Technology and Applications of g code m code cnc

G-code (Geometric Code) and M-code (Machine Code) are fundamental to Computer Numerical Control (CNC) machines, used extensively in manufacturing and automation.

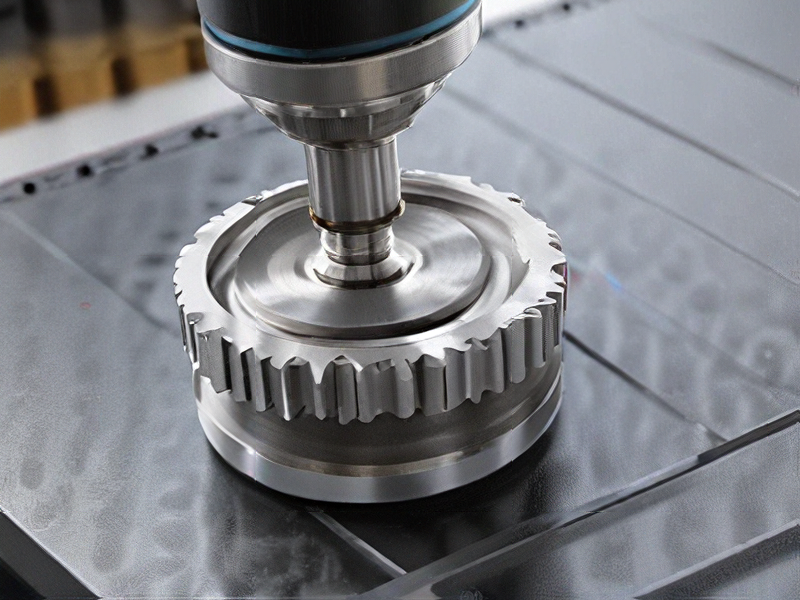

G-code specifies the movements and operations of the machine, such as positioning, feed rate, and tool selection. It consists of standardized commands that tell the machine where to move, how fast to move, and what path to follow. G-codes are essential for controlling machining operations like drilling, cutting, and milling.

M-code, on the other hand, controls auxiliary functions of the machine, such as coolant systems, spindle rotation, and tool changes. These codes activate or deactivate specific machine processes or functions at precise moments during operation. For example, M06 is commonly used to initiate a tool change.

Applications: CNC machines utilize G-code and M-code across various industries, including automotive, aerospace, and electronics manufacturing. These codes enable precise control over machining processes, improving efficiency, accuracy, and repeatability. CNC machining centers, lathes, and routers rely on G-code and M-code to execute complex tasks with minimal human intervention.

Technological Advancements: Modern CNC systems incorporate advanced features like CAD/CAM integration, simulation capabilities, and real-time monitoring. These advancements enhance programming efficiency and machining accuracy, allowing manufacturers to produce intricate parts and components with high precision.

In summary, G-code and M-code are pivotal in CNC technology, driving automation and precision in manufacturing processes across diverse industries. Their continued evolution underscores their critical role in shaping modern production capabilities.

Quality Testing Methods for g code m code cnc and how to control quality

Quality testing methods for G-code and M-code in CNC (Computer Numerical Control) machining involve several key approaches:

1. Syntax Verification: Use software tools to check the syntax and structure of the G-code/M-code for errors and inconsistencies. This ensures that the commands are correctly formatted and will execute properly.

2. Simulation and Verification: Employ CNC simulation software to visualize the toolpaths and simulate the machining process. This helps identify any collisions, errors in toolpaths, or potential machining issues before actual production.

3. Dimensional Inspection: After machining, use precision measurement tools such as calipers, micrometers, or coordinate measuring machines (CMM) to verify the dimensions of machined parts against the design specifications in the G-code.

4. Functional Testing: Test the functionality of the CNC machine by running sample programs and checking for proper execution of commands, accurate positioning, and adherence to speed/feed rates specified in the code.

5. Documentation and Version Control: Maintain comprehensive documentation of G-code/M-code programs, revisions, and changes. Implement version control practices to ensure that the correct and approved programs are used for production.

To control quality effectively, establish clear procedures and standards for programming, testing, and documentation. Regularly review and update these procedures to incorporate lessons learned and improvements. Training operators and programmers on quality standards and inspection techniques is also crucial for maintaining consistent quality in CNC machining operations.

Tips for Procurement and Considerations when Purchasing from g code m code cnc

Tips for Procurement from G Code M Code CNC Suppliers

1. Understand Your Needs:

– Identify the specific CNC machine and tools you need based on your production requirements.

– Consider the types of materials you’ll be working with and the complexity of the parts you need to produce.

2. Research Suppliers:

– Look for reputable suppliers with a proven track record in the CNC industry.

– Read reviews and ask for references to ensure reliability and quality.

3. Compare Prices:

– Obtain quotes from multiple suppliers to ensure competitive pricing.

– Factor in shipping costs, import duties, and other additional expenses.

4. Check Compatibility:

– Ensure the G Code and M Code capabilities of the CNC machine match your production software and existing equipment.

– Verify that the machine supports the required programming languages and interfaces.

5. Evaluate Quality and Features:

– Examine the build quality, precision, and durability of the CNC machines.

– Consider features such as spindle speed, tool change automation, and safety systems.

6. Assess Technical Support and Training:

– Choose suppliers that offer comprehensive technical support and training.

– Verify the availability of manuals, troubleshooting guides, and customer service.

7. Inspect Warranty and Maintenance Services:

– Check the warranty period and terms provided by the supplier.

– Investigate the availability and cost of maintenance services and spare parts.

8. Understand Lead Times:

– Confirm the delivery times to avoid production delays.

– Consider suppliers with flexible shipping options to meet urgent requirements.

Considerations When Purchasing CNC Equipment

1. Total Cost of Ownership:

– Consider not only the initial purchase price but also long-term costs such as maintenance, operation, and training.

2. Technological Upgrades:

– Ensure the machine can be upgraded or retrofitted with new technology to avoid obsolescence.

3. Energy Consumption:

– Evaluate the energy efficiency of the machine to reduce operational costs and environmental impact.

4. Compliance and Certifications:

– Verify that the equipment complies with industry standards and certifications.

By carefully considering these factors, you can make informed procurement decisions that align with your production goals and budget.

FAQs on Sourcing and Manufacturing from g code m code cnc in China

FAQs on Sourcing and Manufacturing from G Code M Code CNC in China

1. What is G Code M Code CNC?

G Code (Geometric Code) and M Code (Machine Code) are programming languages used to control CNC (Computer Numerical Control) machines. G Code primarily deals with the movement of the machine, while M Code handles miscellaneous functions such as starting or stopping the machine.

2. Why source from China?

China is a global leader in CNC manufacturing due to its advanced technology, skilled labor, and cost-effective production. Sourcing from China can significantly reduce manufacturing costs while maintaining high quality.

3. How to find reliable CNC manufacturers in China?

Start by researching and identifying manufacturers with strong reputations and positive reviews. Platforms like Alibaba, Made-in-China, and Global Sources can help. Verify certifications, request samples, and consider factory visits for better assessment.

4. What are the common challenges?

Common challenges include language barriers, quality control issues, and differences in business practices. To mitigate these, use a reputable sourcing agent, clearly communicate your specifications, and implement strict quality control measures.

5. What should be included in the contract?

Contracts should specify the product details, pricing, payment terms, delivery schedules, quality standards, and penalty clauses for non-compliance. Ensuring legal enforceability in both countries is crucial.

6. How to handle quality control?

Regular inspections and audits are essential. Use third-party inspection services to verify compliance with quality standards. Implementing a clear quality assurance process from the start can prevent issues.

7. What are the payment terms?

Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and D/P (Documents against Payment). Negotiating favorable terms that balance risk for both parties is important.

8. How to manage shipping and logistics?

Work with experienced freight forwarders and ensure compliance with international shipping regulations. Properly managing documentation, customs clearance, and choosing the right shipping method (air or sea) are crucial for timely delivery.

9. Are there intellectual property risks?

Intellectual property protection can be challenging. Register your IP in China, use non-disclosure agreements, and carefully select trusted manufacturers to mitigate risks.

By addressing these FAQs, you can better navigate the complexities of sourcing and manufacturing CNC components from China, ensuring a successful and efficient process.