Technology and Applications of flatness gd&t

Geometric Dimensioning and Tolerancing (GD&T) is crucial in manufacturing to specify and control the geometric form of parts. Flatness is one of the fundamental GD&T symbols used to define how much a surface or plane may deviate from a true flat surface.

In applications, flatness GD&T ensures precision in mating parts, such as sealing surfaces in automotive engines or semiconductor manufacturing, where even slight deviations can affect functionality or performance. It helps maintain consistent clearances in assemblies, ensuring proper fit and function of mechanical parts.

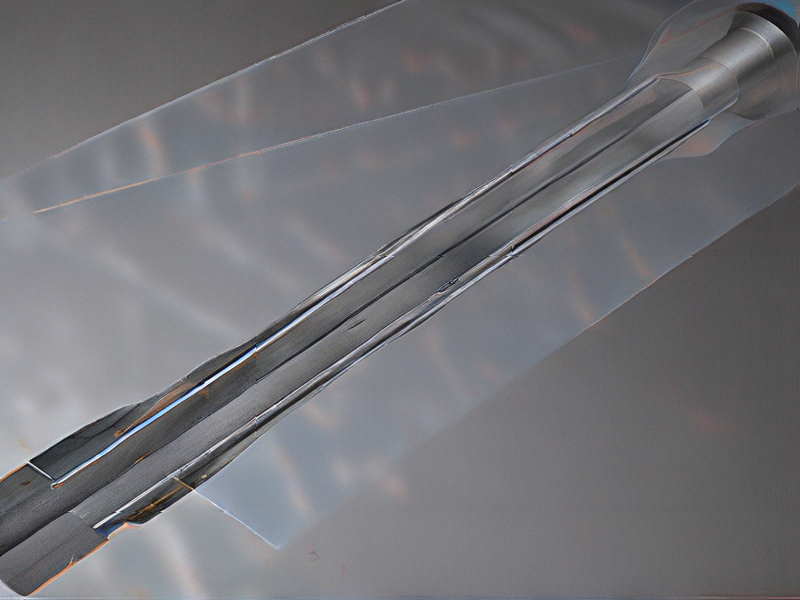

Manufacturing processes utilize flatness GD&T by employing techniques like precision machining, grinding, or lapping to achieve desired flatness tolerances. Measurement tools such as coordinate measuring machines (CMMs) or surface profilometers are used to verify compliance with specified tolerances, ensuring quality and reliability of parts.

Industries like aerospace, automotive, and electronics rely heavily on flatness GD&T to meet stringent performance requirements. For instance, in aerospace, flatness ensures aerodynamic surfaces are smooth and uniform, minimizing drag and enhancing fuel efficiency. In electronics, flatness is critical for the proper functioning of components like semiconductor wafers, where deviations can impact the effectiveness of microelectronic circuits.

Overall, flatness GD&T plays a pivotal role in ensuring the functionality, performance, and reliability of manufactured components across various industries, highlighting its importance in modern manufacturing processes.

Quality Testing Methods for flatness gd&t and how to control quality

To ensure the flatness of a component per GD&T standards, several quality testing methods can be employed:

1. Visual Inspection: Assessing the component against a flat reference surface using visual aids like straightedges or optical comparators.

2. Surface Plate Inspection: Placing the component on a precision granite surface plate and using feeler gauges or dial indicators to measure deviations.

3. Coordinate Measuring Machine (CMM): Utilizing a CMM to scan the surface and generate a 3D model, allowing precise measurement of deviations from flatness.

4. Shadow Graph or Projector: Casting a shadow or projecting light onto the surface to visually highlight deviations from flatness.

To control quality effectively:

1. Establish Clear Specifications: Define allowable tolerances for flatness in accordance with GD&T standards.

2. Use Reliable Measurement Equipment: Ensure calibration and accuracy of tools such as surface plates, CMMs, and straightedges.

3. Implement Statistical Process Control (SPC): Monitor flatness deviations over time to detect trends and prevent non-conformities.

4. Training and Skill Development: Equip personnel with the skills to perform accurate measurements and interpret GD&T specifications.

5. Feedback Loops: Establish mechanisms for feedback from quality inspections to production processes to continuously improve flatness control.

By integrating these methods and controls, manufacturers can ensure components meet required flatness tolerances reliably and consistently.

Tips for Procurement and Considerations when Purchasing from flatness gd&t

When procuring parts with flatness GD&T, focus on these key considerations:

1. Define Requirements Clearly:

Specify the desired flatness level using appropriate GD&T symbols and tolerances. Consider the part’s function and application to determine the necessary accuracy.

2. Material Selection:

Different materials exhibit varying degrees of flatness retention. Choose a material compatible with the desired flatness and expected environmental conditions.

3. Measurement Method:

Ensure the supplier utilizes a reliable measurement method for flatness, such as a precision flatness gauge or optical interferometer. Request measurement reports with traceable calibration data.

4. Inspection Processes:

Inquire about the supplier’s inspection procedures and quality control measures for ensuring flatness compliance.

5. Surface Finish:

The surface finish can affect perceived flatness. Discuss the required surface roughness and how it might influence the measurement results.

6. Environmental Factors:

Consider temperature, humidity, and other environmental factors that could impact part flatness during storage, handling, and use.

7. Supplier Expertise:

Select a supplier with proven experience in manufacturing and inspecting parts with tight flatness tolerances.

By addressing these factors, you can ensure the procurement of flatness-critical parts that meet your specific requirements.

FAQs on Sourcing and Manufacturing from flatness gd&t in China

FAQs on Sourcing and Manufacturing with Flatness GD&T in China

1. What is Flatness GD&T?

Flatness GD&T (Geometric Dimensioning and Tolerancing) is a specification that ensures a surface remains within a specified flatness tolerance. It is crucial for parts that require a high degree of precision.

2. Why source from China?

China offers cost-effective manufacturing solutions, a wide range of suppliers, advanced technology, and extensive experience in precision engineering.

3. How do I ensure quality flatness in parts sourced from China?

Work with reputable suppliers, perform due diligence, request certifications (like ISO 9001), and establish clear communication on quality expectations. Consider third-party inspections and audits.

4. What industries benefit from flatness GD&T?

Industries such as automotive, aerospace, electronics, and machinery often require components with strict flatness tolerances for proper functioning.

5. How do I find reliable suppliers in China?

Use online platforms (like Alibaba), industry trade shows, and business directories. Seek referrals, check reviews, and visit factories if possible.

6. What are the common materials used for parts requiring flatness GD&T?

Common materials include metals (aluminum, steel), plastics, and composites. Material selection depends on the application and required properties.

7. What are the challenges of sourcing from China?

Challenges include language barriers, cultural differences, varying quality standards, and logistical complexities. Mitigate these by working with local agents or consultants.

8. How can I protect my intellectual property (IP)?

Use non-disclosure agreements (NDAs), work with trusted suppliers, and register your IP rights in China.

9. What is the typical lead time for manufacturing?

Lead times vary based on complexity, order volume, and supplier capacity. Generally, expect 4-12 weeks from order placement to delivery.

10. How do I handle logistics and shipping?

Coordinate with your supplier or a logistics company. Ensure proper packaging, handle customs documentation, and choose reliable shipping methods.

Sourcing precision components with flatness GD&T from China can be highly beneficial with proper planning and quality control measures in place.