Technology and Applications of heat metals

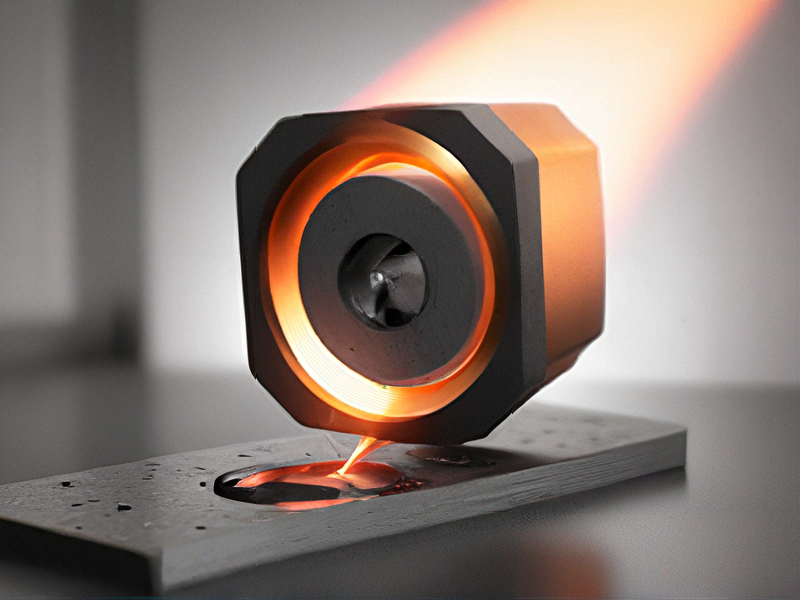

Heating metals is crucial across various industries, employing technologies like induction heating, resistance heating, and flame heating. Induction heating uses electromagnetic induction to generate heat within the metal by inducing eddy currents, suitable for rapid and precise heating without direct contact. It finds applications in welding, brazing, and surface hardening due to its efficiency and control.

Resistance heating passes an electric current through the metal, heating it by resistance, commonly used in electric furnaces for steel production and in heat treatment processes like annealing and tempering. It provides uniform heating but requires proper insulation and control to prevent overheating.

Flame heating utilizes oxy-fuel flames to heat metals, offering flexibility in field operations and large-scale applications like metal cutting, forging, and annealing. It’s cost-effective but may produce uneven heating and require skilled operation.

Applications include automotive manufacturing, aerospace, electronics, and construction. Metals are heated for shaping, joining, hardening, or softening, enhancing mechanical properties or enabling specific manufacturing processes like casting or extrusion. Advanced simulations and controls optimize heating processes, ensuring efficiency and quality in modern industrial applications.

Quality Testing Methods for heat metals and how to control quality

Quality testing for heat-treated metals involves several methods to ensure their mechanical properties and structural integrity are maintained. Here are key methods and quality control measures:

Testing Methods

1. Hardness Testing:

– Brinell, Rockwell, and Vickers tests measure the material’s resistance to indentation, indicating the success of heat treatment.

2. Tensile Testing:

– Measures the material’s strength, ductility, and toughness by pulling a sample until it breaks.

3. Impact Testing:

– Charpy and Izod tests evaluate the material’s toughness and ability to absorb energy during fracture.

4. Microstructural Analysis:

– Metallography: Examines the microstructure using optical or electron microscopy to ensure the correct phase distribution and grain size.

– X-ray Diffraction (XRD): Identifies and quantifies phases present in the metal.

5. Non-Destructive Testing (NDT):

– Ultrasonic Testing (UT): Detects internal flaws.

– Magnetic Particle Testing (MPT): Reveals surface and near-surface defects in ferromagnetic materials.

– Dye Penetrant Testing (DPT): Highlights surface cracks and imperfections.

Quality Control Measures

1. Standard Operating Procedures (SOPs):

– Develop and adhere to SOPs for each heat treatment process, including temperature profiles, cooling rates, and holding times.

2. Calibration and Maintenance:

– Regular calibration of equipment and maintenance to ensure accurate and consistent results.

3. Process Monitoring:

– Use sensors and data loggers to monitor temperatures and cycles in real-time during the heat treatment process.

4. Sample Testing:

– Periodically test samples from each batch to ensure they meet specified criteria.

5. Documentation and Traceability:

– Maintain detailed records of heat treatment processes, test results, and any deviations for traceability and continuous improvement.

By integrating these testing methods and quality control measures, manufacturers can ensure that heat-treated metals meet the required standards and performance specifications.

Tips for Procurement and Considerations when Purchasing from heat metals

When procuring metals, especially those susceptible to heat-related issues, several considerations are crucial:

1. Material Specifications: Define the exact requirements for the metal, including type (e.g., stainless steel, aluminum), grade (e.g., 316L stainless steel), and specific properties (e.g., heat conductivity, corrosion resistance).

2. Supplier Reliability: Choose suppliers with a proven track record in delivering quality metals. Check certifications (ISO, ASTM) and customer reviews to ensure reliability.

3. Heat Resistance: Verify the metal’s tolerance to heat. Factors like melting point, thermal conductivity, and coefficient of thermal expansion are critical. Consult with metallurgical experts if needed.

4. Application Suitability: Ensure the metal’s properties align with the intended application. For heat-exposed environments, consider thermal stability, oxidation resistance, and mechanical strength under elevated temperatures.

5. Cost-effectiveness: Balance quality and cost. Cheaper metals may compromise performance under heat, leading to higher maintenance or replacement costs.

6. Environmental Factors: Evaluate environmental conditions where the metal will operate. Factors like humidity, exposure to chemicals, and outdoor elements can influence material selection.

7. Supply Chain Management: Assess supplier’s ability to maintain consistent supply and handle any disruptions. Establish clear communication channels and contingency plans for unforeseen circumstances.

8. Quality Assurance: Implement stringent quality control measures. Inspect materials upon delivery for compliance with specifications and conduct periodic testing to ensure ongoing quality.

9. Safety and Regulatory Compliance: Ensure metals meet safety standards and regulatory requirements (e.g., REACH, RoHS) applicable to your industry and region.

10. Lifecycle Considerations: Factor in lifecycle costs, including maintenance, repair, and disposal. Opt for metals with long-term durability to minimize lifecycle impacts.

By addressing these considerations systematically, you can enhance procurement efficiency and ensure the suitability of metals for applications exposed to heat.

FAQs on Sourcing and Manufacturing from heat metals in China

FAQs on Sourcing and Manufacturing from Heat Metals in China

1. What are the benefits of sourcing heat metals from China?

– China offers competitive pricing, extensive manufacturing capabilities, and a wide range of suppliers. The country also has advanced technology and a robust supply chain for heat metal products.

2. How can I find reliable suppliers for heat metals in China?

– Use platforms like Alibaba, Global Sources, and Made-in-China. Attend trade shows such as the Canton Fair and Metal + Metallurgy China. Seek referrals and verify suppliers through site visits or third-party inspections.

3. What should I consider when selecting a supplier?

– Assess their manufacturing capabilities, quality control processes, certifications (e.g., ISO), and track record. Ensure they have experience with the specific heat metals you need.

4. How do I ensure the quality of heat metals?

– Request samples, conduct material testing, and perform audits. Use third-party quality inspection services to verify product quality before shipment.

5. What are the common types of heat metals available in China?

– Common types include stainless steel, aluminum alloys, copper alloys, and heat-resistant superalloys. Each type has specific applications based on its properties.

6. What is the typical lead time for manufacturing and delivery?

– Lead times vary based on order size, complexity, and supplier capacity. Generally, it ranges from 4 to 12 weeks. Factor in additional time for shipping and customs clearance.

7. How can I negotiate better terms with Chinese suppliers?

– Build a good relationship, order in larger quantities, and negotiate long-term contracts. Understand market conditions and be prepared to discuss pricing, payment terms, and delivery schedules.

8. Are there any risks associated with sourcing from China?

– Risks include quality inconsistencies, communication barriers, and intellectual property concerns. Mitigate these by thorough vetting, clear contracts, and regular monitoring.

9. What are the payment terms typically offered by Chinese suppliers?

– Common terms include T/T (telegraphic transfer), L/C (letter of credit), and D/P (documents against payment). Negotiate terms that provide a balance between risk and cash flow management.

10. How do I handle shipping and logistics?

– Work with experienced freight forwarders and understand Incoterms. Ensure proper documentation and insurance coverage for your shipments.