Technology and Applications of etching metals

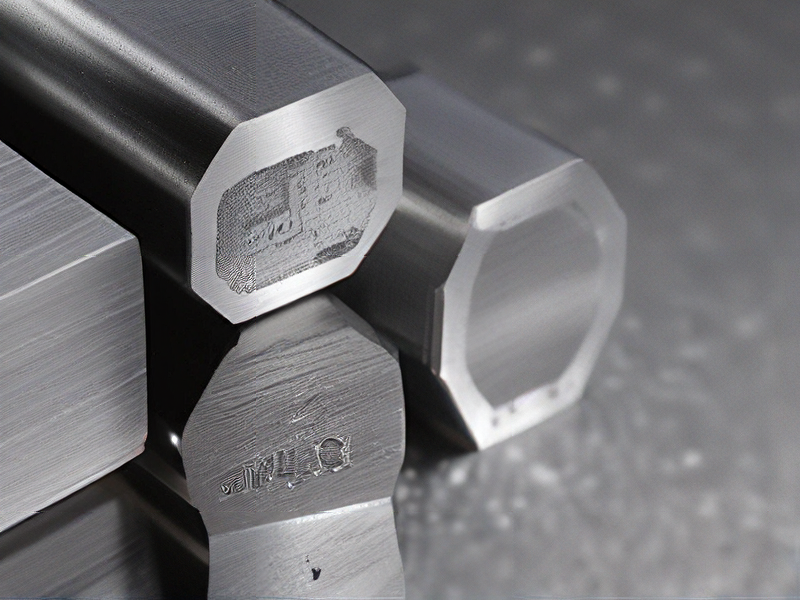

Metal etching is a crucial process in manufacturing and electronics, involving the selective removal of metal to create intricate patterns or circuitry. This technique finds extensive applications in various industries, primarily due to its precision and versatility.

Technology: Metal etching employs chemical, electrochemical, or physical methods to selectively remove metal from a substrate. Chemical etching involves immersing the metal in an etchant solution that dissolves the exposed areas, controlled by masking techniques such as photoresist or stencils. Electrochemical etching utilizes an electric current to dissolve metal, with precise control over the process parameters influencing etch depth and pattern accuracy. Physical etching, including ion beam or laser ablation, vaporizes metal atoms, offering high resolution and minimal material loss.

Applications: Metal etching serves critical roles in electronics for printed circuit boards (PCBs), where it defines conductive pathways. In microelectronics, it fabricates microelectromechanical systems (MEMS) and sensors. In decorative arts and jewelry, etching creates intricate designs and textures on metal surfaces. In aerospace and automotive industries, it produces lightweight components through selective etching of alloys. Medical devices benefit from etching for precise components and implants.

Overall, metal etching’s technological advancements have expanded its applications across diverse sectors, facilitating innovation and efficiency in manufacturing and design processes.

Quality Testing Methods for etching metals and how to control quality

Quality testing methods for etching metals typically involve several key techniques to ensure precise control and adherence to specifications:

1. Visual Inspection: This involves examining the etched surface under appropriate lighting conditions to detect any irregularities such as scratches, cracks, or incomplete etching.

2. Microscopic Analysis: Using optical or electron microscopes to inspect the surface at higher magnifications for fine details and to assess the uniformity of etching.

3. Surface Profiling: Techniques like atomic force microscopy (AFM) or stylus profilometry can measure the surface roughness and profile to ensure it meets the required specifications.

4. Chemical Analysis: Utilizing techniques such as X-ray photoelectron spectroscopy (XPS) or energy-dispersive X-ray spectroscopy (EDS) to analyze the composition of the etched surface, ensuring proper chemical removal and avoiding residues.

5. Dimensional Measurement: Employing tools like coordinate measuring machines (CMM) to verify dimensional accuracy and tolerances post-etching.

To control quality effectively:

– Process Parameters: Monitor and control variables such as etchant concentration, temperature, agitation, and etching time to ensure consistent results.

– Standard Operating Procedures (SOPs): Develop detailed SOPs for etching processes, including handling of chemicals, safety protocols, and quality checkpoints.

– Training and Skills: Ensure operators are trained in proper handling of equipment and interpretation of quality criteria.

– Statistical Process Control (SPC): Implement SPC techniques to monitor process variation and identify trends that could impact quality.

– Feedback Mechanisms: Establish feedback loops where data from quality tests inform adjustments to the process parameters or SOPs.

By integrating these methods and controls, manufacturers can achieve reliable quality assurance in metal etching processes, meeting both functional and aesthetic requirements.

Tips for Procurement and Considerations when Purchasing from etching metals

When purchasing etching metals for procurement purposes, several key considerations can optimize the process:

1. Material Selection: Choose metals based on their suitability for etching techniques. Metals like stainless steel, brass, copper, and aluminum are commonly used due to their etchability and durability.

2. Quality Standards: Ensure suppliers meet industry standards for metal quality. Grades and certifications such as ASTM specifications can validate material integrity and performance.

3. Supplier Reliability: Select suppliers with proven track records in metal supply and etching services. Reviews, references, and supplier audits can help gauge reliability.

4. Cost Efficiency: Balance quality with cost-effectiveness. Consider bulk purchasing, negotiating prices, and evaluating total cost of ownership (including etching process costs).

5. Etching Compatibility: Verify metals are compatible with intended etching methods (chemical etching, laser etching, etc.). Material thickness and surface finish impact etching results.

6. Environmental Impact: Assess suppliers’ environmental practices and compliance with regulations. Sustainable sourcing and recycling initiatives contribute to responsible procurement.

7. Lead Times and Logistics: Plan for lead times and ensure logistics align with production schedules. Just-in-time (JIT) delivery may reduce inventory costs and improve efficiency.

8. Customization Options: Evaluate suppliers’ ability to accommodate custom orders, such as specific alloy compositions or surface treatments.

9. Support Services: Consider additional services offered, such as metal finishing, machining, or packaging, which can streamline supply chain operations.

10. Risk Management: Develop contingency plans for supply chain disruptions. Diversifying suppliers or maintaining safety stock can mitigate risks.

By integrating these considerations into your procurement strategy, you can effectively source etching metals that meet quality standards, operational requirements, and cost objectives.

FAQs on Sourcing and Manufacturing from etching metals in China

FAQs on Sourcing and Manufacturing Etching Metals in China

1. What are the benefits of sourcing etched metals from China?

China offers competitive pricing, high production capacity, advanced technology, and experienced manufacturers. This can lead to cost savings, high-quality products, and quicker turnaround times.

2. How do I find a reliable etching metal manufacturer in China?

Research online directories, industry forums, and trade shows. Utilize platforms like Alibaba, Made-in-China, and Global Sources. Checking company reviews, certifications, and past client references is also crucial.

3. What types of metals can be etched in China?

Chinese manufacturers typically offer etching services for stainless steel, aluminum, copper, brass, and nickel. Custom alloys and specialized metals are also available.

4. What are the common etching processes used?

Common processes include photochemical etching, laser etching, and electrochemical etching. Each method offers different advantages depending on the desired precision and application.

5. How can I ensure the quality of the etched metals?

Request samples before full production, perform quality inspections, and use third-party quality control services. Certifications like ISO 9001 can also indicate a commitment to quality.

6. What is the typical lead time for etched metal products?

Lead times can vary from a few weeks to a few months, depending on the complexity of the project, order size, and the manufacturer’s capacity.

7. What are the payment terms for manufacturers in China?

Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and D/P (Documents against Payment). It’s important to negotiate and agree on terms before starting production.

8. Are there any potential risks when sourcing from China?

Risks include communication barriers, quality inconsistencies, and intellectual property concerns. Mitigate these by maintaining clear communication, regular quality checks, and using legally binding contracts.

9. What logistical considerations should I keep in mind?

Consider shipping times, customs regulations, and import duties. Partnering with a reliable freight forwarder can help navigate these complexities.

10. How can I protect my intellectual property when manufacturing in China?

Use non-disclosure agreements (NDAs), register your IP in China, and work with reputable manufacturers known for ethical practices.

For further information, consulting with sourcing experts or local trade agencies can provide personalized guidance and support.