Technology and Applications of fiber laser cutting machines

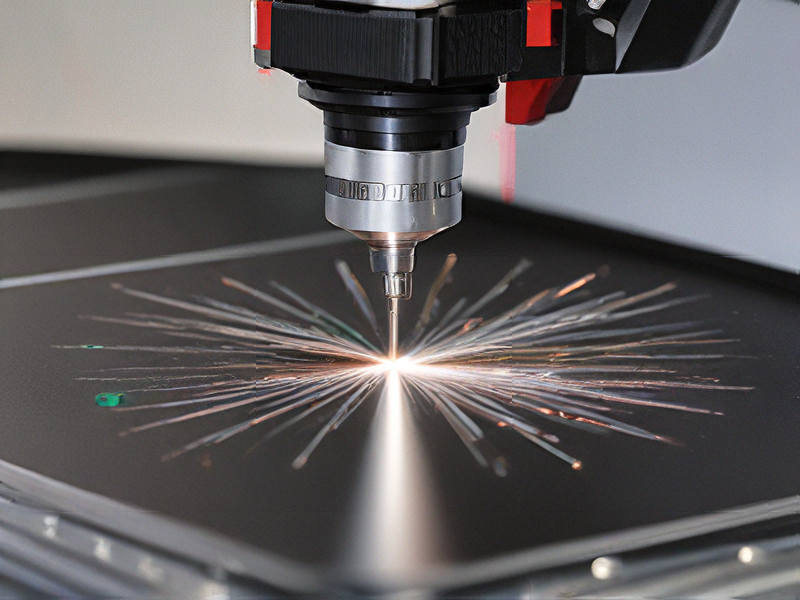

Fiber laser cutting machines represent a significant advancement in industrial cutting technology due to their precision, efficiency, and versatility. These machines utilize fiber optic technology to generate a concentrated beam of light that can cut through various materials with high accuracy and speed.

Key advantages of fiber laser cutting machines include:

1. High Precision: Fiber lasers can achieve extremely fine cuts with minimal heat-affected zones, allowing for intricate designs and close nesting of parts, which maximizes material usage and reduces waste.

2. Speed and Efficiency: They are faster than traditional CO2 lasers and other cutting methods, making them ideal for high-volume production environments. The high energy density of fiber lasers enables rapid cutting speeds across a wide range of materials.

3. Versatility: Fiber lasers can cut a variety of materials including metals (steel, aluminum, copper, etc.), plastics, composites, and even some ceramics. They are widely used in industries such as automotive, aerospace, electronics, and manufacturing.

4. Low Operating Costs: They are more energy-efficient than CO2 lasers and require less maintenance due to their solid-state design. This results in lower operating costs over the machine’s lifetime.

5. Automation and Integration: Fiber laser cutting machines can be easily integrated into automated production lines, enhancing overall manufacturing efficiency and reducing labor costs.

Applications of fiber laser cutting machines span a wide range of industries and tasks, including sheet metal fabrication, pipe cutting, automotive component manufacturing, electronics production, and signage. Their ability to handle complex designs and diverse materials makes them indispensable in modern manufacturing processes where precision and efficiency are paramount.

Quality Testing Methods for fiber laser cutting machines and how to control quality

Quality testing methods for fiber laser cutting machines typically involve several key approaches to ensure consistent performance and output:

1. Dimensional Accuracy Testing: Verify that parts cut by the laser machine adhere to specified dimensions using precision measurement tools like calipers or coordinate measuring machines (CMM).

2. Surface Quality Inspection: Assess the smoothness and cleanliness of cut edges and surfaces to ensure they meet the required finish standards. Visual inspection and sometimes microscopic examination are used.

3. Edge Quality Assessment: Evaluate the sharpness and precision of cut edges, checking for burrs, roughness, or any irregularities that could affect functionality or aesthetics.

4. Material Integrity Checks: Test the material for any signs of heat damage, such as discoloration or distortion, which can impact the structural integrity of the parts.

5. Repeatable Cutting Tests: Conduct tests to verify the machine’s ability to consistently reproduce cuts across various materials and thicknesses, ensuring reliability in production environments.

To control quality effectively:

– Calibration: Regularly calibrate the laser cutting machine and its associated systems to maintain accuracy and consistency.

– Operator Training: Ensure operators are well-trained in machine operation, maintenance, and quality control procedures.

– Process Documentation: Document standard operating procedures (SOPs) for machine setup, operation, and quality checks to maintain consistency.

– Quality Control Checks: Implement routine quality control checks at different stages of production to catch deviations early and make necessary adjustments.

By employing these methods and controls, manufacturers can maintain high-quality standards in their laser cutting processes, ensuring precise, reliable, and defect-free output.

Tips for Procurement and Considerations when Purchasing from fiber laser cutting machines

When procuring fiber laser cutting machines, several key considerations can ensure you make an informed decision:

1. Machine Specifications: Evaluate the cutting capacity, laser power, and maximum sheet size to ensure they meet your production needs. Consider the material types and thicknesses you’ll predominantly work with.

2. Accuracy and Speed: Look for machines that offer high cutting precision and fast processing speeds. This improves efficiency and reduces production time.

3. Ease of Use: User-friendly interfaces and intuitive controls can minimize training time and operational errors. Consider the accessibility of maintenance and support services.

4. Reliability and Durability: Opt for machines known for reliability and durability to minimize downtime and repair costs. Check reviews and warranty options.

5. Operating Costs: Evaluate energy consumption, maintenance requirements, and consumables (like laser gases and lenses) to estimate ongoing operational expenses.

6. Safety Features: Ensure the machine complies with safety standards and includes features like emergency stop buttons, enclosed cutting areas, and laser beam protection.

7. Supplier Reputation: Choose a reputable supplier with a track record of quality products and customer support. Check references and customer reviews.

8. Integration with Existing Systems: If you have existing production systems, ensure compatibility or necessary adaptations for seamless integration.

9. Training and Support: Evaluate the training provided by the supplier and ongoing technical support options to ensure your team can operate the machine effectively.

10. Future Expansion: Consider your future needs for scalability and whether the machine can accommodate potential growth in your business.

By carefully considering these factors, you can select a fiber laser cutting machine that not only meets your current production requirements but also supports your long-term business goals effectively.

FAQs on Sourcing and Manufacturing from fiber laser cutting machines in China

Certainly! Here are some FAQs on sourcing and manufacturing fiber laser cutting machines from China:

1. What are the advantages of sourcing fiber laser cutting machines from China?

China offers competitive pricing due to lower labor and manufacturing costs. Additionally, Chinese manufacturers have extensive experience and advanced technology in producing industrial equipment like laser cutters.

2. How can I ensure quality when sourcing from China?

Research and select manufacturers with good reputations and certifications (ISO, CE). Request samples or visit the factory to inspect production processes and quality control measures firsthand.

3. What are the typical lead times for ordering fiber laser cutting machines from China?

Lead times vary but generally range from several weeks to a few months depending on customization and order volume. It’s essential to clarify lead times and production schedules with the manufacturer.

4. Are there any import duties or regulations to consider when importing laser cutting machines from China?

Yes, import duties, taxes, and regulations apply. Research import requirements in your country and ensure compliance with local standards for safety, emissions, and electrical specifications.

5. Can Chinese manufacturers provide customization options for laser cutting machines?

Yes, many manufacturers offer customization options to meet specific cutting requirements, software integration, or special features tailored to your manufacturing needs.

6. What support and warranty options are typically offered by Chinese manufacturers?

Most manufacturers provide technical support, training, and warranty coverage for their products. Clarify warranty terms, including duration and coverage of parts and labor.

7. How do I handle logistics and shipping when importing laser cutting machines from China?

Work with experienced freight forwarders or logistics partners who specialize in shipping industrial equipment. Plan for packaging, transportation, and customs clearance to avoid delays.

8. What are the payment terms commonly used when sourcing from Chinese manufacturers?

Payment terms may include a deposit, progress payments, and final payment upon inspection or delivery. Negotiate terms that balance supplier security and buyer protection.

By addressing these FAQs, you can navigate sourcing and manufacturing fiber laser cutting machines from China more effectively, ensuring quality, compliance, and cost-efficiency in your procurement process.