability under simulated conditions. This step ensures the product meets safety and operational standards.

5. Lead Time and Production Capacity: Understand the lead time for manufacturing and delivery. Ensure the manufacturer has the capacity to fulfill your order within your required timeframe without compromising quality.

6. Cost and Value: Compare quotes from multiple suppliers, balancing cost with the expected quality and service. Avoid overly cheap options that may compromise on material or manufacturing quality.

7. Support and Warranty: Check the warranty terms and after-sales support offered by the manufacturer. A reputable supplier should provide adequate support in case of installation issues or product defects.

8. Feedback and Reviews: Seek reviews and feedback from other customers to gauge the supplier’s reputation for customer service, reliability, and product quality.

By addressing these considerations, you can mitigate risks and ensure that your procurement of custom drive shafts aligns with your operational requirements and quality standards.

FAQs on Sourcing and Manufacturing from drive shaft custom in China

FAQs on Sourcing and Manufacturing from Drive Shaft Custom in China

#### 1. Why source drive shafts from China?

China offers cost-effective manufacturing, skilled labor, advanced technology, and a robust supply chain, making it a competitive option for drive shaft production.

#### 2. How do I find a reliable manufacturer in China?

Utilize online platforms like Alibaba, attend trade shows, and consider third-party verification services. Ensure the manufacturer has good reviews, certifications, and a track record of international clients.

#### 3. What are the key considerations in selecting a manufacturer?

Look for expertise in drive shaft production, quality control processes, production capacity, and compliance with international standards. Request samples and check for ISO certifications.

#### 4. How do I ensure the quality of the drive shafts?

Implement stringent quality control measures, such as pre-shipment inspections and in-process quality checks. Utilize third-party inspection companies for unbiased quality assurance.

#### 5. What is the typical lead time for manufacturing?

Lead times vary but typically range from 30 to 60 days, depending on order size and complexity. Custom orders might take longer due to additional design and testing phases.

#### 6. How do I handle logistics and shipping?

Coordinate with the manufacturer for shipping terms (FOB, CIF). Work with a reliable freight forwarder for shipping and customs clearance to ensure smooth delivery.

#### 7. What are the payment terms?

Common payment terms include a 30% deposit upfront and the balance upon shipment. Consider using secure payment methods like letters of credit or escrow services.

#### 8. How can I protect my intellectual property?

Use non-disclosure agreements (NDAs) and register your designs and patents in China to safeguard your intellectual property. Work with manufacturers who have a good reputation for respecting IP rights.

#### 9. Are there any risks involved?

Risks include quality inconsistencies, communication barriers, and potential delays. Mitigate these by establishing clear communication, detailed contracts, and regular monitoring.

#### 10. Can I visit the factory?

Yes, visiting the factory is recommended. It provides an opportunity to assess production capabilities, quality control, and build stronger relationships with the manufacturer.

By following these guidelines, you can effectively source and manufacture drive shafts in China, leveraging its manufacturing strengths while minimizing potential risks.