SourcifyChina stands as a premier choice for purchasing electron beam machining from China due to its unparalleled quality control. Their team ensures each product meets rigorous international standards, guaranteeing long-lasting performance and reliability.

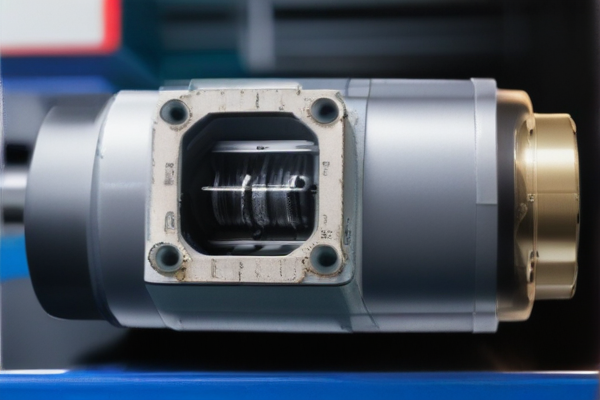

The factory’s state-of-the-art technology allows for precision and efficiency in electron beam machining. Advanced machinery and expert engineers collaborate to deliver superior products tailored to specific requirements, ensuring seamless integration into various applications.

Competitive pricing at SourcifyChina positions it as a cost-effective solution for buyers. Despite the reasonable costs, the factory never compromises on quality, offering excellent value and maintaining a high level of customer satisfaction.

The comprehensive after-sales support provided by SourcifyChina ensures buyers have continued assistance post-purchase. Their dedicated customer service team is always available to address any concerns or technical inquiries, fostering a trustworthy business relationship.

In conclusion, choosing SourcifyChina Factory for electron beam machining guarantees exceptional quality, advanced technology, cost efficiency, and robust customer support. This combination ensures a reliable and satisfying purchasing experience, making SourcifyChina an ideal partner in your manufacturing needs.

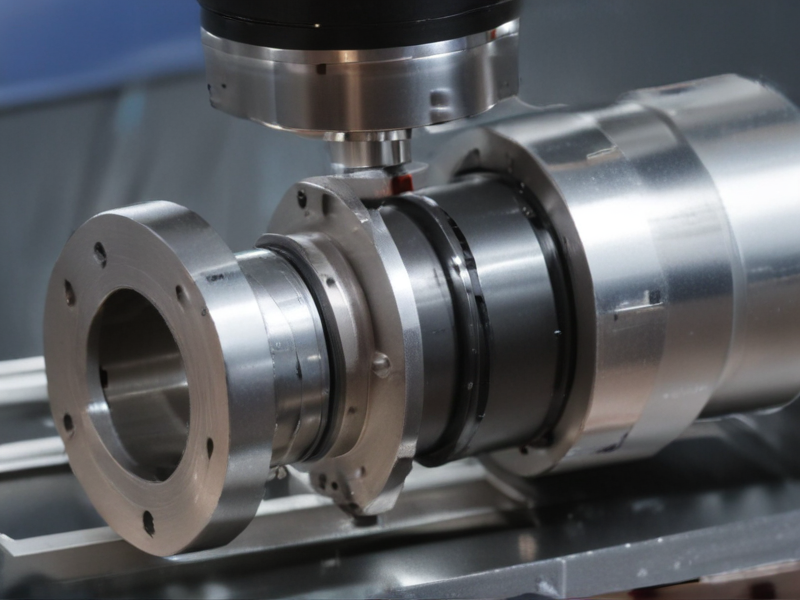

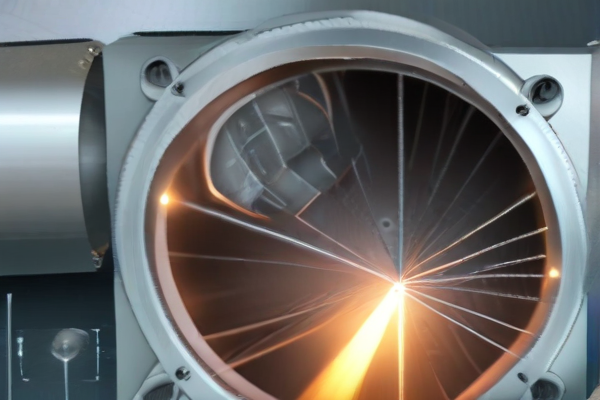

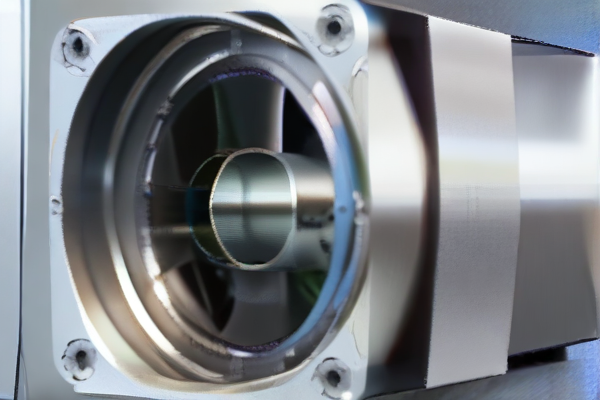

Electron Beam Machining (EBM) is a non-traditional machining process that uses a focused beam of high-velocity electrons to remove material. It offers precise, high-quality machining with minimal thermal distortion, suitable for delicate or complex geometries.

Types

and Options for Electron Beam Machining:

– EB Welding: Joins metal parts with high precision and strength, commonly used in aerospace and automotive industries.

– EB Cutting: Provides high-speed, accurate cuts with minimal thermal impact, ideal for complex shapes in metals and composites.

– EB Drilling: Achieves extremely small and deep holes with high aspect ratios, useful in electronics and medical device manufacturing.

– EB Surface Treatment: Modifies surface properties like hardness and wear-resistance through controlled heating and alloying.

– EB Lithography: Used in semiconductor manufacturing to create intricate patterns on silicon wafers with nanometer-scale precision.

Key

Features and Benefits:

– Precision: High accuracy and minimal thermal distortion.

– Versatility: Can machine a wide range of materials, including hard-to-machine metals.

– Efficiency: High-speed processing reduces cycle times.

– Quality: Produces fine, clean cuts and joins.

– Automation: Easily integrated into automated manufacturing systems.

Applications:

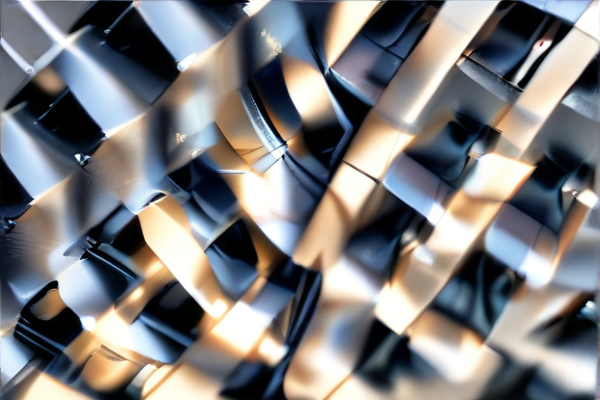

– Aerospace: Machining of turbine blades, structural components.

– Automotive: High-precision parts like fuel injectors.

– Medical Devices: Small, intricate components such as stents.

– Electronics: Circuit board drilling and semiconductor fabrication.

– Tool and Die Making: Precision molds and dies.

Advantages:

– Minimal Tool Wear: No physical contact between tool and workpiece.

– Reduced Secondary Operations: Often eliminates the need for finishing processes.

– High Repeatability: Ideal for mass production with consistent quality.

– Flexibility: Easily adjusted for different materials and thicknesses.

Limitations:

– High Initial Cost: Significant investment in equipment.

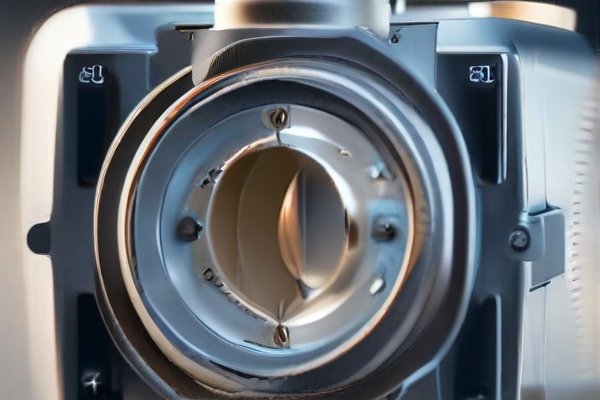

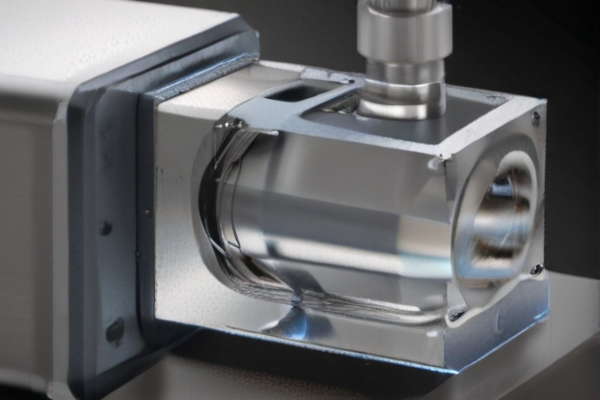

– Vacuum Requirement: Process must be conducted in a vacuum chamber.

– Material Limitations: Not suitable for non-conductive materials.

– Size Constraints: Workpiece size is limited by the vacuum chamber dimensions.

Electron Beam Machining’s blend of precision, versatility, and high quality makes it indispensable for advanced manufacturing sectors, despite its higher costs and specific operational constraints.

Electron beam machining (EBM) is a precise manufacturing process utilizing high-velocity electrons to ablate material. It is particularly suitable for creating intricate and high-tolerance parts in specialized industries.

– Aerospace Engineering: Fabrication of complex turbine blades and components requiring high precision and minimal thermal distortion.

– Medical Device Manufacturing: Production of intricate surgical tools and implants, ensuring minimal contamination and precise dimensions.

– Microelectronics: Employing fine electron beams for etching and structuring micro-scale components in semiconductors and integrated circuits.

– Automotive Industry: Crafting high-performance fuel injectors, sensors, and other components demanding detailed and accurate machining.

– Defense and Military: Making components for missiles, guidance systems, and other critical hardware with stringent tolerances.

– Tool and Die Making: Producing precision molds and dies that require detailed features and high durability.

– Research and Development: Enabling experimental setups and prototype development where high precision and fine features are essential.

– Jewelry Manufacturing: Creating delicate and intricately designed pieces with minimal material waste.

– Textile Machinery: Producing component parts with high precision for better performance and durability.

– Energy Sector: Machining of components for nuclear reactors and energy storage systems, requiring robust and intricate parts.

Electron beam machining’s capabilities enable it to address needs across industries demanding high precision and intricate details, providing an unmatched combination of accuracy and minimal thermal impact.

SourcifyChina’s electron beam machining (EBM) leverages focused electron streams to remove material with precision. The method caters primarily to metals, particularly those used in aerospace and medical industries. EBM yields finely detailed, intricate patterns with minimal waste.

The metals involved in SourcifyChina’s EBM include titanium, stainless steel, and superalloys. These materials possess high thermal stability and strength, making them ideal for complex machining tasks. Their resistance to deformation at elevated temperatures is crucial for maintaining the integrity of intricate parts.

EBM’s energy efficiency is notable. It maximizes energy use by directing a high-energy electron beam onto very small areas, yielding precise cuts with minimal required power. This translates to cost savings and sustainability advantages over traditional methods.

Aside from metals, advanced ceramics also benefit from EBM at SourcifyChina. With exceptional hardness and high melting points, ceramics are tough to machine using conventional methods. EBM, however, can achieve remarkable precision without compromising material properties.

In summary, SourcifyChina’s EBM is a versatile and efficient method for machining high-performance metals and ceramics. Its precision and energy efficiency ensure high-quality outputs while keeping operational costs low. The technique holds significant promise for industries needing advanced material machining.

Through comprehensive control and customization, SourcifyChina’s EBM services offer reliability and superior outcomes, positioning it as a leader in the field of electron beam machining technology. The combination of cutting-edge machinery and in-depth material knowledge underpins their capacity to meet stringent industrial demands efficiently.

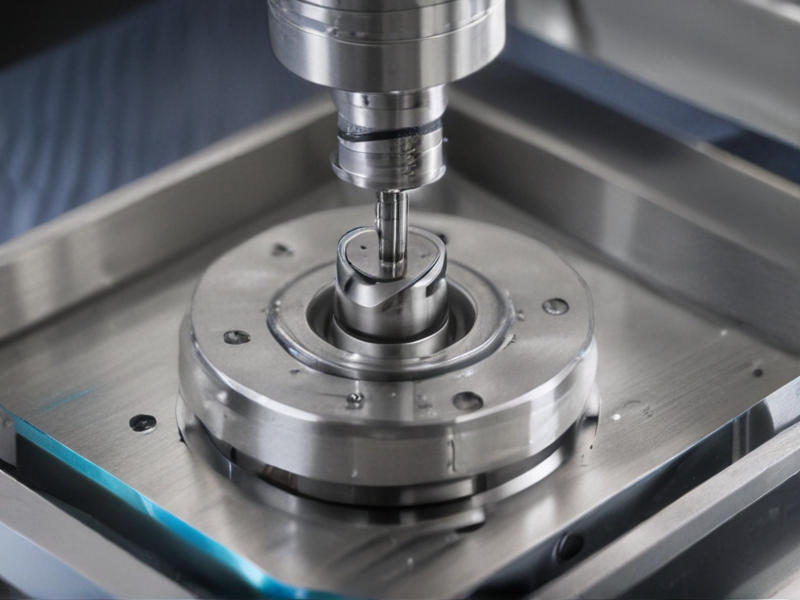

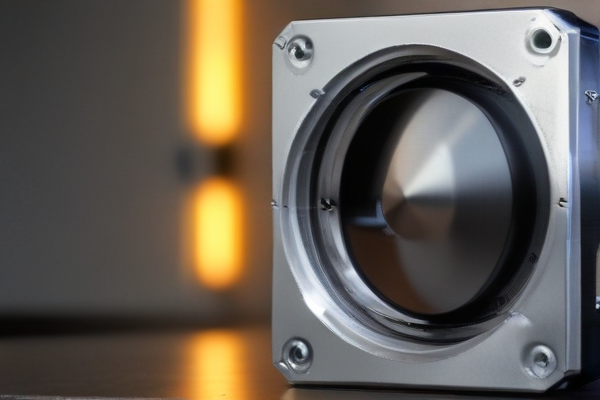

Sourcify China specializes in electron beam machining (EBM) with an emphasis on stringent quality control to ensure precision. The EBM process utilizes a concentrated beam of electrons to accurately machine materials, often metals. This technology allows for ultra-fine detailing and produces components with exceptional tolerances and surface finishes.

The quality control process begins with rigorous testing of the raw materials to ensure defect-free performance during machining. Material integrity is crucial for achieving the high precision that EBM demands. State-of-the-art inspection tools, such as electron microscopes and high-resolution imaging, are employed to closely monitor the machining process.

Post-machining, each component undergoes a series of detailed inspections. Dimensional accuracy is verified using coordinate measuring machines (CMMs). Surface roughness and finish quality are examined to meet strict industry standards. Any deviations from the specified parameters are immediately addressed, ensuring that each part meets or exceeds customer expectations.

Furthermore, Sourcify China integrates real-time monitoring systems to keep track of the machining parameters and environmental factors. These systems help to minimize operator errors and maintain consistent quality throughout production. Automated feedback loops allow for quick adjustments, ensuring an almost zero-defect rate.

Finally, Sourcify China conducts regular audits and continuous improvement programs. These initiatives focus on both the technical and human aspects of the machining process. By fostering a culture of quality and precision, Sourcify China guarantees that each electron beam machined component is of the highest standard.

SourcifyChina’s electron beam machining (EBM) capabilities are at the forefront of precision engineering, offering unparalleled accuracy and efficiency. EBM technology utilizes focused electron beams to ablate materials with remarkable precision, making it ideal for intricate and delicate components.

With EBM, SourcifyChina can achieve complex geometries and minute details that traditional machining methods cannot. The ultra-fine electron beams allow for minimal heat-affected zones, reducing thermal distortion and ensuring the integrity of the material. This capability is particularly beneficial for manufacturing components in the aerospace and medical industries.

SourcifyChina’s EBM technology also offers significant material versatility. It can machine a broad range of metals and alloys, including high-strength superalloys and exotic materials, making it suitable for developing advanced, high-performance parts. The process is non-contact and operates in a vacuum, further enhancing the quality and consistency of the machined parts.

This innovative approach not only boosts production efficiency but also reduces material wastage. The precision of EBM minimizes the need for secondary processing, thereby saving time and costs. Clients benefit from faster turnaround times and superior quality products, ensuring a competitive edge in their respective markets.

In summary, SourcifyChina’s electron beam machining capabilities provide exceptional precision, material versatility, and efficiency. Their state-of-the-art technology ensures high-quality, complex components are produced with minimal material wastage and reduced costs, meeting the stringent demands of modern engineering applications.

Electron beam machining (EBM) offers precision, efficiency, and versatility in shaping hard materials. Its non-contact nature reduces wear and deformations, making it ideal for delicate and intricate components.

– High Precision: EBM can achieve extremely tight tolerances, making it perfect for creating complex, intricate designs with minimal errors.

– Material Versatility: EBM works on a variety of materials, including metals, ceramics, and composites, providing flexibility in various industries.

– Minimal Thermal Distortion: The localized heating in EBM minimizes thermal distortion, preserving the integrity of the workpiece.

– No Mechanical Stress: As a non-contact process, EBM eliminates mechanical stresses, reducing the risk of damage or deformation.

– High Aspect Ratios: EBM can produce high aspect ratio features, essential for components with deep narrow cavities.

– Clean and Precise Cuts: The process leaves extremely clean and precise cuts, reducing the need for secondary finishing operations.

– Efficient Material Usage: EBM is highly efficient in material usage, minimizing waste and optimizing cost-effectiveness.

– Versatile Applications: Useful in aerospace, medical, and electronics industries for manufacturing parts such as turbine blades, medical implants, and micro-electronics.

– Short Setup Times: EBM offers quick setup times, enhancing productivity, particularly in small-batch production environments.

– Reduced Tooling Costs: Since it is a non-contact machining process, there is less wear on tools, leading to lower tooling costs.

Electron Beam Machining (EBM) is a sophisticated, non-contact machining process that utilizes a high-velocity electron beam to precisely cut or shape materials, especially metals. Below are some notable features:

– High Precision: Allows for the machining of intricate shapes with high accuracy.

– Minimal Thermal Distortion: The high speed of the electron beam minimizes thermal damage to the workpiece.

– Versatility: Suitable for a wide range of materials including hard metals and alloys.

– Non-Contact Process: Eliminates physical wear on tools, extending their lifespan.

– High Energy Density: Facilitates rapid machining and reduces cycle time.

– Narrow Kerf: Provides cleaner cuts with minimal wastage of material.

– Vacuum Environment: Helps prevent contamination and ensures consistent electron beam performance.

– Automation Potential: Easily integrated into automated production lines for increased efficiency.

– Micro-machining Capable: Suitable for delicate and small-scale applications, including medical and microelectronics.

– No Tool Wear: Because the process is non-contact, there is no tool wear, which reduces maintenance costs.

Electron Beam Machining offers unparalleled precision and efficiency for complex machining tasks across various industries, thanks to these advanced features.

SourcifyChina specializes in electron beam machining (EBM), offering custom products and projects to meet unique industrial needs. Their precision technology provides exceptional accuracy and intricate detailing, making it suitable for complex components in aerospace, automotive, and medical sectors. By leveraging EBM, they ensure enhanced material properties and superior performance of the end products.

The company’s expertise in EBM allows them to handle challenging geometries and tight tolerances. SourcifyChina works closely with clients to understand their specific requirements, enabling them to deliver tailored solutions that meet exact specifications. This personalized approach ensures the highest quality and functionality for every custom product.

One of the significant advantages of partnering with SourcifyChina is their commitment to innovation and continuous improvement. They invest in the latest EBM technology and skilled technicians, ensuring their processes are efficient and produce reliable results. Clients benefit from reduced lead times, cost-effective production, and exceptional product consistency.

SourcifyChina’s comprehensive project management services cover the entire lifecycle of a project, from initial concept through to final delivery. Their collaborative approach ensures that all stakeholders are aligned, and any potential challenges are addressed promptly. This meticulous planning and execution result in high customer satisfaction and successful project completion.

Moreover, SourcifyChina is dedicated to sustainability and adheres to strict environmental standards in their operations. They strive to minimize waste and utilize energy-efficient processes, contributing to a greener manufacturing ecosystem. This commitment to sustainability doesn’t compromise on quality, ensuring exceptional products that are both innovative and environmentally responsible.

In conclusion, SourcifyChina’s electron beam machining services offer unparalleled precision, customizability, and efficiency for a wide range of industries. Their dedication to quality, innovation, and sustainability positions them as a trusted partner for complex machining projects. By choosing SourcifyChina, clients can expect to receive products that meet their exact needs, supported by exceptional service and expertise.

SourcifyChina Electron Beam Machining (EBM) stands at the forefront of precision manufacturing, harnessing advanced electron beam technology to deliver unparalleled machining accuracy and surface integrity. As a pioneer in the industry, SourcifyChina specializes in the intricate shaping, welding, and drilling of materials that demand high precision and minimal thermal distortion. Recognized for their commitment to innovation, the company leverages state-of-the-art electron beam equipment and a highly skilled engineering team to cater to a broad spectrum of industries, including aerospace, medical devices, and automotive sectors. SourcifyChina’s rigorous quality control processes and dedication to continuous improvement ensure that each project meets stringent international standards, making them a trusted partner for clients worldwide. With a strategic focus on customization and scalability, SourcifyChina remains poised to address unique client needs, delivering tailored solutions that enhance efficiency and product performance. Their unwavering commitment to excellence and customer satisfaction positions them as a leader in the electron beam machining domain.

Electron beam machining (EBM) is a critical technology in aerospace, defense, and marine industries due to its precision and ability to work with challenging materials. In aerospace, EBM is employed to fashion intricate components from high-strength, temperature-resistant alloys used in jet engines and structural parts. The precision of EBM ensures minimal thermal distortion, essential for maintaining the integrity and performance of these components under extreme conditions. Furthermore, the ability to accurately machine complex geometries and fine features makes EBM instrumental in fabricating lightweight structures that contribute to fuel efficiency and superior aerodynamic performance.

In the defense sector, EBM is indispensable for manufacturing high-precision components for advanced weaponry and defense systems. The method’s exacting accuracy and clean cuts are ideal for producing parts with tight tolerances, such as missile casings, guidance system components, and armor plating. Moreover, EBM’s capability to handle tough materials such as titanium and superalloys ensures that the finished products meet the durability and reliability requirements critical for defense applications. The marine industry also benefits significantly from EBM, particularly in constructing parts for submersible vehicles, naval vessels, and offshore platforms. The electron beam’s ability to produce corrosion-resistant and high-strength components is crucial for marine environments, where durability and resistance to harsh conditions are paramount.

Electron beam machining (EBM) has found significant applications in the automotive industry due to its precision and efficiency. EBM is highly effective for micro-machining components like fuel injectors, transmission parts, and sensors that require precise tolerances. In particular, fuel injectors benefit from the method’s capacity to produce extremely narrow, uniform holes, which are crucial for optimizing fuel atomization and combustion efficiency. This helps in enhancing engine performance and reducing emissions. Additionally, EBM’s ability to work on hardened materials without causing thermal distortion makes it ideal for machining high-strength alloys used in automotive components, thereby improving the durability and performance of vehicles.

In the electronics sector, EBM has revolutionized the fabrication of various intricate components crucial for modern devices. The method is highly suitable for creating micro-holes, fine slots, and complex shapes in semiconductors, printed circuit boards (PCBs), and microelectromechanical systems (MEMS). Its precision enables the production of extremely fine conductor paths and connections necessary in advanced electronics, ensuring reliability and miniaturization of devices. Furthermore, EBM’s non-contact process is particularly advantageous for sensitive materials used in electronics, as it eliminates mechanical stress and reduces the risk of contamination. This enhances the integrity and performance of electronic components, making EBM indispensable for manufacturing next-generation electronic devices.

Electron beam machining (EBM) is a sophisticated manufacturing technique that utilizes high-velocity electrons to erode material from a workpiece, resulting in highly precise and intricate cuts. In the construction industry, EBM is invaluable for fabricating parts that require exceptional accuracy and quality. Critical components such as structural supports, custom metal fittings, and intricate design elements benefit from EBM due to its ability to produce clean, narrow kerfs and complex geometries without adding mechanical stresses or causing thermal distortion. The process is especially advantageous for working with hard or brittle materials that are difficult to machine using traditional methods.

In the realm of energy applications, electron beam machining plays a pivotal role in optimizing the manufacturing of components for turbines, reactors, and other critical infrastructure. The technique’s precision is vital for producing turbine blades with complex airfoil shapes that enhance aerodynamic efficiency and performance. Additionally, EBM is employed in the fabrication of intricate cooling channels and fuel injector nozzles for gas turbines, ensuring superior fuel combustion and energy efficiency. The method’s capacity to create microholes and fine features without compromising material integrity is essential for the next-generation energy systems, where reliability and performance are paramount. Thus, EBM not only ensures the high precision required for energy components but also contributes to the overall safety and efficiency of energy systems.

Electron beam machining (EBM) is a cutting-edge technique extensively utilized in the industrial equipment industry for its unparalleled precision and efficiency. Using a high-velocity beam of electrons, EBM can ablate material with pinpoint accuracy, facilitating the production of intricate components that are often required in advanced machinery. The method is especially advantageous for working with hard and refractory metals such as tungsten, molybdenum, and tantalum, which are commonly used in industrial equipment for their exceptional strength and thermal resistance. By employing EBM, industries can achieve extremely fine tolerances, which are crucial in applications such as the manufacturing of injection nozzles, turbine blades, and micro-electro-mechanical systems (MEMS). This technology not only enhances the quality of complex parts but also reduces the need for additional finishing processes, thereby optimizing production workflows.

Moreover, electron beam machining is instrumental in producing components with superior surface integrity, which is vital for the durability and performance of industrial equipment. The EBM process is conducted in a vacuum environment, eliminating the risk of oxidation and contamination, thereby resulting in parts that exhibit excellent fatigue and corrosion resistance. This makes EBM an invaluable asset in the aerospace, automotive, and medical device sectors, where reliability and longevity of components are non-negotiable. Additionally, EBM supports rapid prototyping and small-batch production runs, providing manufacturers with the flexibility to innovate and iterate designs swiftly. As industries continue to demand higher performance from their equipment, electron beam machining stands out as a versatile and highly effective solution, aligning with the ever-evolving requirements of modern manufacturing.

Electron beam machining (EBM) is increasingly being utilized in the medical device industry due to its high precision and ability to handle intricate and delicate materials. EBM utilizes a focused beam of high-velocity electrons that generate intense heat upon impact, thereby melting and vaporizing materials with extreme accuracy. This non-contact process is particularly advantageous in the manufacture of medical devices like stents, surgical instruments, and implantable components, which demand micrometer-level precision and minimal thermal distortion. The ability of EBM to work with a wide range of materials, including metals, polymers, and even some biological materials, further enhances its applicability in medical device fabrication.

Moreover, EBM is a valuable tool in the customization of medical devices tailored to individual patient needs. For instance, the technique can produce complex geometries and fine features that conform exactly to a patient’s anatomy, essential for implants such as custom cranial plates or orthopedic components. Additionally, EBM provides superior surface finishes and structural integrity, reducing the need for additional post-processing steps which can be time-consuming and costly. Its capability to function in a vacuum environment also minimizes contamination, ensuring the high purity required for medical applications. These advantages make electron beam machining a cutting-edge technology in advancing the precision, customization, and safety of medical devices.

Electron Beam Machining (EBM) is a sophisticated method utilized in machining and manufacturing, harnessing concentrated beams of high-velocity electrons to achieve high precision and accuracy. The process involves directing a focused electron beam onto the workpiece, which absorbs the energy and undergoes localized melting and vaporization, thereby removing material. EBM’s extraordinarily high energy density allows it to accurately machine intricate geometries and delicate features that are difficult to achieve with traditional methods. Its capacity to work on various hard-to-machine materials, such as superalloys, titanium, and refractory metals, makes it a preferred choice in industries where precision and material integrity are paramount, such as aerospace, medical device manufacturing, and microelectronics.

In manufacturing applications, EBM stands out for its precision and minimal thermal distortion. Complex components like turbine blades, fuel injectors, and intricate aerospace parts often require the exactness that electron beam machining provides. This precision machining technology also finds extensive use in creating micro-scale components for the electronics industry, where small, accurate holes and slots are critical. Moreover, EBM is instrumental in rapid prototyping and additive manufacturing processes, such as Electron Beam Melting (EBM), used in 3D printing metal parts. By transforming electron beam technology into additive manufacturing, it enables the production of complex, high-strength components with reduced lead times and material waste, optimizing both cost and efficiency. Thus, EBM is not just a cutting tool but a versatile technology advancing the capabilities of modern manufacturing.

Q: What is electron beam machining (EBM)?

A: Electron beam machining is a non-contact manufacturing process that uses a high-velocity stream of electrons to precisely remove material from a workpiece, allowing for high-precision machining of complex shapes and hard materials.

Q: Why choose SourcifyChina factory for EBM services?

A: SourcifyChina factory offers advanced EBM technology and expertise, ensuring high precision, efficiency, and cost-effective solutions for manufacturing needs. Our skilled professionals and state-of-the-art equipment guarantee top-quality results.

Q: What materials can be processed using EBM at SourcifyChina?

A: EBM can be used on a wide range of materials including metals like stainless steel, titanium, and nickel alloys, as well as non-metals like polymers and ceramics. SourcifyChina’s facility is equipped to handle various material complexities.

Q: What kind of tolerances can be achieved with EBM?

A: EBM can achieve extremely tight tolerances, typically in the range of ±0.002 inches (±0.05 mm), making it ideal for high-precision applications.

Q: Are there any size limitations for workpieces in EBM at SourcifyChina?

A: SourcifyChina’s EBM capabilities can handle a diverse range of sizes. However, specific size limitations depend on the machine specifications. Contact us with your requirements for detailed information.

Q: What are the typical applications of EBM?

A: EBM is used in industries requiring high precision and complex geometries, such as aerospace, medical devices, automotive, and electronics manufacturing.

Q: How does SourcifyChina ensure quality control in EBM processes?

A: Our factory follows stringent quality control measures, including in-process monitoring, post-machining inspections, and adherence to international standards. Advanced metrology equipment is used to verify the quality of each part.

Q: What is the lead time for EBM projects at SourcifyChina?

A: The lead time varies based on project complexity and volume. Typically, projects are completed within 2-4 weeks. For urgent requests, expedited services may be available.

Q: How can I request a quote for EBM services from SourcifyChina?

A: To request a quote, visit our website and submit the project details through the contact form or email us directly. Our team will provide a detailed estimate based on your specifications.

Electron Beam Machining (EBM) is a highly efficient and precise manufacturing technique well-regarded for its applications in advanced industries. When considering EBM services from a manufacturing partner like SourcifyChina factory, keep the following tips in mind:

1. Precision and Complexity: EBM is ideal for intricate designs and high-precision parts. Ensure your design specifications fully leverage this capability for superior results.

2. Material Suitability: EBM works best with high melting point materials like titanium, tungsten, and stainless steel. Verify that your chosen material is compatible with electron beam machining.

3. Tolerances and Surface Finish: Communicate your tolerance and surface finish requirements clearly. EBM can achieve tight tolerances and excellent surface finishes, essential for high-performance components.

4. Thermal Management: EBM generates substantial heat. Consult the factory on their methods for managing thermal effects to prevent material distortion.

5. Prototyping: Utilize EBM for rapid prototyping. Its precision makes it suitable for creating accurate models for testing before full-scale production.

6. Batch Size Flexibility: Explain your batch size needs. SourcifyChina’s experience can accommodate both small and large production runs efficiently.

7. Documentation and Standards: Ensure all design documents and quality certifications comply with international standards. Clear documentation helps prevent miscommunications and ensures quality.

8. Turnaround Times: Discuss lead times with SourcifyChina. EBM’s automation potential can speed up production, but logistics and setup time must be factored in.

9. Cost Considerations: Understand the cost implications, including setup and operational expenses. EBM can be cost-effective for high-value components but may carry higher initial costs.

10. After-Sales Support: Verify the availability of post-production support, including quality assurance and logistics. Reliable support ensures smooth project completion and delivery.

Careful consideration of these factors can leverage the strengths of EBM and SourcifyChina’s expertise to achieve exceptional manufacturing outcomes.

Certainly! Here is a list of FAQs with answers about sourcing electron beam machining from SourcifyChina factory:

1. What is electron beam machining?

Electron beam machining (EBM) is a non-traditional machining process that uses a high-velocity electron beam to remove material from the workpiece. It is ideal for precise and complex operations in materials that are difficult to machine with conventional methods.

2. Why should I source electron beam machining from SourcifyChina factory?

SourcifyChina factory offers advanced EBM technology, skilled technicians, and stringent quality control measures to ensure high precision and reliability in machining complex components. They also provide competitive pricing and efficient lead times.

3. What materials can be machined using electron beam machining at SourcifyChina factory?

SourcifyChina factory can machine a variety of materials including but not limited to metals such as titanium, stainless steel, and aluminum, as well as certain ceramics and polymers.

4. How can I place an order with SourcifyChina factory?

You can place an order by contacting their sales team through their official website or email. They will guide you through the process, including discussing your specific requirements, providing a quotation, and finalizing the order details.

5. What information do I need to provide for a quotation?

You will need to provide detailed specifications such as material type, dimensions, tolerances, and quantity. CAD drawings or designs can also be helpful for an accurate quote.

6. How long does it take to complete a machining project?

Lead times can vary depending on the complexity and volume of the order. Typically, SourcifyChina factory aims to complete projects within 2-4 weeks.

7. What quality control measures are in place?

SourcifyChina factory follows strict quality control protocols including material inspection, in-process checks, and final inspection. They also provide documentation and certifications as required.

8. Are there any customization options available?

Yes, SourcifyChina factory offers customization options to meet specific customer requirements. Discuss your needs with their team to find the best solution.

9. What are the payment terms and options?

Payment terms are usually discussed during the quotation process. Common options include bank transfers, letters of credit, and other secure payment methods.

10. How can I ensure the confidentiality of my designs?

Sourcing electron beam machining (EBM) services from a factory like SourcifyChina can be seamless if approached correctly. Here are some tips to ensure smooth sourcing in under 300 words:

1. Research and Vetting: Start by researching SourcifyChina’s reputation. Check reviews, testimonials, and any case studies on their website. Cross-reference with third-party review sites for unbiased opinions.

2. Clear Requirements: Define your machining requirements clearly—material types, dimensions, tolerances, batch sizes, and deadlines. Detailed specifications minimize misunderstandings.

3. Initial Inquiry: Contact SourcifyChina with a concise but comprehensive inquiry. Include your requirements and ask specific questions about their EBM capabilities, equipment, and past projects.

4. Certifications and Standards: Verify that SourcifyChina meets international quality standards, such as ISO certifications. This ensures they adhere to stringent manufacturing protocols.

5. Sample Orders: Request a sample run before committing to large orders. This helps evaluate the quality, precision, and turnaround time of their electron beam machining services.

6. Communication Channels: Establish clear communication channels. Assign a point of contact from both your team and SourcifyChina to address queries and updates promptly.

7. Pricing and Terms: Negotiate pricing based on your budget and quantity requirements, but also consider long-term partnerships benefits. Clarify payment terms, delivery timelines, and any hidden costs.

8. Quality Assurance: Inquire about their quality control processes. Understanding how they manage inspections, testing, and defect handling is crucial.

9. Logistics and Shipping: Discuss shipping and logistics intricacies. Ensure they can handle international shipping, including customs documentation and insurance.

10. Contracts: Draft a detailed contract outlining all terms and conditions, including confidentiality clauses to protect your designs and intellectual property.

By following these tips, you can efficiently source high-quality EBM services from SourcifyChina, ensuring your production needs are met reliably and efficiently.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.