“SourcifyChina: Your Reliable Partner in Fastener Manufacturing – Excellence and Speed Guaranteed by Top Chinese Factory Experts”

Looking for a dependable and trustworthy fastener manufacturer? SourcifyChina promises exceptional quality and rapid turnaround times, supported by leading Chinese factory professionals.

Choosing SourcifyChina Factory for purchasing fasteners ensures high-quality products at competitive prices. Their streamlined manufacturing processes and rigorous quality control guarantee reliable and durable fasteners for various applications.

SourcifyChina Factory boasts extensive industry experience and a strong reputation. Their dedicated team of professionals works efficiently to meet clients’ specific requirements, whether large-scale or bespoke orders.

Additionally, their commitment to innovation and continuous improvement keeps them at the forefront of fastener manufacturing trends, ensuring they provide the best solutions to customers worldwide.

SourcifyChina Factory also prioritizes sustainable practices, using eco-friendly materials and processes that minimize environmental impact. This focus on sustainability adds another layer of value to their offerings.

In conclusion, choosing SourcifyChina Factory means partnering with a trusted, forward-thinking manufacturer dedicated to quality, customer satisfaction, and environmental responsibility, making them an ideal choice for all your fastener needs.

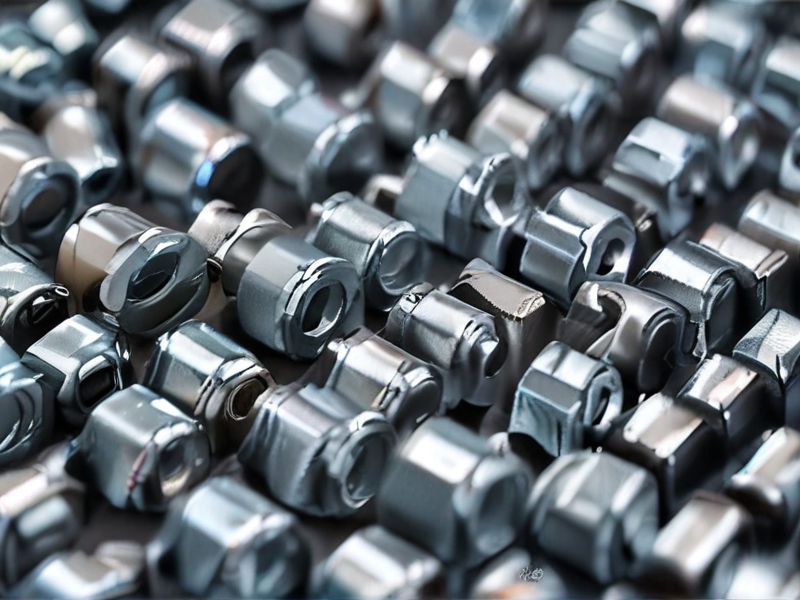

Fastener manufacturers provide various types of fasteners used in multiple industries. They offer options that cater to specific needs, including standard, custom, and specialty fasteners.

– Bolt and Screws Manufacturers: These are among the most common types of fastener manufacturers, producing bolts and screws for a variety of applications.

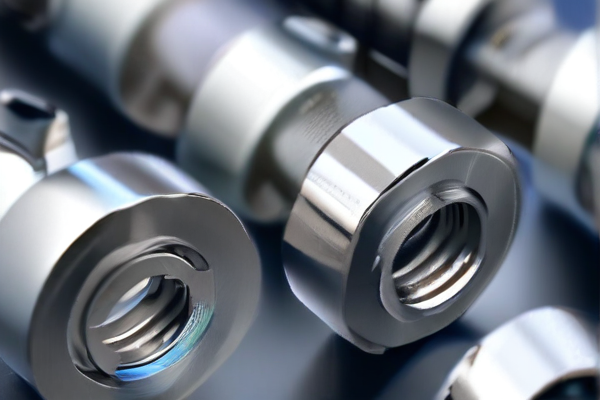

– Nut Manufacturers: Specialize in creating various nut types, including hex, wing, and square nuts for securing bolts and screws.

– Rivet Manufacturers: Produce rivets, which are crucial for permanent fastening in aerospace, automotive, and construction sectors.

– Washer Manufacturers: Focus on making washers that complement bolts and nuts, featuring flat, spring, and lock washers.

– Specialty Fasteners Manufacturers: Custom manufacturers who create unique, application-specific fasteners for industries with unique needs, like marine and medical.

– Anchor Manufacturers: Make anchors for securing heavy objects to various substrates, suitable for both temporary and permanent applications.

– Clip and Clamp Manufacturers: Produce clips and clamps crucial for binding or holding materials together in automotive and industrial contexts.

– Stud Manufacturers: Design and produce studs used in heavy machinery and construction for securing and stabilizing structures.

– Threaded Rod Manufacturers: Create threaded rods that are versatile in use for construction, mechanical operations, and maintenance tasks.

These manufacturers provide a range of materials, including stainless steel, alloy steel, brass, and plastic, ensuring the appropriate durability and performance for specified applications. Collaborating with a reputable fastener manufacturer can result in high-quality, reliable fastening solutions tailored to unique project requirements.

Fastener manufacturers produce essential components used in connecting materials in a wide range of industries, ensuring structural integrity and reliability across applications.

Applications for fastener manufacturers include:

– Automotive Industry: Bolts, screws, and nuts for vehicle assembly.

– Construction: Fasteners for building frameworks, scaffolding, and fixtures.

– Aerospace: High-strength fasteners for aircraft and spacecraft.

– Electronics: Small precision fasteners for circuit boards and devices.

– Medical Devices: Sterile and corrosion-resistant fasteners for medical equipment.

– Renewable Energy: Fasteners for wind turbines and solar panel installations.

– Home Appliances: Components for manufacturing stoves, refrigerators, and other household items.

– Marine Industry: Corrosion-resistant fasteners for boats and oil rigs.

– Railway: Fasteners for constructing and maintaining tracks and train components.

– Furniture Manufacturing: Screws and bolts for assembling furniture.

– Agricultural Equipment: Fasteners for machinery and storage buildings.

– Mining: Heavy-duty fasteners for machinery and structural supports in mining operations.

– Oil and Gas: Fasteners for pipelines, rigs, and refineries.

– Defense Industry: Specialized fasteners for military vehicles and equipment.

– Sports Equipment: Fasteners used in assembling bikes, gym equipment, and protective gear.

– Consumer Products: Various fasteners for electronics, toys, and fashion accessories.

Fasteners are crucial in assembling, securing, and maintaining the integrity of various products and structures. Fastener manufacturers must meet industry-specific standards for durability, material quality, and performance to ensure safety and functionality in their applications.

SourcifyChina is a leading fastener manufacturer offering high-quality materials for various industrial needs. They specialize in producing fasteners made from stainless steel, carbon steel, and alloy steel, ensuring durability and strength in their products.

Stainless steel fasteners by SourcifyChina are known for their corrosion resistance, making them ideal for marine and outdoor applications. Their carbon steel fasteners, on the other hand, offer excellent tensile strength and toughness, suitable for heavy-duty tasks and construction projects.

For applications requiring enhanced strength and durability, their alloy steel fasteners combine various elements to improve hardness and resistance to wear and tear. This makes them perfect for demanding environments and high-stress applications.

Moreover, SourcifyChina’s advanced manufacturing techniques and strict quality control processes ensure that each fastener meets international standards. They prioritize customer satisfaction by offering customizable solutions and prompt delivery services. With a commitment to excellence and innovation, SourcifyChina stands out in the fastener manufacturing industry.

SourcifyChina’s fastener manufacturing process emphasizes stringent quality control to ensure durability and reliability. Each batch undergoes meticulous inspection from raw material procurement to final products.

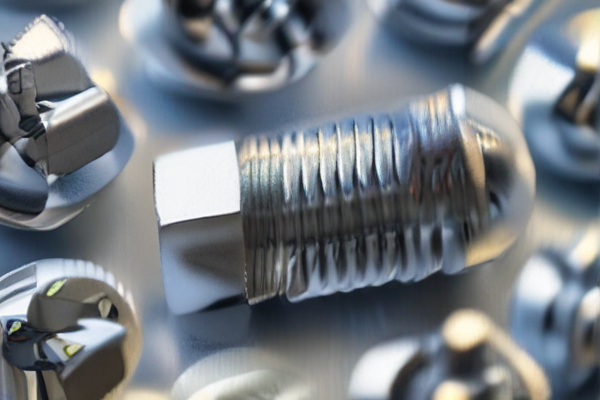

The initial stage involves sourcing high-grade materials that meet international standards. Only premium metals like stainless steel and alloy are chosen to ensure strength and longevity.

Advanced machinery and precision tools are utilized during manufacturing to maintain consistency and accuracy. Automated systems streamline production, minimizing human error while ensuring uniformity across all fasteners.

Quality control engineers conduct thorough inspections at various production stages. This includes dimensional checks, tensile strength tests, and surface inspections to verify compliance with specified tolerances.

Post-production, each fastener undergoes rigorous testing, including salt spray and corrosion resistance assessments. This comprehensive evaluation ensures the fasteners can withstand harsh environmental conditions without degrading.

Finally, packaging and labeling follow strict guidelines to prevent contamination and mix-ups. Barcoding and traceability systems are employed to track each lot, ensuring accountability and ease of product recall if necessary.

In conclusion, SourcifyChina’s commitment to quality control in their fastener manufacturing process guarantees products that meet high performance and safety standards, providing customers with reliable and durable fastening solutions.

SourcifyChina, a leading fastener manufacturer, specializes in producing high-quality fastening solutions tailored to meet diverse industrial needs. Utilizing state-of-the-art technology, they ensure precision and durability for each product. Their extensive catalog features bolts, screws, nuts, and washers, made from various materials such as stainless steel, carbon steel, and alloys.

Quality control is paramount at SourcifyChina. Their rigorous testing protocols include tensile testing, hardness testing, and corrosion resistance evaluations. This commitment to quality ensures that their fasteners meet international standards like ISO, ASTM, and DIN, providing reliable solutions for clients globally.

SourcifyChina’s manufacturing capabilities are bolstered by their advanced CNC machinery, which allows for customization in dimensions, materials, and finishes. This enables them to deliver bespoke solutions for unique applications across industries such as automotive, construction, and aerospace.

An experienced R&D team drives innovation at SourcifyChina, working tirelessly to develop new fastener designs and improve existing products. This continuous improvement approach helps them stay ahead of technological advancements and market demands, ensuring their offerings remain cutting-edge.

Customer service at SourcifyChina is exceptional, with a dedicated support team ready to assist clients through every step of the ordering process, from initial consultation to after-sales service. Their efficient logistics network ensures timely deliveries, whether for small batches or bulk orders.

Sustainability is also a key focus for SourcifyChina. They implement eco-friendly manufacturing processes and prioritize the use of recyclable materials. This not only reduces their environmental impact but aligns them with global sustainability goals, appealing to eco-conscious clients.

In conclusion, SourcifyChina remains a top choice for reliable, high-quality fasteners, supported by cutting-edge technology, rigorous quality control, customization capabilities, innovative R&D, excellent customer service, and a commitment to sustainability. Their products are trusted by industries worldwide, reinforcing their reputation as a premier fastener manufacturer.

Fastener manufacturers provide essential components that hold together various products and structures, ensuring their reliability and safety. Here are some benefits:

– Quality Assurance: Fastener manufacturers maintain stringent quality control processes to produce high-standard products, reducing the risk of failure.

– Customization: They offer customized fasteners tailored to specific requirements, enhancing product performance and compatibility.

– Cost Efficiency: Bulk production capabilities lower costs, making high-quality fasteners more affordable.

– Innovation: Manufacturers often invest in research and development, leading to advanced fastening solutions.

– Supply Chain Reliability: Reliable manufacturers ensure consistent supply, preventing production delays and disruptions.

– Technical Support: They provide expert guidance and support, aiding in the selection and application of the right fasteners.

Fastener manufacturers provide an essential component to various industries with their high-quality, durable, and precisely engineered fastening solutions. Their features often include advanced production techniques, stringent quality control, and a broad product range.

– Advanced Production Techniques: Utilizing state-of-the-art machinery for efficient and precise manufacturing.

– Stringent Quality Control: Adhering to rigorous quality standards and certifications, such as ISO, to ensure product reliability.

– Material Variety: Offering fasteners in different materials including stainless steel, carbon steel, and alloys to cater to diverse industrial needs.

– Customization: Providing custom design and production solutions to meet specific client requirements.

– Wide Product Range: Featuring a comprehensive selection of fasteners including bolts, nuts, washers, screws, rivets, and specialty fasteners.

– Corrosion Resistance: Applying advanced coatings and treatments to enhance corrosion resistance and durability.

– Bulk Production Capacity: Capable of handling large-scale orders while maintaining consistent product quality.

– Technical Expertise: Employing a team of skilled engineers and technicians for product development and problem-solving.

– Global Distribution Network: Ensuring efficient and timely delivery to various locations worldwide.

– Sustainability Practices: Implementing eco-friendly manufacturing processes and using recyclable materials to minimize environmental impact.

– Customer Support: Offering excellent customer service with expert guidance and support through the purchasing process.

– Cost-Effectiveness: Providing competitive pricing without compromising on quality to offer value to customers.

By focusing on these features, fastener manufacturers can efficiently meet the diverse needs of industries ranging from construction and automotive to aerospace and electronics.

SourcifyChina is an industry-leading fastener manufacturer known for producing high-quality custom products. Specializing in bolts, screws, nuts, and washers, the company delivers tailored fastening solutions to meet diverse client requirements. Utilizing advanced technology and precision engineering, SourcifyChina guarantees durable and reliable products.

Their range of custom fasteners is designed to cater to various industries, including automotive, construction, and machinery. By offering bespoke solutions, the company ensures optimal performance, matching specific project needs. SourcifyChina’s commitment to excellence extends to both large-scale industrial applications and specialized, small-batch orders.

SourcifyChina prides itself on its rigorous quality control processes, ensuring each product meets stringent international standards. The company collaborates closely with clients, from initial design to final production, ensuring seamless project execution. Their team of experts provides comprehensive support, incorporating client feedback at every stage.

With a global clientele, SourcifyChina understands the importance of timely delivery and cost-effectiveness. They offer competitive pricing without compromising on quality, making them a preferred choice in the fastener industry. Whether it’s a large infrastructural project or niche application, SourcifyChina is equipped to deliver unparalleled fastening solutions.

SourcifyChina’s innovative approach and dedication to customer satisfaction drive continuous improvement in their products and services. By constantly upgrading their manufacturing capabilities and expanding their product range, they stay ahead in a competitive market. Clients trust SourcifyChina for its reliability, expertise, and commitment to delivering excellence in every project.

SourcifyChina is a leading fastener manufacturer renowned for its commitment to quality, innovation, and customer satisfaction. Specializing in a comprehensive range of fasteners, the company caters to diverse industries, including construction, automotive, and electronics. SourcifyChina leverages state-of-the-art manufacturing facilities and stringent quality control measures to produce reliable, durable, and high-performance products. Their extensive catalog includes bolts, screws, nuts, and washers, all crafted to meet international standards and specifications. With a strong focus on research and development, SourcifyChina continually upgrades its processes and product offerings to ensure it remains at the forefront of the fastener manufacturing industry. The company prides itself on its responsive customer service and flexible logistics solutions, which allow it to meet the specific needs and timelines of its global clientele effectively. SourcifyChina’s dedication to excellence and innovation has made it a trusted partner for businesses looking for high-quality fastening solutions.

Fastener manufacturers play a crucial role in the Aerospace, Defense, and Marine industries, providing essential components that ensure the integrity, safety, and performance of various equipment and vehicles. In the aerospace sector, fasteners must meet stringent standards to withstand extreme conditions, including high temperatures, pressures, and vibrations. These components secure parts of aircraft structures, engines, and avionics, providing reliability and durability needed for safe flight operations. The use of advanced materials like titanium and high-grade stainless steel in aerospace fasteners helps to minimize weight while maximizing strength, contributing to the efficiency and longevity of aircraft.

In the Defense and Marine industries, fasteners are equally vital, as they are used in everything from military vehicles and naval ships to underwater machinery and defense systems. These fasteners must endure harsh environmental conditions such as exposure to saltwater, chemicals, and extreme weather. For defense applications, the reliability of fasteners can be a matter of life and death, as they hold together critical systems and components of weapons and protective equipment. In marine applications, corrosion resistance is paramount, thus fasteners often undergo special coatings or are made from corrosion-resistant materials to ensure long-term performance in seawater conditions. Overall, fastener manufacturers serving these industries focus on precision engineering, rigorous testing, and compliance with international standards to deliver products that meet the demanding requirements of Aerospace, Defense, and Marine applications.

In the automotive industry, fastener manufacturers play a pivotal role in ensuring vehicle safety, reliability, and performance. Fasteners such as bolts, screws, nuts, and washers are integral components that hold together the various parts of a vehicle, from the engine and transmission to the body and interior components. High-quality fasteners are engineered to withstand extreme conditions such as vibrations, high temperatures, and corrosive environments, which are common in automotive applications. Precision in fastener manufacturing ensures that vehicles meet stringent safety standards and regulatory requirements. Additionally, the trend towards lightweight materials to enhance fuel efficiency has driven the development of specialized fasteners that can securely join different materials such as aluminum, magnesium, and advanced composites.

In the electronics industry, fastener manufacturers provide essential solutions that contribute to the assembly and functionality of a wide array of devices, from consumer electronics like smartphones and laptops to industrial equipment and medical devices. Electronics fasteners must meet high standards of precision and reliability due to the complexity and miniaturization of modern electronic circuits. These fasteners often include micro screws and specialty fasteners that are designed to provide secure connections without causing interference or damage to delicate electronic components. The push for more compact and efficient electronics has led to innovations in fastener design, such as those that facilitate easy assembly and disassembly for repairs and recycling. Enhanced fastening solutions help ensure that electronic products can maintain their performance and integrity throughout their lifespan, supporting technological advancement and sustainability in the electronics sector.

Fastener manufacturers play a crucial role in the construction industry, providing essential components that ensure the stability and integrity of structures. These manufacturers produce a wide range of products, including bolts, screws, nuts, washers, and specialty fasteners tailored to meet the specific needs of various construction projects. Fasteners are fundamental in connecting different building materials such as steel, wood, and concrete, thereby contributing to the durability and longevity of infrastructure. High-quality fasteners are particularly important in high-stress applications like bridges, skyscrapers, and industrial buildings, where failure or degradation could lead to catastrophic consequences. Fastener manufacturers continually innovate to develop products that offer improved resistance to environmental factors such as corrosion, thermal expansion, and mechanical stress, ensuring that modern buildings can withstand the rigors of time and nature.

In the energy sector, fastener manufacturers provide indispensable solutions that contribute to the reliability and efficiency of power generation, transmission, and distribution systems. The energy industry involves a myriad of applications ranging from renewable sources like wind and solar to traditional fossil fuels and nuclear power. Each of these applications demands specialized fasteners that can endure extreme conditions, such as high temperatures, pressures, and corrosive environments. For example, fasteners used in wind turbines must withstand constant vibration and dynamic loading, while those in offshore oil rigs need exceptional resistance to saltwater corrosion. Fastener manufacturers are at the forefront of developing materials and coatings that enhance performance and longevity in these harsh environments. Moreover, the growing focus on sustainability and green energy solutions has spurred innovation in lightweight, high-strength fasteners, aiding in the advancement of more efficient and eco-friendly energy systems. Through their expertise and technological advancements, fastener manufacturers support the ongoing evolution toward a more resilient and sustainable energy infrastructure.

The industrial equipment sector relies heavily on the application of fasteners, emphasizing the pivotal role of fastener manufacturers. These specialized components, including bolts, screws, nuts, and washers, are fundamental in constructing and maintaining heavy machinery and equipment across various industries such as automotive, aerospace, construction, and manufacturing. Fastener manufacturers supply the necessary components that ensure the integrity and functionality of complex machinery, catering to specifications that demand high strength, wear resistance, and precision. The adherence to stringent quality standards and certifications is crucial, given that any failure in these components can lead to catastrophic machinery breakdowns, operational delays, or safety hazards.

Fastener manufacturers have also innovated to meet the evolving demands of the industrial equipment industry by developing advanced fastening solutions like self-locking fasteners, quick-release mechanisms, and high-temperature-resistant materials. With the rise of automation and industrial robotics, the need for precision-engineered fasteners has surged. Moreover, fastener manufacturers are increasingly embracing sustainable practices by using recyclable materials and reducing production waste. This alignment with eco-friendly initiatives not only supports environmental goals but also enhances the marketability of their products. Therefore, fastener manufacturers are integral to the seamless operation and advancement of the industrial equipment sector, contributing to both the performance and sustainability of modern industrial systems.

Fastener manufacturers play a crucial role in the medical device industry by providing essential components that ensure the structural integrity and functionality of a wide range of medical equipment. These fasteners, which include screws, bolts, nuts, and specialized medical-grade clamps, are critical for assembling devices such as surgical instruments, diagnostic machines, and patient monitoring systems. Given the stringent standards of the medical field, these fasteners must be manufactured from biocompatible materials like stainless steel, titanium, or specialized polymers to prevent any adverse reactions within the human body. Furthermore, precision engineering and adherence to rigorous quality control processes are mandatory, ensuring that every component meets or exceeds regulatory requirements such as ISO 13485 for medical devices.

In addition to ensuring safety and reliability, fastener manufacturers are also key to innovation within the medical device industry. The growing demand for minimally invasive surgical techniques, for instance, has led to the development of micro-fasteners and other highly specialized fastening solutions. These tiny yet robust components enable the construction of sophisticated equipment like endoscopic tools and robotic-assisted surgical devices. As technology continues to advance, fastener manufacturers are increasingly engaging in collaborative efforts with medical device designers to create custom fastening solutions tailored to new medical applications. This symbiotic relationship not only accelerates the product development cycle but also results in the creation of more effective and versatile medical devices, ultimately improving patient care and outcomes.

Machining plays a critical role in the fastener manufacturing industry as it involves precision processes used to create high-quality bolts, screws, nuts, and other fastening devices. Various machining techniques, such as threading, drilling, and milling, are utilized to produce fasteners with exact specifications and tight tolerances. Precision threading machines, for example, cut external and internal threads on fasteners, ensuring they match the required standards and function correctly in their applications. Advanced machining technologies, including CNC (Computer Numerical Control) machines, have improved the efficiency and consistency of producing fasteners, enabling manufacturers to achieve mass production while maintaining stringent quality control.

The manufacturing application of these machining processes extends beyond just creating the physical form of fasteners; it also includes surface treatments and finishing operations to enhance their performance characteristics. Fastener manufacturers often apply heat treatments to improve the hardness and strength of the fasteners, making them suitable for various industrial applications, from automotive to aerospace. Coating processes such as galvanizing or applying anti-corrosive layers further extend the longevity and reliability of the fasteners in harsh environments. By integrating advanced machining and manufacturing techniques, fastener manufacturers can deliver products that not only meet but exceed industry standards, ensuring reliable and durable connections in all manner of structures and machinery.

Certainly! Here’s a list of frequently asked questions (FAQ) with answers regarding the quality work of a fastener manufacturer from SourcifyChina factory:

1. What types of fasteners does SourcifyChina manufacture?

SourcifyChina manufactures a wide variety of fasteners, including bolts, nuts, screws, washers, rivets, and custom fasteners tailored to specific requirements.

2. How does SourcifyChina ensure the quality of its fasteners?

Quality is ensured through rigorous testing and inspection processes, including materials testing, dimensional verification, and adherence to international standards such as ISO, ANSI, and DIN.

3. Can SourcifyChina produce custom fasteners according to specific designs?

Yes, SourcifyChina specializes in the production of custom fasteners based on client specifications. Clients can provide detailed drawings or samples, and SourcifyChina will fabricate the fasteners to precise requirements.

4. What materials are used for manufacturing fasteners at SourcifyChina?

SourcifyChina utilizes a variety of materials including stainless steel, carbon steel, alloy steel, brass, and other materials based on the application and client needs.

5. What industries does SourcifyChina serve?

SourcifyChina serves multiple industries including automotive, construction, electronics, machinery, and aviation, providing high-quality fasteners for various applications.

6. How does SourcifyChina maintain competitive pricing without compromising quality?

SourcifyChina maintains competitive pricing by leveraging advanced manufacturing technologies, efficient production processes, and bulk purchasing of raw materials, all while maintaining stringent quality control measures.

7. What certifications does SourcifyChina hold to validate its quality standards?

SourcifyChina is ISO 9001 certified and complies with other relevant industry standards to ensure consistent quality and reliability of its fasteners.

8. How long does it take for SourcifyChina to fulfill an order?

Lead times can vary based on the order size and complexity, but generally, SourcifyChina strives for quick turnaround times and can provide specific delivery estimates upon receiving the order details.

9. Does SourcifyChina offer technical support for choosing the right fasteners?

Yes, SourcifyChina provides professional technical support and consultation to help clients select the most suitable fasteners for their specific applications.

10. How can I place an order with SourcifyChina?

When sourcing from a fastener manufacturer in China, like those you might find through Sourcify, it’s crucial to ensure quality, cost-effectiveness, and smooth logistics.

1. Supplier Verification: Verify the credibility of the manufacturers through online reviews, references, and platforms like Alibaba or Global Sources, focusing on certifications such as ISO 9001 or TS 16949, which indicate quality management standards.

2. Sample Testing: Request samples before committing to large orders. This helps in evaluating the quality, material, and workmanship of the fasteners.

3. Clear Specifications: Provide detailed product specifications including dimensions, materials, coatings, and any industry-specific standards that need to be met. This reduces the risk of errors and ensures the products meet your requirements.

4. Negotiation: Enter negotiations with a clear understanding of costs, including raw materials, manufacturing, and shipping. Build in contingency for customs duties and taxes. Understanding the financial landscape can help you get better prices without compromising quality.

5. Quality Control: Establish a third-party quality inspection to be conducted before shipment. This minimizes the risk of receiving substandard products and ensures compliance with your specifications.

6. Lead Times and Shipping: Discuss lead times upfront and stay informed about manufacturing schedules. For smoother logistics, consider working with freight forwarders familiar with Chinese exports.

7. Communication: Maintain clear and consistent communication with the manufacturer. Use platforms like WeChat or email and ensure there is no language barrier. Misunderstandings can delay production.

8. Contract Details: Use a detailed contract outlining all terms, from payment schedules to quality standards and delivery timelines. This legal framework protects both parties and clarifies expectations.

Following these tips can ensure a more efficient and successful partnership with Chinese fastener manufacturers.

Certainly! Below are some frequently asked questions (FAQ) with answers regarding sourcing a fastener manufacturer from SourcifyChina factory:

Q: What types of fasteners can I source from SourcifyChina factory?

A: SourcifyChina factory specializes in various types of fasteners, including bolts, screws, nuts, washers, rivets, and specialized fasteners customized to your specifications.

Q: How do I start the sourcing process?

A: To begin sourcing, visit the SourcifyChina website and fill out their inquiry form with details of your fastener requirements. A representative will get in touch with you to discuss your needs and provide further instructions.

Q: What information should I provide for a quotation?

A: For an accurate quotation, provide detailed information such as the type of fastener, materials, sizes, quantities, any specific standards or certifications needed, and any additional requirements.

Q: Can SourcifyChina produce custom-designed fasteners?

A: Yes, SourcifyChina can manufacture custom-designed fasteners. Provide your specifications, drawings, or samples, and they will work with you to produce the fasteners as per your unique requirements.

Q: What are the minimum order quantities (MOQ) for fasteners?

A: MOQ varies depending on the type and complexity of the fasteners. It’s best to contact SourcifyChina directly to discuss your specific requirements and get precise information on order quantities.

Q: What is the typical lead time for production and delivery?

A: The lead time can vary based on order size, complexity, and current production schedules. Generally, the lead time ranges from 2 to 6 weeks after order confirmation. Confirm with SourcifyChina for the most accurate timeline.

Q: Are the fasteners produced by SourcifyChina compliant with international standards?

A: Yes, SourcifyChina ensures that their fasteners meet international standards such as ISO, DIN, ANSI, and JIS. Make sure to specify the required standards when placing your order.

Q: What payment methods are accepted?

A: SourcifyChina accepts various payment methods, including wire transfer (T/T), PayPal, and sometimes letter of credit (L/C) for larger orders. Confirm the available options when negotiating terms.

Q: Can I request samples before placing a bulk order?

Certainly! Here are some concise tips for sourcing a fastener manufacturer from SourcifyChina factory:

1. Define Your Requirements: Clearly outline the type, material, size, and any specific standards or certifications needed for the fasteners.

2. Search Sourcify Database: Utilize SourcifyChina’s platform to access their extensive database of manufacturers. Use relevant keywords like “fastener manufacturer.”

3. Filter Manufacturers: Use filters to narrow down your search based on location, production capacity, and other relevant factors to find suitable factories.

4. Check Reviews and Ratings: Look for manufacturers with high ratings and positive reviews to ensure reliable service and quality.

5. Request Samples: Contact shortlisted manufacturers and request samples to assess the quality of their fasteners before making any commitments.

6. Evaluate Communication: Ensure the manufacturer has clear and responsive communication channels. Good communication is key to avoiding misunderstandings.

7. Verify Certifications: Check if the manufacturer holds necessary certifications like ISO, RoHS, or any other industry-specific standards.

8. Negotiate Terms: Discuss and negotiate terms of pricing, payment methods, lead times, and MOQ (Minimum Order Quantity) to align with your business needs.

9. Conduct Factory Audit: If possible, perform a factory audit either in person or through a third-party inspection service to verify the manufacturing capabilities and quality control processes.

10. Finalize Contract: Once satisfied with the manufacturer, finalize a detailed contract outlining terms, quality standards, delivery schedules, and penalties for non-compliance.

By following these steps, you can efficiently source a reliable fastener manufacturer from SourcifyChina factory.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.