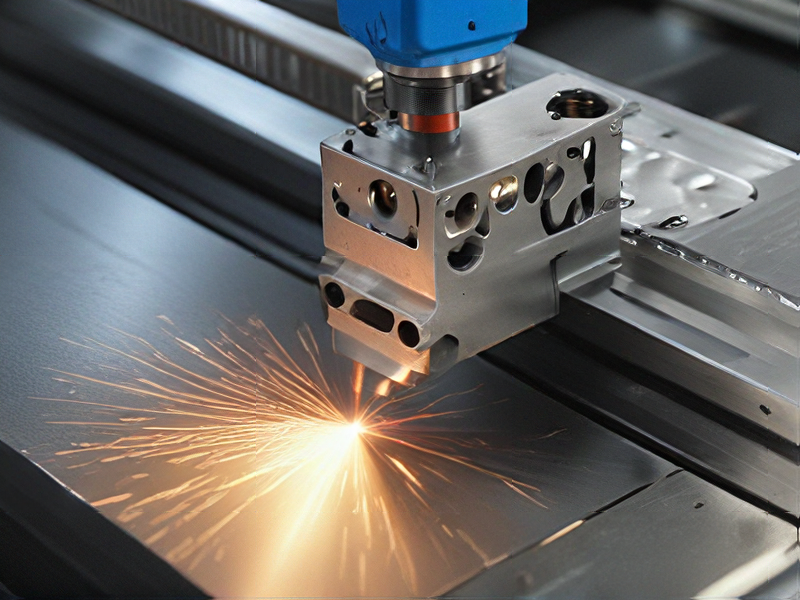

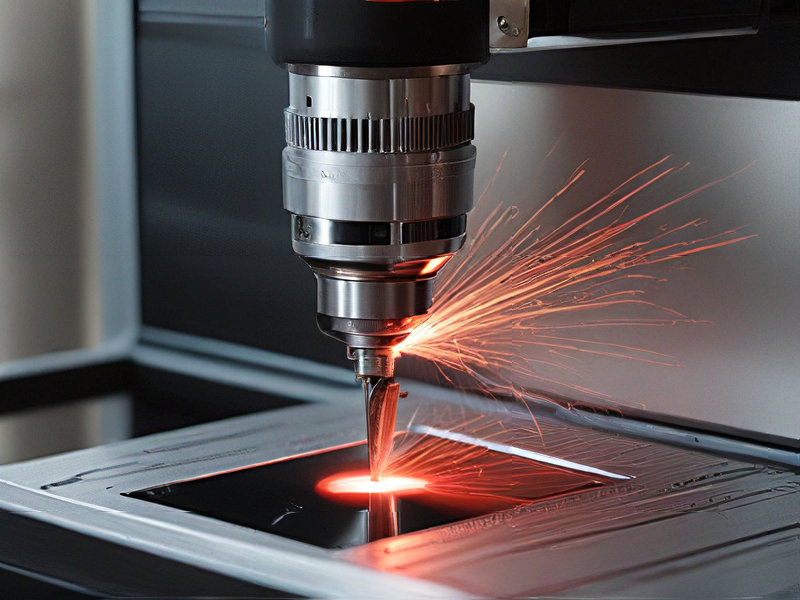

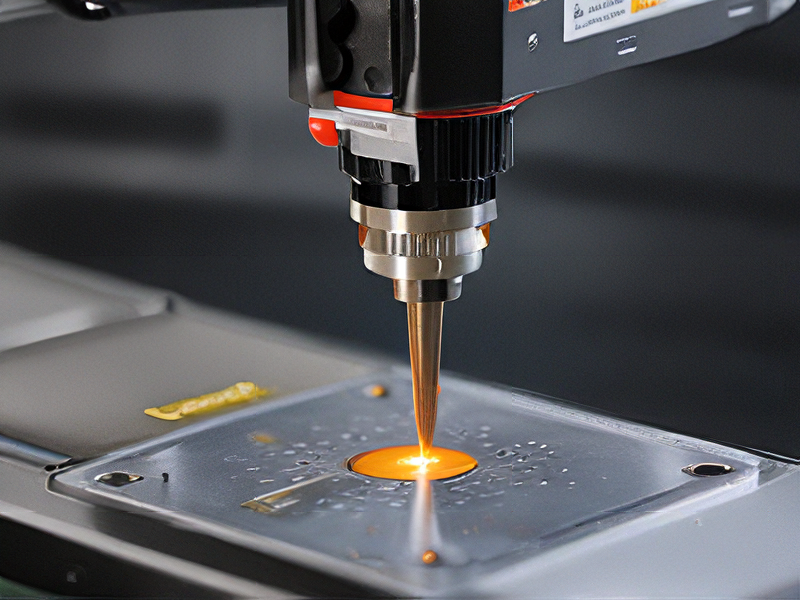

Technology and Applications of engraving laser machine for metal

Engraving laser machines for metal utilize concentrated light beams to mark or cut metal surfaces with high precision. The technology relies on various types of lasers, such as CO2, fiber, and diode lasers, each suited for different materials and applications. Fiber lasers, in particular, are favored for metal engraving due to their efficiency and ability to produce fine details.

Applications of Laser Engraving Machines for Metal:

1. Industrial Manufacturing:

– Component Marking: Serial numbers, barcodes, and QR codes for traceability.

– Tooling: Engraving tools and dies for identification and customization.

– Automotive: Marking engine parts and other components for identification and quality control.

2. Jewelry and Personalization:

– Customization: Personalizing jewelry, watches, and other accessories with intricate designs, names, and dates.

– Prototyping: Creating detailed prototypes of new designs with precision.

3. Electronics:

– PCB Marking: Engraving circuit boards with identifiers and component outlines.

– Device Marking: Marking electronic devices like smartphones and laptops with logos and regulatory information.

4. Medical Devices:

– Tool Identification: Engraving surgical instruments for traceability and compliance with health regulations.

– Prosthetics: Marking prosthetic parts for customization and identification.

5. Aerospace:

– Part Identification: Engraving components for tracking and maintenance purposes.

– Compliance: Ensuring parts meet regulatory requirements through precise markings.

Advantages:

– Precision and Detail: Achieves high accuracy and intricate designs.

– Durability: Engravings are resistant to wear, heat, and chemicals.

– Speed: Faster processing compared to traditional methods.

– Flexibility: Suitable for various metals like steel, aluminum, and titanium.

Laser engraving technology for metal is essential in multiple industries due to its precision, efficiency, and versatility, enabling advancements in manufacturing, personalization, and compliance.

Quality Testing Methods for engraving laser machine for metal and how to control quality

Quality testing for an engraving laser machine for metal involves several methods to ensure precision and consistency. Here are some key techniques:

1. Visual Inspection:

– Method: Regularly inspect engraved samples for defects such as incomplete engravings, irregular depths, and inconsistent line quality.

– Control: Use high-resolution cameras and magnification tools to detect and document defects.

2. Dimensional Accuracy Testing:

– Method: Measure the dimensions of engraved patterns using calipers or micrometers to ensure they match the design specifications.

– Control: Implement a standardized measurement procedure and use statistical process control (SPC) to track deviations.

3. Surface Roughness Testing:

– Method: Use profilometers to measure the surface roughness of engraved areas.

– Control: Establish acceptable roughness standards and perform regular checks to ensure compliance.

4. Material Removal Rate (MRR) Testing:

– Method: Calculate the MRR by measuring the volume of material removed over time.

– Control: Maintain consistent laser power, speed, and focus settings to ensure stable MRR.

5. Heat-Affected Zone (HAZ) Analysis:

– Method: Examine the HAZ using metallographic analysis to ensure minimal impact on the surrounding material.

– Control: Optimize laser parameters to minimize the HAZ and regularly monitor its size.

6. Engraving Depth Consistency:

– Method: Use depth gauges to measure the uniformity of engraving depth across different samples.

– Control: Calibrate the laser machine periodically and monitor for any drift in depth accuracy.

7. Durability Testing:

– Method: Subject engraved samples to wear and corrosion tests to ensure durability.

– Control: Use standardized testing protocols and compare results against benchmarks.

To control quality, implement a robust quality management system (QMS) incorporating these testing methods. Regular machine maintenance, operator training, and real-time monitoring systems are crucial. Documenting test results and performing root cause analysis for any deviations will help in continuous improvement of the engraving process.

Tips for Procurement and Considerations when Purchasing from engraving laser machine for metal

When procuring an engraving laser machine for metal, consider the following tips and considerations:

1. Machine Type and Specifications: Choose between fiber lasers, which are best for metals, or CO2 lasers, which are more versatile but less effective on metals. Ensure the machine’s power (wattage) matches your material’s thickness and type.

2. Accuracy and Precision: Look for machines with high precision and resolution. The accuracy of the laser determines the quality of the engraving, especially for detailed designs.

3. Software Compatibility: Ensure the machine comes with user-friendly software that is compatible with your existing design tools. Good software will streamline the design-to-production process.

4. Durability and Build Quality: The machine should be robust and built from high-quality materials to withstand industrial use. Check for reputable brands known for their longevity and reliability.

5. Cooling System: A good cooling system is crucial to prevent overheating and maintain the machine’s efficiency and lifespan. Fiber lasers typically have more efficient cooling systems.

6. Speed and Efficiency: Consider the machine’s engraving speed, as higher speeds can increase productivity. However, balance speed with precision to ensure high-quality outputs.

7. Maintenance and Support: Look for machines with low maintenance requirements. Ensure that the manufacturer or supplier offers comprehensive support and readily available spare parts.

8. Safety Features: Ensure the machine has adequate safety features such as protective housing, emergency stop buttons, and proper ventilation systems to handle fumes.

9. Cost and Warranty: Balance your budget with the machine’s features. Investing in a high-quality machine can save costs in the long run due to fewer breakdowns and repairs. Check for warranties and after-sales service agreements.

10. Reviews and Testimonials: Research user reviews and testimonials to gauge the machine’s performance in real-world applications. Peer feedback can provide insights beyond the manufacturer’s specifications.

By carefully evaluating these factors, you can make an informed decision that aligns with your production needs and budget.

FAQs on Sourcing and Manufacturing from engraving laser machine for metal in China

Certainly! Here are some frequently asked questions (FAQs) regarding sourcing and manufacturing from engraving laser machines for metal in China:

1. What are the advantages of sourcing engraving laser machines from China?

Sourcing from China often offers competitive pricing due to lower manufacturing costs. Chinese manufacturers also have extensive experience and expertise in producing a wide range of laser machines.

2. How can I ensure the quality of engraving laser machines from Chinese suppliers?

It’s crucial to conduct thorough research and due diligence on potential suppliers. This includes verifying their certifications, requesting samples, and possibly visiting their facilities. Using a reputable sourcing agent or conducting inspections can also help ensure quality.

3. What are the typical lead times for ordering engraving laser machines from China?

Lead times can vary depending on factors like customization, order quantity, and supplier capabilities. Generally, it’s advisable to clarify lead times with suppliers early in the process and factor in additional time for shipping.

4. Are there any potential challenges or risks in sourcing from China?

Challenges can include language barriers, intellectual property concerns, and variations in regulatory compliance. Mitigating these risks involves clear communication, legal safeguards like contracts and agreements, and working with reputable suppliers.

5. What are the payment terms typically used when sourcing from Chinese suppliers?

Payment terms can vary but commonly include options like T/T (Telegraphic Transfer), L/C (Letter of Credit), or Alibaba’s Trade Assurance. Negotiating favorable terms and ensuring clarity on payment milestones are essential.

6. How can I handle logistics and shipping when importing engraving laser machines from China?

Working with experienced freight forwarders or logistics providers can streamline the process. It’s important to understand import duties, customs regulations, and potential import restrictions in your country.

Navigating these aspects thoughtfully can help ensure a successful sourcing and manufacturing experience when dealing with engraving laser machines from China.