SourcifyChina Factory is renowned for its exceptional quality in manufacturing gear generators. With state-of-the-art technology and rigorous quality control processes, they ensure that every product meets international standards and exceeds customer expectations.

Their expertise in the field, coupled with years of experience, positions SourcifyChina Factory as a leader in the manufacturing industry. Buyers benefit from their in-depth knowledge and technical know-how, which drive innovation and reliability in their products.

Competitive pricing is another compelling reason to choose SourcifyChina Factory. They offer cost-effective solutions without compromising on quality, enabling buyers to achieve better margins and successes in competitive markets.

In addition to quality and price, SourcifyChina Factory excels in customer service. Their dedicated team provides personalized support, from initial consultation through delivery and beyond, ensuring a seamless purchasing experience.

Bulk order capabilities are yet another advantage, making SourcifyChina Factory an ideal choice for large-scale projects. Their efficient production lines and robust supply chains guarantee timely deliveries, no matter the order size.

Lastly, SourcifyChina Factory champions environmental sustainability. They implement eco-friendly manufacturing practices and materials, reducing their carbon footprint and promoting responsible consumption. Buyers can trust SourcifyChina Factory for not only superior products but also ethical production values.

A gear generator is a tool used to create gear designs for various applications, ranging from mechanical engineering to hobby projects. These generators offer diverse features to cater to different needs and preferences.

– Online Gear Generators: Web-based tools often free or subscription-based, providing quick and easy design options.

– Software Applications: Dedicated software like AutoCAD or SolidWorks, offering advanced features for professionals.

– 3D Printing Gear Generators: Tools that integrate with 3D printing technology for custom gear prototyping.

– Mechanical Gear Generators: Physical machines used for crafting gears, mostly for industrial purposes.

– Open-Source Gear Generators: Community-driven projects providing customizable and shareable gear design solutions.

– Mobile Apps: Convenient and portable gear design tools accessible via smartphones and tablets.

– Specialized Gear Generators: Programs focusing on specific types of gears such as spur, helical, or bevel gears.

Selecting the right type of gear generator depends on factors such as complexity, precision requirements, and available resources. Online tools are great for quick projects, while dedicated software and mechanical options cater to professional needs.

A gear generator is a versatile tool used for designing and visualizing gears in various fields, ranging from mechanical engineering to hobbyist projects. It streamlines the creation and modification of gear systems.

– Mechanical Engineering: Aids in the design of efficient transmission systems for machines and vehicles.

– Robotics: Essential for creating precise gear systems that drive robotic movements and operations.

– 3D Printing: Facilitates the creation of custom gear parts, enhancing prototyping and functional part production.

– Animation and Games: Generates realistic gear models and mechanisms for use in virtual environments.

– Educational Tools: Serves as a practical resource for teaching the fundamentals of gear mechanics and engineering principles.

– Medical Devices: Helps in designing components for medical instruments requiring intricate gear systems.

– DIY Projects: Provides hobbyists and makers with an accessible way to create gears for various custom projects.

– Watchmaking: Assists in the detailed design of gears for timepieces, ensuring precision and reliability.

– Automotive Industry: Essential for developing and improving gear systems in vehicles for better performance and efficiency.

– Industrial Machinery: Improves the design and maintenance of heavy machinery gear systems, enhancing operational longevity.

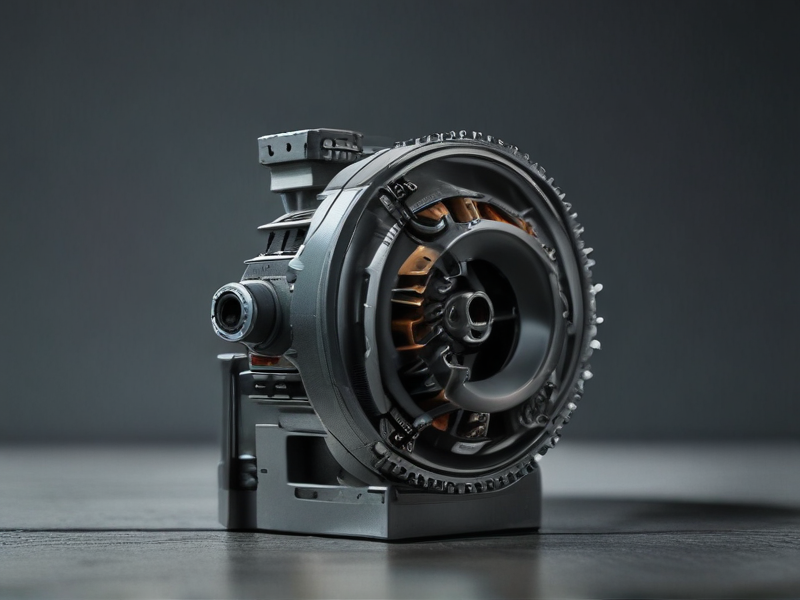

SourcifyChina’s gear generator is crafted using premium materials, ensuring robustness and longevity. Key components include high-grade steel alloys for its gears, providing superior strength and resistance to wear and tear.

The housing of the gear generator is made from durable cast iron, which adds to its overall sturdiness and stability. This ensures the gears remain perfectly aligned during operation, reducing the risk of malfunctions.

For the bearings, industrial-grade ceramics are employed. These materials increase the efficiency of the gear system by minimizing friction and heat generation, resulting in smoother operation and extended service life.

The protective coatings on the gears and housing are designed to withstand harsh environmental conditions. These corrosion-resistant coatings prevent rust, ensuring reliable performance even in challenging industrial settings.

Furthermore, precision engineering is applied to ensure that all parts fit seamlessly together, enhancing the overall performance and efficiency of the gear generator.

In summary, SourcifyChina’s gear generator integrates high-grade steel, cast iron, ceramic bearings, and protective coatings, all meticulously crafted and assembled to provide durable and efficient mechanical power transmission solutions.

SourcifyChina’s gear generator quality control process begins with sourcing premium raw materials. We meticulously select materials that meet stringent standards for durability and performance, ensuring the end product starts on a solid foundation.

Once materials are in-house, they undergo rigorous testing. Each batch is subjected to a series of inspections, including tensile strength and microstructure analysis. These tests guarantee the base material is free from defects, offering a reliable starting point for manufacturing.

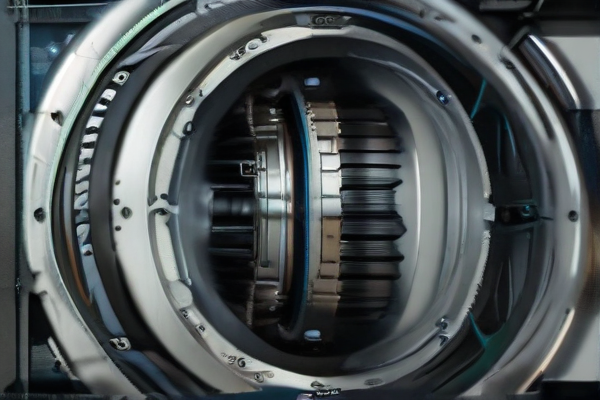

CNC machines are employed for cutting gears with high precision. The programming of these machines is regularly updated to enhance accuracy, reducing the margin for error. Operators are trained to handle these updates, ensuring a seamless transition.

Post-manufacturing, our gears undergo comprehensive dimensional checks using advanced metrology tools. Laser scanners and coordinate measuring machines confirm each gear meets the exact specifications. This step eliminates any discrepancies that could affect performance.

The final phase involves load testing. Gears are subjected to simulated working conditions to ensure they can withstand operational stresses. We employ both static and dynamic tests to assess durability and longevity under real-world conditions.

Each step in SourcifyChina’s manufacturing and quality control process is documented. This traceability allows for quick identification and rectification of any issues, promoting continuous improvement. Our commitment to rigorous quality control ensures that every gear generator we produce meets the highest standards of excellence, reliability, and performance. This multi-stage approach not only guarantees superior products but also solidifies our reputation as a leader in the gear manufacturing industry.

SourcifyChina’s gear generator is a versatile and powerful tool designed for engineers and product developers. It enables the creation of precise and efficient gears tailored to specific requirements, enhancing performance and longevity in mechanical systems.

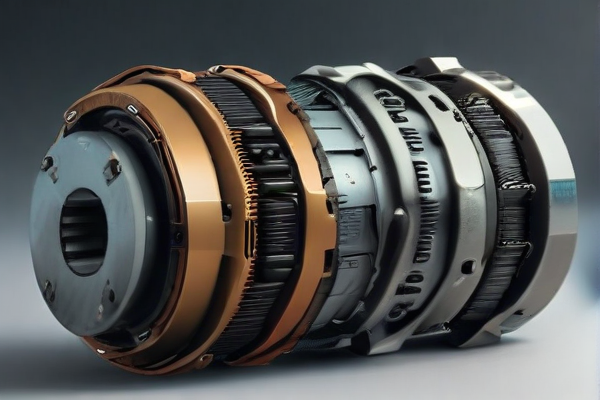

This advanced software supports various gear types, including spur, helical, bevel, and worm gears. Users can easily define parameters such as module, pressure angle, and number of teeth, ensuring optimal performance and compatibility with existing designs.

The gear generator’s intuitive interface and high-level automation significantly reduce development time and errors. It delivers accurate 3D models and technical drawings, streamlining the design-to-manufacturing process and facilitating rapid prototyping and production.

Additionally, SourcifyChina’s gear generator integrates seamlessly with popular CAD and simulation software. This compatibility allows for a smooth transition from design to analysis, ensuring that gears perform well under real-world conditions and meet stringent quality standards.

The gear generator also includes features for material selection and cost estimation, assisting users in making informed decisions about the manufacture and profitability of their designs. This holistic approach ensures that the final product is both high-quality and cost-effective.

Moreover, the tool’s robust database of materials, coatings, and heat treatments provides valuable insights into enhancing gear durability and functionality. Users can experiment with different combinations to achieve the best results for their specific applications.

SourcifyChina’s gear generator stands out for its user-centric design and comprehensive capabilities. By simplifying the complex process of gear creation, it enables engineers to focus on innovation and efficiency, ultimately leading to superior products and improved market competitiveness.

Gear generators are invaluable tools for creating custom gear designs with precision and efficiency. They are essential for mechanical engineering and manufacturing processes.

– Precision and Accuracy: Gear generators ensure highly precise measurements, reducing errors in gear production.

– Time Efficiency: Automating the design process saves significant time compared to manual drafting.

– Customization Options: Easily modify parameters to create gears tailored to specific needs.

– Cost-Effective: Reduces the need for expensive prototypes by allowing virtual testing and adjustments.

– Versatility: Suitable for various gear types, including spur, helical, and bevel gears.

– Enhanced Productivity: Streamlines the workflow, allowing engineers to focus on other critical tasks.

– Resource Savings: Minimizes material waste by optimizing gear design for efficiency.

– User-Friendly Interfaces: Simplifies the design process, making it accessible for both experienced engineers and beginners.

– Integration with CAD Software: Facilitates seamless transfer of gear designs to Computer-Aided Design systems for further refinement.

– Improved Performance: Optimized gear designs contribute to smoother and more efficient mechanical operations.

A gear generator is a specialized software tool used to design and create gears for various mechanical applications. This tool offers numerous features that enhance precision, efficiency, and versatility in gear design.

– Customization Options: Allows users to design gears with specific parameters such as diameter, tooth count, and pressure angle.

– 3D Visualization: Offers real-time 3D rendering to visualize the gear’s structure and intricacies.

– Material Selection: Provides options to select different materials to simulate the gear’s performance under various conditions.

– Simulation Capabilities: Simulates the gear’s performance, wear, and efficiency over time.

– Automated Calculations: Performs complex calculations for gear ratios, torque, and power transmission.

– Export Options: Supports exporting designs to various formats such as CAD files for further processing or manufacturing.

– User-Friendly Interface: Designed with intuitive controls and prompts, making it accessible for both novices and professionals.

– Compatibility: Integrates with various other software tools for seamless design workflows.

– Library of Templates: Includes pre-designed gear templates that can be customized to meet specific needs.

– Error Detection: Automatically identifies and flags potential issues in the gear design, reducing the likelihood of manufacturing errors.

Using these features, engineers and designers can efficiently create precise and functional gears tailored to their specific project requirements.

SourcifyChina specializes in the creation of custom gear products and projects tailored to meet the specific needs of clients. Their gear generator technology allows for precision and efficiency, producing high-quality results every time.

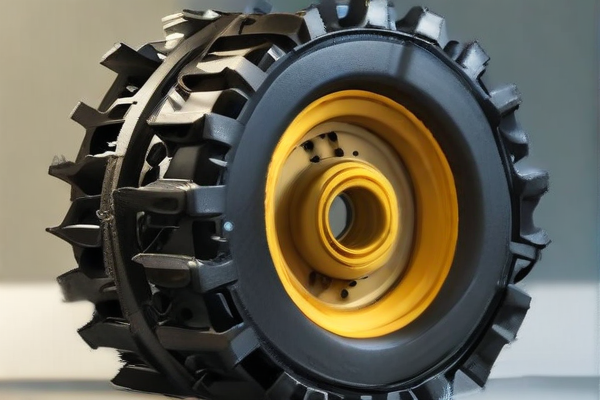

The company offers a wide range of gears, including spur, helical, and bevel gears. Each product is crafted with meticulous attention to detail, ensuring durability and optimal performance in various applications.

Custom projects are a significant part of SourcifyChina’s offerings. Clients can collaborate closely with the design team to create gear systems that perfectly match their requirements, whether for industrial machinery or specialized devices.

Leveraging advanced CAD software and state-of-the-art manufacturing processes, SourcifyChina guarantees that each custom project meets the highest standards of quality and functionality. This commitment to excellence has made them a preferred partner for businesses seeking reliable gear solutions.

Overall, SourcifyChina’s gear generator and custom project capabilities make them a leader in the industry, providing tailored solutions that enhance operational efficiency and performance for clients worldwide.

SourcifyChina Gear Generator is a groundbreaking manufacturing firm specializing in the production of high-precision mechanical gears tailored for various industries, including automotive, aerospace, and robotics. Headquartered in the tech hub of Shenzhen, China, the company utilizes cutting-edge technologies such as computer-aided design (CAD) and advanced CNC machining to deliver gears that meet stringent quality standards and custom specifications. With a focus on innovation and efficiency, SourcifyChina collaborates closely with clients worldwide to provide turnkey solutions that streamline production processes and enhance mechanical performance. Their robust supply chain network ensures timely delivery and competitive pricing, making them a trusted partner for enterprises seeking reliability and excellence in gear manufacturing.

The aerospace, defense, and marine sectors leverage gear generators extensively due to their precision engineering and critical role in ensuring reliable power transmission. In aerospace, gear generators are integral to the functioning of engines, landing gears, and control systems. They help optimize the performance of these systems by providing precise and efficient power management under extreme conditions. By enabling precise gear design and manufacturing, gear generators contribute significantly to the operational safety and durability of aircraft, where even a minor failure can have catastrophic consequences.

In the defense sector, gear generators are utilized in various military vehicles and equipment, such as tanks, artillery, and radar systems, where robust and dependable gear mechanisms are vital. The high-performance demands of military applications require gears that can endure intense operational stress while maintaining smooth functionality. Similarly, marine applications, including propulsion systems of ships and submarines, rely on the accuracy of gear generators to ensure reliable and efficient power transfer in both calm and turbulent waters. Gear generators aid in designing gears that can withstand significant wear and tear, thus enhancing the longevity and operational efficiency of marine vessels. Whether under the sea or in the skies, the precision provided by gear generators is indispensable for mission-critical applications in these advanced fields.

The gear generator is an essential tool in the realm of automotive engineering, solely due to its ability to design gears that are both efficient and precise. In vehicles, gears play a pivotal role in the transmission system, which is responsible for transferring power from the engine to the wheels. By utilizing gear generators, automotive engineers can create gears with specific dimensions and tooth profiles that are optimized for various performance criteria such as noise reduction, durability, and fuel efficiency. This technology enables the development of advanced automatic transmissions, which can seamlessly switch between gears to provide a smoother driving experience and better fuel economy. Furthermore, the precise nature of gear generators helps in minimizing the wear and tear of gear components, thereby extending the lifespan of the vehicle and reducing maintenance costs.

In the electronics industry, gear generators find their applications in the design of precision-driven components in devices such as electric actuators, sensors, and robotics. For instance, in consumer electronics, gear generators are used to design gears in camera lenses that require precise and silent operation for zoom and focus functions. Similarly, in robotics, gear generators aid in creating gears that ensure accurate movements and positioning of robotic arms, enhancing the precision and efficiency of automated tasks. The miniaturization capabilities of gear generators also make them indispensable in the development of compact devices, such as wearable tech and medical instruments, where space constraints are critical. By leveraging the advanced computational algorithms of gear generators, electronics manufacturers can meet the tight tolerances required for high-performance gear systems, ultimately resulting in more reliable and efficient electronic devices.

In the construction industry, gear generators play a pivotal role in enhancing the efficiency and precision of heavy machinery. These sophisticated devices convert various forms of energy into mechanical power that can be harnessed by cranes, bulldozers, and excavators. For example, in a high-rise construction project, gear generators enable cranes to lift substantial loads with reduced energy consumption and heightened operational accuracy. The precise coordination afforded by gear generators also minimizes wear and tear, thereby extending the lifespan of expensive construction equipment. As a result, construction timelines are shortened, and costs are reduced, which is crucial for large-scale infrastructure projects where budgets and deadlines are tight.

In the realm of energy applications, gear generators are integral to the optimization of wind and hydroelectric power systems. These systems rely on gear generators to convert kinetic energy from natural sources into electrical energy efficiently. In wind turbines, the kinetic energy from rotating blades is transferred to a gear generator, which then increases the rotational speed required for electricity production. Similarly, in hydroelectric plants, the movement of water turns turbines connected to gear generators, facilitating the conversion of mechanical energy into a usable electric form. This process not only maximizes energy output but also ensures that renewable energy resources are harnessed optimally, thereby contributing to sustainability and reducing dependency on fossil fuels. Through these applications, gear generators play a crucial role in the broader objective of achieving a more resilient and eco-friendly energy grid.

The industrial equipment industry extensively utilizes gear generators to meet the diverse mechanical transmission demands in various applications. A gear generator is a specialized machine used for designing, fabricating, and honing gears that are critical for the smooth operation of machinery in sectors such as manufacturing, automotive, aerospace, and heavy equipment. These generators ensure the production of high-precision gears that maintain the efficiency and reliability of mechanical systems. By employing advanced CNC (Computer Numerical Control) technology, gear generators can produce gears with intricate designs and exact specifications, catering to complex industrial requirements. As a result, they contribute significantly to reducing downtime and enhancing the longevity of industrial equipment.

Furthermore, gear generators are pivotal in optimizing productivity and operational efficiency in industrial setups. Automated gear generation dramatically reduces the time and labor involved in traditional gear manufacturing processes, thus lowering production costs. High-efficiency gearboxes, produced using gear generators, are integral in driving machinery that manages strenuous tasks, such as material handling, crushing, and drilling. By ensuring high quality and precision in gear production, these generators support the development of machinery with better performance, lower noise levels, and improved energy efficiency. Consequently, industries can achieve higher productivity rates while maintaining lower operational and maintenance costs, making gear generators indispensable in the modern industrial equipment landscape.

Medical devices have increasingly benefited from advancements in gear generator technology, which utilizes computer-aided design (CAD) to create precise, efficient gears tailored to specific medical applications. These gears are fundamental in a variety of devices, including surgical robots, infusion pumps, and prosthetic limbs. In surgical robots, gear generators allow for the creation of highly sophisticated and finely-tuned gear systems that enable smooth and precise movements of robotic arms. This precision is crucial for performing delicate surgeries with higher accuracy and reduced patient recovery times. Infusion pumps, which administer medication at controlled rates, also depend on intricately designed gears to ensure reliable and precise drug delivery, thereby minimizing the risk of dosage errors and enhancing patient safety.

Moreover, the role of gear generators extends to the development of advanced prosthetic limbs. Custom-generated gears in prosthetics facilitate more natural and responsive movements, providing users with improved dexterity and control. This not only enhances the quality of life for amputees but also contributes to better rehabilitation outcomes. Gear generator technology also accelerates the design and prototyping process of medical devices by allowing engineers to experiment with different configurations and materials in a virtual environment, leading to optimized and innovative solutions. Consequently, the integration of gear generator technology in medical device engineering not only improves functionality and reliability but also drives significant advancements in patient care and therapeutic outcomes.

In the realm of machining and manufacturing, the gear generator stands as a pivotal piece of equipment, instrumental in the production of gears essential for various mechanical systems. Gear generators employ methods such as hobbing, shaping, and milling to create high-precision gears tailored to specific applications. The advantage of using gear generators lies in their ability to produce gears with exact tooth profiles and tolerances, which are crucial for maintaining smooth and efficient operation in machinery. These highly specialized machines can handle a range of gear types, including spur, helical, and bevel gears, thus providing versatility and efficiency in gear production.

The gear generator’s application extends beyond merely manufacturing gears to enhancing productivity and reducing cycle times within the manufacturing ecosystem. Advanced gear generators are often integrated with computer numerical control (CNC) systems, allowing for automated, high-speed production while maintaining stringent quality control. This automation not only enhances precision and consistency but also reduces manual intervention, thus minimizing human errors. In industries such as automotive, aerospace, and heavy machinery, where gear reliability and durability are paramount, gear generators contribute significantly by delivering consistently high-quality components. Consequently, they play a critical role in driving innovation and efficiency in modern manufacturing processes, ensuring that complex machinery functions seamlessly and sustainably.

Q: What are the key features of the gear generators manufactured by SourcifyChina factory?

A: The gear generators produced by SourcifyChina are built with high precision, durable materials, and advanced technology to ensure consistent quality and performance. They are customizable to meet specific industry requirements.

Q: What industries can benefit from SourcifyChina’s gear generators?

A: SourcifyChina’s gear generators are suitable for various industries, including automotive, aerospace, manufacturing, and robotics, providing reliable power transmission solutions.

Q: How does SourcifyChina ensure the quality of its gear generators?

A: SourcifyChina employs strict quality control measures, including in-depth testing, precision machining, and the use of high-quality materials. The factory follows international standards, ensuring that each product meets or exceeds industry requirements.

Q: What materials are used in the manufacturing of gear generators at SourcifyChina?

A: SourcifyChina uses top-grade materials such as alloy steel, stainless steel, and other high-performance metals to manufacture durable and reliable gear generators.

Q: Can SourcifyChina provide custom gear generator solutions?

A: Yes, SourcifyChina works with clients to design and manufacture custom gear generators tailored to specific applications and performance requirements.

Q: What is the typical lead time for manufacturing and delivering gear generators?

A: Lead times may vary depending on the complexity and quantity of the order. Generally, SourcifyChina aims to deliver within 4-6 weeks post order confirmation.

Q: Does SourcifyChina offer after-sales support and service for its gear generators?

A: Yes, SourcifyChina provides comprehensive after-sales support, including installation assistance, maintenance guides, and troubleshooting services to ensure optimal product performance.

Q: How can I place an order with SourcifyChina for gear generators?

A: Orders can be placed by contacting SourcifyChina’s sales team via their official website, email, or phone. They will guide you through the order process and customization options if needed.

Q: Are there any minimum order requirements for SourcifyChina’s gear generators?

A: Minimal order quantities may apply depending on the product type and customization needs. It is best to consult with the sales team to understand specific order requirements.

Q: What is the warranty policy for gear generators from SourcifyChina?

When engaging with SourcifyChina for gear generator manufacturing, it’s crucial to follow a few key steps to ensure quality and efficiency:

1. Clear Specifications: Clearly outline your gear requirements, including material, dimensions, tolerances, and performance criteria. Detailed CAD drawings can significantly reduce misunderstandings.

2. Supplier Verification: Ensure SourcifyChina has a good track record for gear manufacturing. Look for certifications like ISO 9001 and inspect their quality control processes.

3. Sample Production: Request samples before committing to full-scale production. This ensures they can meet your specifications and quality standards.

4. Material Selection: Discuss material options with SourcifyChina to ensure the gears will perform optimally in your application. Consider factors such as strength, wear resistance, and cost.

5. Quality Control: Implement regular quality checks during production. Consider third-party inspections to ensure the gears meet your standards.

6. Communication: Maintain consistent and clear communication with the factory. Use project management tools or regular meetings to monitor progress and address any issues promptly.

7. Lead Times: Clearly understand the production and delivery timelines. Verify that SourcifyChina can meet your deadlines without compromising quality.

8. Cost Analysis: Obtain a detailed quote that includes all costs—material, labor, shipping, and any potential tariffs. This helps in budgeting and avoiding hidden expenses.

9. Intellectual Property: Protect your designs with appropriate agreements to ensure your proprietary information is safeguarded.

10. After-Sales Support: Ensure SourcifyChina provides adequate after-sales support, including strategies for handling defects or issues that may arise post-delivery.

By following these tips, you can enhance the efficiency and quality of your gear generator manufacturing process with SourcifyChina.

Sure! Here is a concise FAQ list for sourcing a gear generator from SourcifyChina factory:

Q1: What types of gear generators do you offer?

A1: SourcifyChina offers various types of gear generators including spur gear generators, helical gear generators, bevel gear generators, and worm gear generators, catering to diverse industrial applications.

Q2: How can I request a quotation?

A2: You can request a quotation by visiting our website, filling out the contact form with your specific requirements, or directly emailing us at [email protected].

Q3: Are there minimum order quantities (MOQs) for gear generators?

A3: Yes, the MOQ varies depending on the product type and specifications. Generally, it starts at 50 units. Please contact us for precise details regarding your order.

Q4: What is the lead time for order fulfillment?

A4: The lead time typically ranges from 4 to 8 weeks depending on the complexity and quantity of the order. We provide estimated timelines once the order is confirmed.

Q5: Can I get a sample before placing a bulk order?

A5: Yes, samples are available upon request. Sample fees and shipping costs may apply, which can be refunded upon placement of a bulk order.

Q6: What quality assurance measures are in place?

A6: SourcifyChina implements stringent quality control measures including material inspection, in-process checks, and final product testing to ensure the highest standards.

Q7: Do you offer customization for gear generators?

A7: Absolutely! We provide customization services based on your specific design, dimensions, and material preferences to meet your unique needs.

Q8: How are the orders shipped?

A8: Orders are shipped via sea or air freight according to customer preferences. We work with reliable logistics partners to ensure timely and safe delivery.

Q9: What payment methods are accepted?

A9: We accept multiple payment methods including T/T (Telegraphic Transfer), L/C (Letter of Credit), and PayPal. Payment terms are provided during the quotation process.

Q10: How can I contact customer service for further inquiries?

A10: For any additional questions or support, you can reach our customer service team via email at [email protected] or call our helpline at +86 123 4567 890.

Sourcing a gear generator from a “SourcifyChina” factory can be streamlined by following these steps:

1. Initial Research: Begin by researching reputable factories on platforms like Alibaba, Made-in-China, or Global Sources. Filter results for highly rated suppliers with verified credentials.

2. Detailed Inquiry: Contact multiple suppliers to request detailed quotations. Be specific about your requirements, such as the type of gear generator, materials, dimensions, and any technical specifications.

3. Verify Credentials: Ensure the factory is verified on the platform and consider requesting certifications like ISO 9001. This verifies their quality management systems.

4. Sample Request: Ask for a sample before placing a bulk order. This lets you evaluate the quality firsthand.

5. Communication Clarity: Maintain clear and concise communication. Use simple language and be specific about terms, conditions, and timelines to avoid misunderstandings.

6. Negotiate Terms: Discuss payment terms, warranties, and after-sales service. Consider a Letter of Credit (LC) for larger orders to mitigate financial risks.

7. Site Visit: If feasible, conduct a factory visit or hire a third-party inspection service. This helps verify the factory’s production capabilities and quality control processes.

8. Logistics Planning: Decide on logistics early. Consider whether you’ll handle shipping or if the supplier offers a complete door-to-door service. Compare costs of FOB (Free on Board), CIF (Cost, Insurance, and Freight), etc.

9. Legal Agreement: Draft a clear contract covering all terms, including quality standards, delivery schedule, and penalties for non-compliance. Employ legal assistance if necessary.

10. Start Small: For the initial order, start with a smaller quantity to test the supplier’s reliability and product quality.

Following these steps will help ensure a smooth and successful sourcing process from a SourcifyChina factory.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.