Technology and Applications of how to cut sheet metal

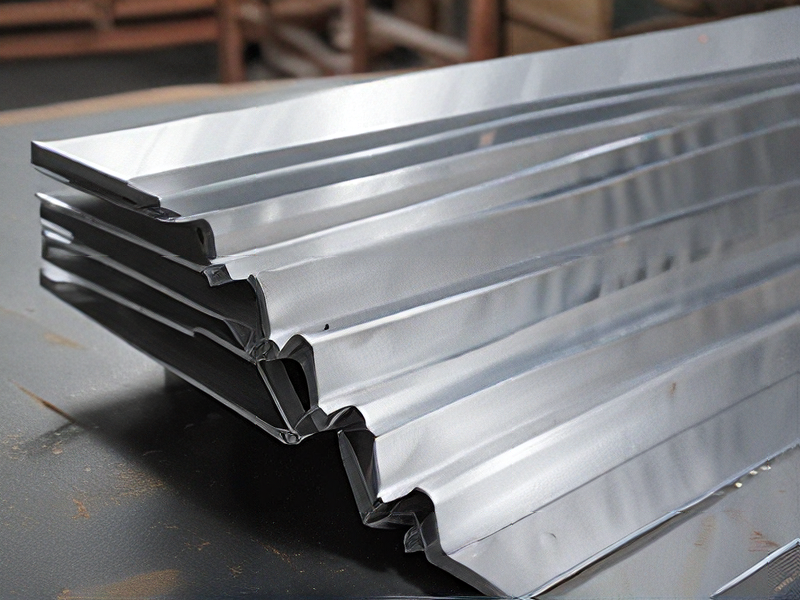

Cutting sheet metal involves various technologies and applications tailored to different needs and precision requirements. The primary methods include:

1. Mechanical Cutting: This involves tools like shears, saws, and punches.

– Shearing: Uses a pair of blades to cut straight lines. It’s common in industrial applications for its speed.

– Sawing: Bandsaws or circular saws cut metal, often used in workshops for versatility.

2. Thermal Cutting: Utilizes heat to cut through metal.

– Oxy-fuel Cutting: Involves an oxygen-fuel gas flame to heat the metal, followed by a high-pressure jet of oxygen to cut. Suitable for thicker materials.

– Plasma Cutting: Uses a plasma torch to melt and cut metal. It’s fast and accurate for both thin and thick sheets.

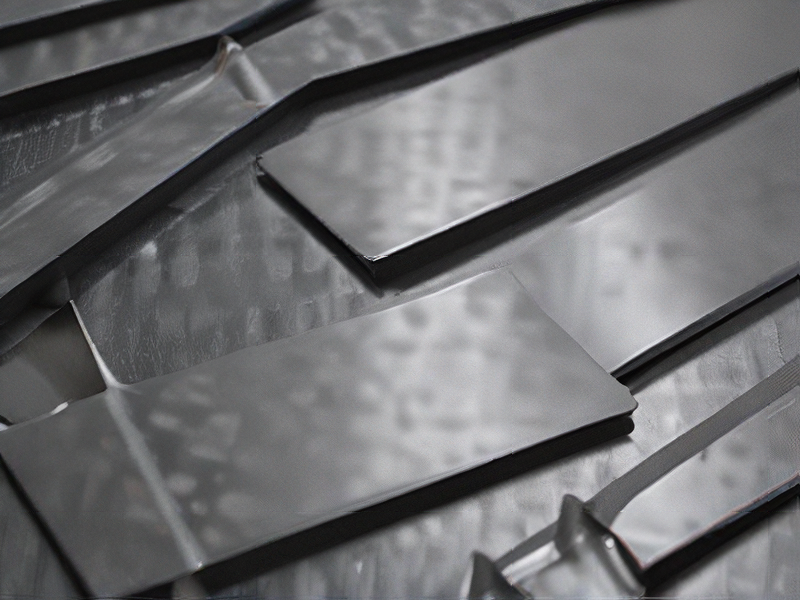

– Laser Cutting: Employs a focused laser beam to melt and vaporize the metal. It offers high precision and is ideal for intricate designs and thin sheets.

3. Abrasive Cutting: Uses grinding wheels or abrasive materials.

– Water Jet Cutting: Employs a high-pressure jet of water mixed with abrasive particles to cut metal. It’s precise and doesn’t generate heat, preventing material warping.

4. Electrical Discharge Machining (EDM): Utilizes electrical discharges to erode the metal. It’s highly precise and used for complex shapes but is slower and costlier.

Applications:

– Manufacturing: Creating components for machinery, vehicles, and electronics.

– Construction: Cutting beams, sheets, and reinforcements for buildings.

– Art and Design: Crafting metal sculptures and intricate designs.

– Aerospace and Automotive: Precision parts for engines and structures.

– Home Repairs: Customizing or repairing household items.

Each method’s choice depends on the metal type, thickness, required precision, and specific application needs.

Quality Testing Methods for how to cut sheet metal and how to control quality

When cutting sheet metal, quality control is crucial to ensure precise cuts and consistent results. Here are some effective methods:

1. Precision Tools: Use high-quality tools such as laser cutters, plasma cutters, or water jet cutters for accurate and clean cuts. These tools offer precise control over cutting parameters.

2. Templates and Jigs: Utilize templates or jigs to maintain consistency across multiple pieces. They ensure each cut meets exact specifications, reducing variability.

3. Measurement and Inspection: Regularly measure and inspect cut pieces using tools like calipers, micrometers, or CMM (Coordinate Measuring Machine). This ensures dimensional accuracy and adherence to tolerances.

4. Operator Training: Properly train operators on equipment operation, safety protocols, and quality standards. Skilled operators reduce errors and improve efficiency.

5. Quality Assurance Checks: Implement checkpoints during and after cutting processes to verify dimensions, angles, and surface finish. This proactive approach identifies issues early.

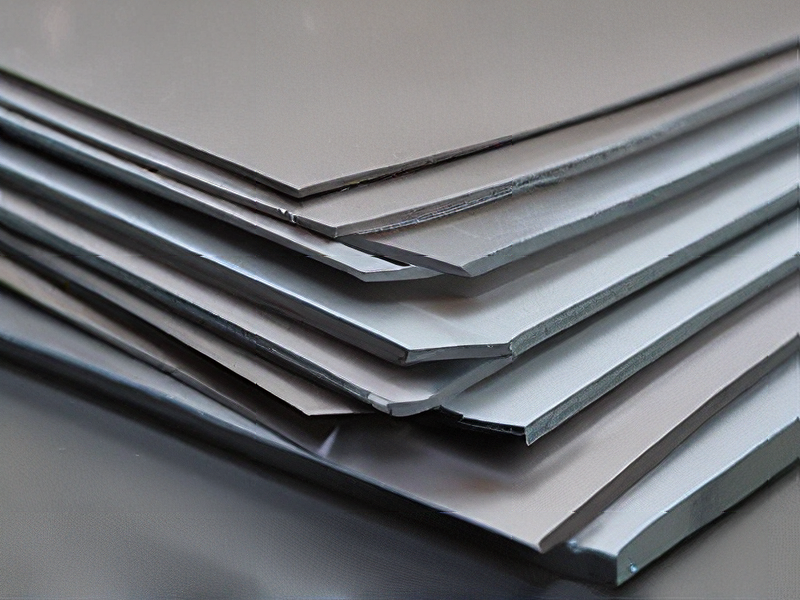

6. Material Handling: Handle sheet metal carefully to prevent distortion or damage before and after cutting. Minimize handling to reduce scratches or dents.

7. Process Documentation: Maintain clear documentation of cutting processes, parameters, and quality standards. This facilitates consistency and allows for traceability.

8. Feedback Mechanism: Establish a feedback loop where operators can report issues or anomalies encountered during cutting. This facilitates continuous improvement.

By integrating these methods into your sheet metal cutting processes, you can effectively control quality, minimize waste, and ensure that each piece meets the required specifications.

Tips for Procurement and Considerations when Purchasing from how to cut sheet metal

When procuring tools or equipment for cutting sheet metal, several key considerations ensure efficiency, safety, and cost-effectiveness. Here are some tips and considerations:

1. Quality and Durability:

– Opt for high-quality tools made from durable materials to withstand the demands of sheet metal cutting.

– Consider reputable brands known for their reliability and performance.

2. Type of Sheet Metal:

– Identify the type of metal you’ll be cutting (e.g., aluminum, steel, copper) as different metals may require specific cutting tools or techniques.

3. Cutting Tools and Techniques:

– Manual Tools: Tin snips are ideal for small, straightforward cuts. Aviation snips are better for intricate shapes.

– Power Tools: Electric shears, nibblers, and plasma cutters are suitable for larger or more complex tasks.

– CNC Machines: For high precision and volume, consider Computer Numerical Control (CNC) machines.

4. Thickness of the Metal:

– Ensure the tools you select can handle the thickness of the sheet metal. Different tools have varying capabilities in terms of cutting thickness.

5. Safety Features:

– Choose tools with built-in safety features such as guards and automatic shut-off to prevent accidents.

– Always use appropriate personal protective equipment (PPE) like gloves, goggles, and ear protection.

6. Cost and Budget:

– Balance cost with quality. Investing in slightly more expensive, high-quality tools can save money in the long run by reducing replacement frequency and improving efficiency.

– Consider total cost of ownership, including maintenance and spare parts availability.

7. Ease of Use and Ergonomics:

– Select tools that are comfortable to handle, reducing fatigue and increasing productivity, especially for long-duration tasks.

8. Supplier Reliability:

– Choose reputable suppliers with good reviews and reliable customer support. They should offer warranties and after-sales service.

9. Environmental Considerations:

– Look for tools that are energy-efficient and produce minimal waste. Consider suppliers with sustainable practices.

10. Compliance and Standards:

– Ensure tools comply with relevant industry standards and regulations to maintain safety and quality.

By considering these factors, you can make informed procurement decisions that enhance efficiency, safety, and overall project success in sheet metal cutting.

FAQs on Sourcing and Manufacturing from how to cut sheet metal in China

When sourcing and manufacturing products, especially involving sheet metal in China, here are some frequently asked questions:

1. How do I find a reliable sheet metal manufacturer in China?

Finding a reliable manufacturer involves thorough research, including online platforms like Alibaba, trade shows, and referrals. It’s crucial to vet potential suppliers by reviewing their certifications, customer feedback, and visiting their facilities if possible.

2. What are the typical methods used to cut sheet metal in Chinese factories?

Chinese manufacturers employ various cutting methods such as laser cutting, CNC punching, water jet cutting, and mechanical shearing. The choice depends on factors like material type, thickness, and project requirements.

3. How can I ensure quality control during sheet metal fabrication?

Implementing a comprehensive quality control process is essential. This includes specifying tolerances, conducting regular inspections during production, and performing final checks before shipment. Communication with the manufacturer about quality standards is key.

4. What are the cost considerations when manufacturing sheet metal in China?

Costs depend on factors like material type, thickness, complexity of design, and volume. Chinese manufacturers often offer competitive pricing due to lower labor costs, but shipping, tariffs, and import duties should also be factored into the total cost.

5. What are the lead times for manufacturing sheet metal products in China?

Lead times vary based on the manufacturer’s capacity, current workload, and complexity of the project. Typically, lead times range from a few weeks to several months, including time for production, quality control, and shipping.

By addressing these FAQs, businesses can navigate the sourcing and manufacturing process for sheet metal in China more effectively, ensuring quality, cost-efficiency, and timely delivery of their products.