Choosing SourcifyChina Factory for purchasing ferrous and non-ferrous metals from China ensures high-quality products tailored to your specifications. Their rigorous quality control processes guarantee that each batch meets international standards, providing you with reliable materials for your manufacturing needs.

SourcifyChina Factory has a streamlined logistics network, ensuring timely delivery of your metal orders. Their robust supply chain management minimizes delays and keeps your production schedules on track, reducing downtime and increasing efficiency.

Competitive pricing is another key advantage of sourcing metals from SourcifyChina Factory. They leverage strong relationships with local suppliers to negotiate better rates, passing the savings on to you. This cost-effective approach helps you maintain a competitive edge in your market.

Moreover, SourcifyChina Factory offers exceptional customer service, with dedicated account managers to support you throughout the purchasing process. Their team is always available to address any concerns, provide updates, and guide you through complex orders, ensuring a seamless experience from start to finish.

By choosing SourcifyChina Factory, you also benefit from their extensive industry expertise. With years of experience in metal sourcing, their knowledgeable staff can advise on the best materials and processes for your specific applications, further optimizing your production outcomes.

Ferrous metals contain iron, making them strong and magnetic, perfect for construction and automotive industries. Non-ferrous metals are lighter, non-magnetic, and resist corrosion, ideal for electrical and plumbing uses.

Types and Options for Ferrous Metals:

– Steel: Carbon added to iron; used in buildings, tools, and vehicles.

– Cast Iron: High carbon content; utilized in pipes, machines, and automotive parts.

– Wrought Iron: Malleable iron with low carbon; used in fences and gates.

– Alloy Steel: Iron combined with other metals; employed in specialized industrial applications.

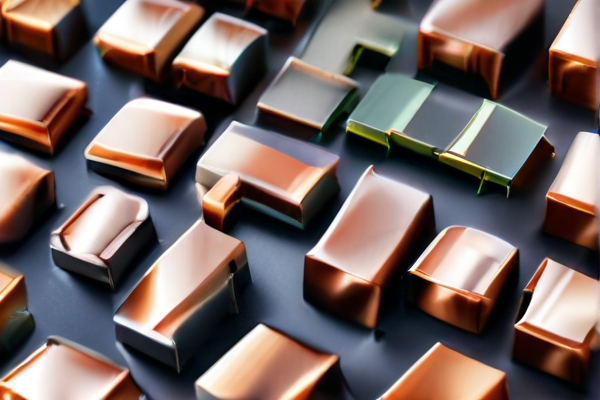

Types and Options for Non-Ferrous Metals:

– Aluminum: Lightweight and corrosion-resistant; used in airplanes, packaging, and electronics.

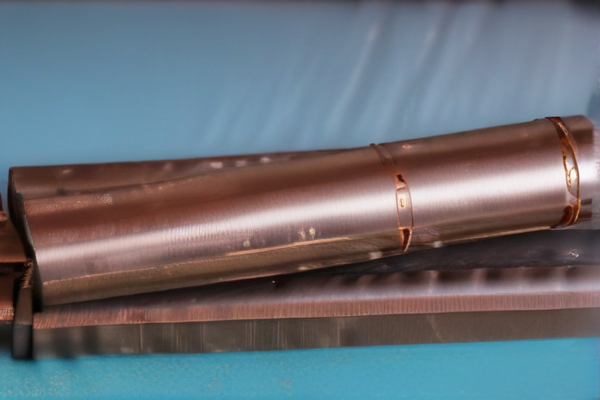

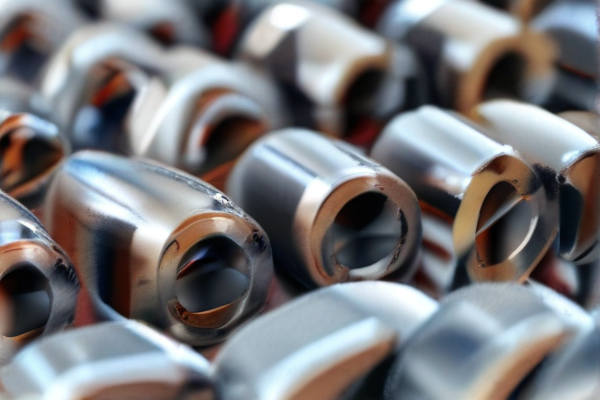

– Copper: Excellent electrical and thermal conductivity; essential in wiring, plumbing, and roofing.

– Brass: Alloy of copper and zinc; utilized in musical instruments, fittings, and decorative items.

– Bronze: Alloy of copper and tin; used in statues, bearings, and marine hardware.

– Lead: Dense and malleable; employed in batteries, radiation shielding, and roofing.

– Zinc: Corrosion-resistant; primarily used for galvanizing steel and in die-casting.

– Magnesium: Lightest structural metal; applied in aerospace, automotive, and electronic devices.

– Nickel: Improves corrosion resistance and strength; used in stainless steel, batteries, and coins.

– Titanium: High strength-to-weight ratio and corrosion-resistant; used in medical, aerospace, and industrial applications.

These diverse materials provide options suited to various industry needs, influenced by factors such as strength, weight, conductivity, and corrosion resistance.

Ferrous and non-ferrous metals play critical roles in various industries due to their distinct physical and chemical properties. Ferrous metals contain iron, while non-ferrous metals do not, broadening their application spectrum.

Applications for Ferrous Metals:

– Construction: Steel in beams, columns, and frames.

– Automotive: Engine components, chassis construction.

– Machinery: Manufacturing equipment, tools.

– Infrastructure: Bridges, railways, pipelines.

– Storage: Tanks, silos, containers.

Applications for Non-Ferrous Metals:

– Electronics: Copper in wiring, circuit boards.

– Aerospace: Aluminum for aircraft structures.

– Energy: Copper, aluminum in power lines, batteries.

– Plumbing: Copper pipes, fittings.

– Jewelry: Gold, silver, platinum in accessories.

SourcifyChina specializes in procuring both ferrous and non-ferrous metals for various industries. Ferrous metals, primarily composed of iron and its alloys, offer exceptional strength, making them ideal for construction and heavy machinery. They are known for their durability and robustness, suitable for applications requiring high tensile strength and resistance to wear and tear.

On the other hand, non-ferrous metals, which include aluminum, copper, and zinc, are known for their lightweight properties and resistance to corrosion. These materials are perfect for electrical applications, transportation industries, and consumer goods, where weight and durability are important factors.

SourcifyChina ensures that the sourced metals meet stringent quality standards, providing reliability and excellence. Their extensive network allows them to offer competitive prices and timely deliveries, ensuring that projects run smoothly without material delays. The company also focuses on sustainable sourcing, adhering to eco-friendly practices in the procurement process.

By offering a comprehensive range of both ferrous and non-ferrous metals, SourcifyChina caters to a wide array of industrial needs. This dual specialization allows them to be a one-stop shop for businesses looking for metal resources, enhancing operational efficiency and reducing procurement hassles.

SourcifyChina is committed to stringent quality control in the manufacturing of both ferrous and non-ferrous metals. The company prioritizes material selection and adheres to international standards to guarantee the highest quality.

The quality control process begins with the careful selection of raw materials. SourcifyChina sources only certified materials from reputed suppliers to ensure product reliability and durability.

Metals undergo thorough inspection before entering the production line. Advanced analytical techniques like spectrometric analysis are employed to verify the material composition, ensuring it meets the specified requirements.

During manufacturing, processes are continuously monitored. The use of state-of-the-art machinery and experienced engineers ensures precision in every stage, from casting to final product finishing.

Post-production, each metal product is rigorously tested. Mechanical properties are assessed using tensile, hardness, and impact tests, while surface integrity and dimensions are checked for compliance with exacting standards.

SourcifyChina places high importance on traceability. Each batch of material is documented and tracked through the entire manufacturing cycle, allowing for transparency and ensuring accountability.

Lastly, SourcifyChina values customer feedback. Quality control extends beyond production feedback loops to incorporate client input, aiding in continuous improvement and meeting customer needs effectively.

In summary, SourcifyChina’s comprehensive quality control process ensures that both ferrous and non-ferrous metal products meet the highest standards. From raw material selection to post-production testing, every step is meticulously managed to deliver exceptional quality and customer satisfaction.

SourcifyChina excels in the procurement and supply of ferrous metals, including iron, steel, and alloys. They maintain a vast network of reliable suppliers, ensuring consistent quality and timely deliveries to meet industrial demands.

Their expertise extends to non-ferrous metals, such as aluminum, copper, and brass. This proficiency allows them to cater to various industries, providing metal solutions that are both versatile and durable, suitable for diverse applications.

SourcifyChina employs stringent quality control measures. Their rigorous inspections and testing protocols ensure that all supplied metals conform to international standards, providing clients with peace of mind.

Beyond sourcing, they offer value-added services like custom metal fabrication and machining. These services enable clients to receive ready-to-use components, saving time and reducing production costs.

In summary, SourcifyChina’s comprehensive capabilities in both ferrous and non-ferrous metals make them a trusted partner in the metals industry. Their commitment to quality, timeliness, and customer satisfaction sets them apart.

Ferrous and non-ferrous metals offer a wide range of benefits due to their diverse properties, making them indispensable in various industries.

Benefits

of Ferrous Metals:

– Strength and Durability:

– Ferrous metals like steel and cast iron are extremely strong and durable, suitable for construction and manufacturing industries.

– Magnetic Properties:

– Many ferrous metals exhibit magnetic properties, making them useful in electrical and electronic applications.

– Cost-Effectiveness:

– Generally more affordable due to their abundant availability, lowering the overall production cost.

– Recyclability:

– Highly recyclable, reducing the environmental impact and conserving natural resources.

Benefits

of Non-Ferrous Metals:

– Corrosion Resistance:

– Metals like aluminum, copper, and brass resist corrosion, making them ideal for outdoor and marine applications.

– Lightweight:

– Non-ferrous metals are generally lighter, which is advantageous for aerospace, automotive, and construction industries.

– High Conductivity:

– Excellent electrical and thermal conductivity, making them crucial in electrical wiring and heat dissipation solutions.

– Malleability:

– Non-ferrous metals can be easily shaped and formed, allowing for intricate designs and applications in artistic and industrial fields.

Both ferrous and non-ferrous metals possess unique attributes that cater to specific needs, ensuring their continual relevance across a multitude of applications.

Ferrous metals contain iron, making them magnetic and prone to rust, while non-ferrous metals are resistant to corrosion and generally more malleable.

Features

of Ferrous Metals:

– Contains Iron: Main component is iron.

– Magnetic: Easily magnetized.

– High Strength: Strong and durable.

– Rusting: Prone to oxidation and rust.

– Hardness: Generally tougher and harder.

Common

Ferrous Metals:

– Steel

– Cast Iron

– Wrought Iron

Features

of Non-Ferrous Metals:

– Corrosion Resistant: Less likely to rust.

– Non-Magnetic: Not magnetic.

– Lightweight: Usually lighter than ferrous metals.

– Malleability: Easier to shape and bend.

– Electrical Conductivity: Often better conductors of electricity.

Common

Non-Ferrous Metals:

– Aluminum

– Copper

– Zinc

– Brass

SourcifyChina specializes in both ferrous and non-ferrous metals, offering custom products tailored to specific client needs. Our extensive range includes steel, aluminum, copper, and more, ensuring high-quality materials for diverse applications.

We pride ourselves on precise engineering and craftsmanship. From heavy machinery parts to lightweight, corrosion-resistant components, our products are designed to meet stringent industry standards. Rigorous quality control ensures every item aligns with client specifications.

Our experienced team is adept at managing complex projects. We offer end-to-end solutions, from initial concept and material selection to final production. With state-of-the-art technology, we guarantee efficient, cost-effective outcomes.

SourcifyChina emphasizes customer satisfaction. With transparent communication and flexible services, we build lasting partnerships. Tailored solutions and timely deliveries are our hallmarks. Trust us for your next metal component requirement.

SourcifyChina is a distinguished company specializing in the procurement and supply of both ferrous and non-ferrous metals, catering to a broad range of industrial requirements. With a strong foothold in China, the company leverages its extensive network and deep-rooted relationships with leading manufacturers to source high-quality metals at competitive prices. The term ‘ferrous metals’ primarily refers to iron and steel, known for their durability and strength, making them indispensable in construction, automotive, and heavy machinery industries. Conversely, ‘non-ferrous metals’ such as aluminum, copper, and zinc are prized for their lightweight properties, resistance to corrosion, and excellent electrical conductivity, finding applications in aerospace, electronics, and renewable energy sectors. SourcifyChina’s commitment to rigorous quality control, timely delivery, and customer-centric service model has positioned it as a trusted partner for businesses seeking reliable metal supplies. The company’s expertise ensures clients receive materials that meet exacting international standards, while its strategic geographic placement allows for efficient logistics and reduced lead times, enhancing overall supply chain efficiency.

Aerospace, defense, and marine industries heavily rely on the specific properties of both ferrous and non-ferrous metals to meet their demanding operational requirements. In the aerospace sector, ferrous metals like specialized steel alloys are utilized for critical structural components due to their exceptional strength, rigidity, and durability. For instance, landing gear components and aircraft frames leverage high-strength steels to withstand significant stress and fatigue. Similarly, the defense industry employs ferrous metals in the production of armored vehicles, military-grade weaponry, and infrastructure due to their superior toughness, hardness, and resistance to extreme conditions. The superior load-bearing capabilities and cost-effectiveness of ferrous metals make them indispensable in applications where safety and reliability cannot be compromised.

On the other hand, non-ferrous metals such as aluminum, titanium, and copper play an equally crucial role, particularly in scenarios where weight reduction, corrosion resistance, and thermal conductivity are paramount. Aerospace applications extensively use aluminum and its alloys for aircraft skins and components because of their excellent strength-to-weight ratio and resistance to atmospheric corrosion, which are vital for fuel efficiency and longevity. Titanium, with its remarkable corrosion resistance and strength, is valuable in high-performance jet engines and critical aerospace fasteners. The marine industry leverages non-ferrous metals like copper and its alloys, including brass and bronze, for their excellent resistance to saltwater corrosion, ensuring longevity and reliability in both shipbuilding and offshore structures. This strategic use of both ferrous and non-ferrous metals enables enhanced performance, security, and lifespan in extreme environments inherent to aerospace, defense, and marine applications.

In the automotive industry, ferrous metals, primarily iron and steel, play a significant role due to their high strength, durability, and cost-effectiveness. Steel, in particular, is used extensively for chassis construction, engine blocks, and various structural components owing to its excellent mechanical properties and availability. Advanced high-strength steels (AHSS) are increasingly popular as they offer superior strength and lightweight properties, crucial for improving vehicle fuel efficiency and reducing emissions. Cast iron, another ferrous metal, is preferred for components like brake discs and engine cylinders because of its excellent thermal conductivity and wear resistance. The industry’s shift towards electric vehicles has also seen the development of specialized steels that can withstand higher temperatures and electrical demands of electric motors.

Non-ferrous metals, such as aluminum, copper, and magnesium, are vital in enhancing the performance and efficiency of modern vehicles. Aluminum is widely used in automotive applications due to its lightweight nature, which helps reduce the overall vehicle weight and improve fuel efficiency. Car manufacturers often employ aluminum for body panels, engine components, and transmission casings. Copper is essential for electrical systems due to its superior conductivity and is commonly found in wiring, electrical connectors, and motor windings. Similarly, magnesium, being one of the lightest structural metals, is used in alloy forms for components like wheels, steering columns, and engine blocks, aiding in reducing vehicular weight further. The continuous innovation in non-ferrous materials is crucial as vehicles become more technologically advanced and environmentally conscious.

In the electronics sector, ferrous metals such as silicon steel and ferrites are integral for their magnetic properties, often used in transformers, inductors, and motor cores. Silicon steel, known for its low hysteresis loss, enhances the efficiency of power transformers and electric motors. Ferrites, a class of ceramic compounds consisting of iron oxide mixed with metallic elements, are vital in creating inductors and transformers due to their high magnetic permeability and electrical resistivity. These properties make ferrous metals indispensable for the miniaturization and efficiency of modern electronic devices.

Non-ferrous metals hold an equally prominent role in electronics due to their excellent electrical and thermal conductivity, corrosion resistance, and versatility. Copper is a fundamental material in the fabrication of printed circuit boards (PCBs), connectors, and wiring owing to its superior conductivity and reliability. Aluminum is frequently used in heat sinks and casings for electronic devices, providing effective thermal management solutions. Additionally, precious metals like gold and silver serve critical functions in connectors and contact points due to their exceptional resistance to oxidation and superior conductivity. The ongoing drive towards smaller, more powerful, and efficient electronic devices continues to propel advancements in non-ferrous metal applications.

Ferrous metals, primarily containing iron, are pivotal in construction due to their strength and durability. Steel, the most common ferrous metal, is widely used in building frameworks, reinforcing bars, and structural components because of its high tensile strength and ability to withstand heavy loads. Cast iron and wrought iron are also utilized in certain construction applications, such as columns, railings, and decorative elements, for their robustness and malleability. These metals often undergo treatment to resist corrosion, ensuring long-lasting infrastructure. The combination of strength, availability, and economic feasibility makes ferrous metals indispensable in the construction industry.

Non-ferrous metals, characterized by the absence of iron, find significant application in both construction and energy sectors due to their distinct properties. Aluminum, for example, is lightweight yet strong, making it ideal for building facades, window frames, and roofing structures. Its excellent corrosion resistance extends the lifespan of these components in various environmental conditions. Copper, another crucial non-ferrous metal, is highly conductive and used extensively in electrical wiring, plumbing, and heating systems. This extends into energy applications where copper’s efficiency in electrical conductivity and heat exchange is paramount for grid infrastructure and renewable energy technologies. The diversity and specialized properties of non-ferrous metals enable innovative solutions across construction and energy sectors, driving progress and sustainability.

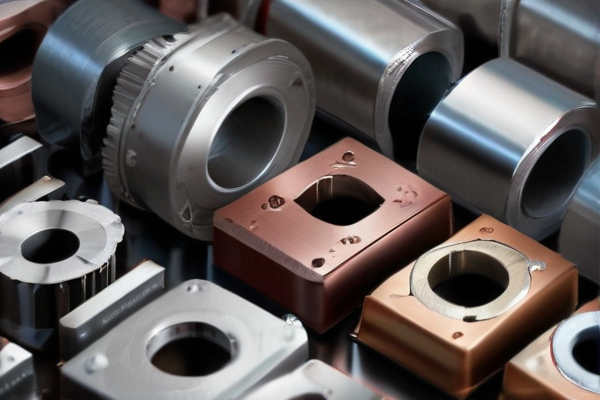

In the industrial equipment sector, the application of both ferrous and non-ferrous metals is pivotal to the construction, functionality, and longevity of machinery and infrastructure. Ferrous metals, primarily constituted of iron and its alloys like steel, are renowned for their high tensile strength, durability, and cost-effectiveness. These characteristics make them ideal for constructing heavy-duty equipment such as cranes, excavators, boilers, and conveyor systems that are integral to industrial operations. The magnetic properties of ferrous metals also find utility in the manufacturing of motors and generators. However, their susceptibility to corrosion necessitates protective coatings or the use of stainless steel, which contains chromium to resist oxidation. The diverse alloy compositions available within the ferrous category enable tailored solutions to specific industrial demands, balancing strength, ductility, and resistance to wear.

On the other hand, non-ferrous metals such as aluminum, copper, and titanium offer unique advantages that make them indispensable in various industrial applications. Aluminum’s lightweight yet high-strength nature makes it perfect for equipment where weight reduction is critical, such as in aerospace components and portable machinery. Its excellent thermal and electrical conductivity is also exploited in heat exchangers and electrical systems. Copper, known for its superior electrical and thermal conductivities, is widely used in wiring, piping, and as a critical component in electric motors and generators. Titanium, although more expensive, brings unparalleled strength-to-weight ratio and corrosion resistance, making it suitable for high-stress, high-temperature environments such as chemical processing plants and marine equipment. The strategic use of non-ferrous metals enhances the performance, efficiency, and operational lifespan of industrial machinery, providing robust solutions where ferrous metals may fall short. Together, these metals enable the industrial equipment sector to achieve optimal performance across a spectrum of demanding applications.

Medical devices heavily rely on the unique properties of both ferrous and non-ferrous metals to ensure functionality, durability, and patient safety. Ferrous metals, primarily composed of iron, are integral in crafting surgical instruments and orthopedic implants. Alloys like stainless steel are highly favored due to their exceptional corrosion resistance, strength, and biocompatibility. Surgical tools such as scalpels, forceps, and retractors benefit from stainless steel’s rigidity and ability to maintain sharpness, ensuring precision and reliability. Orthopedic implants, including screws, plates, and rods, often use alloys like 316L stainless steel, which offers excellent tensile strength and fatigue endurance necessary for load-bearing applications. These properties are paramount in ensuring the longevity and effective performance of medical devices exposed to the human body’s dynamic environment.

Non-ferrous metals, devoid of iron, play a crucial role in a variety of medical applications due to their lighter weight, corrosion resistance, and biocompatibility. Titanium, for instance, is a star player in the domain of prosthetics and dental implants due to its exceptional strength-to-weight ratio and compatibility with human tissue. This allows for implants that are both durable and less burdensome for patients. Additionally, titanium’s ability to osseointegrate, or bond directly with bone, enhances the success rates of implants. Another vital non-ferrous metal, aluminum, finds applications in lightweight medical device casings and diagnostic equipment due to its ease of fabrication and resistance to corrosion. Copper and its alloys are employed in electronic components of medical devices, leveraging their excellent electrical conductivity and antimicrobial properties. Collectively, the distinct characteristics of non-ferrous metals allow for the innovation and enhancement of various medical technologies, ultimately contributing to improved patient outcomes and the advancement of medical science.

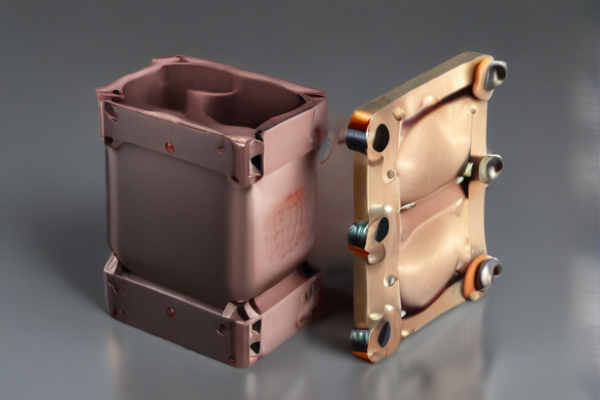

Machining and manufacturing processes heavily rely on both ferrous and non-ferrous metals due to their diverse properties and applications. Ferrous metals, primarily composed of iron, include steel and cast iron, which are renowned for their strength, durability, and magnetic properties. These metals are integral to the automotive, construction, and heavy machinery industries. The machining of ferrous metals often involves processes such as turning, milling, drilling, and grinding. Advanced techniques like CNC (Computer Numerical Control) machining provide precision and efficiency, making it possible to create intricate designs and complex components. Moreover, the ability to alloy ferrous metals with elements like carbon, chromium, and manganese enhances their mechanical properties, including hardness and resistance to wear and corrosion, further broadening their application scope.

Non-ferrous metals, such as aluminum, copper, and titanium, bring unique advantages to machining and manufacturing due to their distinct properties, such as lightweight, high conductivity, and excellent resistance to corrosion. These metals are crucial in industries like aerospace, electronics, and medical devices, where performance and reliability are paramount. Aluminum, for instance, is extensively used for its excellent machinability and ability to form complex shapes with precision. Copper, known for its superior electrical and thermal conductivity, is vital for electrical components and heat exchangers. Titanium’s exceptional strength-to-weight ratio and biocompatibility make it indispensable for aerospace components and medical implants. The machinability of non-ferrous metals often requires specialized tooling and techniques to address issues such as softer material properties or tendencies to gall or bond with cutting tools. Overall, the choice between ferrous and non-ferrous metals depends on the specific requirements of durability, strength, weight, and environmental resistance in the manufacturing application.

Q1: What types of ferrous and non-ferrous metals do you manufacture?

A1: SourcifyChina manufactures a wide range of ferrous metals such as steel and cast iron, and non-ferrous metals including aluminum, copper, and brass. We cater to diverse industry needs with precise compositions and specifications.

Q2: How do you ensure the quality of your metal products?

A2: We adhere to stringent quality control protocols. Our process includes raw material inspection, in-process quality checks, and final product testing using advanced technologies like spectroscopy and ultrasonic testing to ensure consistency and reliability.

Q3: Can you provide custom metal formulations?

A3: Yes, we offer custom metal formulations to meet specific customer requirements. Our team of metallurgists works closely with clients to develop tailor-made solutions that match exact specifications and performance criteria.

Q4: What certifications do SourcifyChina hold?

A4: SourcifyChina holds several key certifications including ISO 9001 for quality management, ISO 14001 for environmental management, and OHSAS 18001 for occupational health and safety. These certifications reflect our commitment to high standards in manufacturing.

Q5: What is your typical lead time for orders?

A5: Lead times vary depending on the complexity and volume of the order. Typically, standard orders are fulfilled within 4-6 weeks. Custom orders may require additional time. We strive to meet our customer’s deadlines through efficient production planning.

Q6: Do you offer prototyping and small batch production?

A6: Yes, SourcifyChina offers both prototyping and small batch production to help clients with product development and market testing. This service allows for flexibility and quicker adjustments before committing to larger volumes.

Q7: How do you manage environmental sustainability?

A7: We employ eco-friendly practices including recycling scrap materials, reducing energy consumption, and using environmentally friendly production technologies. Our ISO 14001 certification underscores our commitment to sustainability.

Q8: What industries do you serve?

A8: We serve a wide range of industries such as automotive, aerospace, construction, electronics, and machinery. Our versatile manufacturing capabilities allow us to adapt to varied industry requirements.

Q9: Can we visit your factory for an inspection?

When sourcing from factories like SourcifyChina, understanding the nuances between ferrous and non-ferrous metals is crucial for quality and efficiency. Below are some tips tailored to their manufacturing processes:

1. Material Specifications: Clearly define the type and grade of material required. Ferrous metals (like steel and iron) and non-ferrous metals (such as aluminum, copper, and brass) have distinct properties. Accurate specifications ensure proper material sourcing.

2. Supplier Verification: Check the factory’s expertise and history in manufacturing specific metals. SourcifyChina can provide detailed supplier profiles, but personal audits and third-party inspections are advisable.

3. Manufacturing Capabilities: Ensure the factory has the necessary equipment and technology. For ferrous metals, look for advanced furnaces, rolling mills, and heat treatment facilities. Non-ferrous metal processes might require specialized casting and extrusion equipment.

4. Quality Control: Implement rigorous quality control procedures. Non-ferrous metals are more prone to impurities, while ferrous metals need precise carbon content management. Request detailed QC protocols and regular inspection reports.

5. Prototyping and Sampling: Prioritize prototyping and sample testing. This step helps in identifying any potential issues early in the production process, saving time and costs.

6. Sustainability Practices: With increasing focus on environmental practices, inquire about the factory’s sustainability measures. Recycling capabilities and waste management are crucial, especially for non-ferrous metals.

7. Communication: Maintain clear and continuous communication with the factory. A dedicated project manager from SourcifyChina can bridge any language or cultural gaps.

8. Compliance and Certifications: Verify that the factory adheres to international standards and holds necessary certifications (ISO, RoHS, etc.). Compliance ensures product reliability and market acceptability.

By focusing on these areas, you can effectively leverage SourcifyChina’s manufacturing capabilities to produce high-quality ferrous and non-ferrous metal goods.

Sure, here are some Frequently Asked Questions (FAQ) for sourcing ferrous and non-ferrous metals from SourcifyChina factory:

1. What types of ferrous and non-ferrous metals can I source from SourcifyChina?

SourcifyChina provides a wide range of ferrous metals such as steel, cast iron, and wrought iron. For non-ferrous metals, we offer aluminum, copper, brass, zinc, and more.

2. How can I get a quote for my metal sourcing needs?

You can get a quote by contacting us via our website, email, or phone. Provide detailed specifications, quantities, and required certifications to receive an accurate quote.

3. What are the minimum order quantities (MOQ) for sourcing metals?

The MOQ varies depending on the type of metal and specific requirements. Typically, the MOQ is specified in the quotation once your sourcing needs are reviewed.

4. Do you offer custom metal fabrication services?

Yes, SourcifyChina offers custom fabrication services including cutting, bending, welding, and machining to meet your specific project requirements.

5. How long will it take to receive my order?

Lead times depend on the complexity and quantity of your order. Generally, it can take between 2 to 6 weeks for manufacturing and shipping.

6. Are quality certifications available for the metals sourced from SourcifyChina?

Yes, we provide quality certifications such as ISO, ASTM, and other relevant standards upon request to ensure you receive high-quality materials.

7. What are the payment terms for orders placed with SourcifyChina?

We offer flexible payment terms including T/T (Telegraphic Transfer), L/C (Letter of Credit), and other options as discussed during the quotation process.

8. Do you provide samples before bulk ordering?

Yes, we can provide samples for a small fee, which will be deducted from your bulk order once confirmed.

9. How is shipping handled, and can you assist with logistics?

We offer various shipping methods, including sea freight, air freight, and express shipping. Our logistics team can assist with customs clearance and documentation.

10. What should I do if I encounter issues with my order?

Contact our customer support team immediately. We are committed to resolving any issues promptly to ensure your satisfaction with our services.

These FAQs provide a concise overview of common inquiries related to sourcing metals from SourcifyChina, supporting potential clients in making informed decisions.

Sourcing ferrous and non-ferrous metals from a manufacturer like SourcifyChina can be streamlined by following these tips:

1. Understand Material Requirements: Clearly define the type, grade, and specifications of the metals you need. Ferrous metals include steel and iron, while non-ferrous metals cover aluminum, copper, and more.

2. Research SourcifyChina: Investigate SourcifyChina’s capabilities, previous client reviews, and their experience with the specific metals you require. Confirm their expertise and quality certifications.

3. Request Samples: Before committing to large orders, request samples of both ferrous and non-ferrous metals to assess quality. Analyze the samples for adherence to your specified standards.

4. Compliance and Standards: Ensure that SourcifyChina complies with international material standards and has the necessary quality assurance processes in place, such as ISO certifications.

5. Communicate Clearly: Maintain clear and detailed communication regarding your requirements, expectations, and deadlines. Use technical drawings or specifications to avoid any misunderstandings.

6. Negotiate Terms: Discuss payment terms, minimum order quantities, lead times, and shipping arrangements upfront. Aim for flexible terms that suit your business needs.

7. Visit the Factory: If feasible, conduct an on-site visit to evaluate the factory’s production capabilities and conformity with international standards.

8. Quality Assurance: Establish quality control protocols, including third-party inspections if necessary, to ensure the metals meet your standards throughout the production process.

9. Logistics Planning: Coordinate with SourcifyChina for efficient shipping and logistics arrangements, considering costs, delivery times, and import regulations.

10. Build a Relationship: Develop a good working relationship with the supplier for potential long-term collaboration, which can lead to better terms and reliability.

By following these steps, you can effectively source quality ferrous and non-ferrous metals from SourcifyChina for your manufacturing needs.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.